Methane-Air Combustion Dynamics in Gas Turbine Combustor

$140.00 $70.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Analysis of Methane-Air Combustion Dynamics in Gas Turbine Combustor

Introduction

This report presents a comprehensive Computational Fluid Dynamics (CFD) analysis of methane-air combustion in gas turbine combustor using ANSYS Fluent. The study aims to investigate the complex flow behavior, species transport, and temperature distribution within the combustor, providing insights into the combustion process and its efficiency.

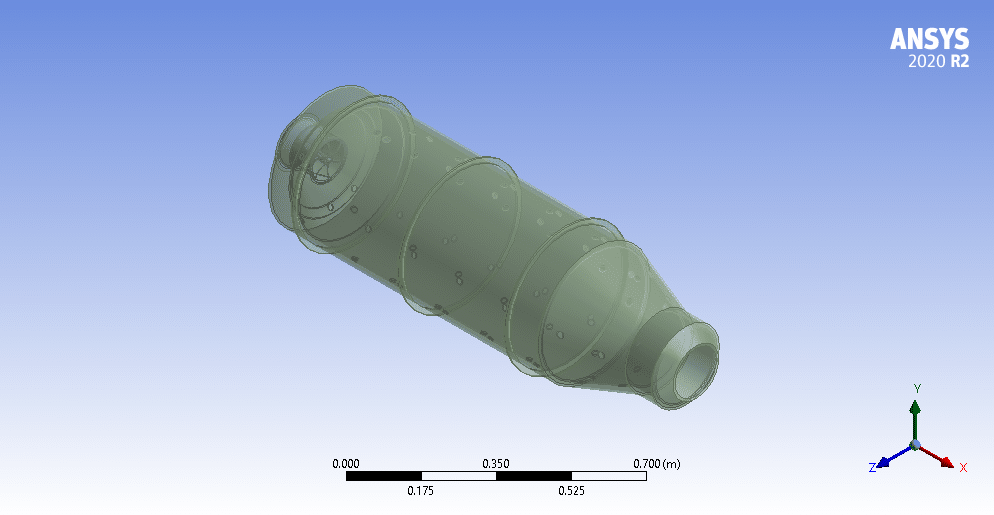

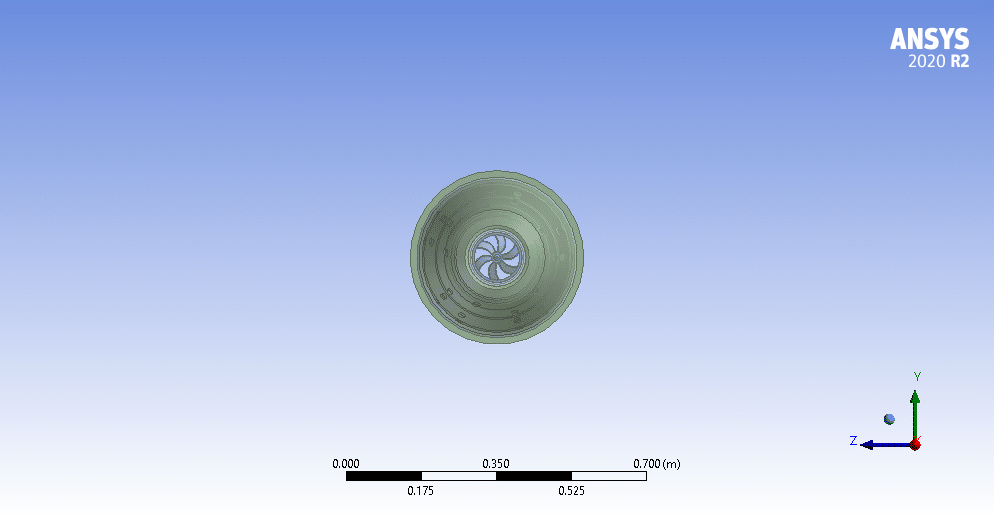

The simulation geometry represents a quarter section of a cylindrical combustor, utilizing symmetry to reduce computational costs while maintaining accuracy. The domain features two inlets: a central fuel inlet for methane and a surrounding air inlet. This configuration is typical for many gas turbine combustors, allowing for efficient fuel-air mixing and combustion.

