Microfluidic Droplet Generator, ANSYS Fluent Tutorial

$120.00 $60.00 Student Discount

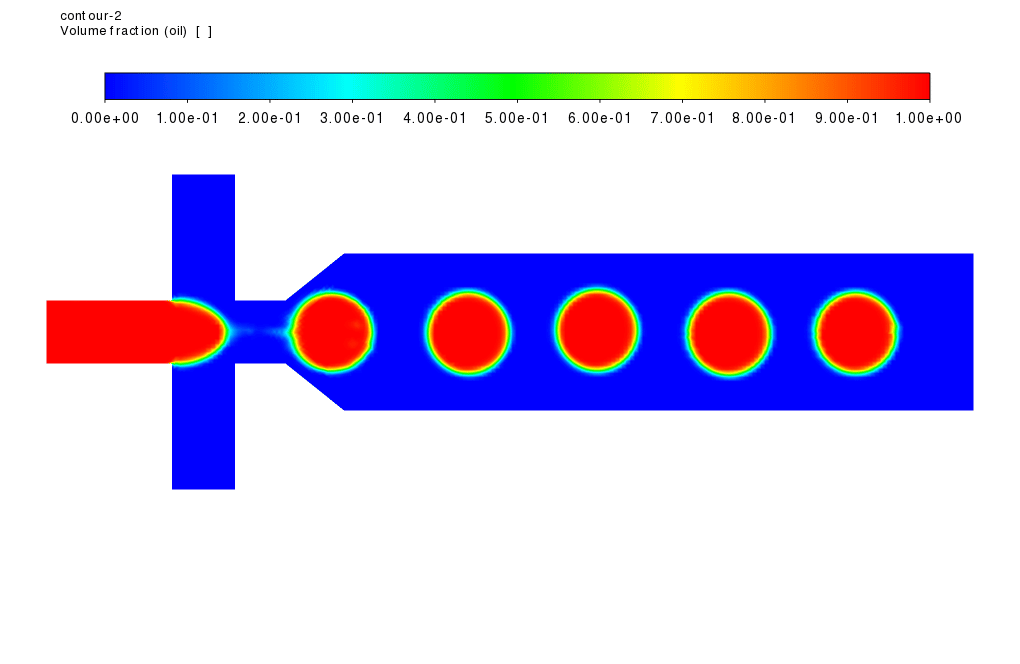

- The problem numerically simulates the Microfluidic Droplet Generator using ANSYS Fluent software.

- We design the 2-D model by the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 10,441.

- We perform this simulation as unsteady (Transient).

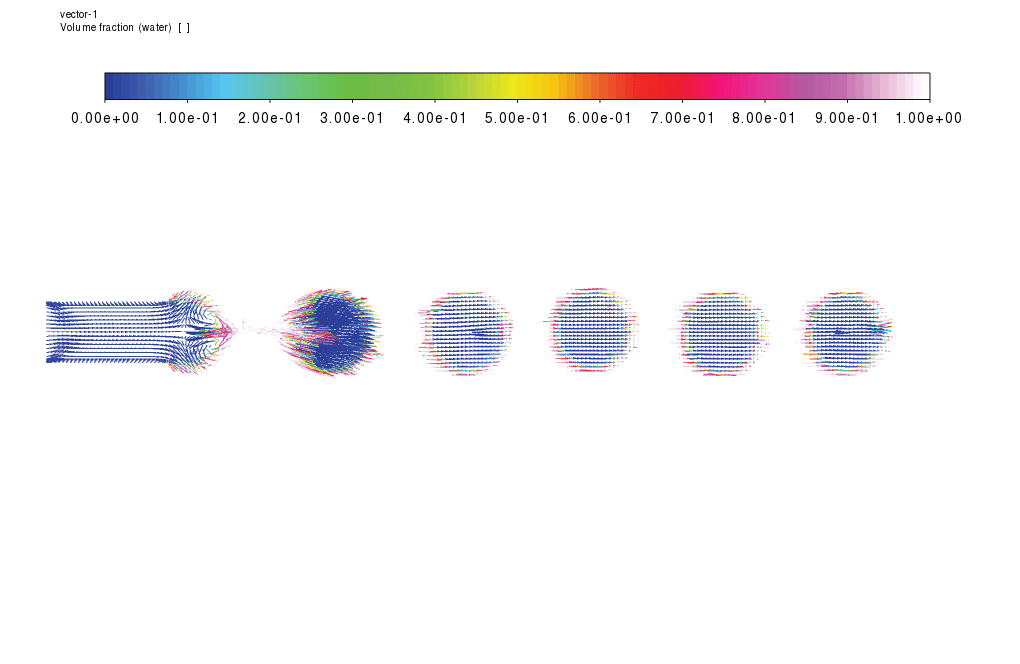

- The multiphase VOF model is used to model the phases of water and oil.

