Manifold of Engine CFD Simulation by Species Transport

$100.00 $50.00 Student Discount

In this project, steady air flow mixing with fuel is investigated in an engine manifold with 3 outlets, where only one outlet is open and the other 2 outlets are blocked.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Manifold of Engine CFD Simulation by Species Transport, ANSYS Fluent

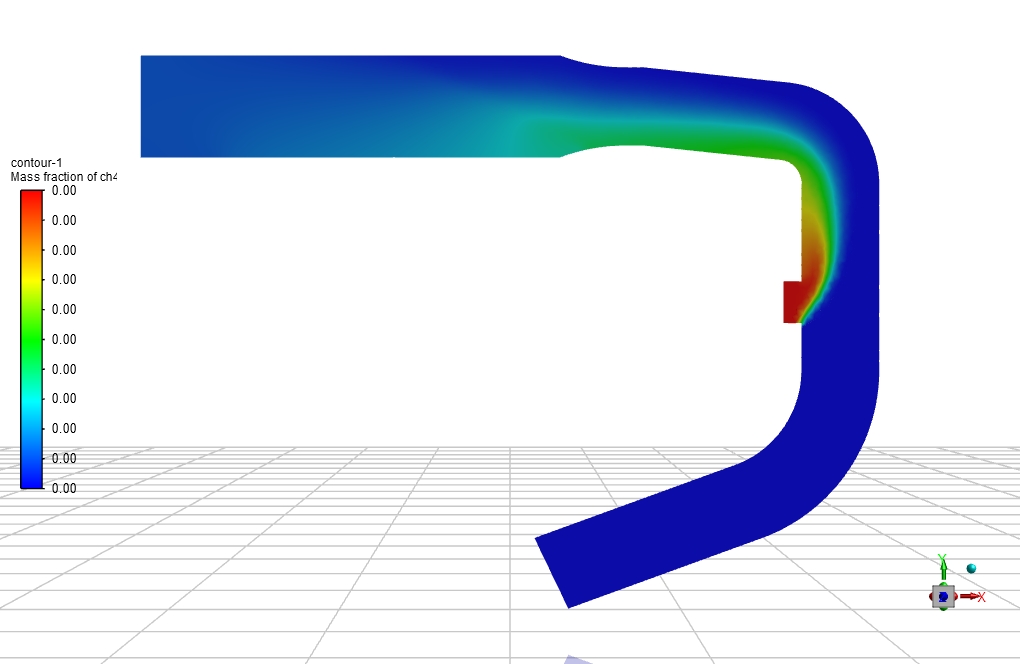

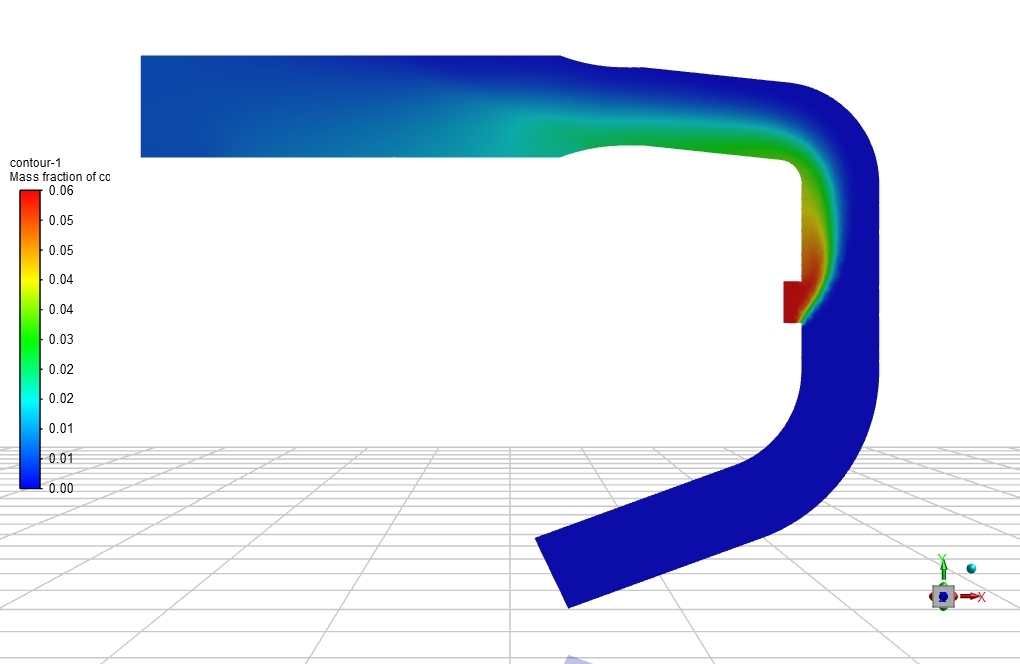

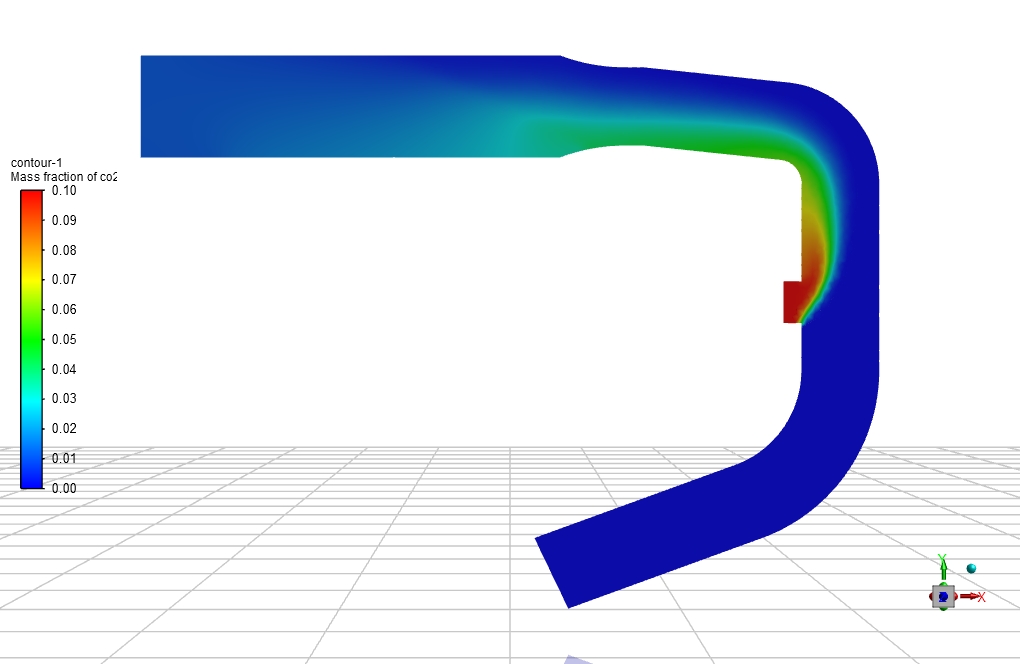

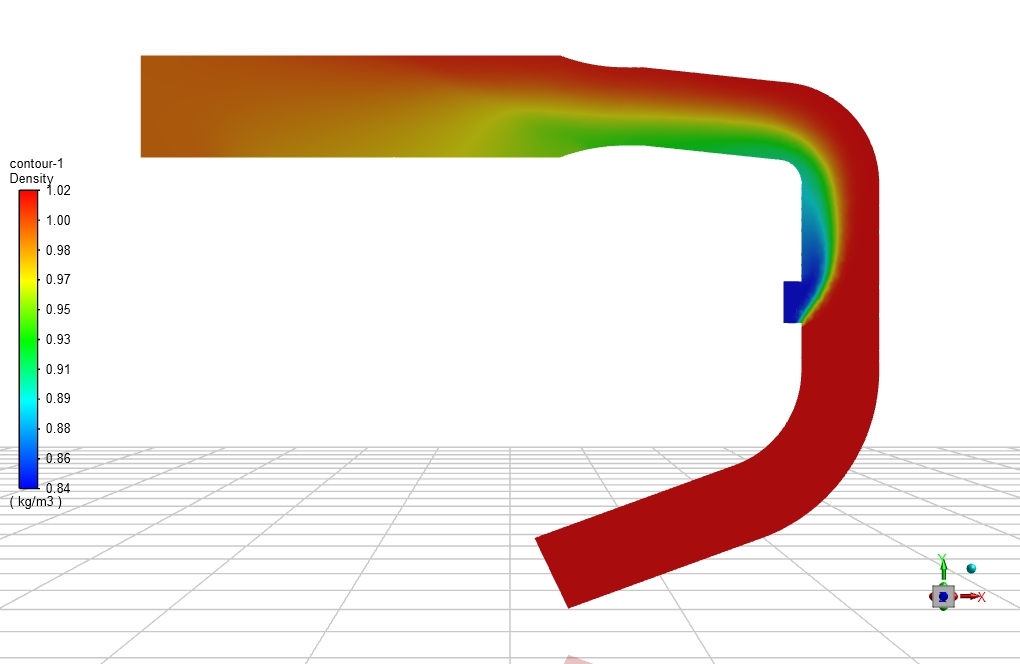

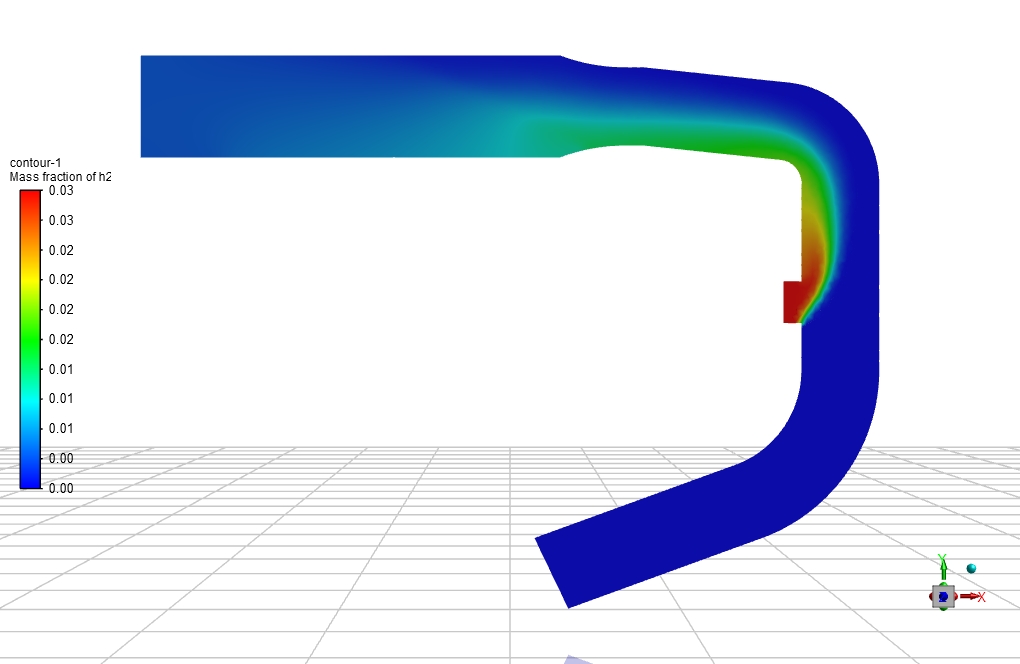

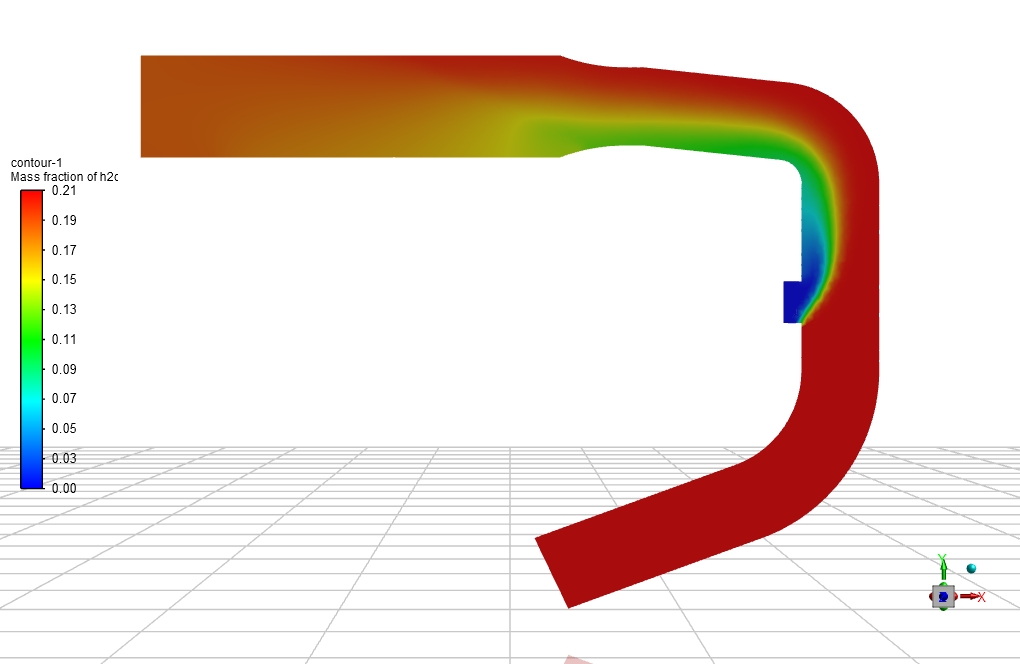

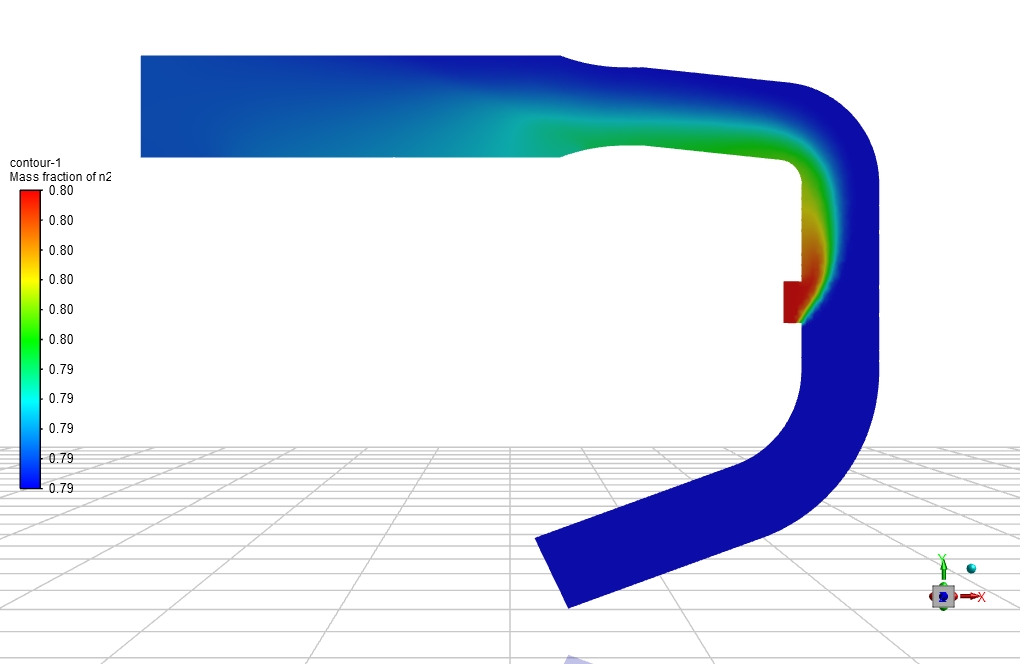

