Mass Transfer Macro UDF, Evaporation and Condensation Rate CFD Simulation

$270.00 $135.00 Student Discount

- The problem numerically simulates the evaporation and condensation using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

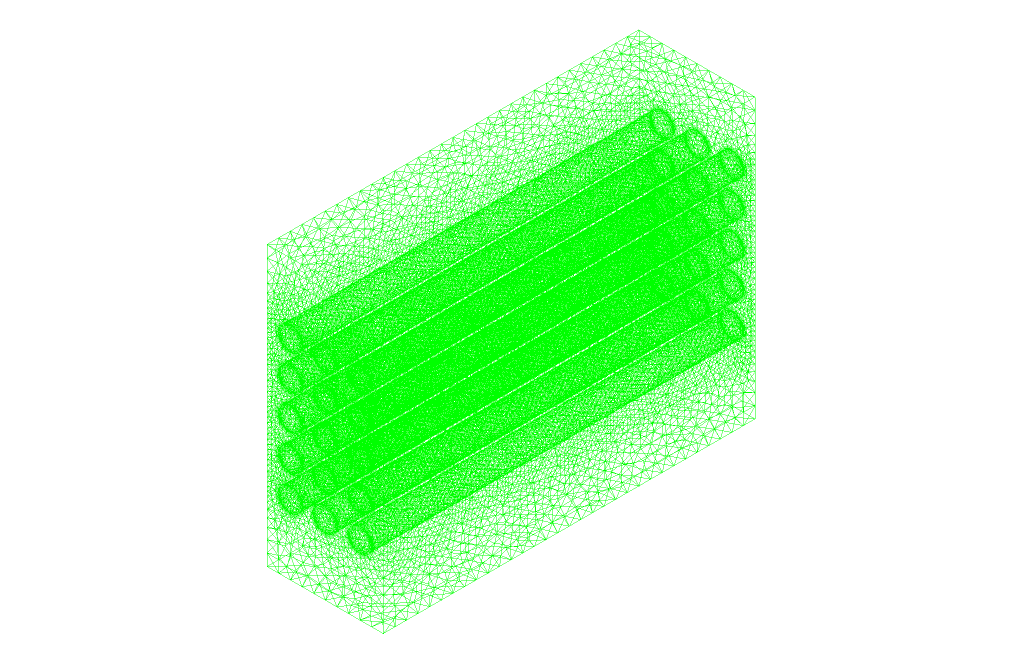

- We mesh the model with ANSYS Meshing software; the element number equals 1,574,100.

- We use the VOF Multiphase model to define water, liquid, and vapor.

- We define a Mass Transfer between water liquid and water vapor.

- We use the User-Defined Function (UDF) to define a mass transfer (evaporation and condensation).

- We use the Mass-Transfer Macro for UDF.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, we performed a numerical simulation using ANSYS Fluent software’s User-Defined Function (UDF). For this CFD product, we used MASS_TRANSFER Macro to write UDF programming.

This product is the 3rd chapter of the User-Defined Function (UDF) Training Course.

