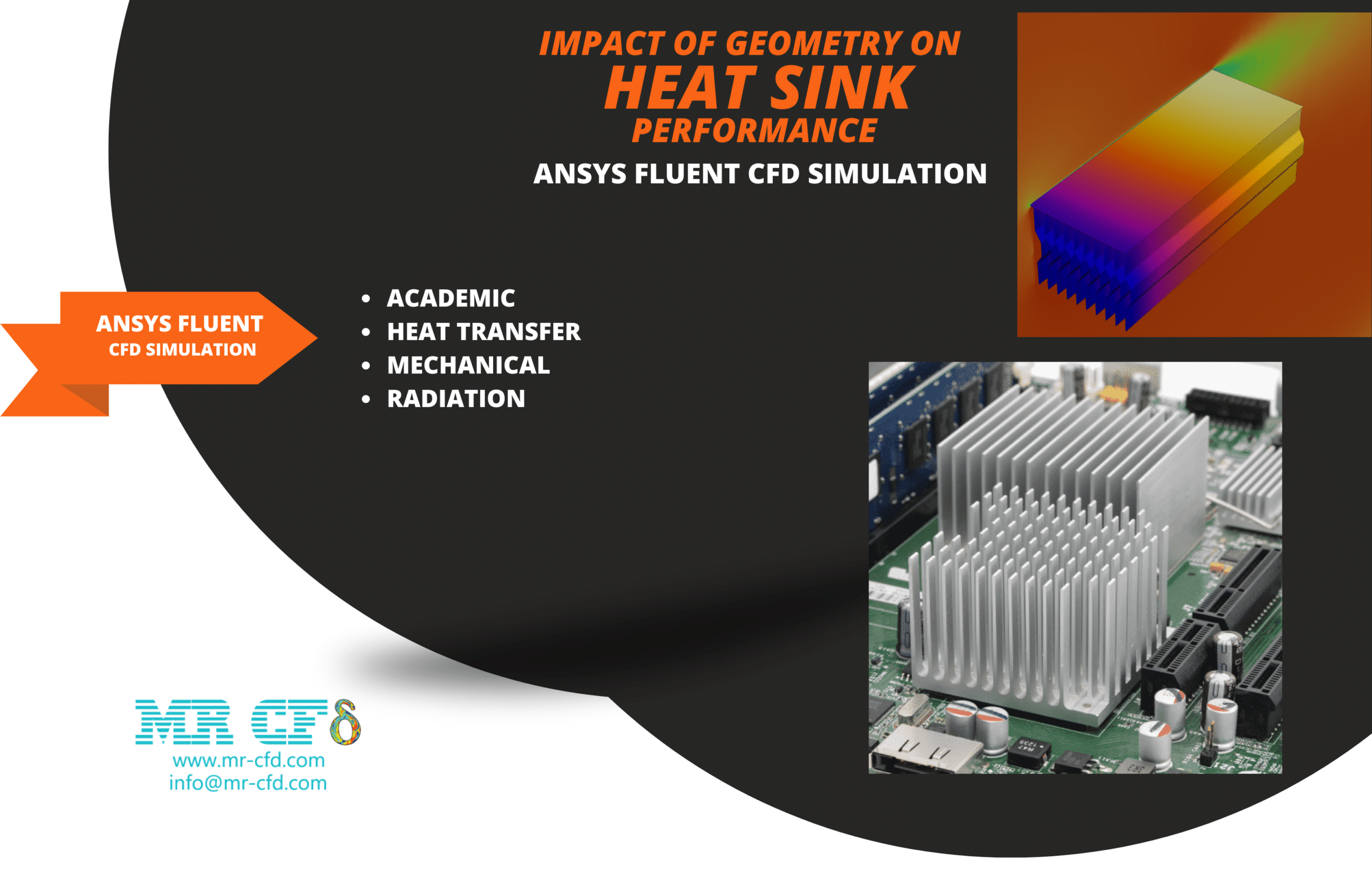

Impact of Geometry on Heat Sink Performance

$140.00 $70.00 Student Discount

- This study compares the thermal performance of open and enclosed heat sink designs using CFD simulations

- The open design features exposed fins, while the enclosed design has a closed-top

- 3-D symmetry model designed using ANSYS Design Modeler software

- model meshed with ANSYS Meshing software, and the element number equals 2,599,334.

- The discrete Ordinates (DO) radiation model was activated to simulate the impact of solar irradiation

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study investigates the thermal performance of two distinct heat sink geometries using Computational Fluid Dynamics (CFD) simulations. The primary objective is to compare and contrast the cooling efficiency of these designs while considering the influence of solar radiation. The simulations were conducted using ANSYS Fluent, a widely recognized CFD software package, to analyze heat transfer, flow patterns, and temperature distributions within the simulated domains.

The CFD simulations were performed on two distinct heat sink geometries: an open-style design featuring a series of fins with exposed surfaces and an enclosed design with a closed top and fins enclosed within the structure.

The geometries were designed in ANSYS Design Modeler and subsequently meshed using ANSYS Meshing, resulting in a total of 2,599,334 elements for each model. This mesh density ensured adequate resolution for capturing the intricate flow and heat transfer phenomena within the heat sink geometries.

Methodology

The simulation setup employed a steady-state, pressure-based solver, and considered gravity in the vertical direction (Y-axis).

The energy equation was enabled to account for temperature variations throughout the domain.

The SST k-omega turbulence model was selected to capture the turbulent flow characteristics.

Additionally, the Discrete Ordinates (DO) radiation model was activated to simulate the impact of solar irradiation on the heat sink performance.

Results and Discussion

The CFD simulations reveal significant differences in temperature distribution between the two geometries. The open design exhibits a more uniform temperature distribution, with higher temperatures concentrated near the base of the heat sink. This suggests that the exposed fins facilitate heat dissipation more effectively. Conversely, the enclosed design shows greater temperature variation, with higher temperatures concentrated within the enclosed space. This indicates that the closed top restricts heat transfer and reduces the cooling efficiency.

The velocity magnitude contours demonstrate a more streamlined flow pattern in the open design, with the air efficiently passing through the exposed fins. This efficient air flow promotes heat convection and contributes to the overall cooling efficiency. The enclosed design presents a more turbulent flow pattern, with stagnant air pockets within the enclosed space. The restricted air flow hinders heat transfer, leading to higher temperatures within the enclosed area.

The CFD simulations demonstrate that the open-style design exhibits superior thermal performance compared to the enclosed design. The exposed fins and streamlined flow pattern contribute to efficient heat dissipation. The enclosed design, while potentially offering structural advantages, suffers from reduced heat transfer due to restricted air flow and stagnant air pockets. This study provides valuable insights for future optimization of heat sink design, potentially leading to improved cooling performance and energy efficiency in various applications.

You must be logged in to post a review.

Reviews

There are no reviews yet.