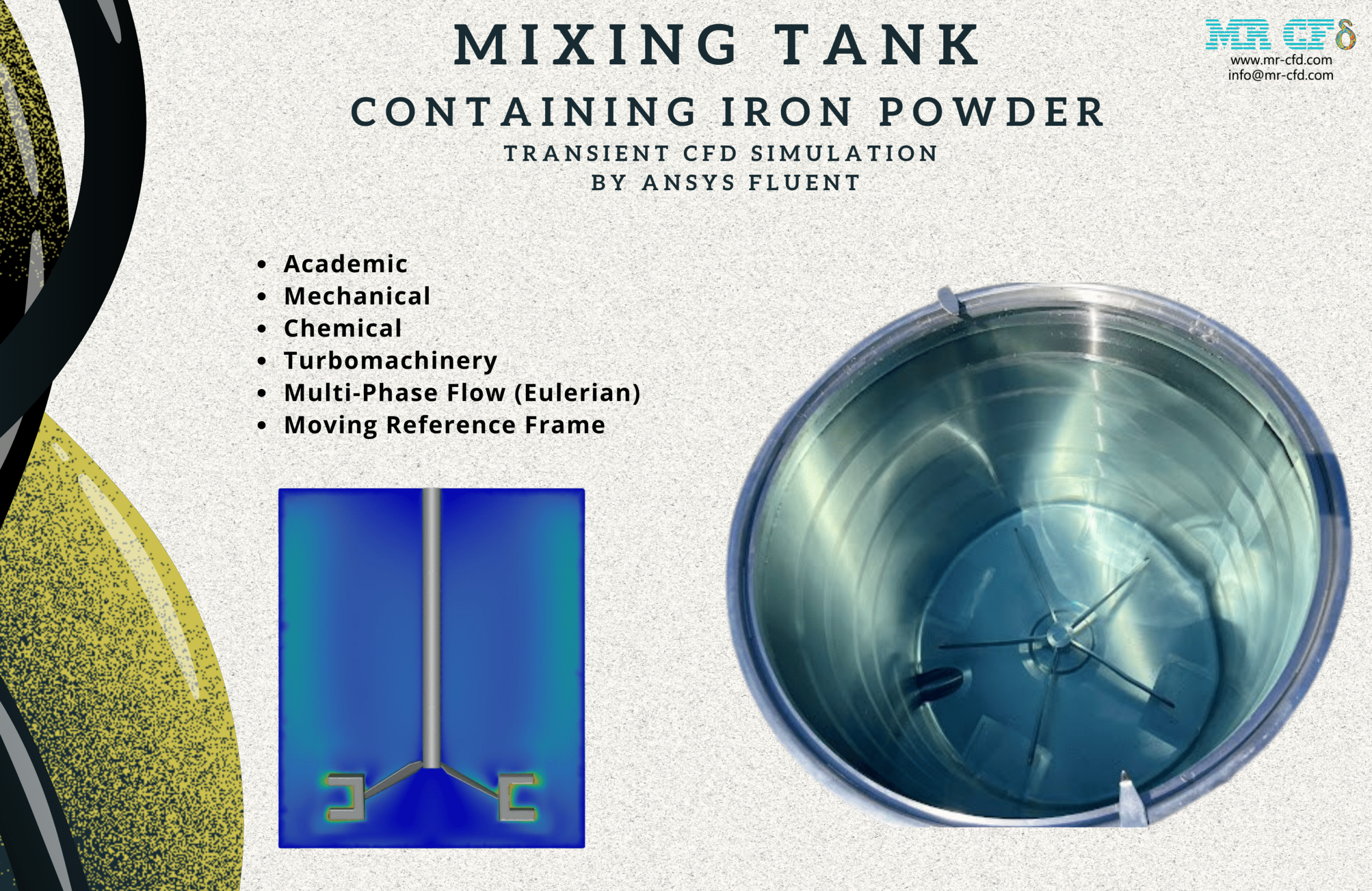

Mixing Tank Containing Iron Powder, Transient CFD Simulation by ANSYS Fluent

$140.00 $70.00 Student Discount

- This report presents a simulation of the mixing of water and iron powder in a cylindrical tank with a rotating impeller using the Eulerian multiphase method.

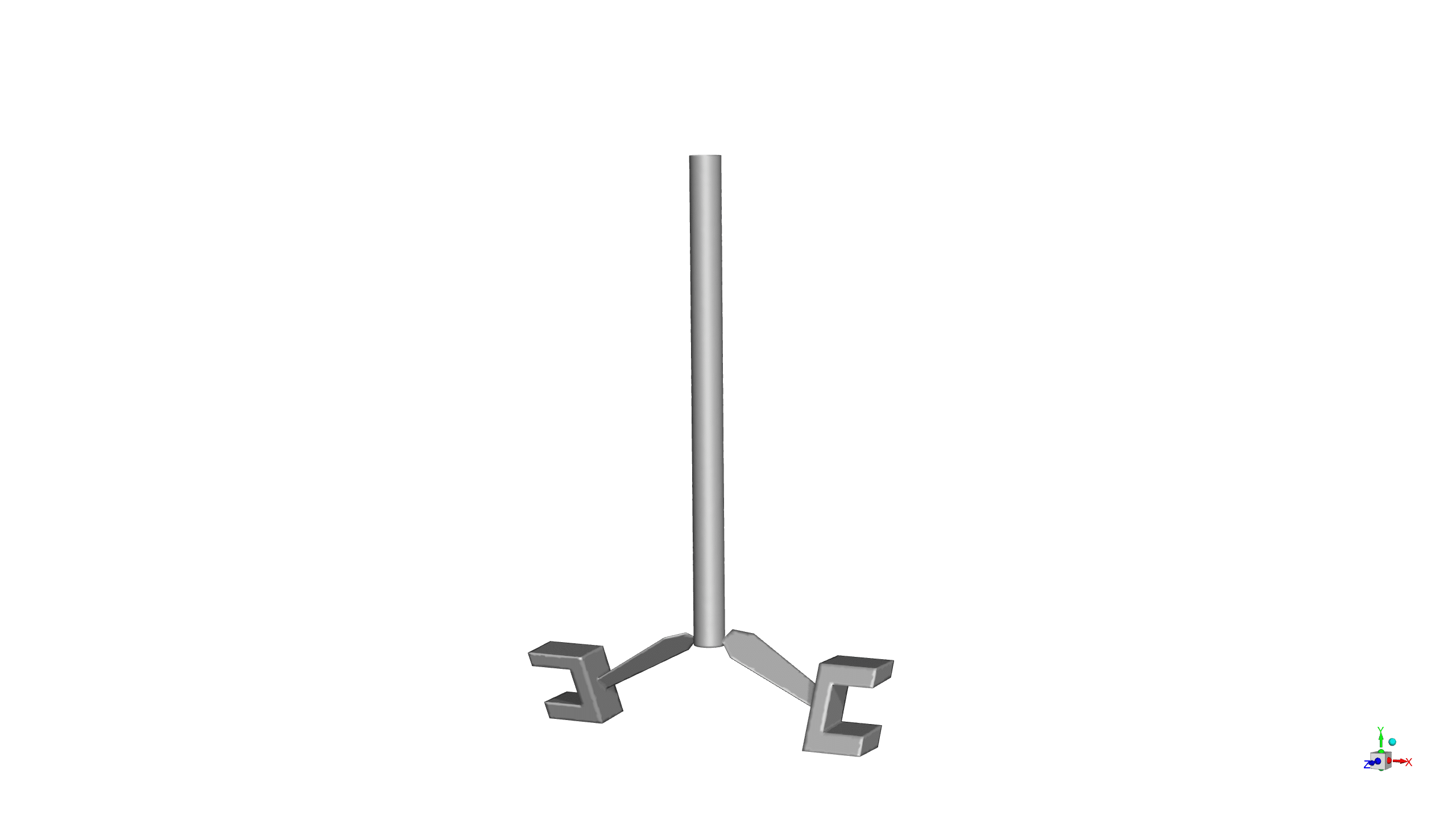

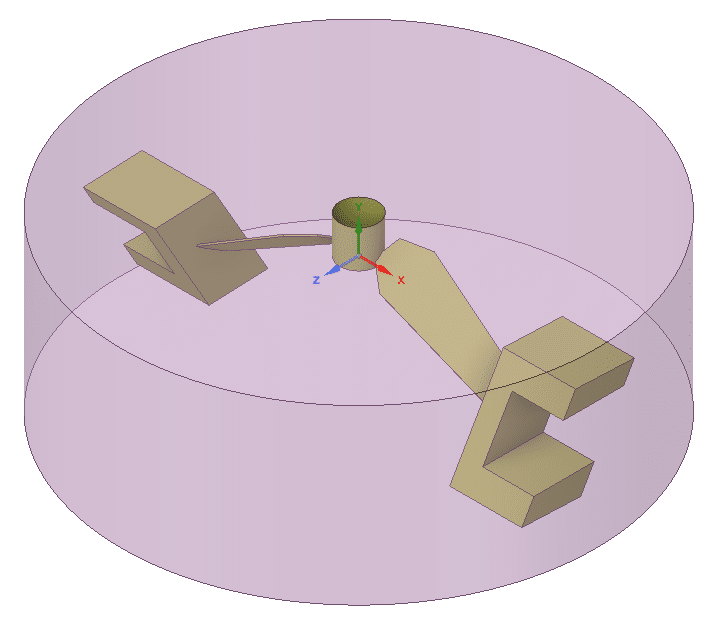

- The geometry of the mixing tank was created using ANSYS SpaceClaim software.