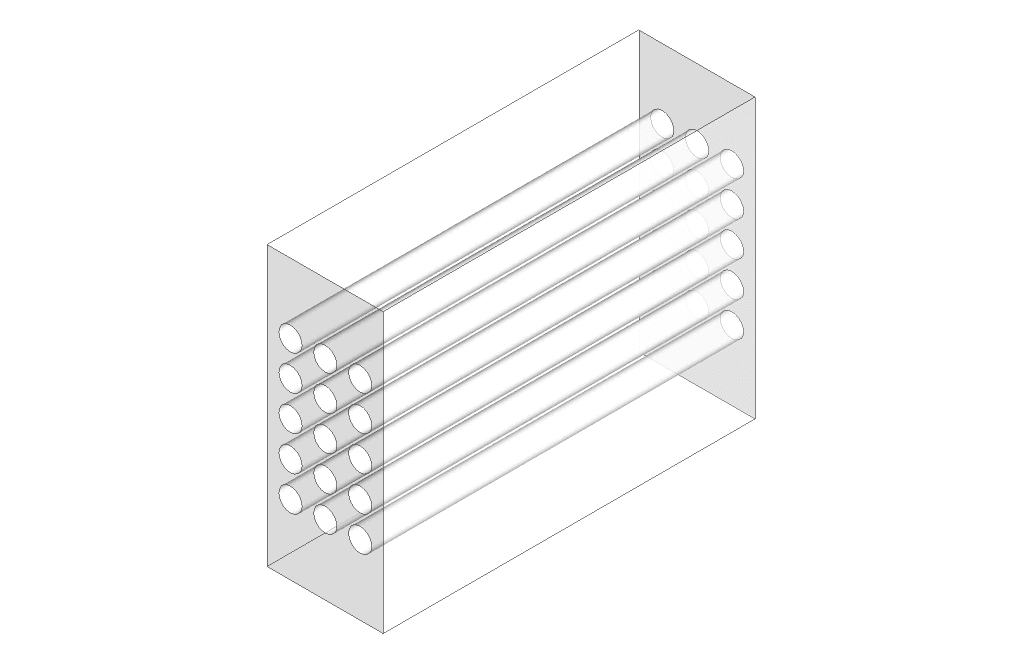

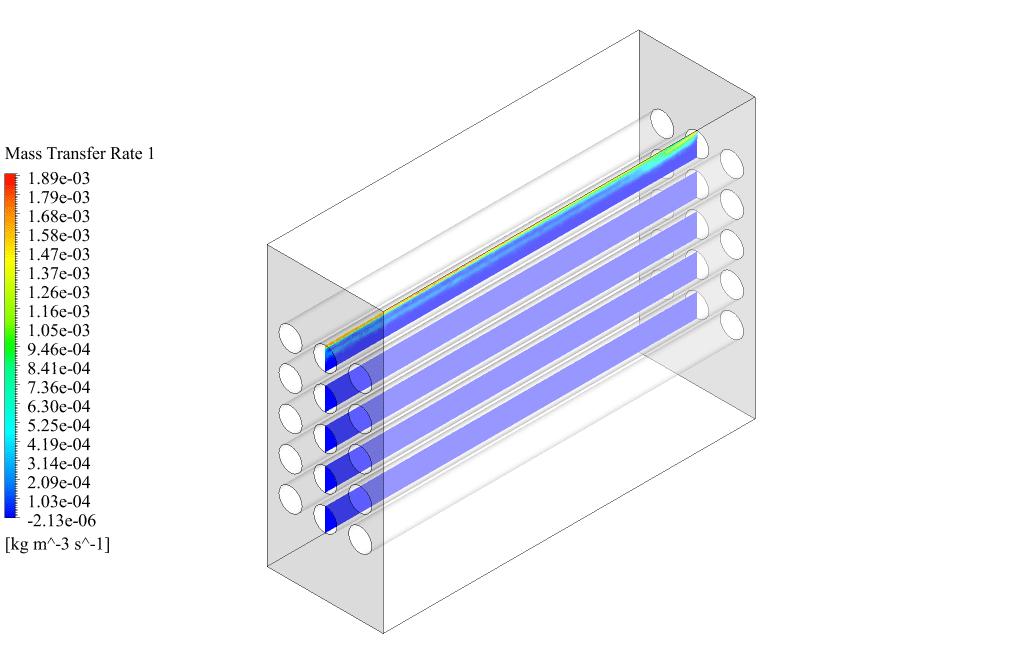

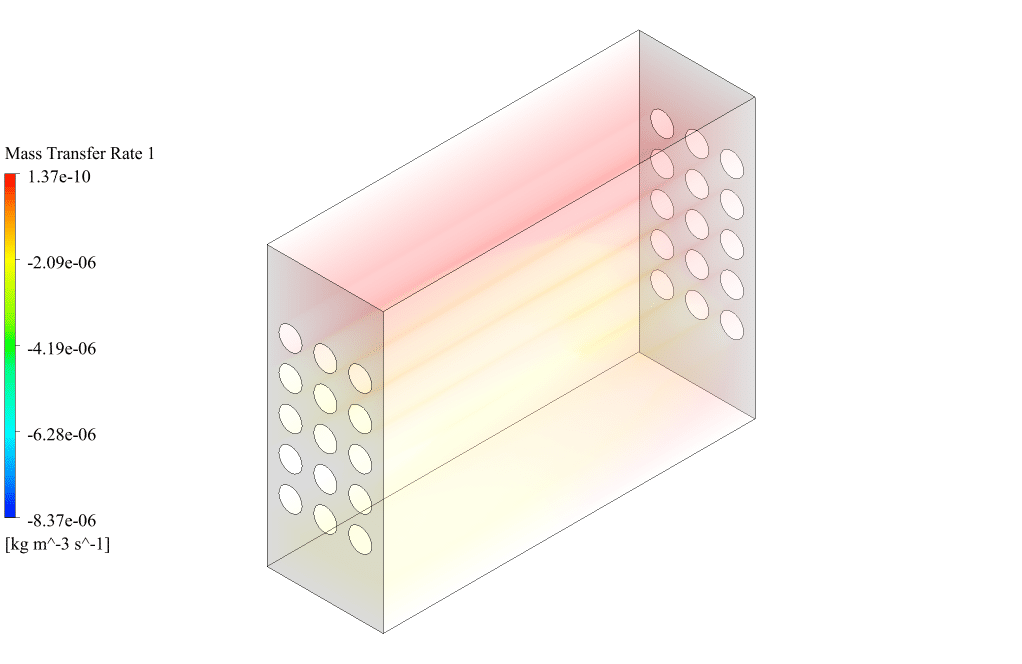

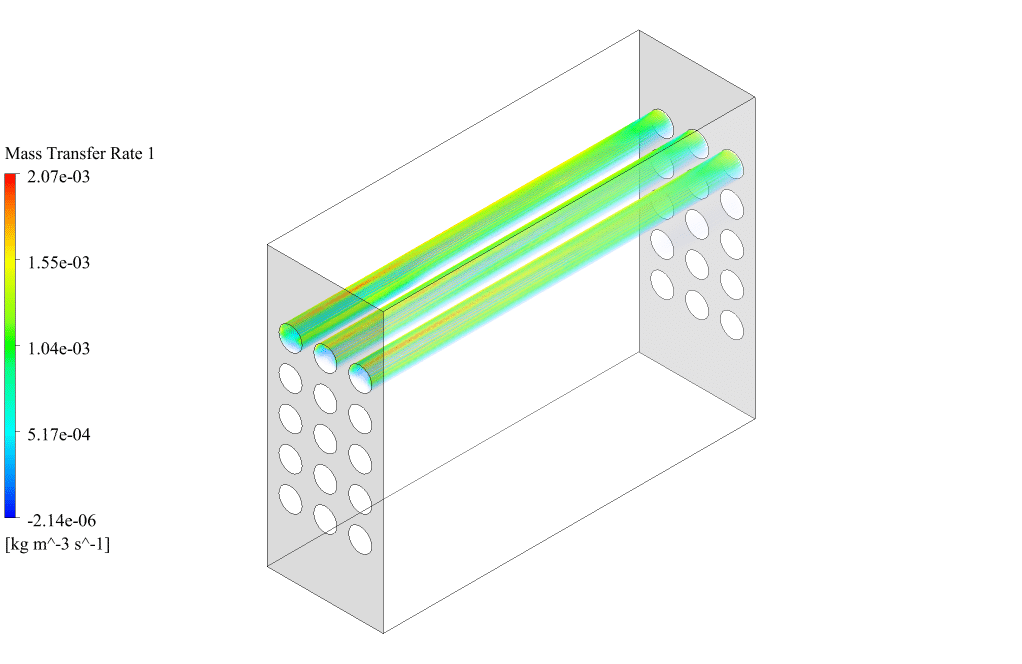

We considered a chamber inside which several rows of tubes are placed. Water vapor enters from the chamber’s top and exits from the bottom. Liquid water also passes through the internal tubes of the chamber.