- Surface tension modeling along wall adhesion is enabled.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

The present project investigates the performance of a microfluidic droplet generator device using ANSYS Fluent. Microfluidic droplet generator devices are specifically used in biomedical and bio-engineering fields. Clinicians or scientist are seeking after a method to analyze biological entities away from their natural habitat and in vitro.

This product is the second chapter of the VOF Multiphase Model Training Course.

However, separating biological entities is a sensitive task and must be done with extreme care. Due to the dimensions of these biological entities, the separation process is done using microfluidic separation devices. The microfluidic droplet generator is universally used to create droplets in which biological entities are trapped. These droplets can be analyzed away from the rest of the sample under a microscope.

The geometry is designed in ANSYS Design Modeler software.

In addition, an unstructured mesh grid is generated using ANSYS Meshing software. As a result, 10,441 cells were generated.

Microfluidic droplet generator Methodology

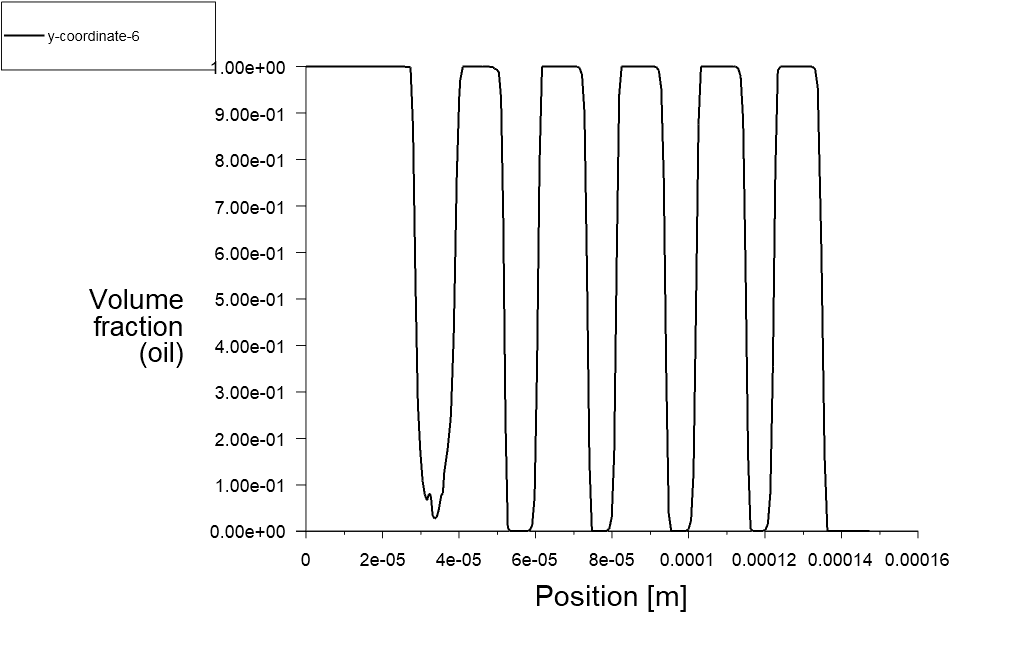

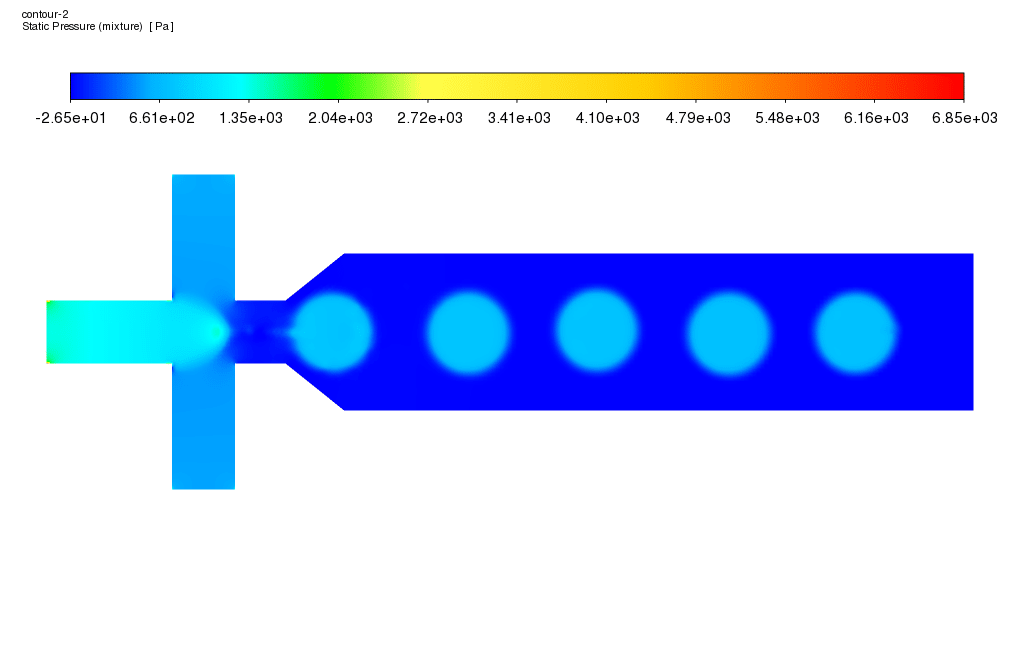