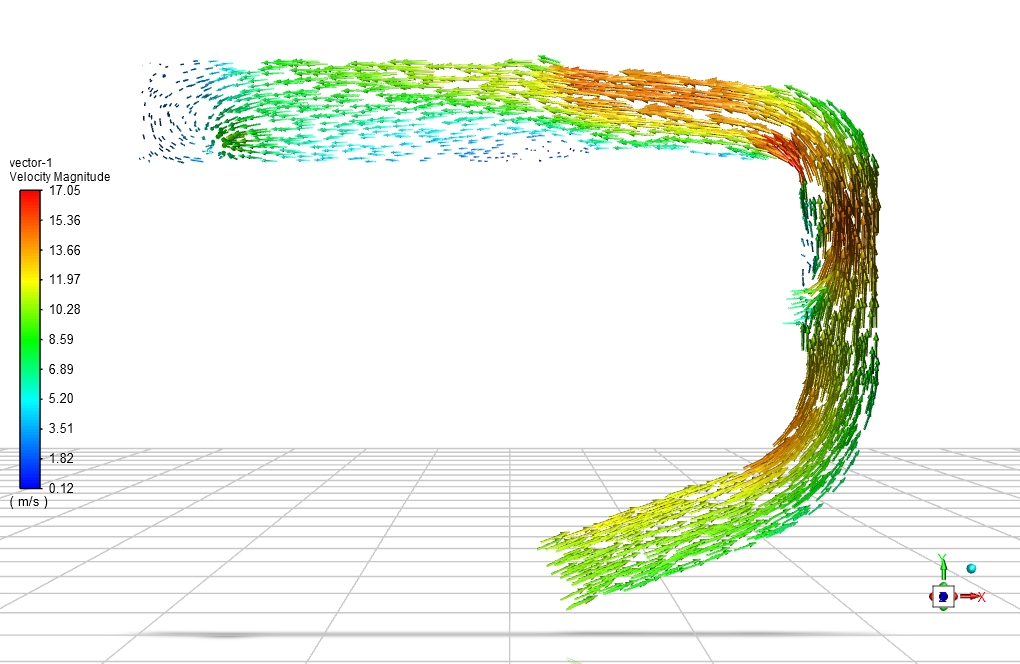

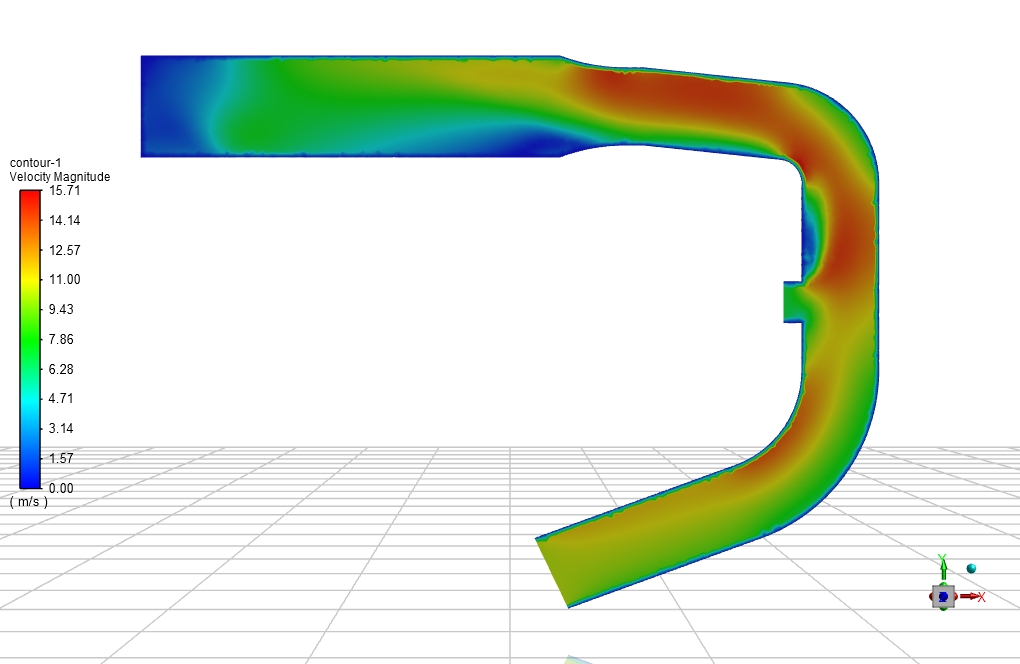

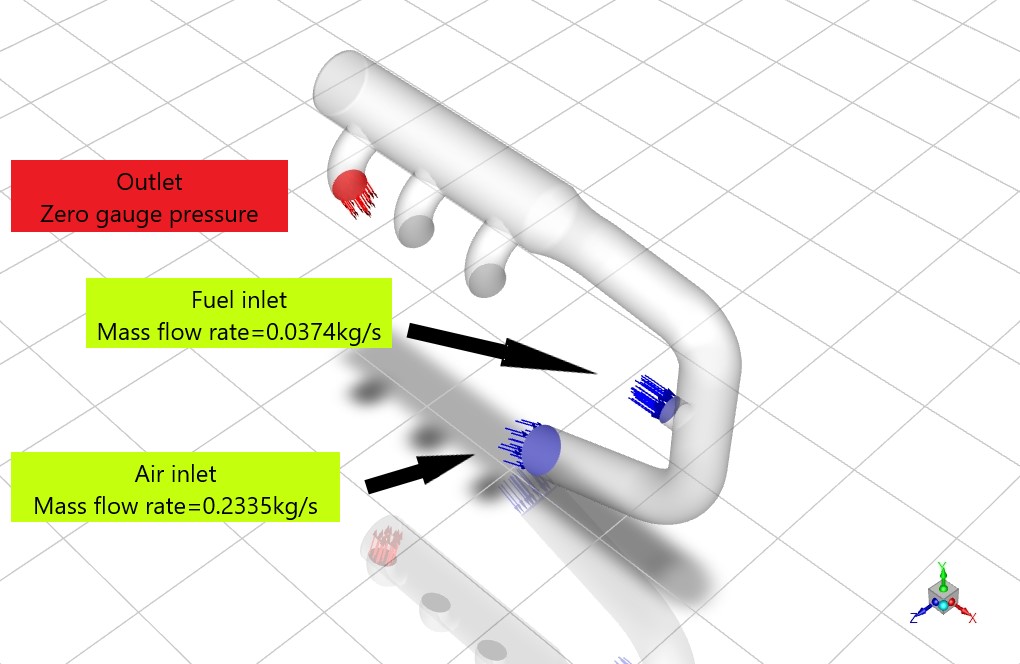

In this project, steady air flow mixing with fuel is investigated by ANSYS Fluent in a 3-outlet manifold where only one outlet is adequate, and the other 2 outlets are blocked. Two inlets provide air and fuel flow into the domain. Air and fuel flow rates are equal to 0.2335 and 0.0374 kg/s. Species entering the domain via air inlet are nitrogen and oxygen with mass fractions equal to 0.79 and 0.21, respectively. Species entering the domain via fuel inlet are CO, CH4, CO2, N2, and H2, with mass fractions equal to 0.06, 0.004, 0.1, 0.081, and 0.03, respectively.