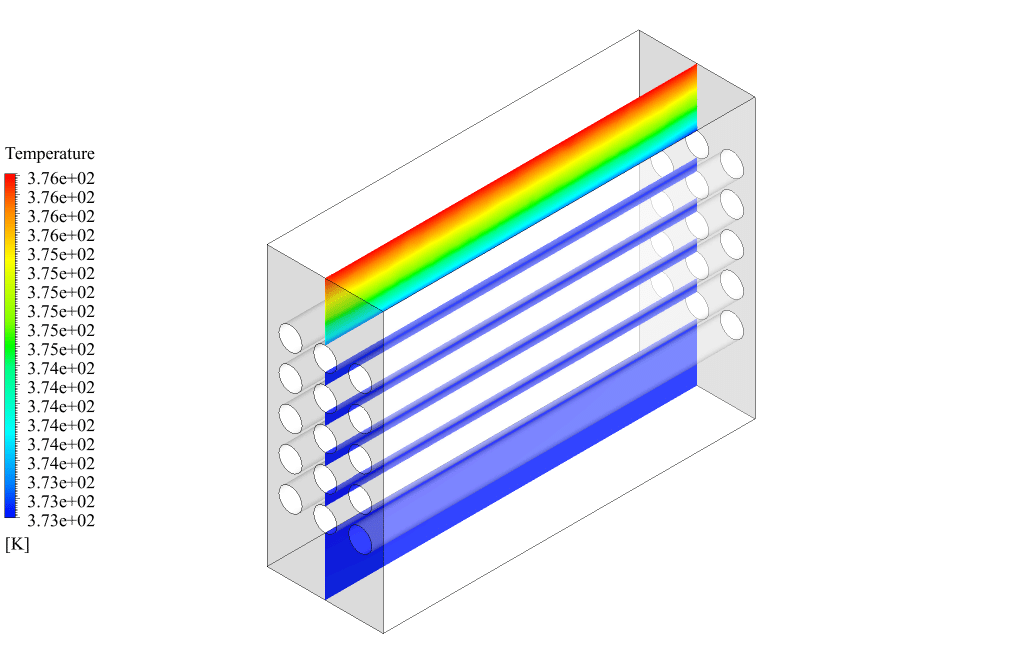

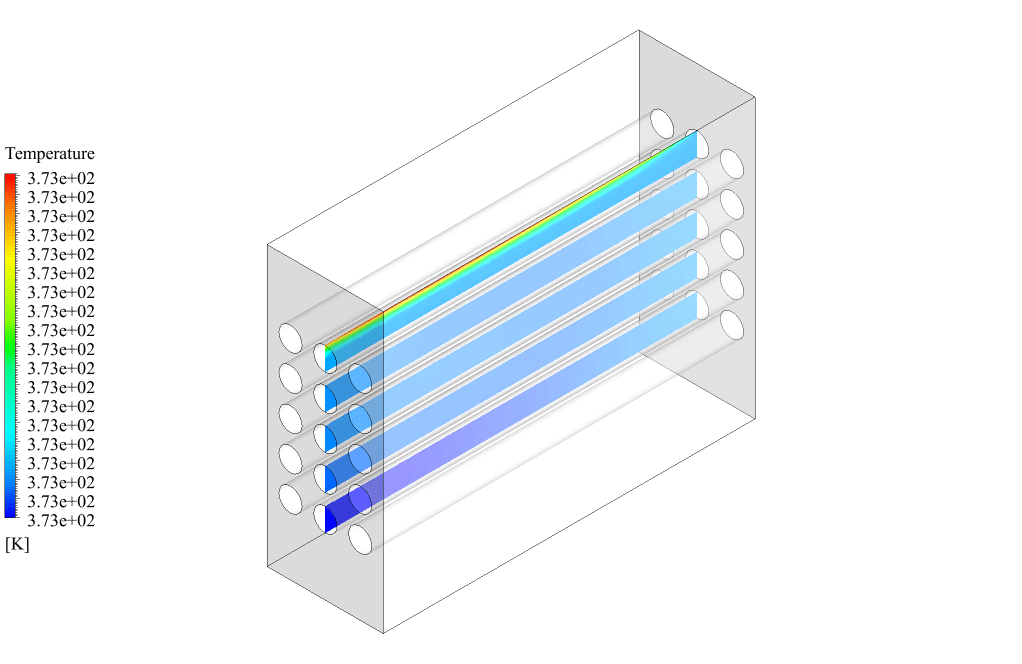

The temperature difference between the water vapor inside the chamber and the liquid water inside the pipes leads to heat transfer. This heat transfer can lead to phase exchange. If water vapor reaches below the saturation temperature, condensation occurs. If the liquid water reaches above the saturation temperature, evaporation occurs.

In this project, we intend to estimate the evaporation and condensation rates. In the first step, we modeled the geometry in 3D with Design Modeler software. Then, we meshed the model with ANSYS Meshing software. The