- A high-quality mesh of about 1,260,000 tetrahedron elements was generated using ANSYS Meshing software.

- Appropriate Eulerian interphase forces and settings were applied and the Moving Reference Frame (MRF) method was used.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Investigation of the effect of impeller rotation on the mixing of iron powder particles in a two-phase flow of water and iron powder, ANSYS Fluent Training

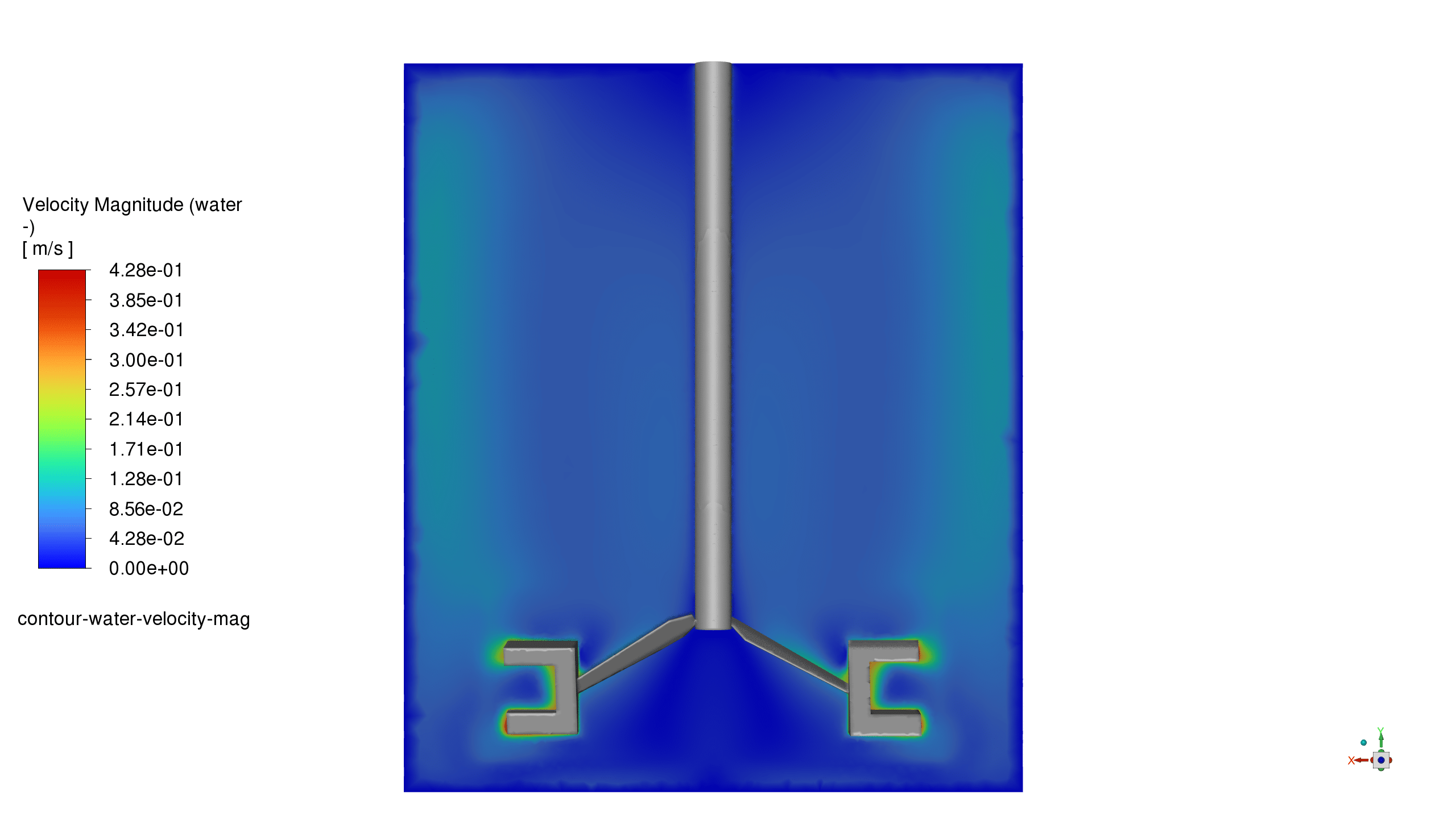

A mixing tank typically consists of a cylindrical vessel and one or more impellers. The impellers are driven by an external motor that rotates them. When the impellers rotate, they create a flow of fluid in the tank. This flow can be axial (up and down) or radial (outwards towards the wall of the tank), depending on the type of impeller used. The fluid flow causes the substances in the tank to move and collide with each other leading to their mixing. The closed mixing tank contains water liquid while the impeller starts rotating with 120 Revolutions per minute angular velocity, creating a massive vortex in the middle of the tank.

