Mechanical Engineering Training Package, Advanced Users, Part 1, 10 Exercises

$299.00 $149.50 Student Discount

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all ADVANCED users.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

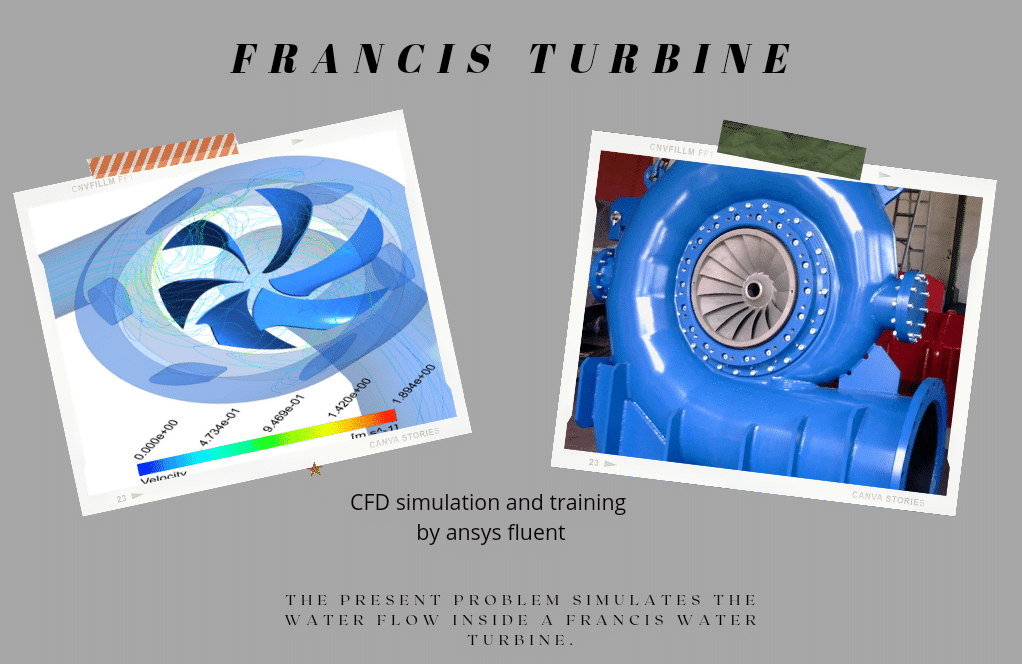

Mechanical Engineering – ANSYS Fluent Training Package, 10 Practical Exercises for ADVANCED Users (Part 1)

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all ADVANCED users.

In project number 1, a Porous Mixer for Increasing the Heat Transfer of Nanofluid is simulated. mixing hot (303k) and cold (293) nanofluid flows were investigated while mixing these two streams once using 28 mixers and once using 54 mixers modeled as a porous medium.