Mesh is unstructured, and 1,574,100 cells are created. Finally, we numerically simulated the current model based on the CFD method by ANSYS Fluent software.

Methodology (UDF)

In this project, we define two fluids: liquid water and water vapor. So, we used the Multiphase model. We use the Volume of Fluid (VOF) multiphase model since we intend to prevent two fluids from mixing.

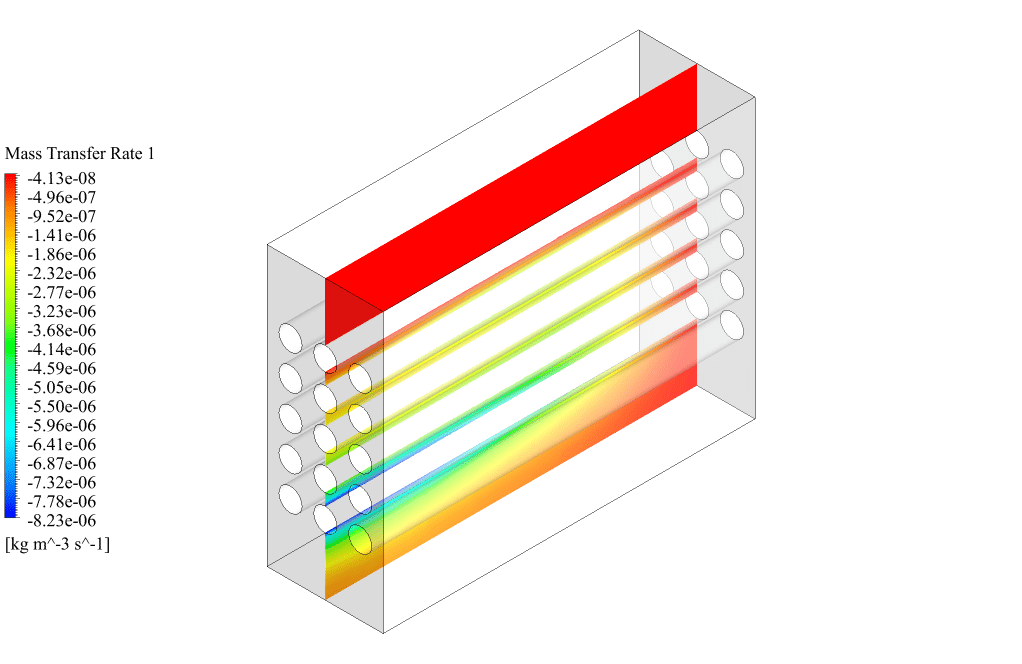

Since we aim to model the phenomenon of evaporation and condensation, we need to define a Mass Transfer between liquid water and water vapor. So, we used a User-Defined Function (UDF) to define the mass transfer rate.