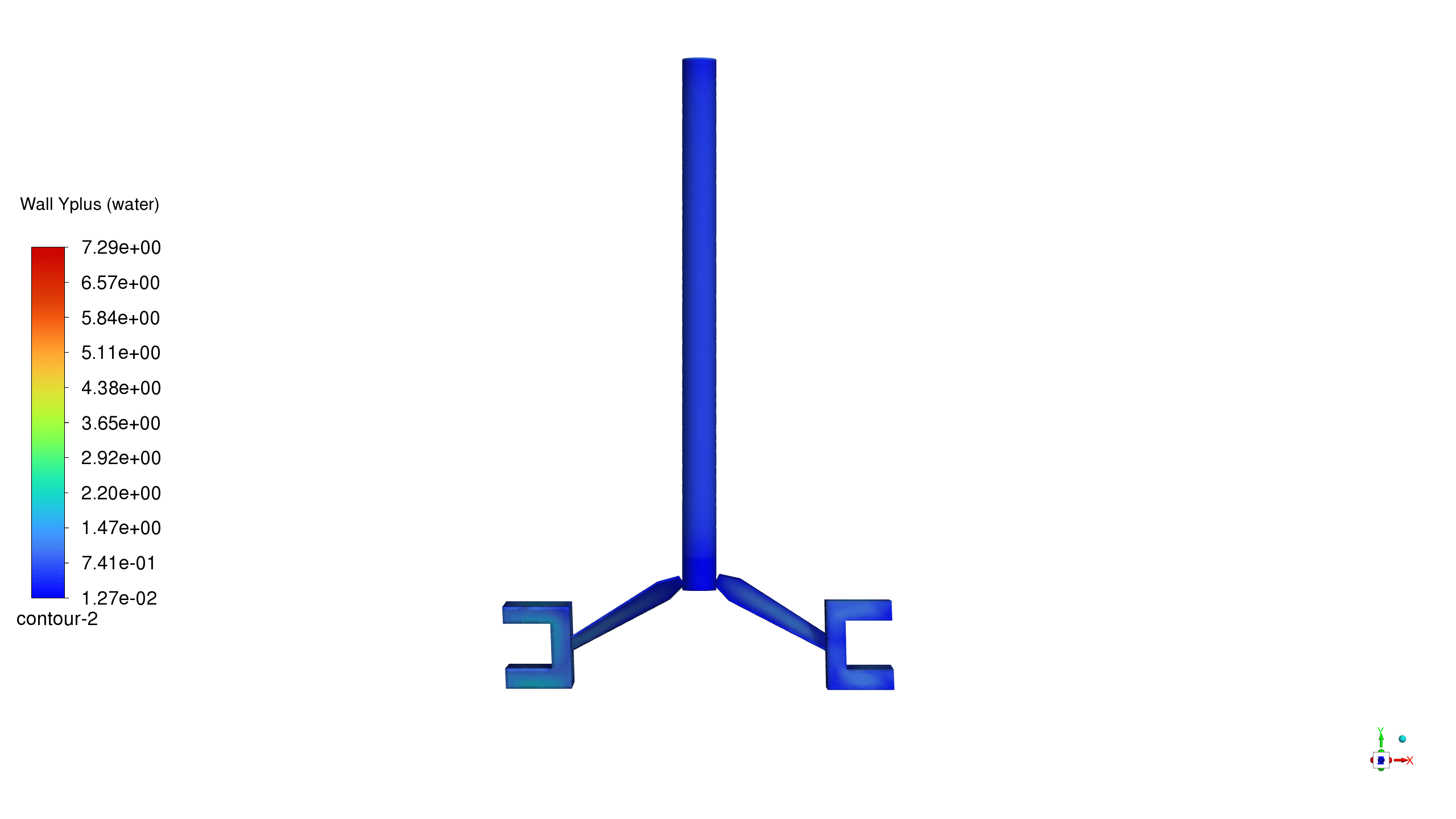

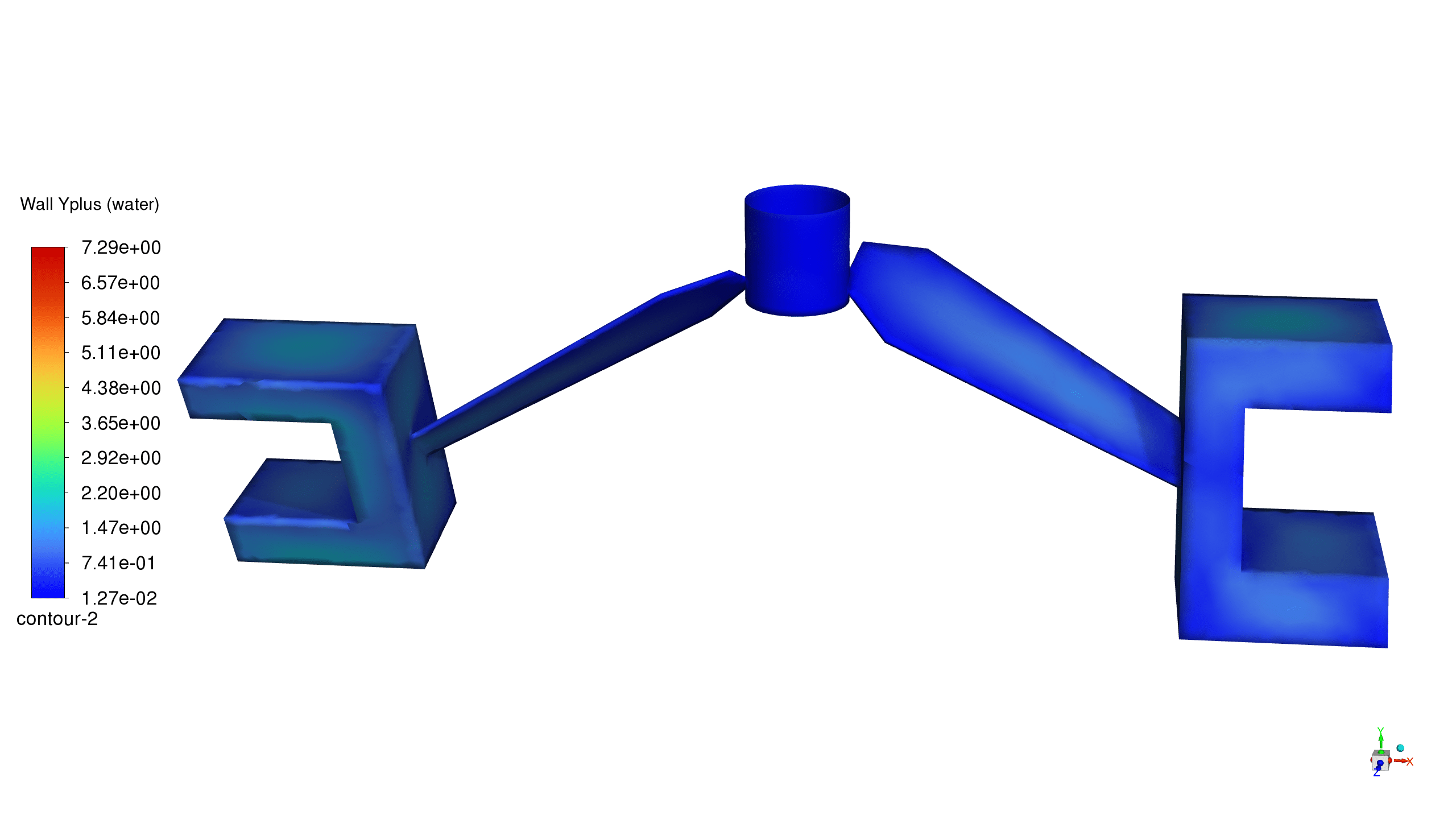

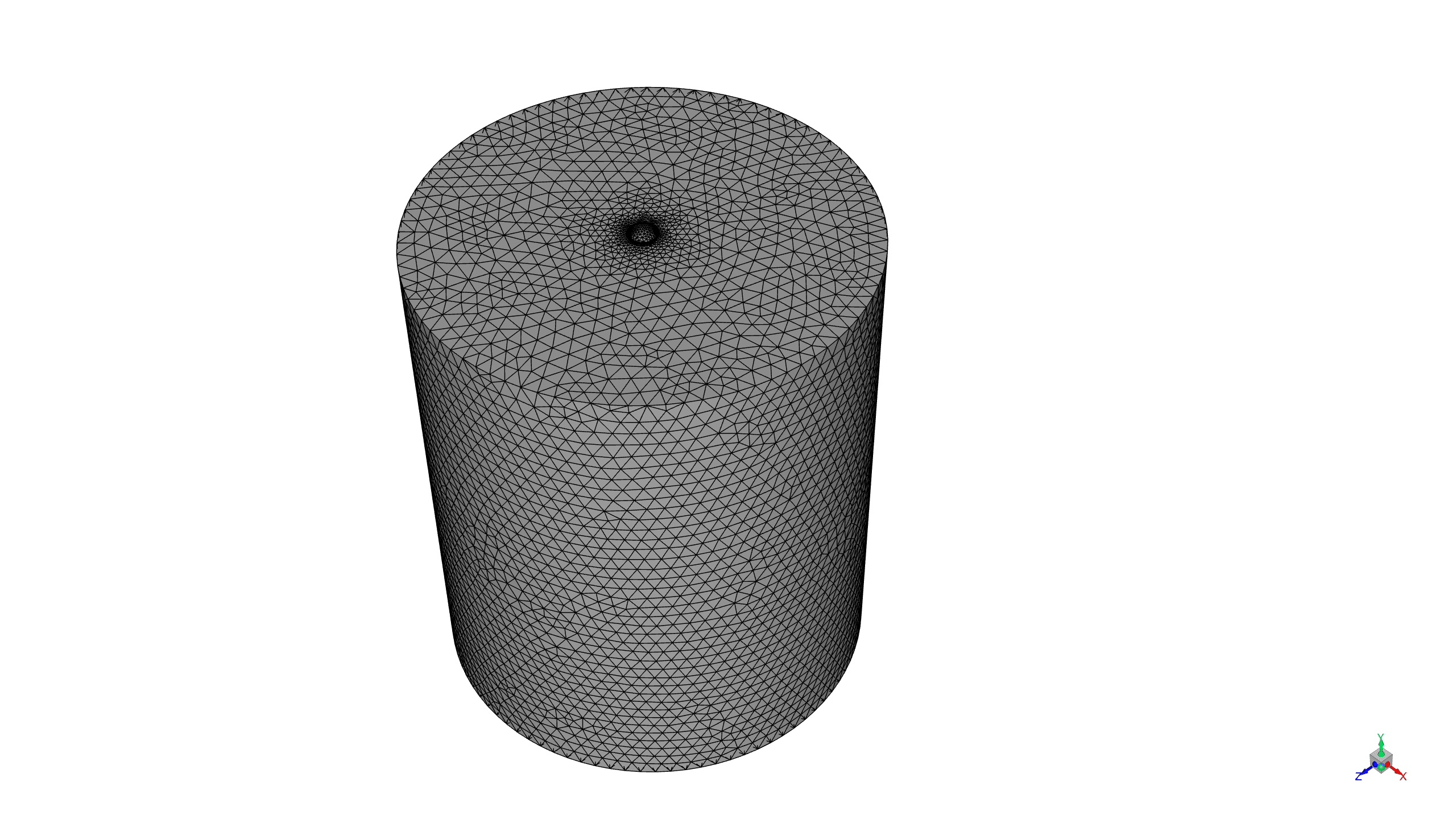

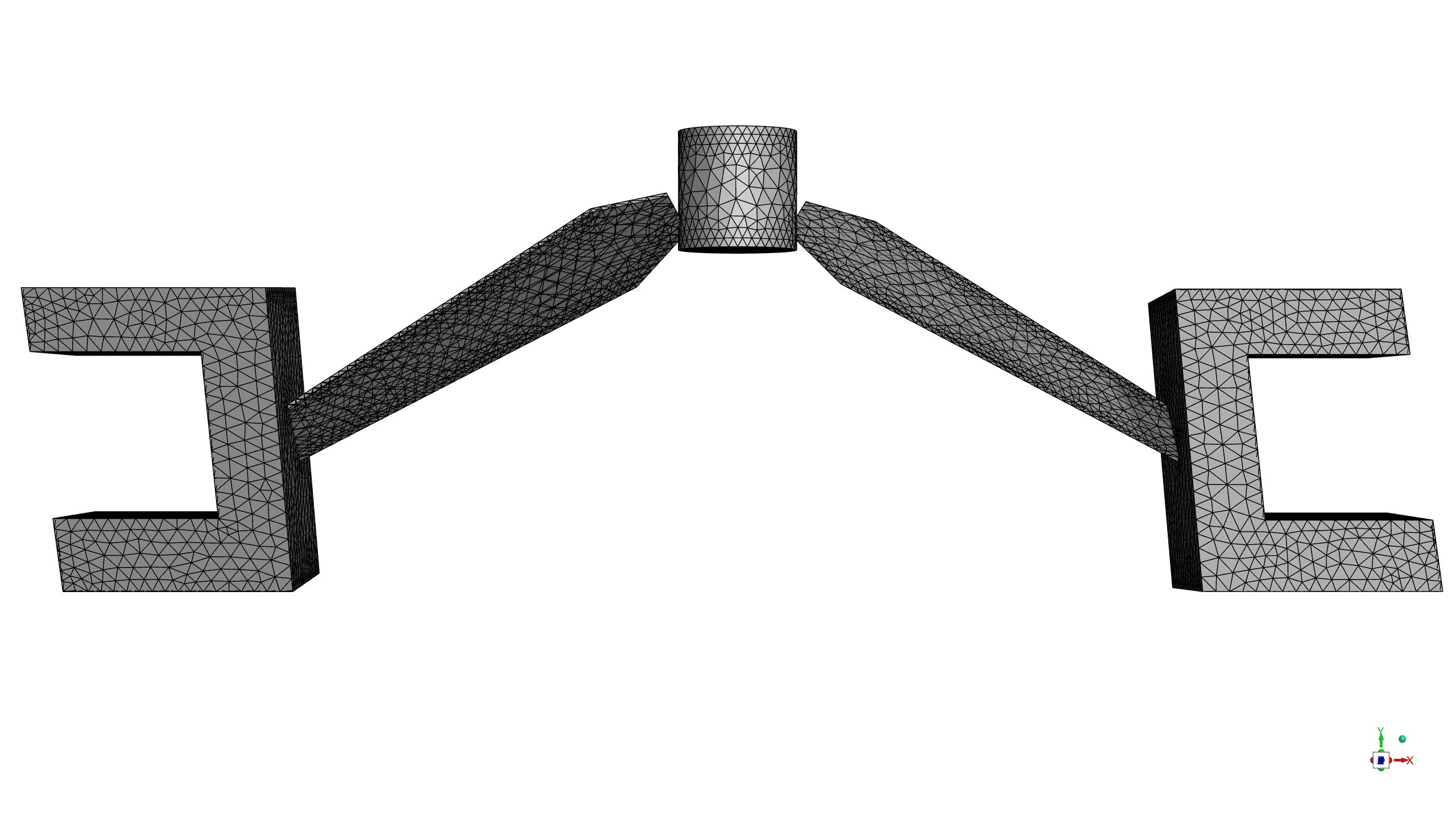

The geometry of the present model is three-dimensional and has been designed using ANSYS SpaceClaim software. We do the meshing of the present model with ANSYS Meshing software. The mesh type is unstructured, and the element number is about 1,260,000. Around the shaft and impeller, a boundary layer mesh with 5 layers is applied so that y+ does not get too high in these sensitive areas.

Methodology

A pressure-based, transient solver was employed to capture the interaction between the water and iron powder phases over time in the mixing tank. Iron powder particles with a density of 7800 (kg/m^3) and diameter of 10 micrometers were used. The realizable k-epsilon turbulence model was used because it provides improved predictions for flows with strong streamline curvature, vortices, and rotation. A suitable wall function was implemented to accurately resolve the near-wall region, which is essential for capturing detailed interactions between fluid flow and particle dynamics near the impeller walls. Additionally, appropriate forces and models were considered to enhance the accuracy of the Eulerian multiphase model settings used in the analysis. The Moving Reference Frame (MRF) method was used to simulate the rotation of the impeller.

Results and Conclusion

From the simulation, the following results are obtained:

