Minimizing Pressure Drop by Adjoint Solver (RBF), ANSYS Fluent CFD Simulation Training

$120.00 $60.00 Student Discount

- The problem numerically simulates the pressure drop in a tube with a U-shaped bend using ANSYS Fluent software.

- We design the 2-D model by the Design Modeler software and then mesh it with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 26400.

- We aim to Minimize the pressure drop in a three-step simulation.

- We use the Adjoint Solver to analyze the Shape Sensitivity.

- The Design Optimization is performed with the Gradient-based Optimizer.

- We use the Radial Basis Function (RBF) to apply Mesh Morphing.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This project is related to the numerical simulation of the Pressure Drop in a tube with a U-shaped bend using Ansys Fluent software. We aim to optimize the Design of this model using an Adjoint Solver and Gradient-Based Optimizer.

Such modeling is done in Three stages. First, we perform the conventional flow simulation. In the second step, we analyze the Sensitivity with the adjoint solver. Finally, we change the model’s design to achieve Optimal performance with the gradient-based optimizer.

The adjoint solver provides a series of data that is expressed in the form of sensitivity analysis. We focus on Shape sensitivity.

This tool identifies which areas of the geometry have the greatest influence on system performance.

So we need to define a target parameter. This output parameter is called Observable. In the present work, we have defined the pressure drop as observable.

So, the adjoint solver is based on the pressure drop in the tube. Wherever more sensitivity is shown, i.e., Displacement of the boundary or Deformation of the shape of the design, it has a greater effect on the pressure drop.

We use the sensitivity analysis data in the gradient-based optimizer. In this tool, we specify how the observable should be changed. For example, in this project, we consider Decreasing the pressure drop. This means changing the pipe geometry to Minimize the pressure drop. These changes should lead to an optimal design.

We modeled the geometry of the project using Design Modeler software. This model is the computational zone inside a tube with a U-shaped bend.

Then we meshed the model with Ansys Meshing software. The model mesh is Structured, and the number of cells is equal to 26400.

Adjoint Solver Methodology

We used the adjoint solver in this project to obtain the sensitivity data. For this purpose, we defined the pressure drop (pressure difference between inlet and outlet) as observable.

We then used the sensitivity data to solve the gradient-based optimizer. Before solving the gradient-based optimizer, we performed some settings in the Design Tool tab.

In the section of the zone to be modified, we only determined the inner wall of the tube for deformation.

Then we created a rectangle shape Region in the vicinity of the pipe bend. We considered this square an area of the domain where geometry and mesh changes are supposed to occur.

When the shape is deformed, and its boundaries are moved, the mesh around this area changes.

To apply mesh changes, we used the Mesh Morphing technique. There are three methods for mesh morphing: polynomial, direct interpolation, and Radial Basis Functions (RBF).

In this project, we used RBF for mesh morphing. For the radial basis function, the mesh deformation is interpolated from the control points.

In the Objective part, we determined the value of observable changes. In this way, the pressure drop will Decrease by 3 %.

We set the Design Number to Ten, so we can see a 3 % reduction in the pressure drop in the ten stages.

Adjoint Solver Conclusion

As we said, the present simulation is done in three consecutive steps. So we investigated the results in three steps.