Engine Manifold Geometry and mesh

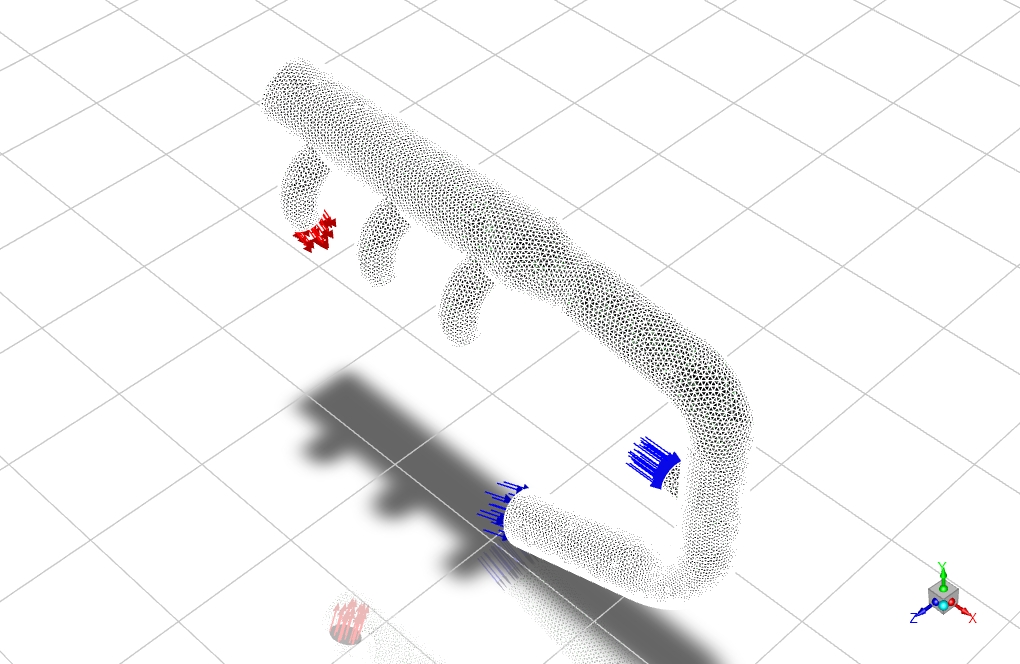

The geometry of the fluid domain is designed in the Design Modeler, and the computational grid is generated using ANSYS Meshing. The mesh type is unstructured, and the element number is 231646.

Solver configuration

Critical assumptions:

- The solver type is assumed Pressure Based.

- Time formulation is assumed to be Steady.

- Gravity effects are neglected.

The following table summarizes the defining steps of the problem and its solution.

