Internal Gear Pump CFD Simulation, ANSYS Fluent Training

$240.00 $120.00 Student Discount

- The problem numerically simulates the Internal Gear Pump using ANSYS Fluent software.

- We design the 2-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 50,106.

- We perform this simulation as unsteady (Transient).

- We use the Dynamic Mesh Model to define deforming and moving zones.

- We use the user-defined function (UDF) to define the rotational motion of gears.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This project is related to the numerical simulation of the Internal Gear Pump using Ansys Fluent software. A pump is a mechanical device for moving and transferring all liquids from one place to another. In this way, by increasing the pressure, pumps cause liquids to move to a higher height (by increasing the head) and even lower (such as tanks).

The pump takes mechanical energy from an external source, such as a motor, and transfers it to the fluid passing through it. As a result, the energy of the fluid increases after leaving the pump.

The energy transfer to the pump fluid is done in two dynamic and displacement methods. Therefore, pumps are divided into positive displacement pumps and dynamic or non-positive displacement pumps. Positive displacement pumps are divided into two groups: rotary (such as gear, lobe, and vane) and reciprocating (piston and diaphragm).

A gear pump is one of the most common pumps to increase the hydraulic power of a fluid. Gear pumps move liquids using gears. These gear pumps are made of two types of internal and external gears.

Internal gear pumps consist of two gears that rotate in the same direction, so one gear is inside the other. When two gears make contact with their teeth, fluid is trapped. Now, when the teeth are separated from each other due to rotation, high-pressure fluid is rotated through the ribs to the outlet.

In these internal gear pumps, a crescent between the inner and outer gear directs the flow path to the outlet.

We modeled the geometry of the project using Design Modeler software.

The geometry is related to an internal gear pump. The computational domain includes the internal space of the pump with two non-concentric gears inside each other. A crescent is also placed in the space between two gears.

Then we meshed the model with Ansys Meshing software. The model mesh is unstructured, and the number of cells equals 50,106.

Internal Gear Pump Methodology

This project simulated the water flow inside an internal gear pump.

We aim to model the rotation of two gears inside the pump. The gears’ rotation changes the fluid’s behavior in the pump momentarily. So, the mesh of the computing domain deforms over time.

Then we used the Dynamic Mesh Model. We generally use a dynamic mesh whenever we have a moving boundary or a deforming zone.

Here, two gears are rotating in the same direction. So this causes the mesh to deform over time. Therefore, we define a Rigid Body to define the rotational motion of the gears. We use a user-defined function (UDF) to define the motion of the rigid body.

According to the rotational motion of the gears as a rigid body, the mesh zone around the gears is deformed. So, for this zone, we use the Deforming option.

Due to the nature of this modeling, fluid behavior is time-dependent. Hence, we use the unsteady (Transient) solver.