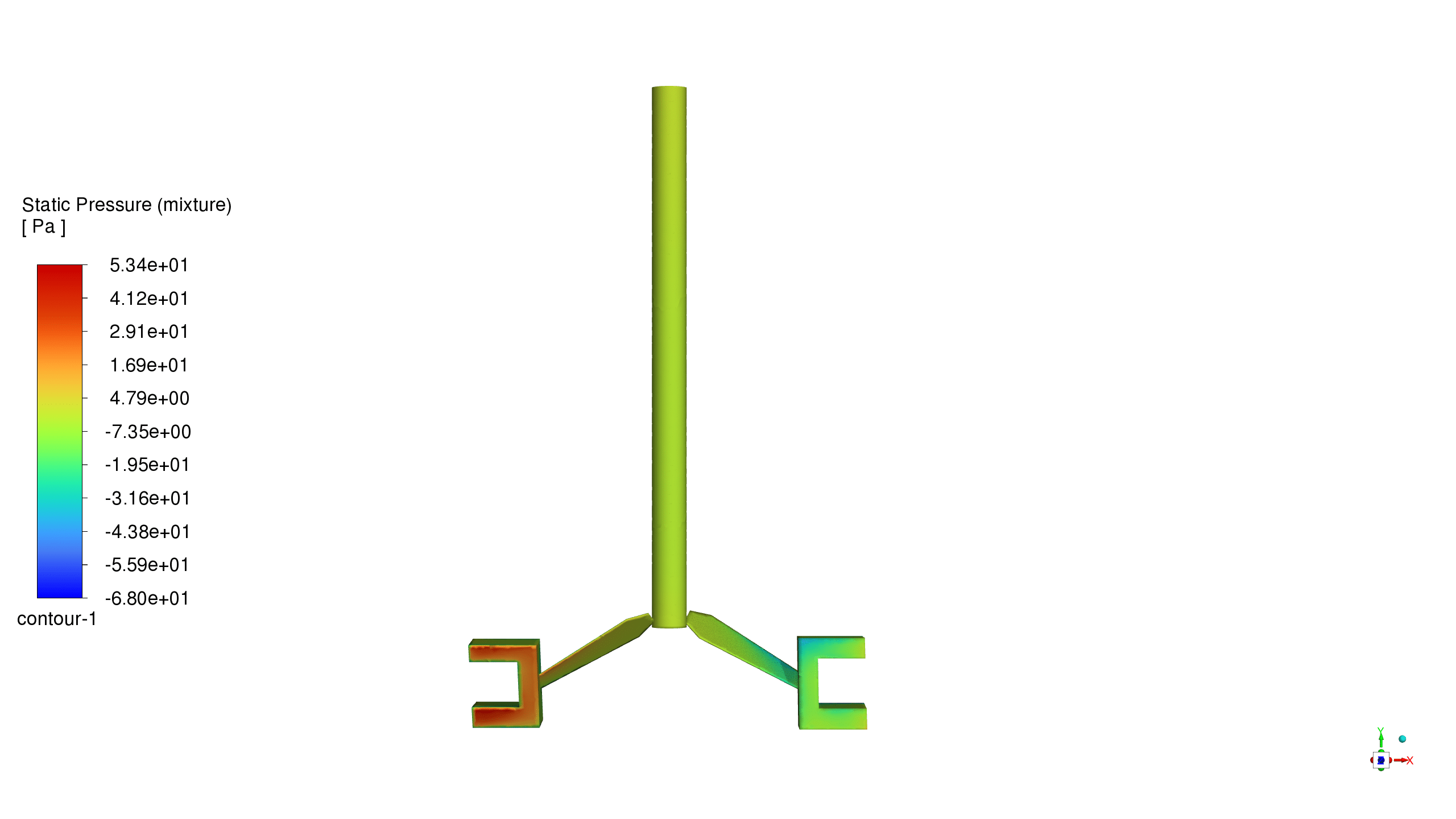

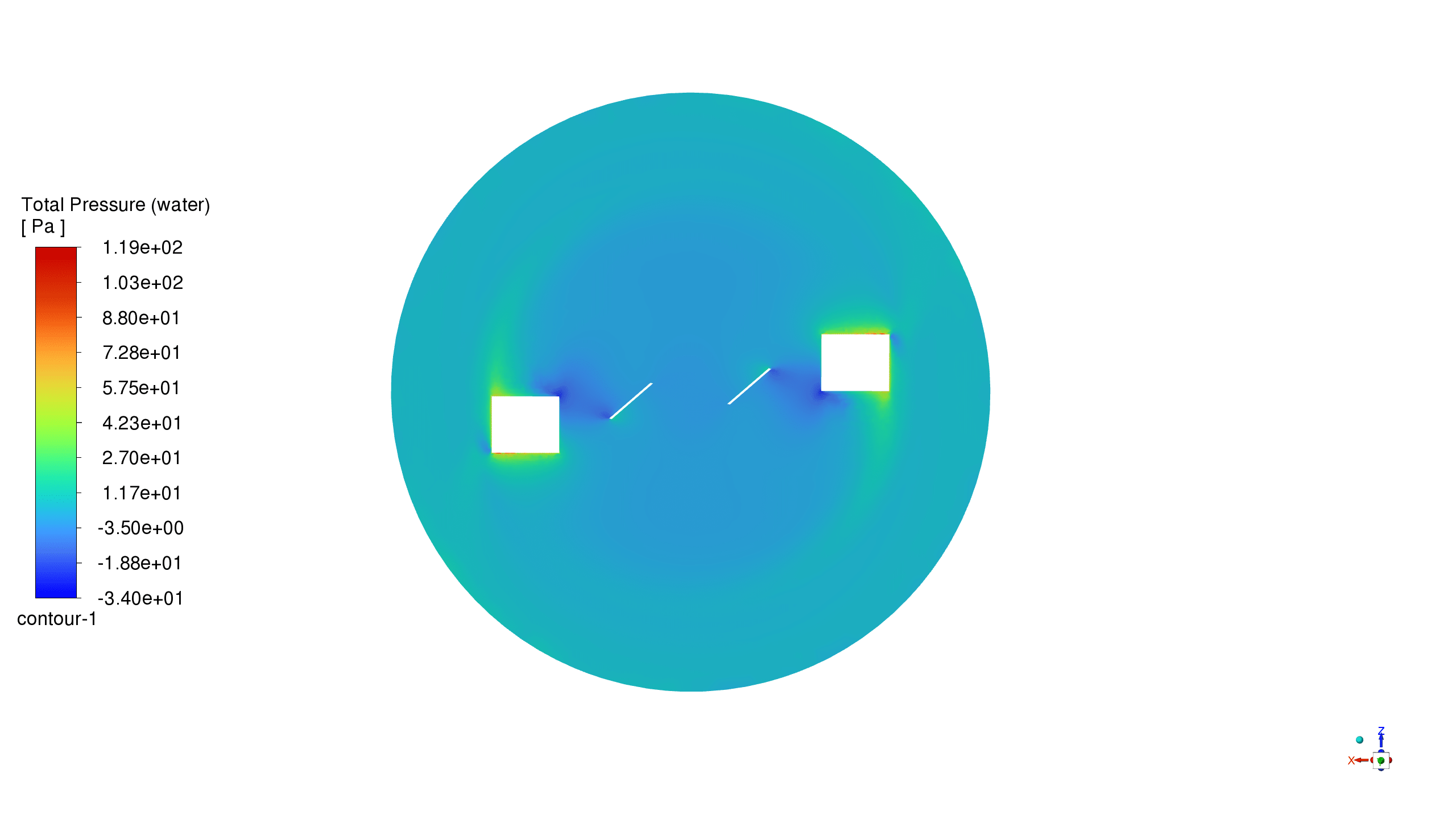

- In the case of pressure, it is visible that the amount of water pressure in front of the impeller is much more than the amount behind it.