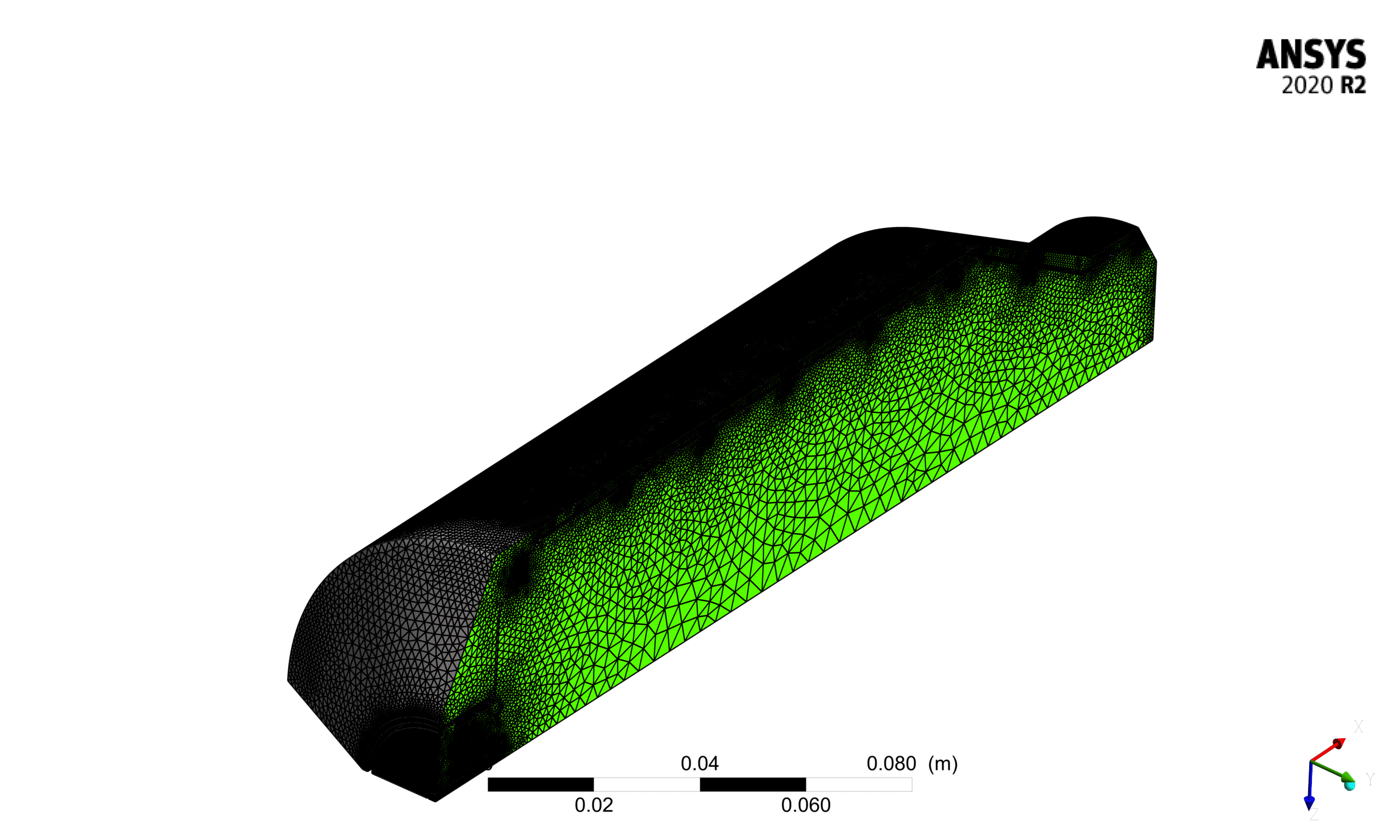

The geometry was designed using ANSYS SpaceClaim and meshed in ANSYS Meshing with a total of more than 2 million elements. This high-resolution mesh ensures accurate capture of the complex flow features and combustion dynamics within the combustor.

Methodology

A pressure-based, steady-state solver was employed to capture the time-averaged behavior of the combustion process.

The energy equation was enabled to model the temperature distribution throughout the domain accurately.

To account for turbulence, the Realizable k-epsilon model with standard wall function was selected, providing a good balance between accuracy and computational efficiency for complex flows.