Internal Gear Pump Conclusion

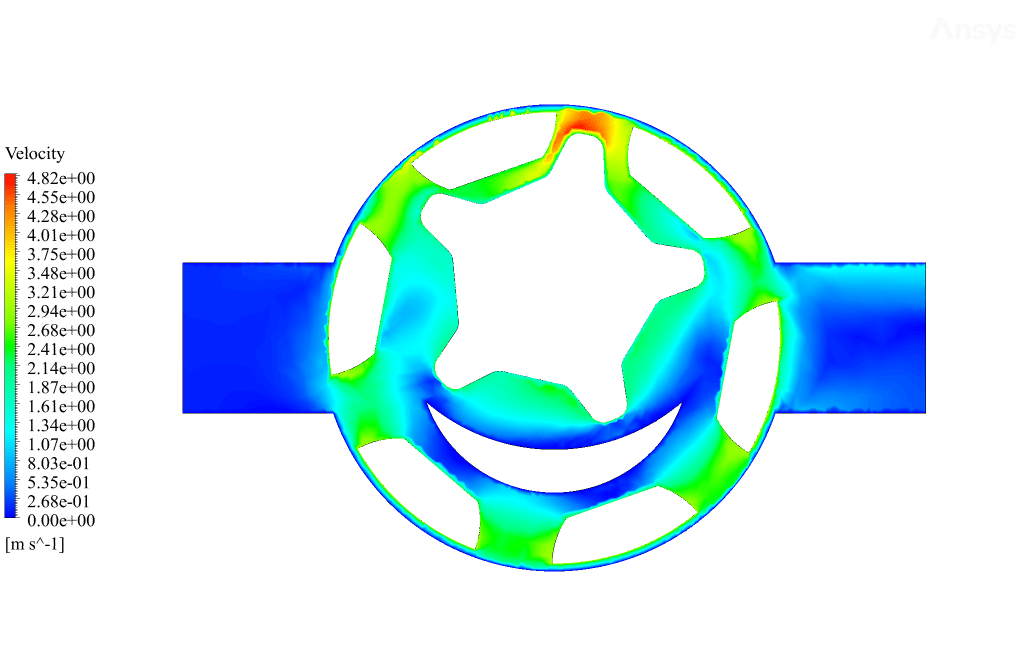

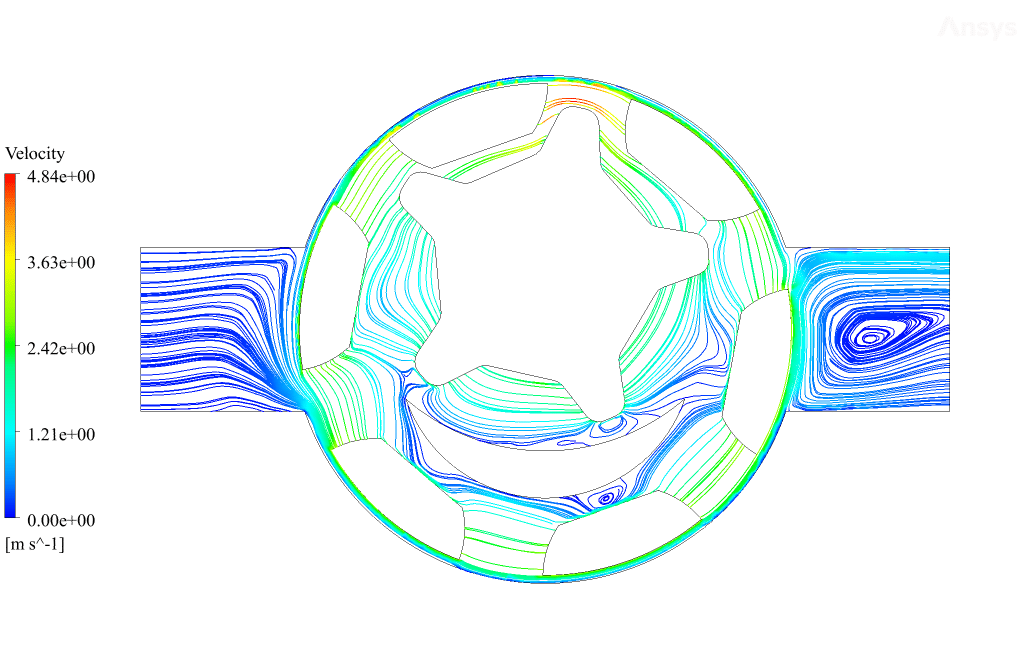

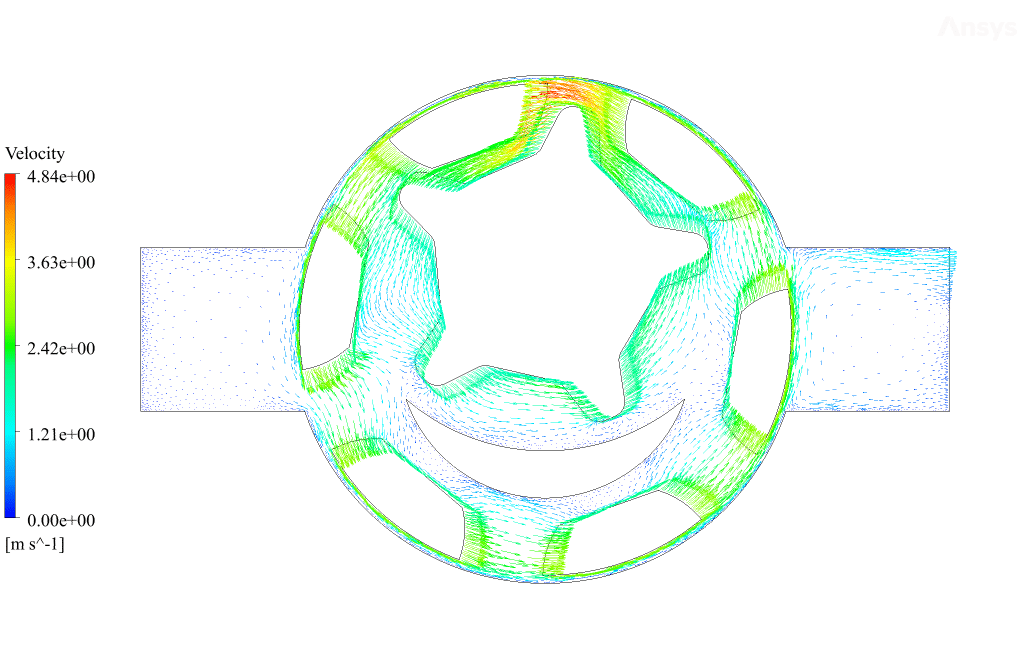

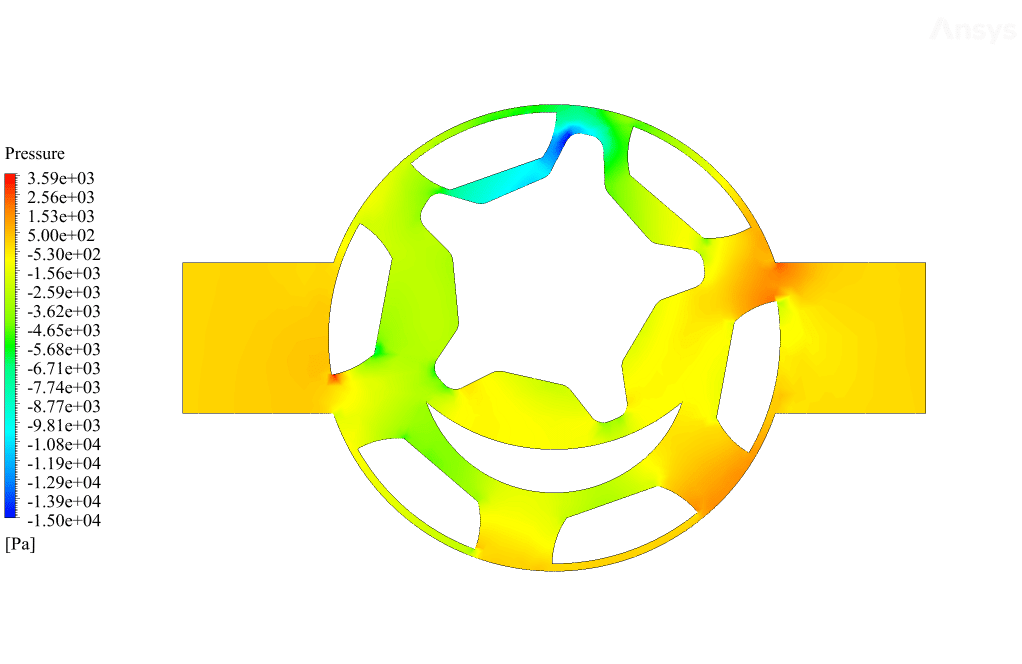

After the solution, we obtained pressure, velocity contours, and velocity vectors. Because the gears rotate over time, we obtained the velocity and pressure contours animation.

The results show that this gear pump is working correctly. This pump can transfer the fluid well and increase the fluid’s pressure. The fluid is trapped in the space between the gears in contact. Then this fluid is pushed towards the outlet with high pressure.