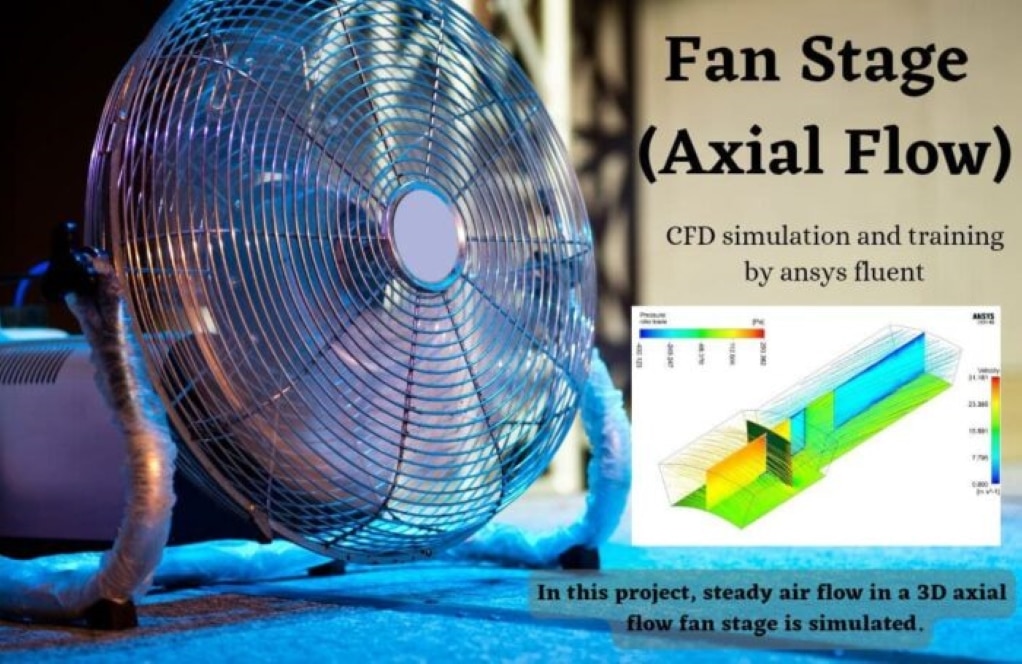

In practical exercise number 2, steady airflow in a 3D geometry of the fan stage is simulated. Fan stage is a common apparatus used for creating steady airflow in mechanical industrial applications used in the cooling process of newly painted body parts. The periodic boundary condition is used for simulation of the real fan stage at the lowest computational cost.

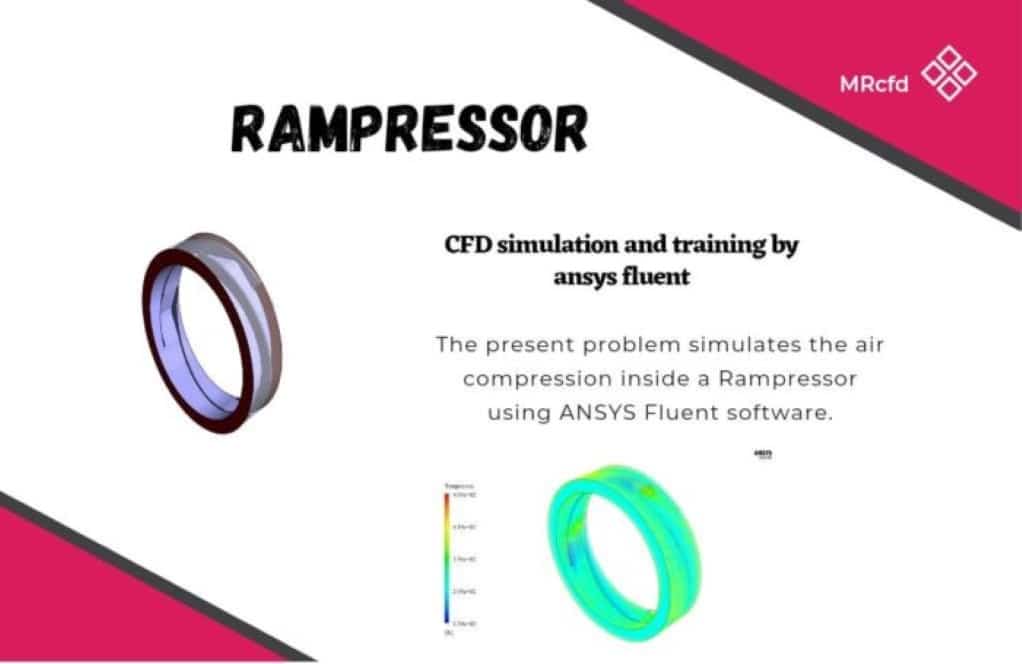

Problem number 3 simulates the air compression inside a Rampressor. The Rampressor is a unique type of ultrasonic compressor rotor that operates at a high-pressure ratio, and engine technology and gas compression are the ramjet ultrasonic shock wave. The operating mechanism of these compressors is such that the gas flow passes through a fixed outer cover and a sloping surface or inner ramp; While this inner surface has a ramp with its rotational motion relative to the fixed body, it increases or decreases the gas passage.