In this project, the multiphase VOF model is used to simulate the two phases of water and oil (buffers such as PBS can be used instead of water, and biological flows such as blood, etc. can be used instead of oil in real biological applications).

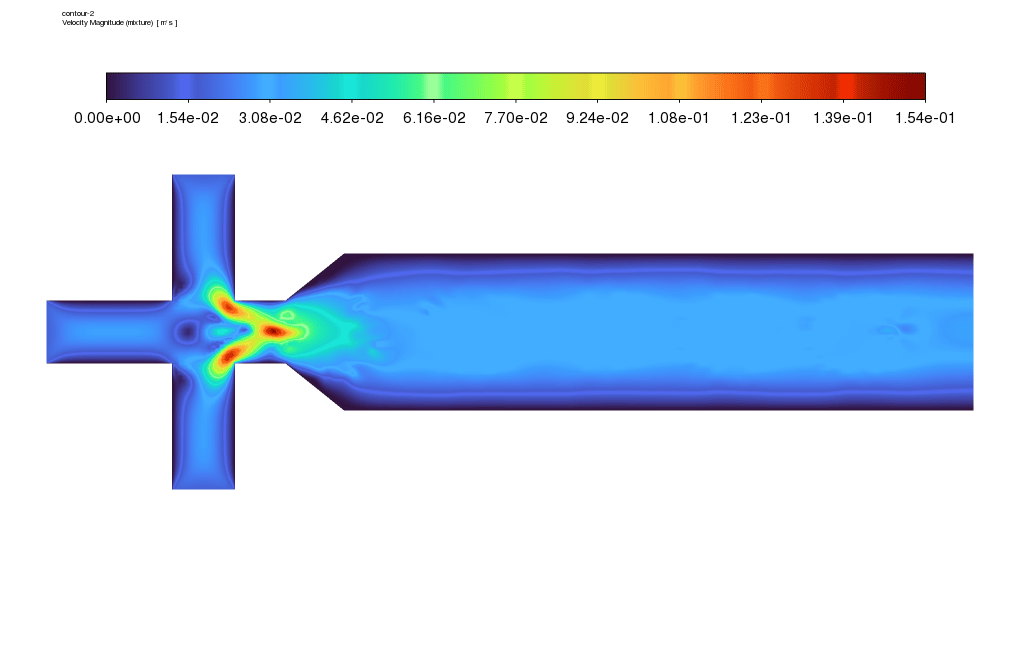

Surface tension modeling along wall adhesion is enabled to prevent the oil flow crawling toward the water inlet boundary and ensure the generation of detached droplets. Patching option is exploited to lessen the computational time needed for the oil flow to fill the respective inlet section.

Conclusion

In this project droplet generation inside a microfluidic device is investigated. By changing the flow inlet velocity for the two existing phases, the number and diameter of the droplets can be changed. This numerical simulation is beneficial for biological applications in which biological entities from the initial samples to be analyzed for further uses.

Jayce Walker –

The tutorial was super helpful, and the microfluidic droplet generator was fascinating to learn about. The explanation of surface tension and its role in droplet formation was especially clear. Well done!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our tutorial on the microfluidic droplet generator was helpful for you and that you gained clarity on the role of surface tension in droplet formation. If you need further assistance or have more feedback, feel free to reach out.