| Models (Engine Manifold) | ||

| Energy | On | |

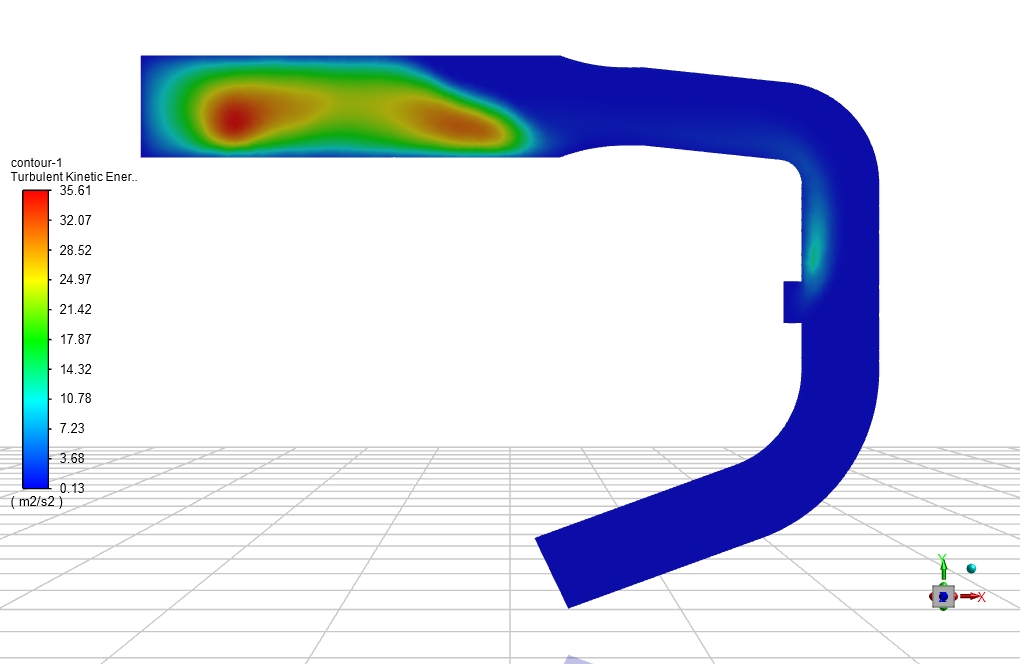

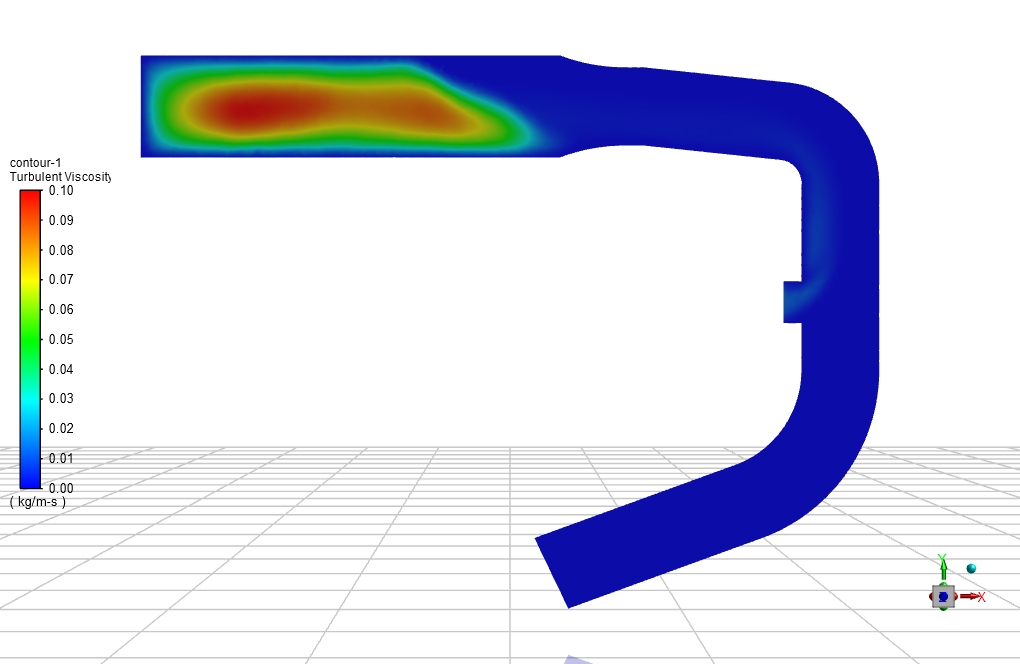

| Viscous | K-epsilon model | Standard |

| Near wall treatment | Enhanced wall treatment | |

| Species transport | Model | Species transport |

| Options | Inlet diffusion (on) | |

| The diffusion energy source (on) | ||

| Mixture properties | Mixture-template | |

| Materials (Engine Manifold) | ||

| Fluid | Definition method | Fluent Database |

| Material name | CO2 | |

| Material name | CO | |

| Material name | H2 | |

| Material name | CH4 | |

| Material name | N2 | |

| Material name | O2 | |

| Material name | H2O | |

| Boundary conditions (Engine Manifold) | ||

| Inlet_air | Type | Mass flow inlet |

| Mass flow rate | 0.2335 kg/s | |

| Turbulent intensity | 4% | |

| Hydraulic diameter | 0.05 m | |

| Species | N2 (0.79) | |