Practical exercise number 4 simulates the condensation process inside a shell and tube condenser. The process of condensation means the conversion of a fluid from a gaseous phase to a liquid phase; This means that when the fluid vapor reaches a saturation temperature, it turns into a liquid.

Problem number 5 simulates well drilling and sludge separation. In this simulation, a cylindrical hole is considered a well, inside which a rotating body in the shape of a cylinder is placed. Inside the cavity, a Non-Newtonian material for drilling operations flows.

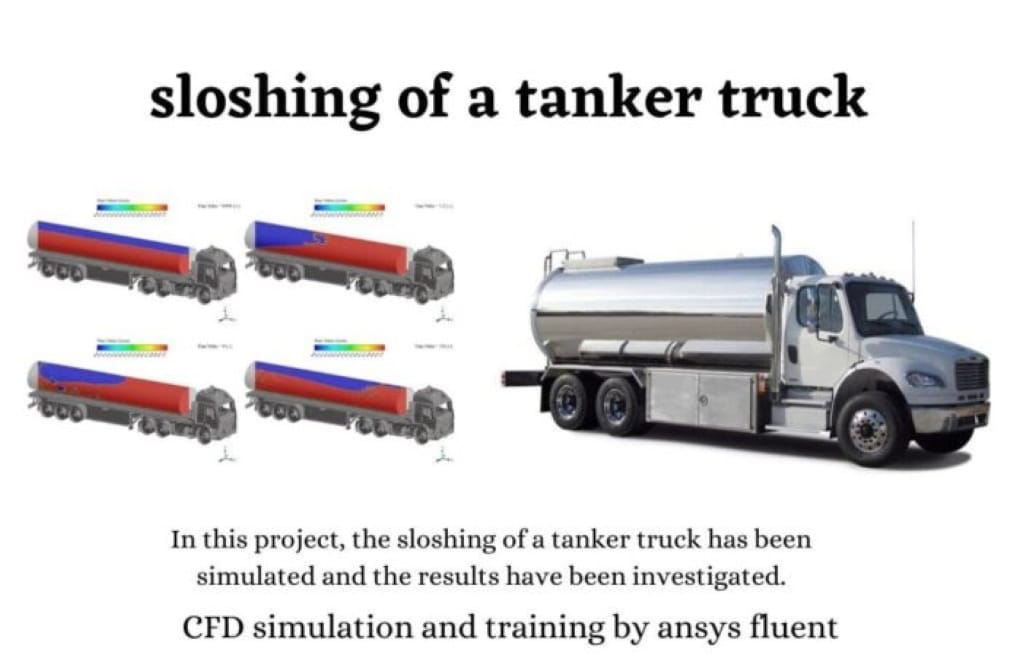

In project number 6, a numerical effort has been used to simulate the sloshing of a tanker truck. The Volume of Fluid (VOF) model has been used to simulate and solve the two-phase flow field equations. The primary phase is air and, the secondary phase is water.