The Species Transport model was activated with Volumetric Reaction to simulate the chemical reactions occurring within the combustor. The Eddy-Dissipation model was chosen for Turbulence-Chemistry Interaction, which is suitable for fast chemistry in turbulent flows. The reaction mechanism was set up for methane-air combustion.

Results

The CFD simulation provides valuable insights into the combustion process within the gas turbine combustor:

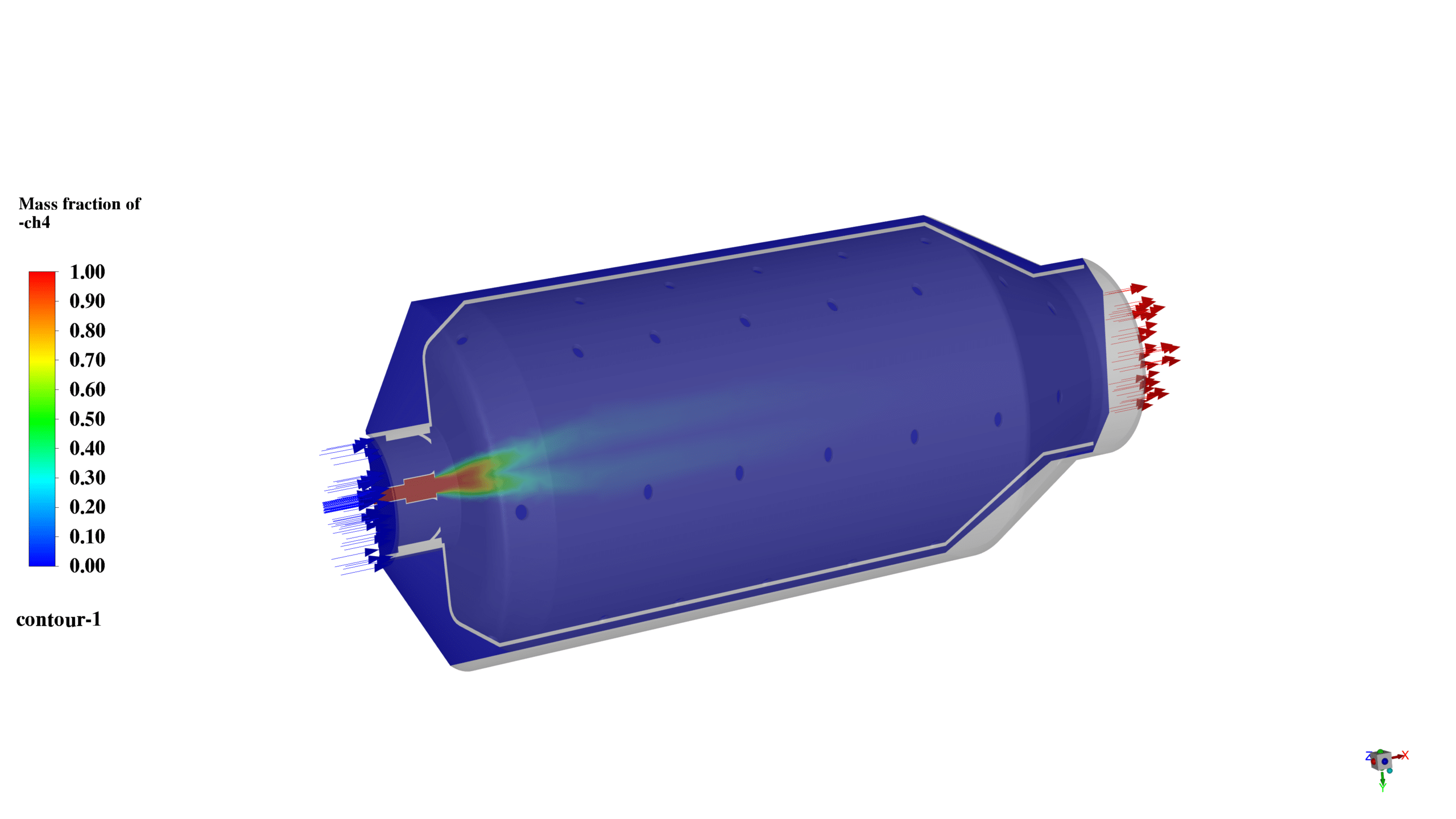

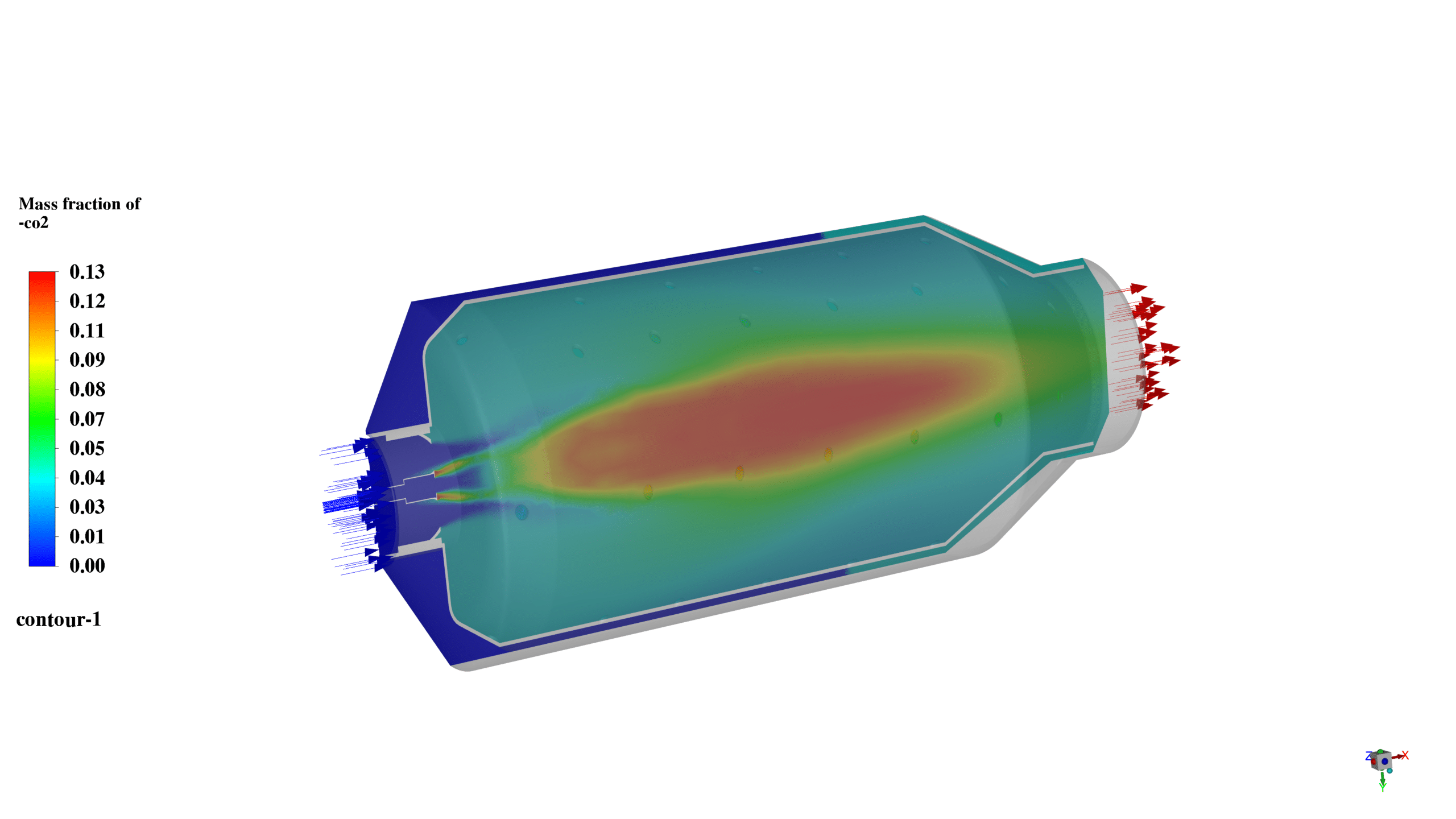

- Species Distribution: The CH4 (methane) mass fraction contour shows a high concentration at the central inlet, rapidly decreasing as it mixes with air and combusts. This indicates efficient fuel consumption. The CO2 mass fraction contour reveals the combustion products, with the highest concentrations in the core of the flame and downstream regions, suggesting complete combustion.