| O2 (0.21) | ||

| Inlet fuel | Type | Mass flow inlet |

| Mass flow rate | 0. 0374 kg/s | |

| Turbulent intensity | 5% | |

| Hydraulic diameter | 1 m | |

| Species | N2 (0.801) | |

| CO (0.06) | ||

| CH4 (0.004) | ||

| CO2 (0.1) | ||

| H2 (0.03) | ||

| Solver configurations (Engine Manifold) | ||

| Pressure-velocity coupling | Scheme | PISO |

| Spatial discretization | Gradient | Least square cell-based |

| Pressure | Standard | |

| Momentum | Second order Upwind | |

| K | First order Upwind | |

| Epsilon | First order Upwind | |

Results and discussion

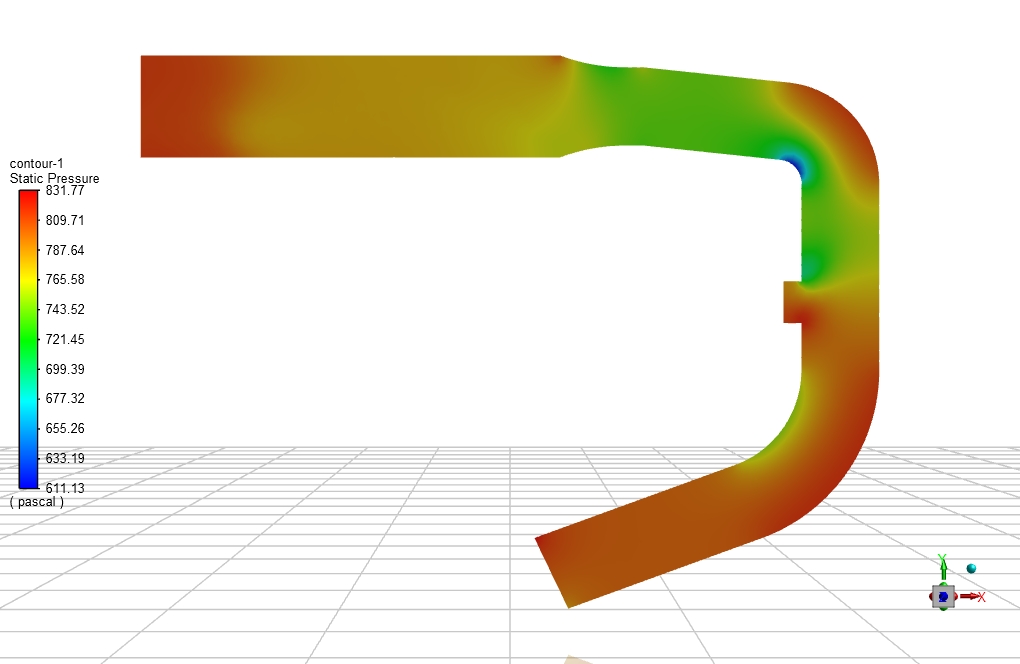

The mixture mass flow rate at the outlet is equal to 0.2709012 kg/s. Although 2 outlets are considered walls and are blocked, mixture pressure on these surfaces is critical. Pressure on outlets 1 and 2 equals 771.44639 and 780.98142 Pa, respectively.