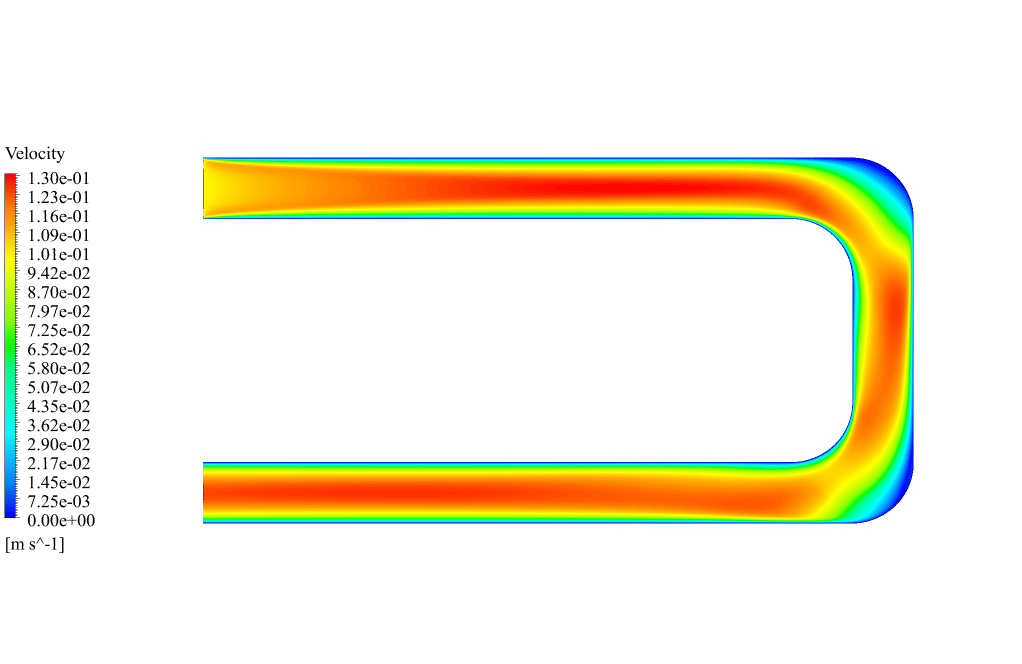

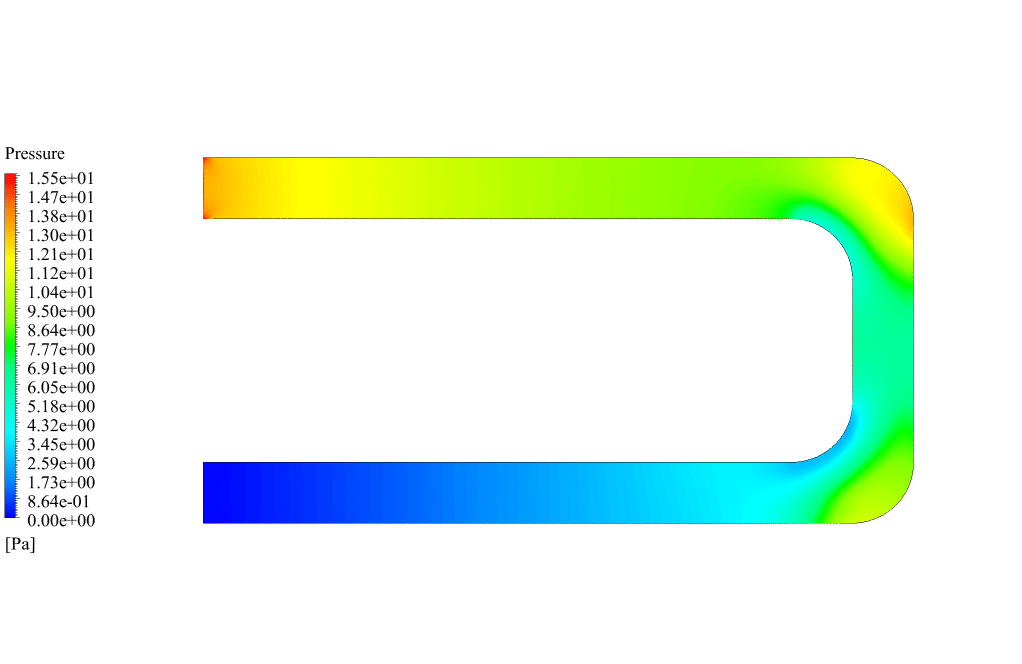

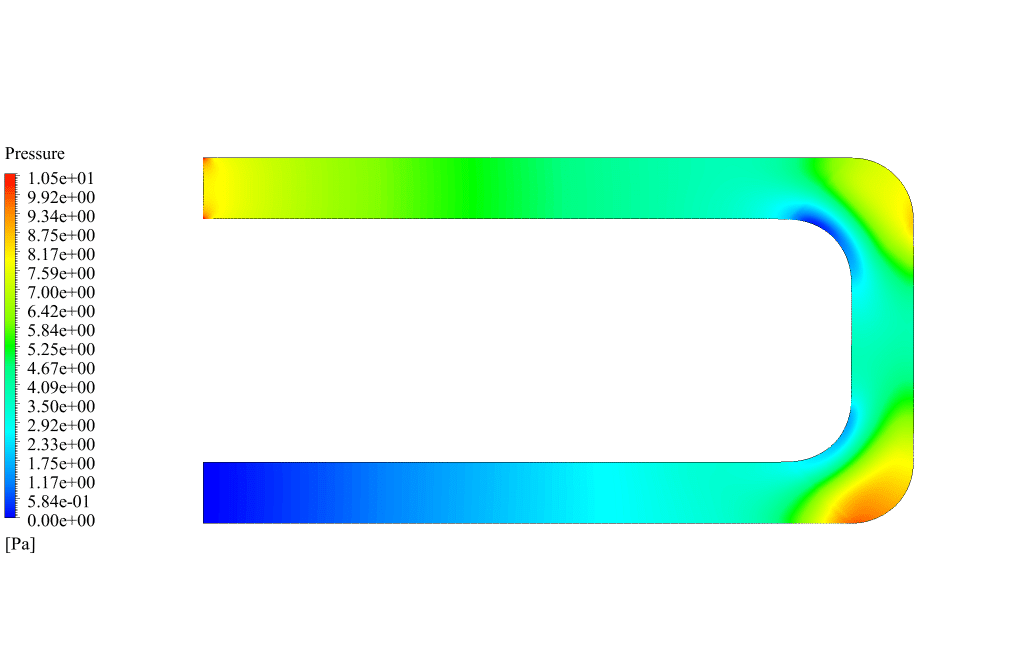

In conventional flow simulation, we obtained velocity and pressure contours. These contours showed the distribution of velocity and pressure inside the domain.

The pressure contour shows that the fluid flow experiences a pressure drop after passing through the pipe bend.