Annetta Batz –

I am incredibly impressed by the level of detail in this tutorial for the microfluidic droplet generator CFD simulation. The explanation on setting up different fluid properties and the care taken to model surface tension is excellent. Understanding such critical factors in the simulation provides a solid grounding for us to run similar studies on our experiments with other biofluids.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear you found the tutorial detailed and instructive, especially regarding the setup of fluid properties and surface tension modelling. We strive to provide clear guidance for these complex topics to support our users in their CFD simulation needs. If you ever have more questions or require further assistance with your simulations, please don’t hesitate to reach out. Best of luck with your experiments!

Dr. Luther Kilback DVM –

I was truly impressed by how effectively the VOF Multiphase Model was used in this tutorial! The explanation of droplet formation and the ability to control droplet size was particularly enlightening. The tutorial was detailed and made understanding complex principles quite manageable. Great work!

MR CFD Support –

We’re thrilled to hear that the tutorial on the microfluidic droplet generator helped you understand the complex principles of droplet formation, and you could appreciate the versatility of the VOF Multiphase Model. Thank you for sharing your positive experience!

Felicity Walker –

I’m amazed by how well the software handled the microfluidic droplet generator’s simulation! It looks like a powerful tool for biomedical research.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the ANSYS Fluent tutorial for the microfluidic droplet generator met your expectations and proved to be a valuable asset for your research needs.

Jacklyn Feeney –

I just finished going through the Microfluidic Droplet Generator tutorial from MR CFD Company and I am genuinely impressed with the richness of information provided. Understanding how microfluidic devices work and being able to simulate them is crucial for my bioengineering studies. The guidance on handling two-phase flow using the VOF model was detailed and the tip on using patching to speed up the simulation process was a practical piece of advice that I plan on implementing in my future computational projects. Thank you MR CFD for an exceptional learning experience!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our tutorial on the Microfluidic Droplet Generator was helpful to you and that you were able to gain practical knowledge for your bioengineering studies. We’re committed to providing high-quality and informative content, and it’s always rewarding to see our work appreciated by our customers. Keep an eye on our future tutorials for more insights!

Mrs. Brooklyn Langworth –

This course sounds perfect for my thesis on bioengineering applications. How well does the simulated separation compare with the actual performance in a lab setting?

MR CFD Support –

The simulation has been carefully configured to mimic the actual microfluidic droplet generation process. Due to the precise modeling of multiphase flow and considerations like surface tension and wall adhesion, the simulation results are quite representative of what can be expected in a laboratory setting. However, every physical experiment may have nuances, and results might vary slightly due to external factors that are challenging to include in simulations.

Baby Gislason –

This tutorial sounds amazing for biomedical applications. I’m curious, can this simulation also show the behavior of individual cells within the droplets?

MR CFD Support –

Unfortunately, the simulation focuses only on the generation and behavior of the droplets themselves, not on individual cells. The VOF Multiphase Model simulates the interaction between water and oil but doesn‘t provide cell-level resolution. For simulating individual cell dynamics within droplets, additional methods or more specialized software might be necessary.

Elizabeth Cole –

The tutorial was very insightful. It helped me understand the role of flow inlet velocities on droplet formation. Great work on explaining a complex topic simply!

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our microfluidic droplet generator tutorial was helpful to you. Understanding the impact of flow velocities on droplet generation is crucial for applications in the biomedical field. If you have any more questions or need further assistance, feel free to reach out. Happy learning!

Ms. Romaine Ryan IV –

The tutorial was well-crafted and informative. I could clearly see the impact of flow inlet velocity on droplet size and frequency within the microfluidic device. Great work on relating the process to real bio-engineering applications!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Microfluidic Droplet Generator tutorial useful for understanding the effects of flow velocities on droplet formation. If you have any more questions or need further assistance with our products, feel free to reach out!

Prof. Teresa Gorczany PhD –

The way the droplet size is controlled was fascinating. Could the same setup be used for other fluids with different properties, or would that require significant changes to the model?

MR CFD Support –

Yes, the same setup can be used for simulating other fluids with different properties. However, it is important to update the fluid properties such as density, viscosity, and surface tension according to the specific fluids being analyzed to ensure accurate simulation results.

Ms. Myrna Little Sr. –

I am very impressed with how the microfluidic droplet generator simulation captures the sensitive process of separating biological entities. This looks like a vital tool for researchers and clinicians working with biological samples.

