Moving Reference Frame (MRF) Training Package, 10 Practical Exercises for INTERMEDIATES

$199.00 $99.50 Student Discount

This CFD training package is prepared for INTERMEDIATE users of ANSYS Fluent software in the Moving Reference Frame (Frame Motion) area.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Moving Reference Frame (MRF) – ANSYS Fluent Training Package, 10 Practical Exercises for INTERMEDIATE Users

This CFD training package is prepared for INTERMEDIATE users of ANSYS Fluent software in the Moving Reference Frame (Frame Motion) area. You will learn and obtain comprehensive training on how to simulate medium projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

This training package includes 10 practical exercises to train the necessary proficiency you will require to start doing average computational fluid dynamics (CFD) MRF simulations on your own using Ansys Fluent software. Qualified training movies and comprehensive CFD concepts explanations, including setup, solution, results, and all perspectives of carrying out CFD simulations in Ansys Fluent.

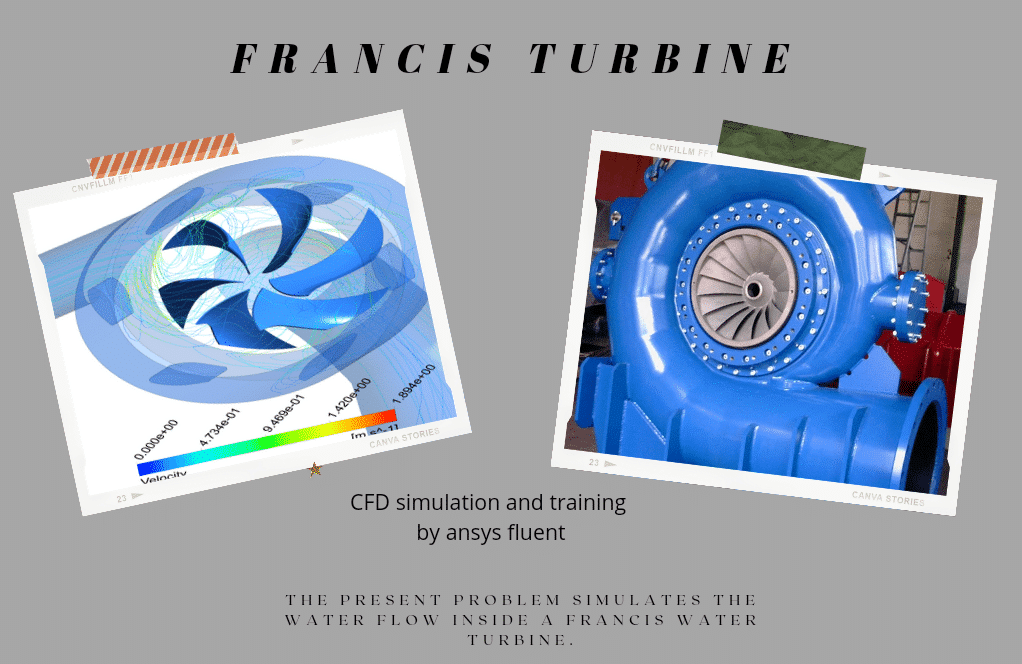

Turbine

Project number 1 simulates the water flow inside a Francis water turbine. A water turbine is turbomachinery that converts kinetic energy from water flow or potential energy from water height differences into rotational motion. Francis turbines are one of the types of water turbines that can use both kinetic and potential energy for power generation at the same time due to the location of their blades. The water flow is then transferred to the turbine runner blades with a certain flow rate, and as a result, the desired work is produced by rotating these blades by the water flow. Finally, the outflow of water from the turbine runner blades will be axial.