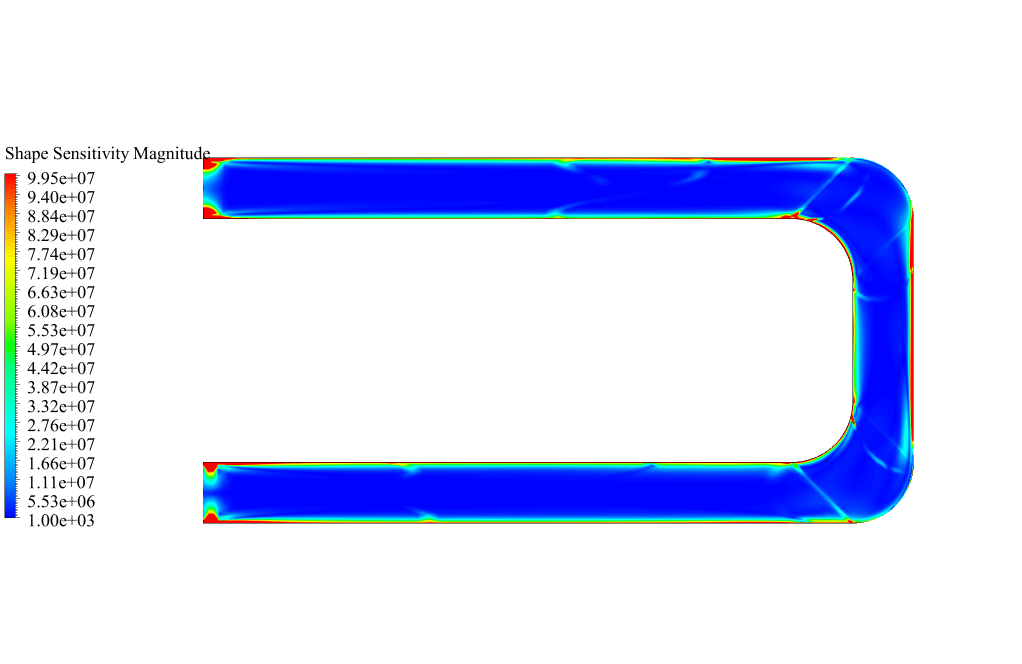

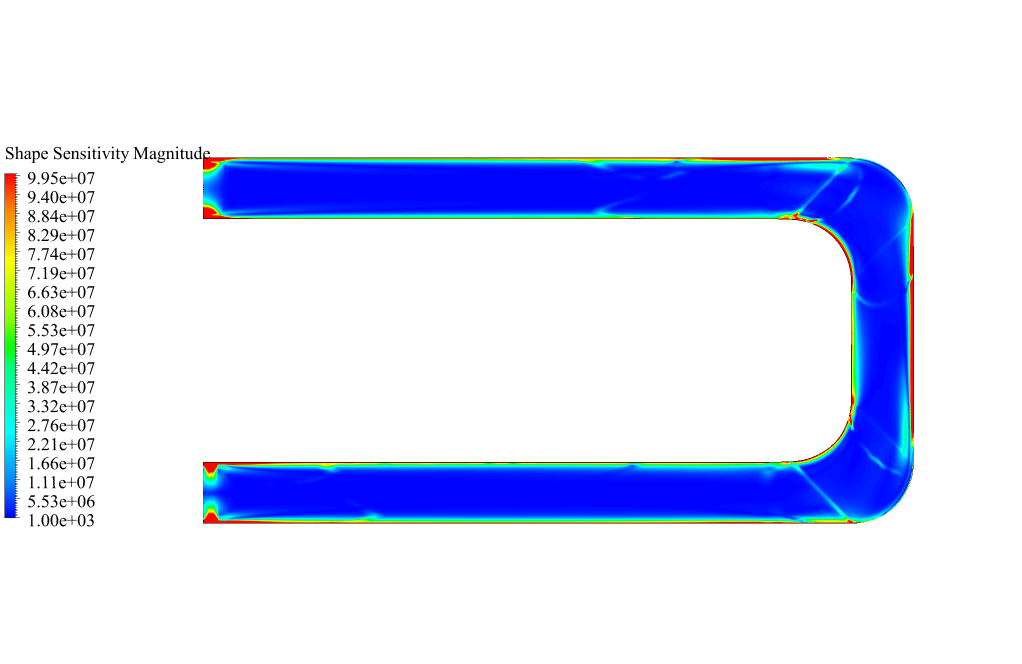

We analyzed the sensitivity in the adjoint solution. We obtained the shape sensitivity contour inside the tube.

The highest sensitivity is shown in the vicinity of the pipe bend. This means that boundary displacement and shape deformation in these areas have the greatest effect on the value of pressure drop.

So to reduce the pressure drop, we need to focus on bend of the geometry. In the final solution by the gradient-based optimizer, the geometry undergoes deformation.

This displacement and deformation lead to the minimization of the pressure drop. The pressure drop before optimization was equal to 13.228147 Pa. After performing the second and third steps, this pressure drop reached the value of 8.1441545 Pa. So we conclude that the pressure drop has decreased by 38 %.