Hallie Mitchell –

Can this simulation be extended to model other types of manifolds?

MR CFD Support –

While the current simulation focuses on an engine manifold, it can be extended to model other types of manifolds. We are open to contributions and can customize the simulation to accommodate your specific needs.

Juwan Bernhard –

The species transport simulation described is for an engine manifold with a complex fuel and air mixing process. Was any specific challenge encountered in defining and managing the multiple species and their interactions within the simulation set-up? And how was it addressed?

MR CFD Support –

When dealing with multiple species, particularly in the context of combustion processes or mixflow scenarios like in engines, the main challenge is to ensure accurate representation of individual species’ interaction, diffusion, and chemical reactions if any. In ANSYS Fluent, the Species Transport Model and options such as inlet diffusion are used to account for these interactions correctly. To address the challenge, the simulation has respective mass fractions for different species predefined at their inlets, and special attention is given to the species’ properties such as diffusivity through comprehensive model settings. Fluent’s robust algorithm is configured to handle the complex physics associated with multiple species transport.

Prof. Jorge Lindgren V –

Can the simulation model the effects of different fuel types on the engine manifold performance?

MR CFD Support –

Yes, the simulation can model the effects of different fuel types on the engine manifold performance. This allows for a comprehensive analysis of manifold performance for different fuel types.

Ms. Shirley Towne V –

The project description is excellent! It provides a great deal of technical insight into the simulation setup. Is the version of ANSYS Fluent used for the simulation compatible with recent hardware setups such as high-performance GPUs for faster computation?

MR CFD Support –

Thank you for the positive feedback on the project description. ANSYS Fluent is continually upgraded to take advantage of recent hardware advancements, including high-performance GPUs. Although this project didn’t specify hardware details, typically, the latest versions of Fluent support GPU acceleration, helping to speed up computations and make simulations more efficient. It’s advisable to check the system requirements for the specific version of ANSYS Fluent being used to ensure hardware compatibility.

Katrine Lang –

The intricate details of the simulation are impressive! Can you explain how the mixing of fuel and air affects the outcome of the simulation?

MR CFD Support –

Thank you for your kind words! In CFD simulations involving combustion engines, the mixing of fuel and air greatly influences combustion efficiency, power output, and emission levels. Proper mixing ensures that fuel molecules can find sufficient oxygen atoms for combustion, thereby affecting engine performance and the formation of pollutants like NOx. In this study, through the species transport model, we see a realistic distribution of individual species, which helps predict the quality of mixing and combustion processes if extended to reacting flows or predicts possible incomplete mixing zones leading to inefficient combustion.

Mr. Jeramie Powlowski IV –

I found the details on species mass fractions exceptionally precise. How does the study ensure the accuracy of these fractions during the simulation process?

MR CFD Support –

In simulations like these, the accuracy of species mass fractions is ensured by meticulously setting up the Species Transport Model and specifying the mass flow rates at the inlets accurately. The species mass fractions are inputs to the problem, taken from experimental or theoretical data, and the solver maintains these fractions as boundary conditions. By using a finely discretized mesh and appropriate solver settings, the model reliably simulates the species transport phenomena throughout the manifold.

Bradley Christiansen –

How computationally intensive is this simulation?

MR CFD Support –

The computational intensity of the simulation depends on several factors, including the complexity of the geometry, the number of cells in the mesh, and the complexity of the species transport and reaction models. However, ANSYS Fluent is highly optimized for CFD simulations and can efficiently handle large, complex simulations.

Javon Crist –

How accurate is the simulation in predicting the engine manifold performance?

MR CFD Support –

The simulation uses advanced models for turbulence, multiphase flow, and species transport, which allows it to accurately predict the engine manifold performance.

Skylar Eichmann –

The review is highly informative and shares detailed outcomes of the engine manifold simulation, however, as a new learner to CFD, could you explain a bit more about how the Species Transport Model works and its importance in this simulation?

MR CFD Support –

The Species Transport Model in ANSYS Fluent allows for the simulation of the mixing and reaction of multiple species within a flow field. In the context of this engine manifold simulation, it’s crucial because it predicts the concentration distribution of each species, which is necessary when examining how air and different fuel components mix. Since the performance of an engine greatly depends on the quality of fuel-air mixing, accurate species transport modeling provides insights into optimization for combustion efficiency.

Ms. Lilian Roberts MD –

The review says one of the outlets is adequate and the other two are blocked. Can you describe the effects of the blocked outlets on mixture distribution within the manifold?

MR CFD Support –

Your question is a great observation about the simulation setup. The blocked outlets create a backpressure in the manifold that alters the flow patterns. This influences the velocity and pressure fields, leading to a non-uniform mixture distribution, especially around the blocked outlets. The CFD simulation accounts for the effects of these blocked outlets and allows us to analyze how they impact the overall mixing efficiency of air and fuel within the manifold.