MR CFD Support –

We’re thrilled to hear that our Microfluidic Droplet Generator tutorial has met your expectations and is capable of demonstrating the delicate process of handling biological entities. We are particularly pleased when our products serve as valuable resources for scientific and medical practitioners. Thank you for recognizing the importance of our simulation in the bio-engineering field. If you have further feedback or need assistance with any other of our products, please feel free to reach out to us.

Wilma O’Connell PhD –

This is fantastic! Being able to control the diameter and number of the droplets could yield significant insights in the biomedical field. The attention to detail in each phase of the procedure assures accuracy for in vitro analysis. Kudos on a great tutorial!

MR CFD Support –

We greatly appreciate your positive feedback on our Microfluidic Droplet Generator tutorial. If you ever need further assistance or have additional questions about applying the tutorial to your specific research, always feel free to reach out to us. Thank you for sharing your experience!

Ariane Terry –

I’m very pleased by how well this microfluidic droplet generator tutorial explained the complex VOF Multiphase Model. The step-by-step guidance made it easy to follow, and the graphical representations really helped me visualize the process. This will surely be useful for many dealing with biomedical applications.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to know that the microfluidic droplet generator tutorial was helpful and that the guidance provided clarified the process for you. It’s our aim to make complex models accessible and easier to understand, and we’re pleased to hear that we could be of assistance in your biomedical applications. If you have any more questions or need further assistance, please do not hesitate to reach out.

Salvatore VonRueden –

I used this simulation for a project and it was really helpful, the results were very accurate!

MR CFD Support –

Thank you for your kind words! It’s great to hear that our microfluidic droplet generator simulation met your project’s needs with accuracy. We always strive to provide high-quality simulations and tutorials for a variety of applications. If you have any further feedback or require additional assistance in the future, please don’t hesitate to contact us.

Lonie Rippin –

I truly appreciate the education given on the microfluidic droplet generator simulation using ANSYS Fluent. The detailed consideration of surface tension and wall adhesion shows a thoughtful approach and surely will assist in understanding droplet generation dynamics in microfluidic devices. Thanks for providing a comprehensive learning tool.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our tutorial on the microfluidic droplet generator simulation was helpful to you. Your understanding of the complexities involved in droplet formation, including the effects of surface tension and wall adhesion, is essential for advancing in microfluidic research. We always strive to deliver detailed and practical learning materials. If you have any further questions or need assistance in the future, don’t hesitate to reach out to us!

Shawna Daugherty –

I found the explanation on droplet generation very intriguing. Ca nyou tell me more about how the patching option improves the simulation process?

MR CFD Support –

To improve the setup process and reduce computational time, the patching option pre-fills the oil phase in the assigned inlet area so that you don’t have to wait for oil to fill this area during the simulation run. This approach kick-starts the simulation with the initial condition closer to the desired steady state, allowing the droplet formation to be observed without having to simulate the initial filling transient period.

Janelle Witting DDS –

The tutorial was really informative with clear steps and good explanations. The VOF Multiphase Model concepts were well-presented and easy to understand.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our tutorial was helpful in understanding the VOF Multiphase Model. If you have any further questions or need more assistance with ANSYS Fluent, please feel free to reach out.

Arno Herzog –

The tutorial sounds very interesting! Is this product suitable for beginners, or should I have some prior knowledge in CFD or ANSYS Fluent to fully understand and benefit from it?

MR CFD Support –

This tutorial is designed to accommodate learners with varying levels of expertise. While some foundational understanding of CFD concepts and familiarity with ANSYS Fluent would certainly enhance your learning experience and allow you to grasp the material more deeply, the tutorial aims to provide comprehensive guidance to users who might be new to the subject as well.

Prof. Mitchell Wunsch –

The explanation was extremely clear and detailed. This tutorial must be a valuable resource for anyone working or studying in the fields of biomedical or bio-engineering. Well done on creating such an informative learning tool. The simulations included make the topic much more accessible and allow for practical understanding which isn’t always easy to achieve with such complex subjects.

MR CFD Support –

Thank you for taking the time to review our Microfluidic Droplet Generator tutorial. We are thrilled to hear that you find it informative and helpful for biomedical and bio-engineering applications. It’s always a pleasure to receive such positive feedback, and we’re glad that our product has contributed to your understanding of the subject. If you have any further questions or require additional resources, don’t hesitate to reach out.

Mr. Kamryn Kozey –

I’ve learned a lot from this tutorial! It was fascinating to see how the microfluidic droplet generator works in simulation. The explanation was clear, and the tutorial made the complex concepts understandable. Great work creating such an informative and easy-to-follow guide!