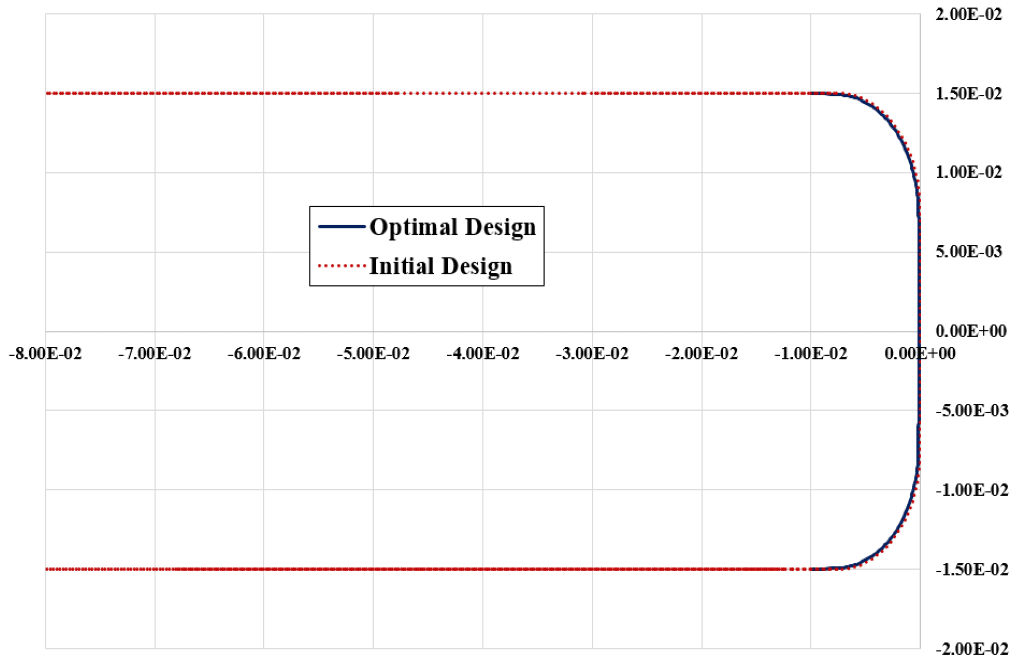

Also, we displayed the graph of the location of different points in two states: initial and optimal design. We can see the shape deformation and boundary displacement. The maximum boundary displacement is equal to 8.95115e-7 m, and the average displacement is equal to 3.37765e-7 m.

Finally, we can say that we achieved our goal, and the pressure drop was reduced with the design optimization method.

Merle Rogahn Sr. –

I am delighted with the detailed explanation of the process that the training provides. Still, I’m quite curious, did the optimized design also consider potential impacts on flow turbulence or possible negative effects on structural integrity after the boundary is deformed?

MR CFD Support –

Thank you for your positive feedback and for your intriguing question! The aim of the adjoint solver was primarily to minimize the pressure drop while considering the constraints on permissible geometry deformation. In our optimization process, factors like flow turbulence and structural integrity would indeed play critical roles and should be among the criteria being accounted for in order to maintain the tube’s operational performance and durability post-optimization. While the focus here was on pressure drop reduction, similar methodologies are used to ensure other critical performance parameters are likewise optimized or maintained within acceptable limits.

Dr. Verner Haley –

The description of the Adjoint Solver project was incredibly thorough, and I found the three-step process logical and informative. The results indicating a pressure drop decrease by 38% highlight the efficacy of the boundary shape optimizations. Really pleased with the educational value of this content!

MR CFD Support –

Thank you for taking the time to leave a positive review. We’re thrilled to hear that you found the training material on the Adjoint Solver and its three-step optimization process informative and helpful. It’s great to see that the content enhanced your understanding of CFD design optimizations and their impact on system performance. If you’re interested in more in-depth exploration of similar topics or have any additional feedback, please let us know. We appreciate your engagement with our learning products.

Beatrice O’Conner –

I’m impressed by how the design optimization significantly reduced the pressure drop in the pipe! Great use of the adjoint solver and RBF morphing technique to achieve such an improvement.

MR CFD Support –

Thank you for your positive feedback! It’s fantastic to hear that you are impressed with the successful application of the adjoint solver and the RBF morphing approach to reduce pressure drop. Our aim is always to provide comprehensive training that delivers practical and impactful results. If you have any further questions or wish to delve deeper into these techniques, please don’t hesitate to contact us.

Odessa Rosenbaum MD –

I’m thrilled with the way this training course explained the optimization process using the adjoint solver. The step-by-step breakdown of sensitivity analysis and use of the RBF mesh morphing technique were particularly informative. How does mesh quality impact the results when using RBF morphing?