We need to use the Mass Transfer Macro (DEFINE_MASS_TRANSFER macro) for this UDF. According to this UDF, we considered the temperature of 373.15 equivalent to saturation temperature. If the temperature is lower than the saturation temperature, the condensation relation is defined; if the temperature is higher than the saturation temperature, the evaporation relation is defined.

Conclusion (UDF)

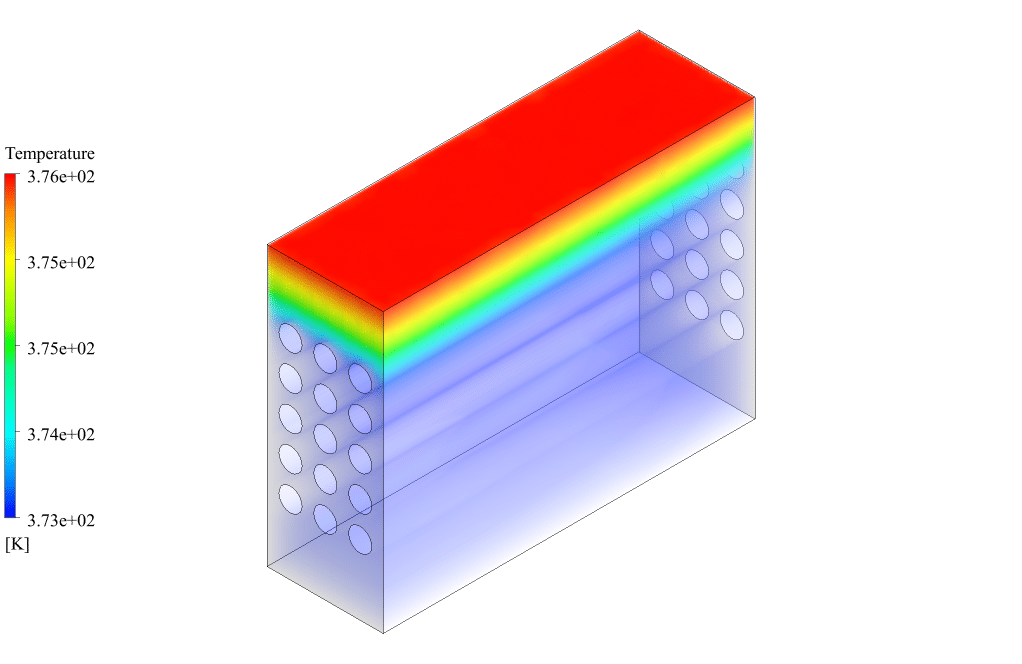

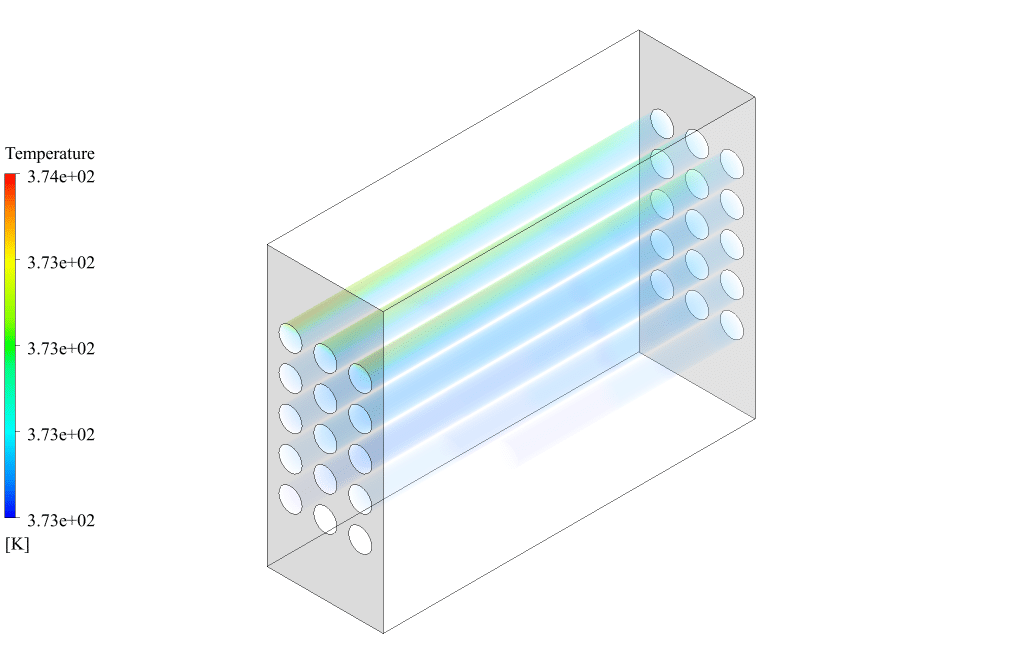

After completing the calculation, we will review the results. To analyze the results, we obtain some contours. We obtain the volume fraction of water (liquid), the volume fraction of water (vapor), and temperature contours. The contours show that heat transfer leads to evaporation and condensation.

Inside the chamber, the water vapor reaches below the saturation temperature, resulting in condensation. Inside the pipes, the water vapor reaches above the saturation temperature, resulting in evaporation. We conclude that we performed the current numerical simulation correctly, and our UDF worked correctly.

Mrs. Effie Ziemann –

I successfully simulated the evaporation and condensation process using your UDF learning product, and the results were visibly clear in the contours provided. Truly a solid resource for understanding the complexities of mass transfer in multiphase simulations.

MR CFD Support –

We greatly appreciate your positive feedback on our UDF learning product. It’s fantastic to hear that the resource aided your understanding of complex mass transfer processes in CFD. Thank you for choosing our simulation tools and for taking the time to share your successful experience!

Arlene Dare –

The UDF methodology for predicting evaporation and condensation is fascinating! I’m interested to know if we can adjust the saturation temperature in the UDF based on different atmospheric conditions.

MR CFD Support –

Yes, you can adjust the saturation temperature in the UDF to match specific atmospheric or experimental conditions. The saturation temperature is a parameter set within the UDF code, and by changing this value, you can simulate the effects of different temperatures on the mass transfer rates of evaporation and condensation in the simulation.

Donny Carter Jr. –