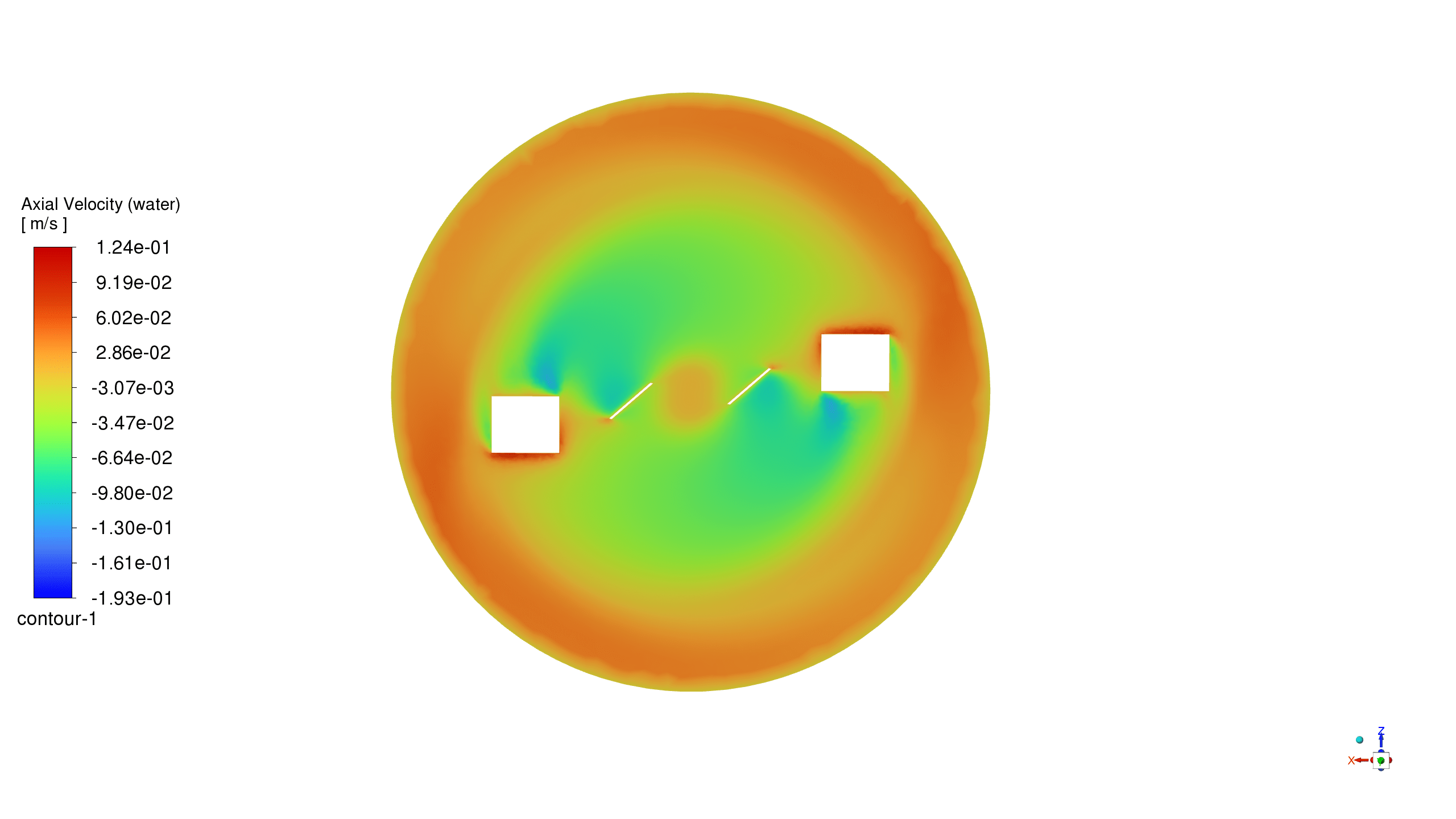

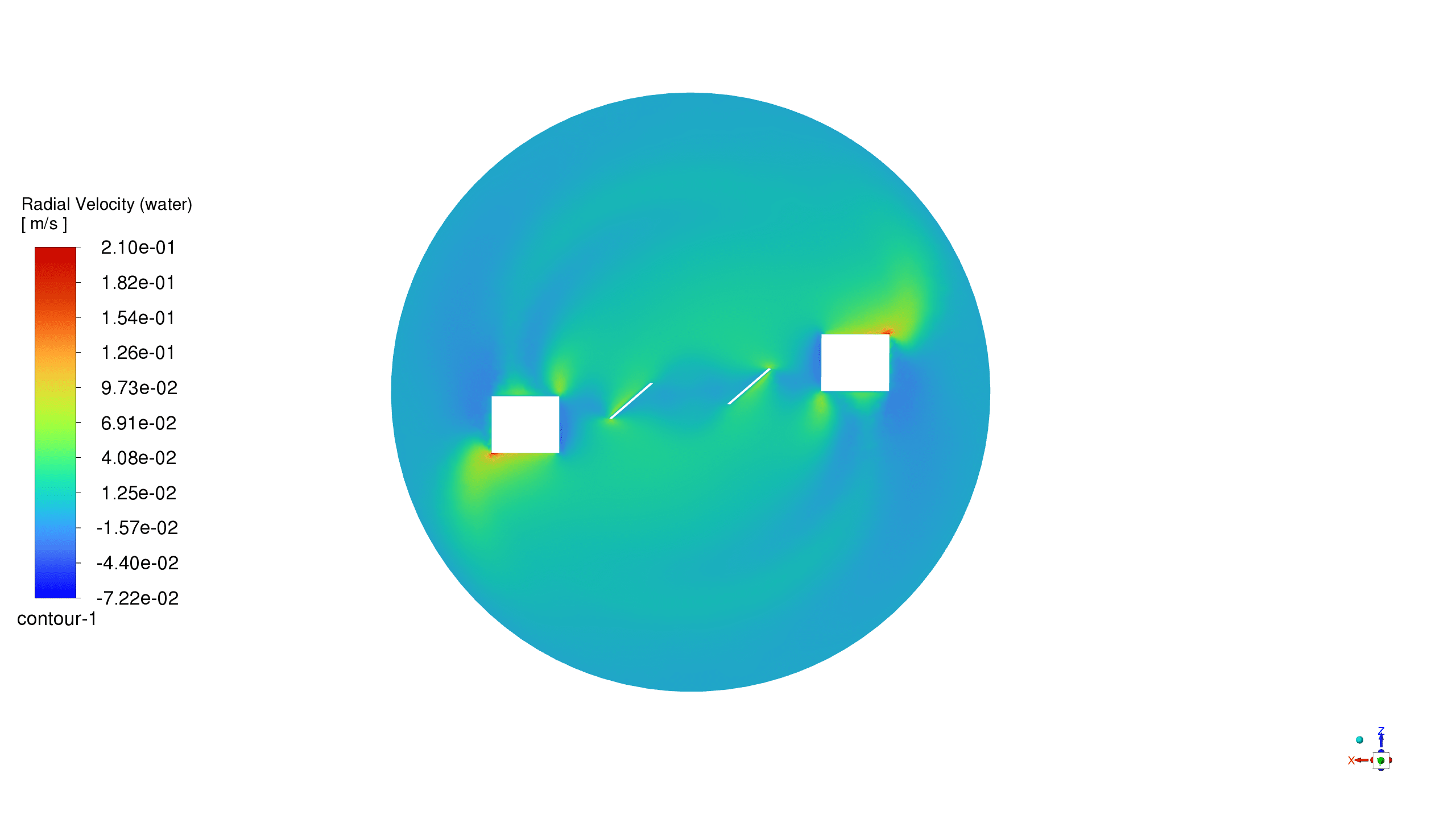

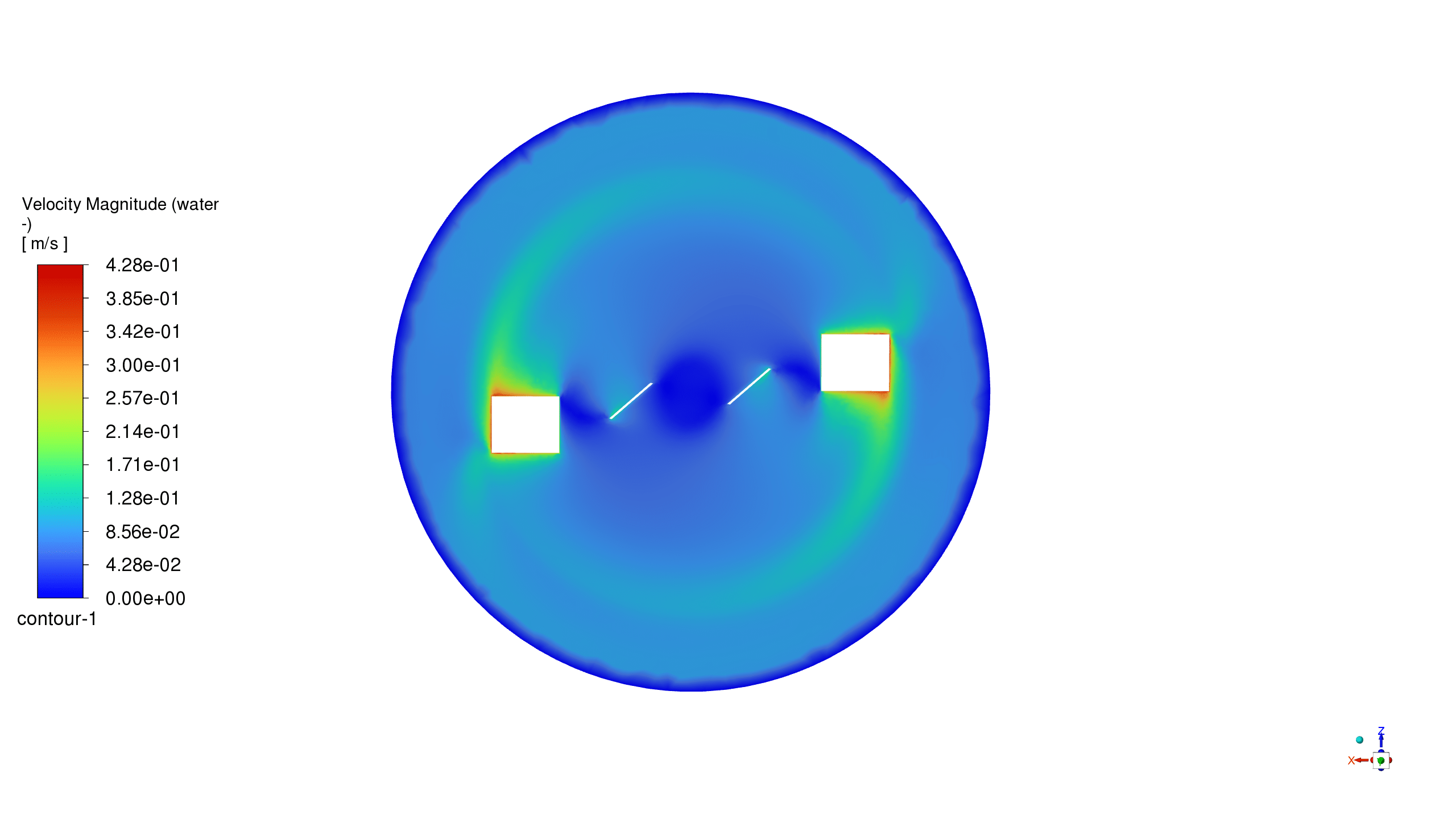

- water axial and radial velocity contours from above and the water velocity magnitude from front are shown in the figures. As was expected, the speed of the flow front of the impeller is more than in other areas in the domain.

- From the y+ contours, it is evident that the y+ values of the rotating components (shaft and impeller) are approximately in the range of 0 to 7.3. This indicates that the chosen wall function is functioning correctly, with the y+ values falling within the acceptable range for its application.