MR CFD Support –

Thank you for your kind words! It’s fantastic to hear that our tutorial on the microfluidic droplet generator was helpful to you. We strive to provide clear and comprehensive learning materials, and your feedback is greatly appreciated.

Maymie Mitchell –

This tutorial was quite illuminating! The clarity in explaining the droplet generation process and the use of the VOF Multiphase Model will be beneficial for my own research efforts. The explanation of flow velocity’s impact on droplet size is particularly useful.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial on the microfluidic droplet generator has been helpful in your research. If you have any further questions or need assistance with your work, please don’t hesitate to reach out.

Maryam Lowe –

How does the simulation ensure detached droplet formation and prevent oil flow from crawling towards the water inlet?

MR CFD Support –

In this simulation, surface tension modeling along with wall adhesion properties are enabled. These settings help to create distinct boundary interactions between the oil and water phases, which ensures the formation of individual, detached droplets instead of having the oil phase crawl towards the water inlet.

Nash Schinner –

I was impressed by how effectively the microfluidic droplet generator was simulated. The use of the VOF Multiphase Model Training Course for such precise work seems to be very insightful, especially the consideration of surface tension and wall adhesion to ensure proper droplet formation. Can’t wait to apply this method to my research work!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the tutorial on the microfluidic droplet generator has been helpful for your research. If you have any further inquiries or need assistance when applying the simulation techniques to your work, please feel free to reach out.

Jaron Donnelly –

I’m astounded by the level of detail in the Microfluidic Droplet Generator tutorial. The meticulous approach to simulating biomedical processes can revolutionize experimental setups. Thank you!

MR CFD Support –

We’re beyond pleased that our Microfluidic Droplet Generator tutorial has impressed you! Realistic simulations and in-depth resources are at the heart of what we aim for, especially in critical fields like biomedical research. Thank you sincerely for your feedback!

Annette Brakus –

What measures are taking place to ensure the accuracy of the simulation for such sensitive biomedical applications?

MR CFD Support –

In simulations of this nature, stringent measures are taken to ensure accuracy for sensitive biomedical applications. These would typically include verification of physical properties of the simulated fluids, resolution of the mesh to capture the important details of the flow, and validation of simulation results against empirical data or analytical solutions when available. Numerical schemes of high fidelity and boundary conditions mimicking the actual physical processes closely also contribute to ensuring the accuracy of the simulations.

Martine Borer PhD –

The tutorial was thorough and the step-by-step approach was very helpful! Droplet generation was clearly demonstrated, and I can see its practical use in biomedical research.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the tutorial was helpful and that you could clearly understand the droplet generation process. It’s great to know that you see its application in biomedical research. We are here to support your learning journey, so if you have any more questions or need further assistance in your studies, do not hesitate to reach out. Best of luck with your research!

Brandi Strosin –

I appreciated the detailed explanation about how droplet generation can be controlled. It’s clear that flow inlet velocity alteration is a significant factor. Could you detail what other parameters might be adjusted to fine-tune the droplet generation process?

MR CFD Support –

I’m glad you found the information helpful! Apart from the flow inlet velocity, you can adjust parameters such as phase density, surface tension between fluids, channel dimensions, and fluid viscosity to fine-tune the droplet generation process. Each factor plays a role in droplet size, formation frequency, and stability, allowing for careful control based on the application’s specific needs.

Aiyana Reilly –

The tutorial was very informative! I was especially fascinated by the use of the VOF multiphase model. It helped me grasp the creation of droplets within the microfluidic device, and linking the size and frequency of the droplets to the inlet velocities made a lot of sense.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial on the microfluidic droplet generator was helpful and informative. It’s great to know that the application of the VOF multiphase model to control droplet size and frequency resonated with you. Stay tuned for more insightful content!

Verona Watsica –

The concept of separating biological entities with such precision is intriguing. How does the microfluidic droplet generator ensure that each droplet contains only one biological entity for analysis?

MR CFD Support –

Unfortunately, we cannot provide specific details on cellular behavior within the droplets as it’s not covered in the information provided. However, the accuracy in separating biological entities in this microfluidic droplet generator simulation is generally ensured by precise control of the droplet size compared to the size of the biological entities and careful manipulation of the flow rates and fluid properties, ensuring that ideally one entity is encapsulated per droplet. However, the exact method would be defined based on the specifics of the device and the experimental setup used in the laboratory.