How is the saturation temperature chosen in the context of this project, and is it adjustable in the UDF if a different application necessitates a different value?

MR CFD Support –

In this project, the saturation temperature is set at 373.15 K, which corresponds to the boiling point of water at atmospheric pressure. If you need to adjust the saturation temperature for a different application, you can modify it directly in the UDF according to the requirements of your particular simulation.

Kay D’Amore –

I appreciated the clarity provided on how UDF is applied to model mass transfer phenomena. Are the relative humidity effects considered in these calculations?

MR CFD Support –

Thank you for your interest in our Mass Transfer CFD simulation product. In this particular simulation, the main focus is on temperature-driven phase changes between liquid water and water vapor, using a specific set of assumptions and conditions. The effect of relative humidity is not explicitly mentioned as a parameter in this setup. To include relative humidity, an additional setup considering the vapor content of air and corresponding interactions would be required.

Kade Friesen –

After completing this simulation and learning from it, I was impressed by the advanced approach taken to model evaporation and condensation. This UDF training course using the MASS_TRANSFER Macro seems to provide excellent insights into these complex phenomena in a multiphase system.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found our UDF training course and the MASS_TRANSFER Macro approach enlightening. If you ever decide to dive deeper into UDF programming or face any challenges with complex CFD simulations in the future, feel free to reach out. Your success is our greatest satisfaction!

Ophelia Keebler III –

I’m highly impressed with the way UDF has been applied for phase change simulation. Mass transfer through phase change can be difficult to capture, and it seems this training described it very elegently!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our UDF training for evaporation and condensation simulation met your expectations and provided a clear understanding of the mass transfer process. Effective application of User-Defined Functions in ANSYS Fluent can indeed be vital in accurately simulating complex processes. We appreciate your feedback!