MR CFD Support –

In the adaptive meshing technique using RBF morphing, the quality of the mesh is crucial to the accuracy and convergence of the simulation results. When implementing mesh morphing, the mesh must be fine and flexible enough to handle the changes in geometry without deteriorating its quality. Poor mesh quality can lead to numerical errors and affect the reliability of the optimization performed by the adjoint solver. ANSYS Fluent has quality criteria that ensure the generated mesh appropriately reflects the geometry transformations during the optimization process.

Roscoe Tillman –

I found the use of adjoint solver to reduce pressure drop fascinating. Could you tell me more about how the design changes specifically contribute to the lowered pressure from a technical standpoint?

MR CFD Support –

In the optimization process using the adjoint solver, the design changes target areas of high sensitivity to reduce pressure drop. Generally speaking, smooth curves replace sharp bends in the geometry, and unnecessary obstructions are minimized to facilitate a smoother flow. Adjustments might include widening or reshaping the passageways at strategic points to reduce flow constriction and turbulence. In essence, the optimization process refines the geometry to create a more streamlined flow path, directly addressing factors such as flow separation and vortices, which contribute to pressure losses.

Marvin Bode –

Your product seems remarkable for understanding the concept of design optimization in a CFD context. Could you please tell me if this training course also includes hands-on practice with Ansys software for mesh morphing techniques?

MR CFD Support –

Yes, this training course includes practical exercises with Ansys software to ensure that users gain hands-on experience with mesh morphing techniques, particularly with Radial Basis Functions (RBF). Users will have the opportunity to work on mesh deformation and optimization within the Ansys environment.

Garry Schulist –

Fantastic learning experience! The step-by-step optimization process was very clear and easy to understand. This training provides valuable insights into how CFD can be applied to real-world problems in an effective and computationally efficient manner. Appreciated the detailed explanation on adjoint solver methodology and hand-on approach to mesh morphing technique with RBF. The decrease in pressure drop by 38% showcases the practical effectiveness of what was taught. Well done!

MR CFD Support –

Thank you for your kind words and for recognizing the quality and practicality of our CFD training. We are thrilled to learn that you found the step-by-step process clear and that the adjoint solver methodology met with your expectations. It’s wonderful to hear that our training could provide you with actionable insights that demonstrate effective real-world applications. We appreciate your feedback and look forward to assisting you in any future learning endeavors!

Prof. Zora Glover DDS –

According to the description, what version of ANSYS FLUENT software was used for the training course on minimizing pressure drop?

MR CFD Support –

There is no specific version of ANSYS Fluent mentioned in the training course description for the CFD project on minimizing the pressure drop using the Adjoint Solver with RBF Morph.

Elmore Moore –

Could you please tell me if the optimization of the U-shaped tube design refined the mesh during the process, and how did mesh refinement affect the accuracy of results?

MR CFD Support –

In the optimization process using the RBF Morph technique, instead of conventionally refining the mesh, we used the mesh morphing approach to manipulate the mesh according to the shape deformations. Mesh morphing via Radial Basis Functions allowed for effectively redistributing the mesh in accord with the geometry changes, maintaining a high-quality mesh throughout the deformation steps. Accuracy was preserved because the RBF Morph technique ensured that the mesh is sufficiently dense in critical areas, especially where high sensitivity to deformation was detected near the U-shaped bend, thus influencing the pressure drop observably. The mesh quality fundamentally affects results accuracy; hence, care was taken to sustain a structured topology to minimize numerical diffusion and protect solution fidelity.

Darwin Gutkowski –

I found the numerical simulation fascinating, especially the 38% reduction in pressure drop. Can you explain more about how the mesh morphing helps optimize the design to achieve this level of improvement in pressure drop?

MR CFD Support –

Mesh morphing is a numerical technique that allows the geometry of the computational mesh to be altered without remeshing. By using Radial Basis Functions (RBF) in this project, the mesh around the highly sensitive area (the tube’s bend) was intelligently adapted based on the results from the sensitivity analysis. This adjustment helped optimize the geometry, smoothing out areas creating high resistance to flow, thereby effectively reducing the pressure drop across the system by 38%. RBF Morph is key to enabling the mesh to deform smoothly, ensuring accurate prediction of fluid behavior as the shape evolves to its optimized form.