Johnson King –

My experience with the Internal Gear Pump CFD Simulation was enriching! The detail in pressure and velocity contours allowed me to understand the fluid dynamics within the pump vividly. I could see how effectively the gear rotation was modeled, and the animations added a great degree of clarity. Excellent training quality by MR CFD Company!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Internal Gear Pump CFD Simulation provided you with a clear understanding of the pump’s operations and fluid dynamics. It’s fantastic to know that the details and animations enhanced your learning experience. We appreciate your review and are here if you have any more questions or need further assistance!

Lola Crona –

Everything about the CFD simulation work on the Internal Gear Pump by MR CFD was clear and easy to follow! The dynamic interactions and the mesh deformations were fascinating to watch in the animations. I’ve learned a lot about gear pumps and their modeling.

MR CFD Support –

Thank you for your positive review! We’re pleased to hear that our simulation allowed you to understand the intricate workings of an internal gear pump and that the tutorial provided a clear learning path. It is always inspiring to know that our work can facilitate an enriching learning experience. We appreciate your feedback and are here if you have any more queries or need further assistance with CFD simulations.

Abner Torphy –

The in-depth analysis and simulation outlines for the Ansys Fluent training on the Internal Gear Pump are incredibly educational. Thanks to them, the whole concept of how internal gear pumps function is super clear to me now!

MR CFD Support –

Thank you very much for your positive feedback! We are thrilled to hear that our training material on the Internal Gear Pump using Ansys Fluent has provided you with a clear and comprehensive understanding of the pump’s operation. If you have any further questions or need more information, feel free to reach out to us. We’re here to help you on your learning journey!

Eldora Bernhard I –

I just finished the Internal Gear Pump CFD Simulation course by MR CFD, and the learning experience was amazing! The animations of the pressure and velocity contours really helped me to understand the functioning inside an internal gear pump. Moreover, the UDF programming for the gear’s rotation provided in-depth knowledge into how fluid dynamics can be customized in simulations.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Internal Gear Pump CFD Simulation training helped deepen your understanding of gear pump mechanics and fluid dynamics. We always strive to provide detailed and practical knowledge through our courses. If you have further inquiries or need more assistance, feel free to reach out!

Dr. Ephraim Davis IV –

I’m totally satisfied with how this course of Internal Gear Pump simulation has improved my understanding about gear pump mechanisms. The use of animations to demonstrate fluid movement and pressure changes was very helpful!

MR CFD Support –

Thank you for sharing your positive experience with our Internal Gear Pump CFD Simulation training! We’re thrilled to hear that the course enhanced your understanding and that you found the animations particularly beneficial. Your feedback is much appreciated, and we’re here to support your continued learning journey in CFD using ANSYS Fluent. Don’t hesitate to check out our other training materials for even more insights into various CFD applications.

Geo Gerhold –

The way this internal gear pump technology optimizes hydraulic power transfer is fascinating! Its precision engineering for efficient fluid movement is commendable.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the simulation of the internal gear pump in ANSYS Fluent was able to capture your interest with its detailed representation of hydraulic power optimization. If you have any further questions or need more insights, feel free to ask. We appreciate your review.

Donny Wuckert –

The internal gear pump simulation was articulate and informative. Especially useful was understanding how the dynamic mesh model accounts for continuous gear movement leading to fluid pressure changes – fascinating!

MR CFD Support –

Thank you! We are delighted to hear that our Internal Gear Pump simulation with a dynamic mesh model could provide you with clear insights into the operation of such pumps. Your feedback is much appreciated, and we’re glad you found the content informative and interesting!

Michel Johnson –

The description of the results mentions animation. Is there a video of the simulation available that showcases how the gears move and how the fluid flow changes over time?

MR CFD Support –

The review references animations of velocity and pressure contours, but it does not explicitly confirm the availability of a video. We do often create animations to visualize the simulation outcomes better, but for specific requests like access to a video demonstration, please contact our support team, and they’ll be able to assist you further.