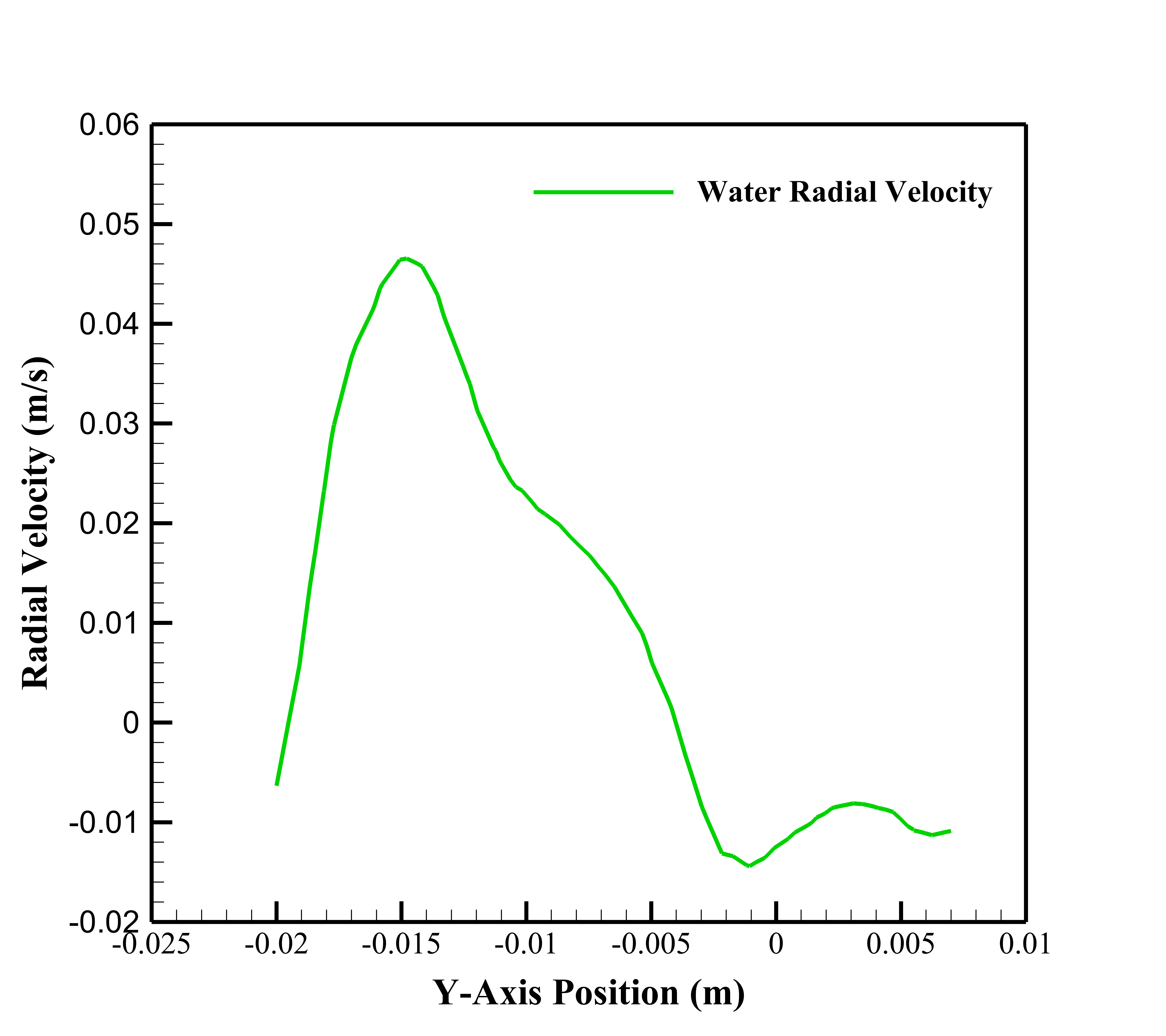

- The radial velocity of water versus position on a line along the y-axis near the impeller is shown in the figures. As can be seen from the graph, the maximum radial velocity of the water occurs approximately halfway through the impeller blade and is about 0.048 (m/s). It should be noted that the negative values of the velocity in this graph indicate the direction of the radial velocity vector, meaning that at those locations the radial velocity vector is pointing toward the center of the impeller, not outwards.

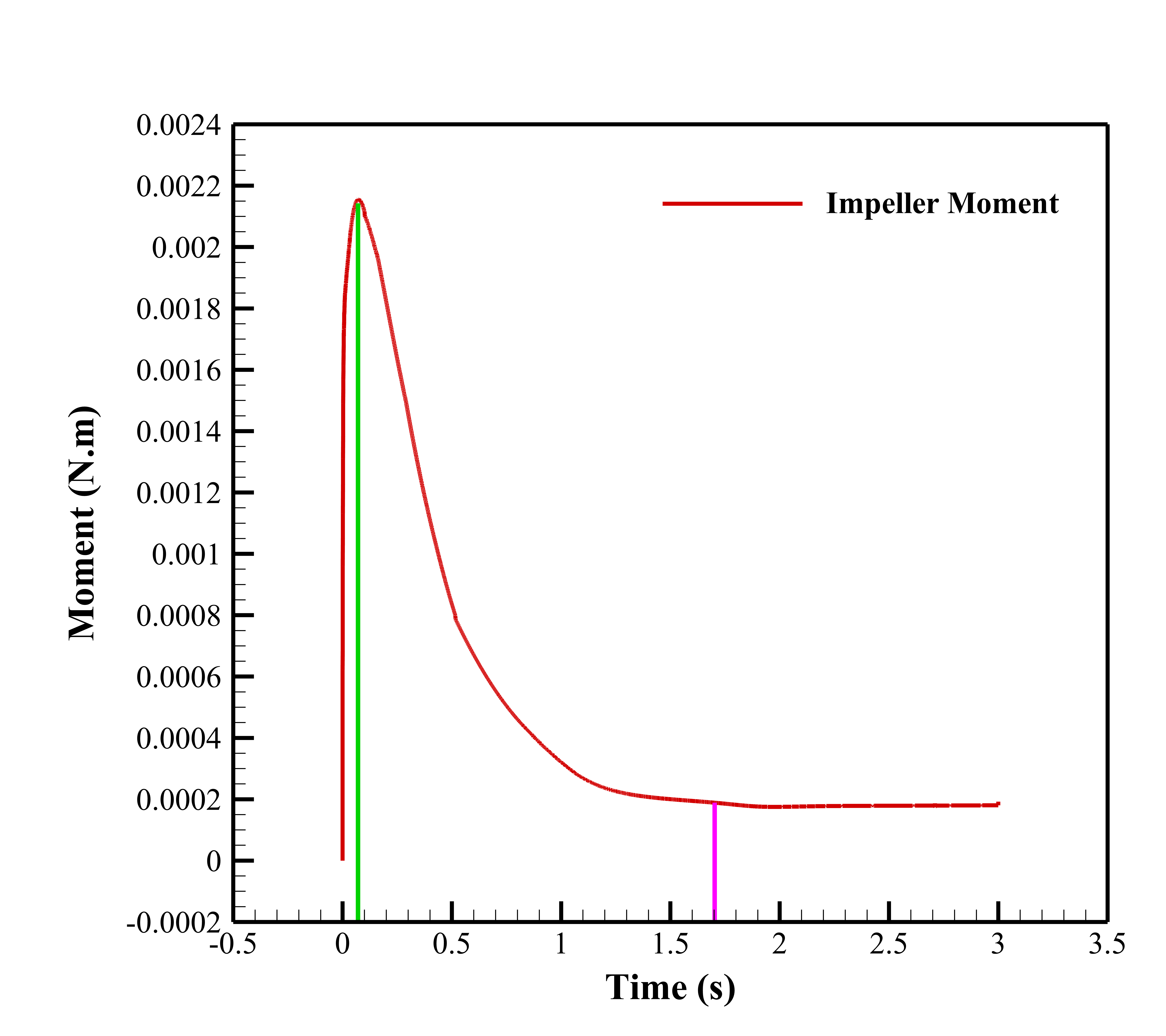

- The moment on the impeller versus time graph is shown in the figures. We see that the moment on the impeller increases significantly (up to about 0.00215 N.m) in the initial moments of the solution (up to about 0.08 s). After that, until about 1.7 (s), the moment on the impeller decreases and again takes a constant value of 0.0002 (N.m). This initial jump in moment is because the impeller starts rotating from rest.

Stephania Hackett –

I had a great experience with the ‘Mixing Tank Containing Iron Powder, Transient CFD Simulation by ANSYS Fluent’, especially how it handles the multiphase flow and turbulence. Well done!

MR CFD Support –

Thank you for your positive review! We’re thrilled to hear that you had a great experience with our simulation product and found the treatment of multiphase flow and turbulence insightful. If you have any more feedback or need further assistance in the future, please don’t hesitate to reach out.