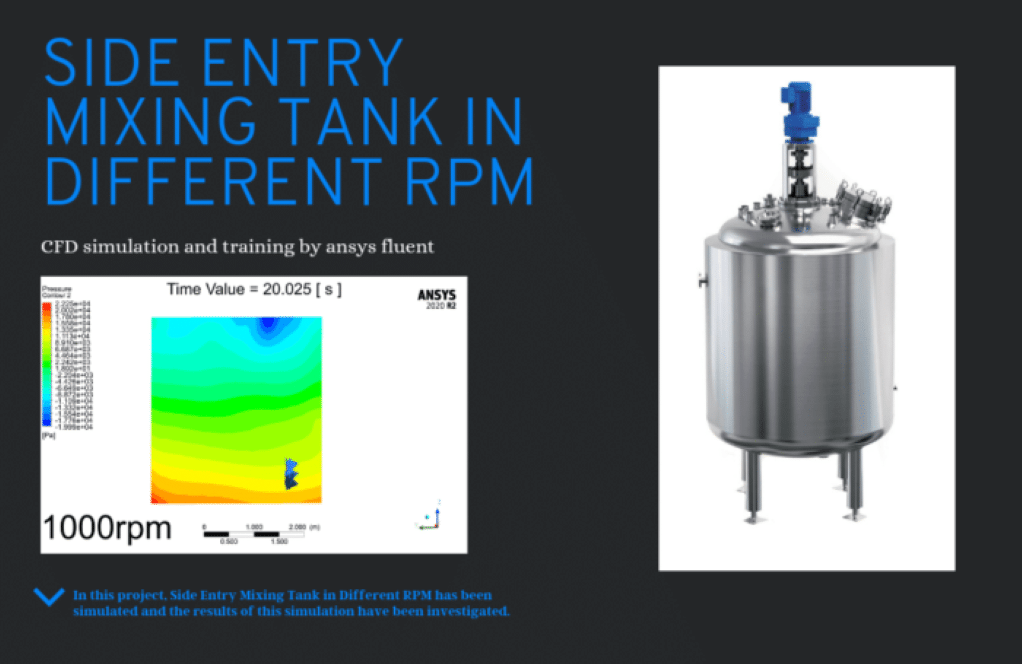

In practical exercise number 7, Side Entry Mixing Tank in Different RPM has been simulated. The mixing process is essential in many industries; for example, in the mechanical and also oil and gas industry. Water deposition causes much damage to storage tanks, which causes corrosion, leakage, and perforation of the source.

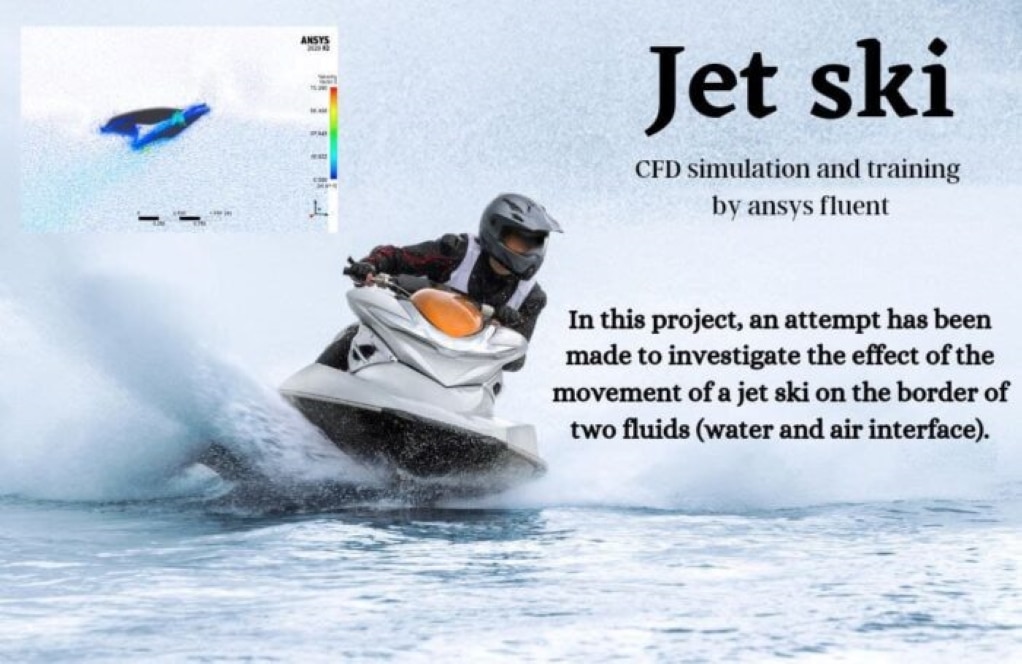

In project number 8, an attempt has been made to investigate the effect of the movement of a jet ski on the border of two fluids (water and air interface). The computational domain consists of an inlet wherein the water enters with a mass flow rate of 50000Kg/s and a pressure outlet. The multi-phase VOF model is activated for solving multi-phase flow equations and the standard k-epsilon model is exploited to account for the turbulence in fluid flows.