Gisselle Baumbach I –

This training clarified a lot about internal gear pumps for me, especially the UDF part for the gear rotation. The animations were super helpful in understanding the flow dynamics. Great course!

MR CFD Support –

Thank you for your kind review! We’re thrilled to hear that the training on internal gear pump simulation was enlightening, and you found the animations particularly helpful. Understanding user-defined functions and the dynamic aspects of the flow is crucial, and we’re glad our course could effectively demonstrate those concepts. We appreciate your feedback!

Miss Anastasia Kovacek –

Thanks for this comprehensive training module on internal gear pump simulation using ANSYS Fluent. It was incredibly informative, and the methodology section was particularly helpful in understanding the setup for the dynamic mesh model!

MR CFD Support –

We’re thrilled to hear that you found the internal gear pump CFD simulation training module comprehensive and informative. Thank you for your positive feedback, and we’re glad the methodology content was beneficial to your understanding. If you need further assistance or have more questions, feel free to reach out. Happy simulating!

Geovany West –

The Internal Gear Pump CFD tutorial was so well-constructed that everything was clear as day. Incredible that such a complex mechanism was broken down into understandable simulations. Kudos to the team for making CFD accessible and fun!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Internal Gear Pump CFD tutorial comprehensive and enjoyable. Our goal is to make CFD more approachable, and your comment reaffirms the hard work we put into our training materials. Your enthusiasm for our product really motivates us!

Dr. Emerson Lesch –

I am blown away by the level of detail in the Internal Gear Pump CFD simulation. The dynamic mesh and usage of UDF to define gear rotation are particularly impressive. Enables truly understanding the pump mechanics and fluid behavior – fantastic learning resource from MR CFD Company.

MR CFD Support –

Thank you so much for your kind words! We are delighted to hear that you found the Internal Gear Pump CFD simulation detailed and educational. We strive to provide valuable and accurate CFD learning resources, and your feedback is greatly appreciated.

Robyn Russel –

The course is pretty well-done! The animations truly helped me grasp how the gears interact and the fluid moves because of that. The concept of using dynamic mesh for simulating the moving parts was new to me, but now I feel I’ve got it thanks to this clear explanation.

MR CFD Support –

Thank you for leaving such a positive review! We’re ecstatic to hear that our animations and explanations helped deepen your understanding of the internal gear pump simulation. Grasping the concept of dynamic mesh is indeed crucial for simulations involving moving parts, and we’re glad our training was able to assist you in this. If you ever need more clarifications or decide to deepen your CFD knowledge, don’t hesitate to explore our other learning resources!

Sydney Skiles –

The 3D model animation of the simulation was really insightful. It gave me a clear understanding of how the gears interact with the fluid. Great work on visualizing the process!

MR CFD Support –

Thank you for your kind words! We are pleased to hear that the 3D model animation helped you understand the interaction between the gears and the fluid in an internal gear pump. If you have any further questions or need additional information, feel free to reach out. We appreciate your feedback!

Genevieve Schuppe –

Fantastic learning material! The detailed explanation of the Dynamic Mesh Model implementation helps understand the complexities of simulating moving boundaries in an internal gear pump. Seeing animations that showcase pressure and velocity changes really solidify the real-time operations of gear pumps.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our training material on the internal gear pump simulation met your expectations and offered a comprehensive learning experience. It’s great to know that the animations and explanations enhanced your understanding of dynamic mesh applications in CFD. Your appreciation motivates us to continue providing high-quality educational content.

Cindy Aufderhar –

I found the detailed aspects of dynamic mesh handling fascinating. Would you mind explaining a bit more about how the Rigid Body motion in the simulation is coordinated with the Dynamic Mesh to faithfully replicate the pump action? Just looking to get a sense of the kind of user-defined functions you might employ for that.