Mrs. Brandyn Rempel –

Could you expand on how the Eulerian multiphase model is configured and what are the key setup parameters in the simulation of the mixing tank with iron powders?

MR CFD Support –

In the Eulerian multiphase model for the mixing tank simulation, the key setup parameters include defining two separate phases with distinct material properties. The base fluid (water) has a density of 998.2 kg/m3 and a viscosity of 0.001003 kg/m.s. The secondary phase is comprised of iron powder particles with a density of 7800 kg/m3, a viscosity of 0.01 kg/m.s, and particle diameter set to 1e-05 meters. Additionally, the simulation is unsteady and utilizes the k-omega SST model for capturing turbulence effects. The mesh motion method allows the impeller to rotate at 240 revolutions per minute, creating flow dynamics that result in mixing within the tank.

Chance Parisian –

The visualizations and details provided in the simulation seem outstanding. Great to see an effective mixing action achieved through the simulation. Thank you to the MR CFD team for offering insight into the mixing process within this configuration.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation provided useful visualizations and details. It’s our pleasure to offer valuable insights into the mixing process, and we appreciate you recognizing the team’s efforts. Looking forward to assisting you with any future CFD projects!

Anais Kunde –

I’m highly impressed by the level of detail in the simulation of the two-phase mixing process. The results provided give excellent insights into the dynamics within a mixing tank.

MR CFD Support –

Thank you for your positive review! We’re glad you found the simulation detail and results informative and insightful. It’s always our goal to provide thorough analysis in our CFD projects. If you have any further inquiries or need assistance with similar simulations, feel free to reach out to us.

Anastasia Pagac Sr. –

The experience with the Mixing Tank simulation was extraordinary! The detailed analysis around the impeller really showed how the pressure changes. And watching the fluid dynamics due to the impeller’s rotation provided excellent insight into the mixing process.

MR CFD Support –

We’re thrilled to hear that you had an excellent experience with the Mixing Tank simulation! It’s fantastic to know that the analysis provided you with valuable insights into the fluid dynamics within the mixing process. Thank you for your positive feedback, and we hope our products continue to meet your expectations!

Mattie D’Amore –

Fantastic simulation for visualizing multiphase flow dynamics! The level of detail on iron powder mixing and vortex formation was particularly impressive. Great job!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found the multiphase flow dynamics visualization impressive and the iron powder mixing details informative. If you have any more questions or need further assistance, feel free to reach out!

Johnny Upton –

I was utterly fascinated by the detailed analysis of the iron powder mixing process. The practical application of CFD in industrial processes was well demonstrated in this project, and the clarity of the visualizations greatly helped in understanding the mixing dynamics.

MR CFD Support –

We’re thrilled to hear that our simulation project provided clear insight into the mixing process and proved helpful to you. Understanding industrial applications through CFD analysis is crucial, and we are glad the visualizations enhanced your understanding. Thank you for your positive review!

Nettie Orn II –

I was impressed with the clarity of the simulations and the level of detail provided in the pressure and velocity contours. The visualizations made it easy to understand the impact of the impeller’s rotational motion on the water and iron powder mixture.

MR CFD Support –

We’re delighted to hear that our simulation visualizations enhanced your understanding of the mixing process. Thank you for sharing your positive experience with the level of detail in our CFD simulation.

Mr. Clifford Pouros –

The description mentions utilizing the k-epsilon turbulence model, can you explain why this is the case instead of using a different turbulence model for the simulation?

MR CFD Support –

The k-epsilon turbulence model is chosen for this simulation because it provides a good balance of accuracy and computational efficiency. This model is known for being robust and reliable for a wide range of turbulent flow problems and is a common choice for mixing applications. Moreover, it effectively addresses the turbulent kinetic energy (k) and its rate of dissipation (epsilon), which are significant in predicting the mixing dynamics and turbulent energy distribution within the mixing tank.

Felipe Paucek –

Fantastic learning resource to understand mixing simulation! The clarity provided by the contours helped solidify my grasp on how different parameters interact in a dynamic system like this.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that the simulation aided your understanding and helped you visualize the dynamic interactions within the mixing tank. We’re pleased our learning products are effective and appreciate your appreciation.

Sophia Schoen –

The tutorial for the Transient CFD Simulation of the Mixing Tank was fantastic! Your step-by-step guidance helped me understand not only the settings for a transient simulation with rotating parts but also the fluid and particle interaction. I’m particularly impressed with the attention to detail in demonstrating how particles of iron powder mix in the fluid—excellent work!

MR CFD Support –

Thank you for your kind words and for noticing the attention to detail in the mixing tank simulation tutorial. We are thrilled to hear that the tutorial was helpful and that you were able to gain a better understanding of transient simulation and particle interaction in ANSYS Fluent. If there’s anything else you want to dive into or need further assistance with, please don’t hesitate to reach out!

Mrs. Willie Yundt –

I’m impressed with the detailed approach taken to simulate the mixing process in a two-phase system. The precision in defining the physical properties and the rotation of the impeller indicate a high level of accuracy in the model. This detailed analysis must provide crucial insights for industrial applications.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the detailed simulation of the mixing tank met your expectations and provided accurate results. We strive to offer comprehensive models that can be useful for industrial applications and engineering challenges. Your satisfaction is our priority, and we look forward to assisting you with any future CFD needs.

Winnifred Kirlin PhD –

Wow, the inclusion of turbulence intensity contours and the visualization of pressure changes due to the impeller’s movement sound fascinating!

MR CFD Support –

Thank you for your kind words! We’re glad to hear you find the turbulence intensity contours and pressure change visualization in the mixing tank simulation impressive. It’s our goal to provide insightful CFD analysis that helps users visualize complex flow dynamics clearly. If you have any questions or need further information, feel free to ask!

Harvey McLaughlin II –

The multiphase model was really insightful, but could you please clarify how the particles’ velocity distribution is affected by the impeller’s motion and the initial suspension condition?

MR CFD Support –

The impeller’s rotation generates a complex flow pattern inside the tank. The particles’ velocity distribution will be primarily influenced by the turbulent flow currents created by the impeller blades. Furthermore, the initial condition of particle suspension, such as uniform or concentrated at specific points, will also play a role in how quickly the particles are dispersed throughout the liquid phase.

Miss Angela Bauch –

I am truly impressed by the complexity and detail reflected in the simulations, especially how the mixing dynamics have been thoroughly explored. It’s evident that high-quality insight into fluid behaviors within a rotating environment has been achieved—which must be quite instrumental for designing efficient mixing tanks.

MR CFD Support –

We are glad that you noticed the level of detail and complexity in our simulation. It’s our goal to provide comprehensive information to help our customers understand and design more efficient systems. Thank you for taking the time to leave such a positive and meaningful review.

Kris Heidenreich –

The project’s results seem highly detailed. Has there been an evaluation of the mixing efficiency, such as homogeneity over time?

MR CFD Support –

Thanks for your positive feedback! The analysis focuses on the flow characteristics within the tank such as pressure and velocity, and provides insights into the turbulent intensity. However, the simulation specifically captures the rotational effects of the impeller on the flow and dispersion of particles. Determining mixing efficiency is a more advanced application that relies on additional diagnostic measures such as the concentration distribution over time. If these results were critical, there might be an extended study or post-processing conducted to evaluate homogeneity and overall mixing efficiency.

Ms. Elenora Berge –

In the mixing tank simulation, how is the particle diameter chosen and does it affect the simulation results significantly?

MR CFD Support –

The particle diameter in the mixing tank simulation is selected based on the size of the solid particles (iron powder) you aim to simulate. It affects the simulation results significantly as it determines how the particles will behave in the fluid and interact with it, influencing parameters such as settling velocity, collision rates, and mixing efficiency.

Moshe Douglas –

I found the simulation on the mixing tank with iron powder fascinating! I appreciate the detailed breakdown of both the methodology and conclusions. Could you share some insights on how changing the impeller speed might affect the mixing efficiency and distribution of iron powder within the tank?

MR CFD Support –

In this simulation, impeller speed directly influences the flow pattern, mixing rate, and overall homogeneity of particle distribution. Increasing the impeller speed would enhance the turbulence and kinetic energy, leading to a more fine and thorough mix where the iron powder distribution is more uniform. However, overall mixing efficiency can be complex as excessively high speeds can create undesirable flow patterns like vortex formation, or even damage particles. It’s about finding an optimal balance for the specific application requirements.