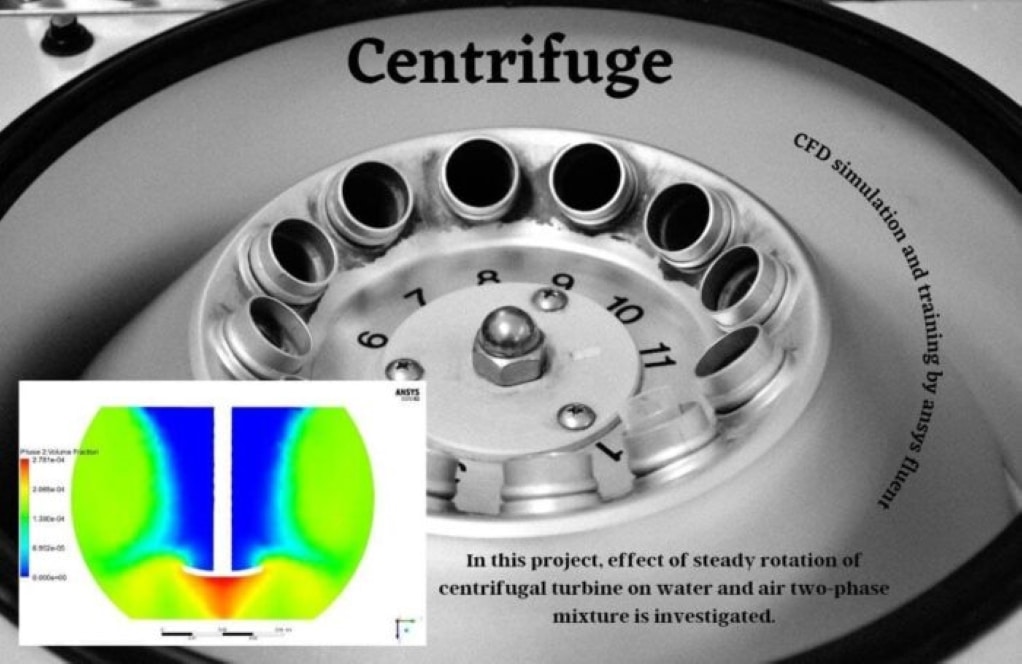

In practical exercise number 9, the effect of steady rotation of centrifugal turbine on water and air two-phase mixture is investigated. The multiphase MIXTURE model is used to solve water and air phases interactions. The secondary phase (air) volume fraction has very low values in the 0.0001 order which proves the validity of the MIXTURE multi-phase model in this project since for applying the MIXTURE Multi-Phase model the secondary phase volume fraction should be less than 15%.

The present problem simulates the boiling process inside a nanotube. A nanotube is a tube that is made at the nano-scale by nano-particles. This type of tube’s diameter can be about a few nanometers; While their length can reach several millimeters.

Golda Swaniawski –

How is the simulation of turbulent flows managed in this package?

MR CFD Support –

This package comprises exercises that delve into the simulation of turbulent flows. It aids in comprehending the impact of turbulence on fluid flow behavior. Furthermore, we have the capability to modify these simulations to cater to your particular prerequisites.

Miss Gwen Feeney –

Could you provide more details about the solver settings used in this package?

MR CFD Support –

Sure! The solver settings in this package are designed to provide optimal solutions for a variety of flow scenarios. These settings can be customized according to your unique needs.

Adonis Adams –

What types of simulations does this package cover?

MR CFD Support –

Great question! This package covers a variety of simulations, including fluid flow, heat transfer, and multiphase flow. We can adjust these simulations based on your unique requirements.

Mr. Jeramie Cummerata II –

How can these exercises help me understand the principles of Computational Fluid Dynamics (CFD)?

MR CFD Support –

These exercises offer a comprehensive understanding of the fundamental principles of CFD, such as discretization, numerical methods, and solver settings. They can be tailored to reflect your specific scenarios or requirements.