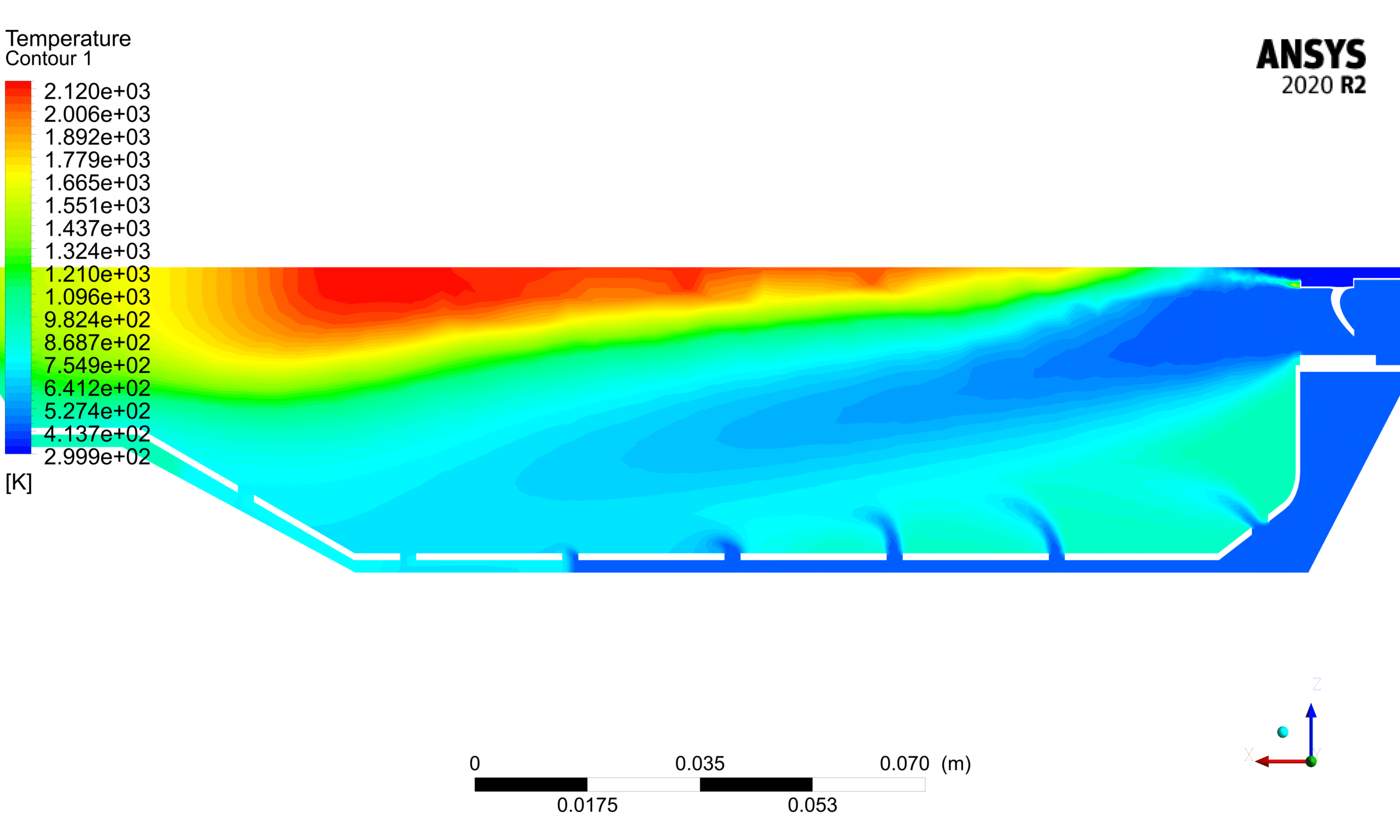

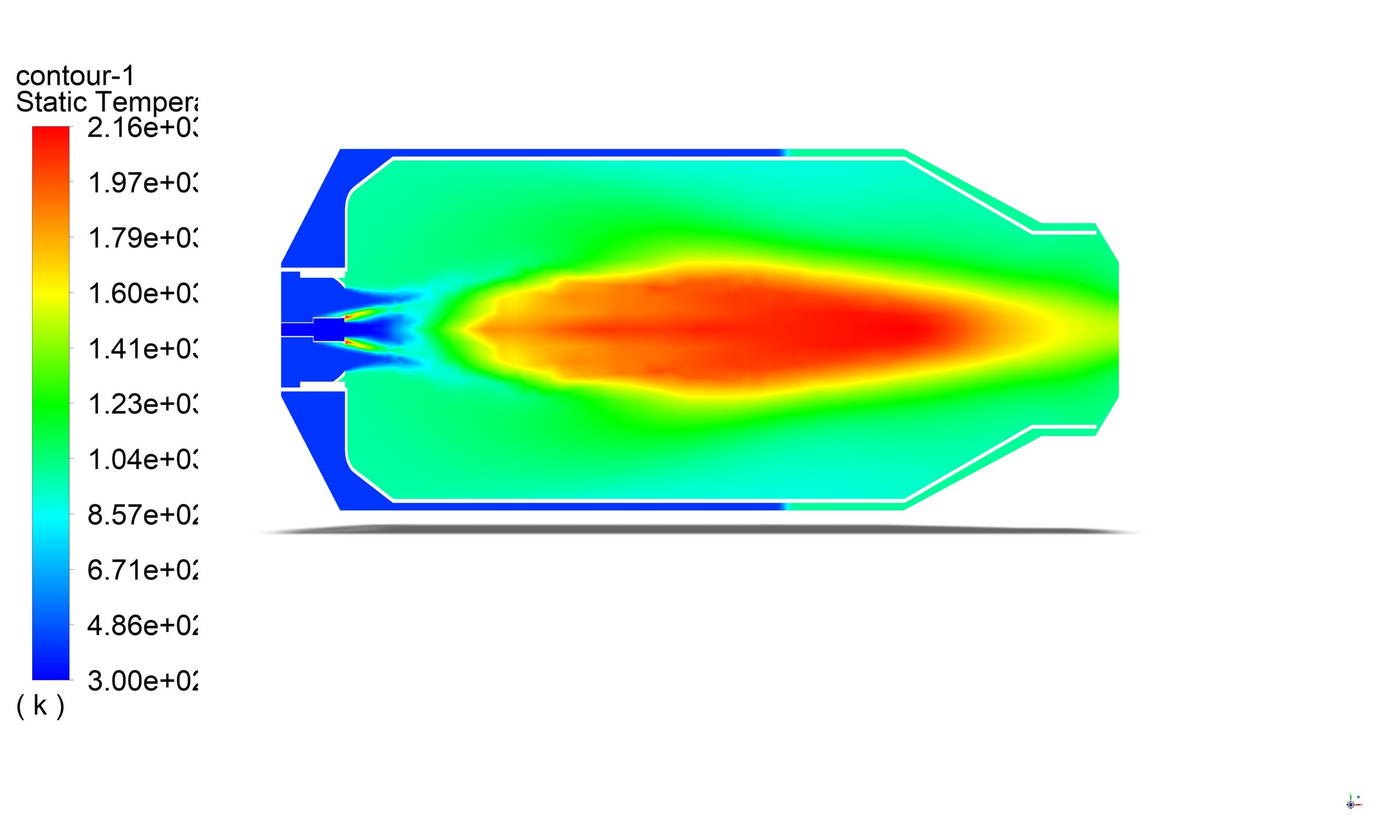

- Temperature Distribution: The temperature contour reveals a clear flame structure with peak temperatures reaching approximately 2160K in the primary combustion zone. This temperature is within the expected range for methane combustion, indicating efficient energy release. A gradual temperature decrease is observed moving downstream and towards the combustor walls, highlighting the importance of proper cooling design for the combustor liner.