Dawn Dietrich –

The reduction in pressure drop is impressive! How significant is the durability of the optimized tube post-modification? Does the report include considerations for the tube’s long-term structural integrity?

MR CFD Support –

My apologies, but as an AI, I don’t have access to proprietary or non-public data including the specifics of the report or experimental results on such projects post-optimization. For inquiries regarding the durability and long-term structural integrity of the optimized tube, I would recommend directly consulting with the engineers or experts at MR CFD who have performed the simulation and analysis.

Willard Kohler –

Can this simulation process with an adjoint solver and gradient-based optimizer be applied to more complex geometries, like multiple bends or varying diameters in the system?

MR CFD Support –

The methodology of combining an adjoint solver with a gradient-based optimizer for pressure drop reduction is applicable to a variety of geometrical configurations, including systems with multiple bends or varying diameters. The sensitivity analysis and optimization can be adapted to account for the complexities of different geometries to achieve the desired performance improvements.

Sigrid Feeney –

I thoroughly enjoyed learning through this project. It clearly articulated the process of decreasing pressure drops in a real-world engineering application and the use of the adjoint solver was quite enlightening.

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that the training was clear and informative. It’s great to know that our project helped in enhancing your understanding of the design optimization process in engineering applications.

Lessie Hirthe –

Could the same optimization method be used for larger systems with multiple bends, or are there scalability limitations with the current software and methodology?

MR CFD Support –

Yes, the same optimization process can generally be employed for more complex systems with multiple bends. However, the larger and more complex the system, the greater the computational resources and time required. Scalability may be limited by the available computational power and the efficiency of the algorithms used within ANSYS Fluent.

Madalyn Douglas –

I just finished working through the ‘Minimizing Pressure Drop by Adjoint Solver (RBF), ANSYS Fluent CFD Simulation Training,’ and I’m thoroughly impressed! The tutorial was incredibly detailed, and the step-by-step guidance through the optimization process was crystal clear. Also, the use of RBF for mesh morphing was fascinating and watching the pressure drop after optimization was fulfilling. Fantastic work on a challenging topic!

MR CFD Support –

Thank you for your kind words and positive feedback. We’re thrilled to hear that the training provided clear instructions and that you found the mesh morphing process with RBF intriguing. It’s rewarding to know that the training helped you understand the complexities of CFD optimization. Your success is truly a testament to the value we hope to provide our users. If you ever have any more questions or need further assistance, we’re always here to help. Happy simulating!

Mr. Tyshawn Ankunding –

All the information was great to read! I appreciate knowing that the pressure drop was significantly reduced by 38%. Can you mention the additional benefits besides minimizing pressure drop that such an optimization process might bring to a real-world piping system?

MR CFD Support –

Thanks for your kind words! Aside from reducing the pressure drop by 38%, optimizing a piping design can lead to several additional real-world benefits such as improving the flow distribution, which may enhance energy efficiency. Also, it can contribute to the longevity of the pipe system by lowering the stress and potential wear on bends and joints. Moreover, optimization can help in reducing noise and vibration issues associated with turbulent flow, thereby improving overall system performance.

Rocio Sanford PhD –

I greatly appreciated the clear explanations on optimizing the design to minimize pressure drops in tubes. The methodology outlined in the training makes the complex process understandable, and the significant reduction achieved by 38% in the pressure drop is quite impressive.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training materials are helpful and that the step-by-step methodology was clearly explained. It’s wonderful to know that the optimization process displaying a 38% reduction in pressure drop was particularly noteworthy for you.

Cicero Shanahan MD –

Thanks to the detailed RBF course, I now better understand how to perform optimization using the adjoint solver. The practical examples showing how to reduce the pressure drop by optimizing the shape of the tube was really insightful.

MR CFD Support –

We’re thrilled to hear that you found the RBF Morph training course to be insightful! Thank you for sharing your positive experience. It’s great to know the course helped you understand optimization techniques using the adjoint solver and their practical applications. If you need further assistance or more resources for learning, feel free to contact us.