MR CFD Support –

In this simulation, the Rigid Body motion of the gears is coordinated with the Dynamic Mesh to accurately replicate the internal gear pump’s performance. This coordination is achieved through a User-Defined Function (UDF) that prescribes the rotation of the gears. UDFs in ANSYS Fluent are written in C programming language and are used to customize the motion, boundary conditions or add various enhancements to the simulation. For the gear pump, the UDF would control the angular velocity and position of the gears in relation to time, synchronising the mesh deformation with the gears’ rotation ensuring that the fluid motion and pressurisation within the pump occur realistically as would be expected in an actual pump operation.

Mr. Chandler Bode –

I am delighted with the detail provided in the gear pump simulation. The animations of pressure and velocity were particularly useful in understanding the fluid dynamics within the pump – kudos to the team for such practical insights!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the animations useful and that they helped in understanding the complex fluid dynamics at play in the gear pump simulation. Our team puts a lot of effort into making our training materials as informative and user-friendly as possible. Your feedback is greatly appreciated!

Amaya Kilback –

I’m deeply impressed by the level of detail in the CFD simulation of the Internal Gear Pump performed in ANSYS Fluent. The inclusion of dynamic mesh to simulate rotating gears and the use of a UDF for defining the rigid body motion demonstrate meticulous planning and execution. Well done MR CFD on providing such a comprehensive learning tool.

MR CFD Support –

Thank you very much for your positive feedback! We’re thrilled to hear that you found our Internal Gear Pump CFD simulation to be detailed and comprehensive. At MR CFD, we strive to provide educational content that helps users understand complex simulations in ANSYS Fluent. Knowing that our training materials meet your expectations encourages us to continue delivering high-quality tutorials and simulations. We appreciate you taking the time to review our product.

Mrs. Zoie Kulas MD –

The training for the Internal Gear Pump CFD Simulation with ANSYS Fluent was practical and really enriching. The use of dynamic mesh and UDF to model the gears’ rotation was particularly illuminative, and the animations helped to visualize the process effectively. Understanding the pumping mechanism through the CFD perspective gave me much clearer insight into the pump operations. Great job on the detailed breakdown!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the training enriching and that the use of dynamic mesh and the UDF was enlightening for you. It’s great that the animation aided your understanding of the internal gear pump’s operation. We strive to provide detailed and clear educational resources, and we’re glad we could help. If you have any more questions or need further assistance, feel free to reach out!

Grant Farrell –

The detail and intricacies of the Internal Gear Pump CFD Simulation training seem outstanding. As an engineer, gaining insights into the rotation effects and dynamic mesh applications is invaluable. The use case of gears in fluid movement was well exemplified.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our training has provided valuable insights and practical knowledge to you as an engineer. Your appreciation motivates us to continue delivering high-quality learning resources. If you have any further feedback or need assistance with similar projects, feel free to reach out.

Melisa Stroman –

The details on how the gear rotation is specifically modeled enhances my understanding of the simulation. Great work on illustrating the dynamic nature of the internal gear pump!

MR CFD Support –

Thank you for the positive feedback! We’re glad to hear that the explanation of gear rotation and dynamic mesh modeling has provided you with a clear understanding. If you have any more questions or need further information, please feel free to reach out.

Jakob Balistreri –

I’m in awe of how well-structured and detailed the simulation design is. Focusing on unsteady dynamics truly captures the complex behavior of fluid within the internal gear pump mechanism. Well done!

MR CFD Support –

Thank you for your kind words! We always strive to provide the most accurate and detailed simulations to reflect the complexity of real-life engineering scenarios. Your feedback is very much appreciated!

Ms. Sister Hamill –

I was really impressed by how smoothly the gears seemed to operate in the simulation. It helped me visualize the actual function of an internal gear pump incredibly well!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation was able to provide clear visualization and enhance your understanding of the internal gear pump’s operation. It’s our goal to offer high-quality and informative simulations that can facilitate learning in an effective way. Your feedback is greatly appreciated!

Julie DuBuque –

This content was extremely useful for understanding the basic function and simulation processes of an internal gear pump. I’m really impressed by the level of detail and explanation.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that our training helped you gain a better understanding of internal gear pump simulations. If you have any further questions or need additional assistance, please don’t hesitate to reach out. Your satisfaction is our top priority!