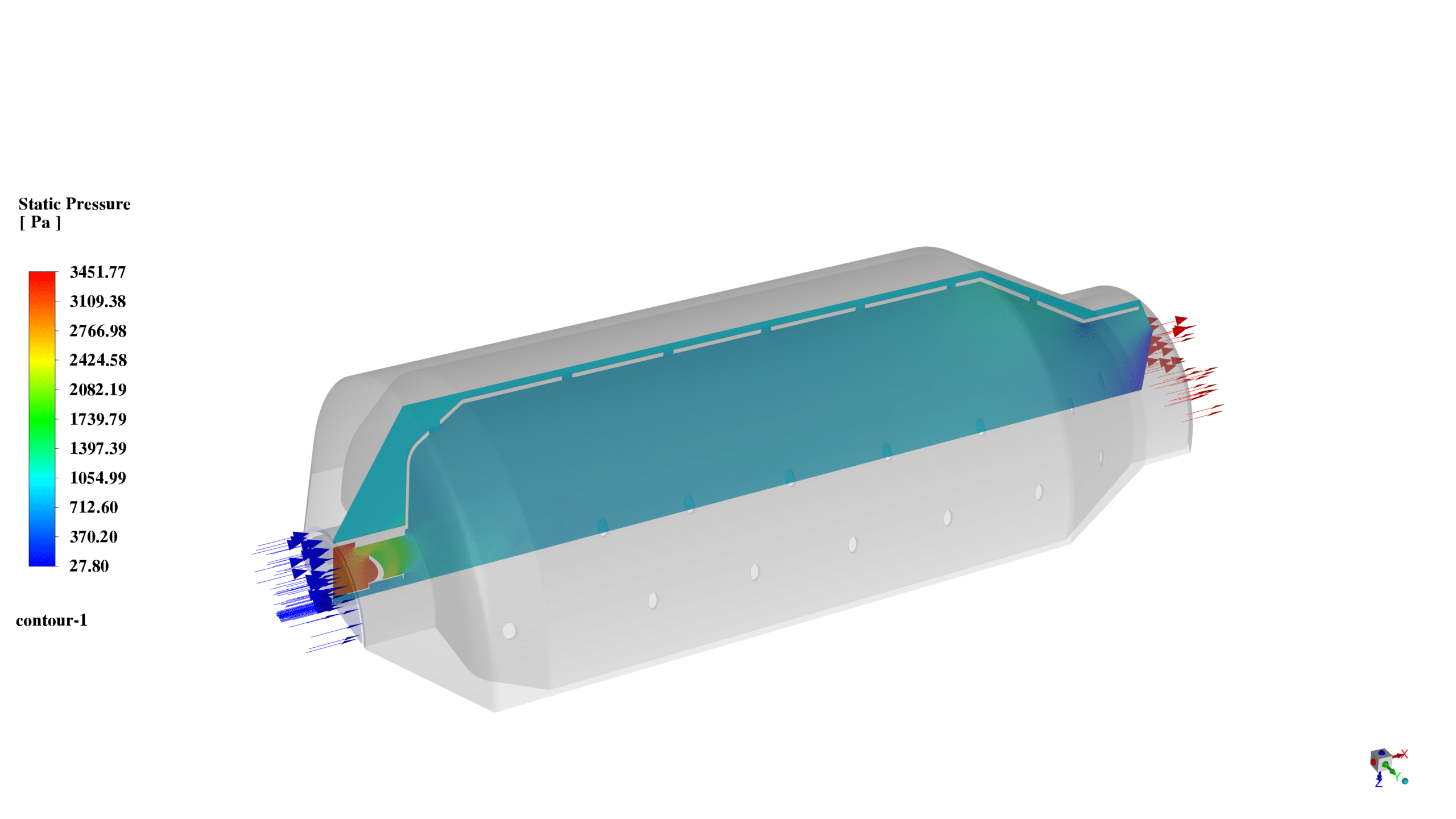

- Pressure Distribution: The static pressure contour shows higher pressures near the inlets and lower pressures towards the outlet, driving the flow through the combustor. Pressure variations are relatively small (range of about 3400 Pa), suggesting a well-designed flow path with minimal pressure losses, which is crucial for overall engine efficiency.

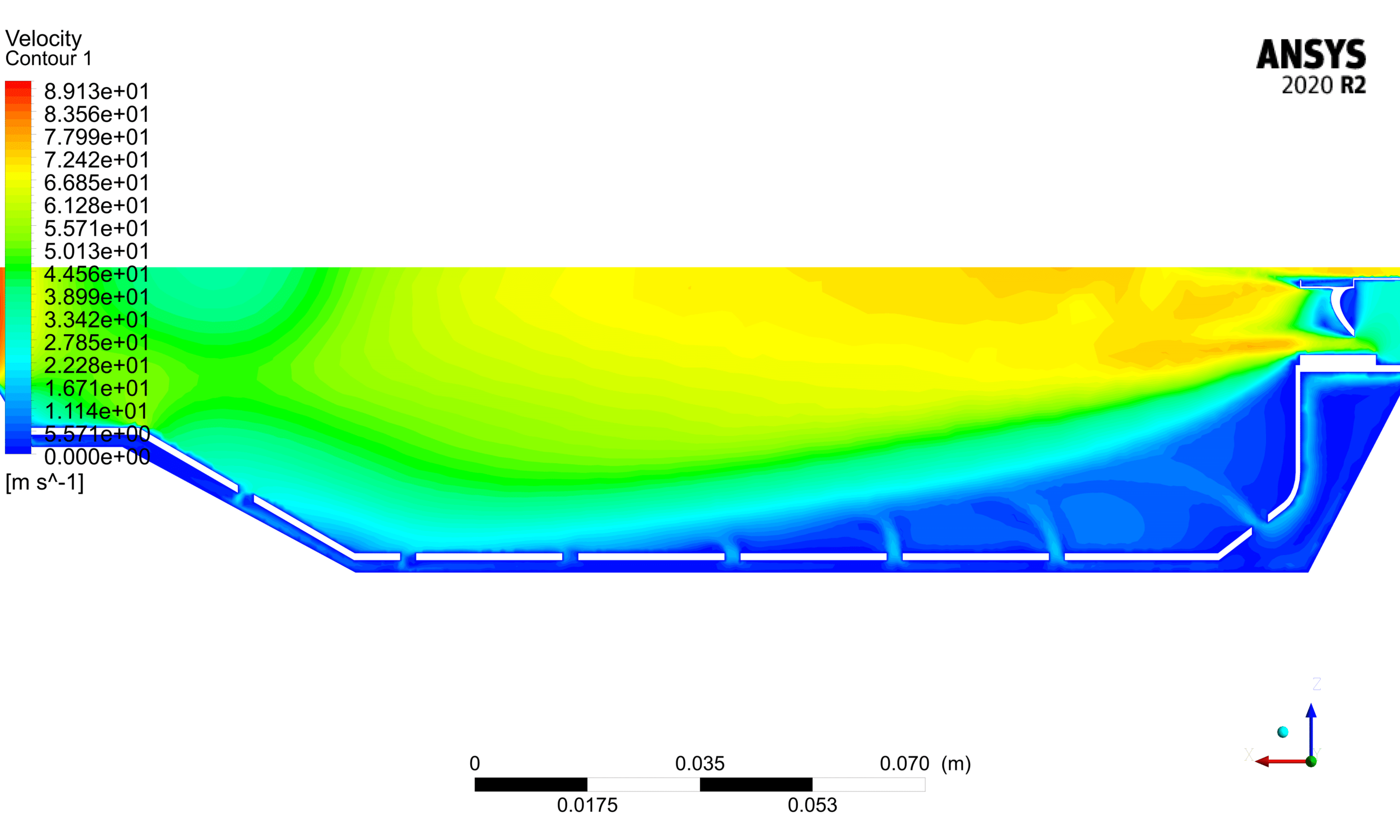

- Velocity Field: The velocity magnitude contour displays peak velocities of about 90 m/s in the core flow region. Lower velocities are observed near the walls due to boundary layer effects and in recirculation zones. These recirculation zones likely contribute to flame stability and improved combustion efficiency by providing additional residence time for reactants.

In conclusion, the CFD analysis successfully captures the key features of methane-air combustion in the gas turbine combustor. The simulation reveals efficient fuel-air mixing, complete combustion, and a well-defined flame structure. The temperature and velocity distributions indicate effective energy release and flow management within the combustor.

The results suggest that the current combustor design promotes stable combustion and minimizes pressure losses, which are crucial for overall gas turbine performance. However, the high temperatures observed near the combustor walls highlight the need for effective cooling strategies to ensure component longevity.

Future work could include transient simulations to capture time-dependent phenomena such as combustion instabilities. Parametric studies could be conducted to optimize the combustor design for improved performance and reduced emissions. Additionally, more detailed chemistry models could be incorporated for enhanced accuracy in predicting pollutant formation, particularly NOx emissions, which are a key concern in gas turbine combustors.

Reviews

There are no reviews yet.