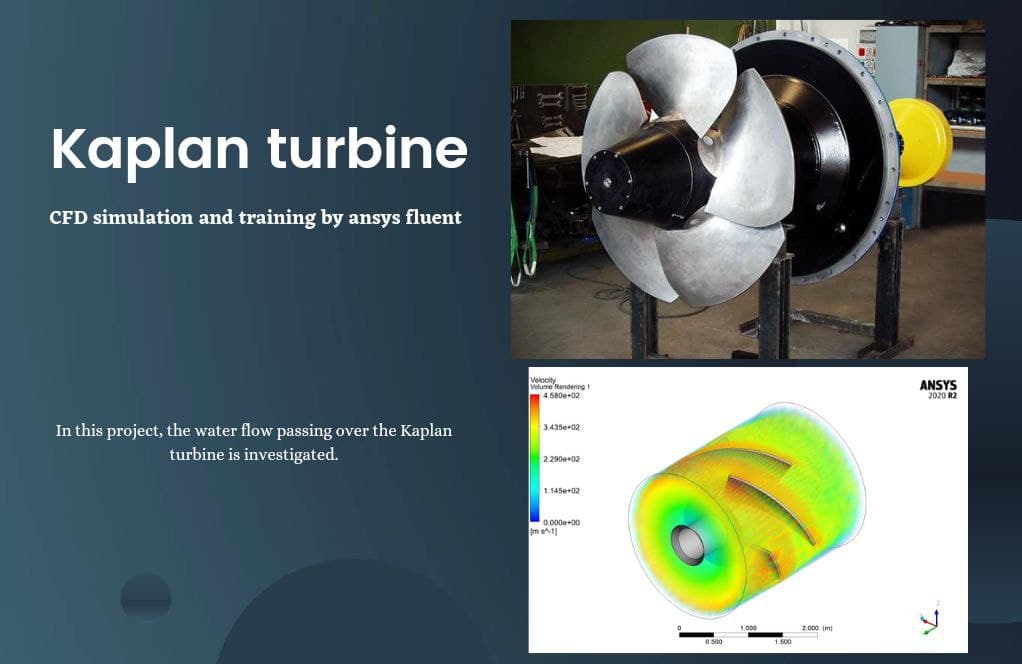

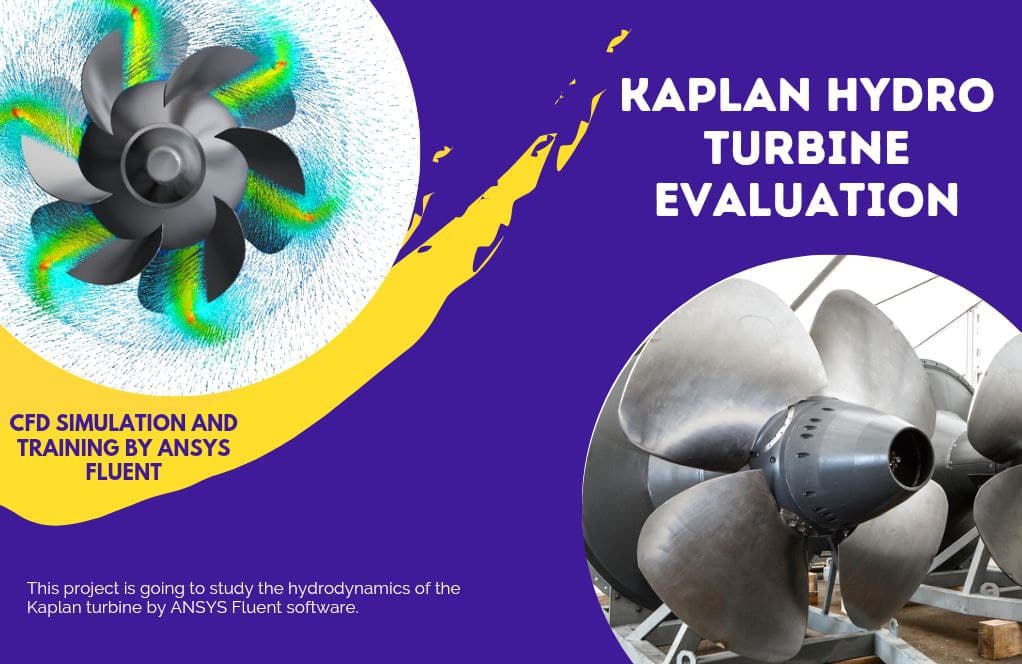

In project number 2, the water flow that passes over the Kaplan turbine is investigated. The Kaplan turbine rotates at 3300 rpm and sucks the water in. RNG k-epsilon model is exploited to solve turbulent flow equations. It should be noted that the MRF (Frame Motion) option has been activated to model the rotation of the turbine.

In project number 3, we will study the hydrodynamics of the Kaplan turbine. The geometry included a small size Kaplan turbine with 125 [mm] as a new prototype. Our static domain consists of an 8 [m] long rectangle, and our rotary domain is the Kaplan geometry with 16.5 RPM as the angular velocity. Besides understanding the physics involved with this geometry, we have also investigated the performance of the current Kaplan turbine by evaluating the drag force.

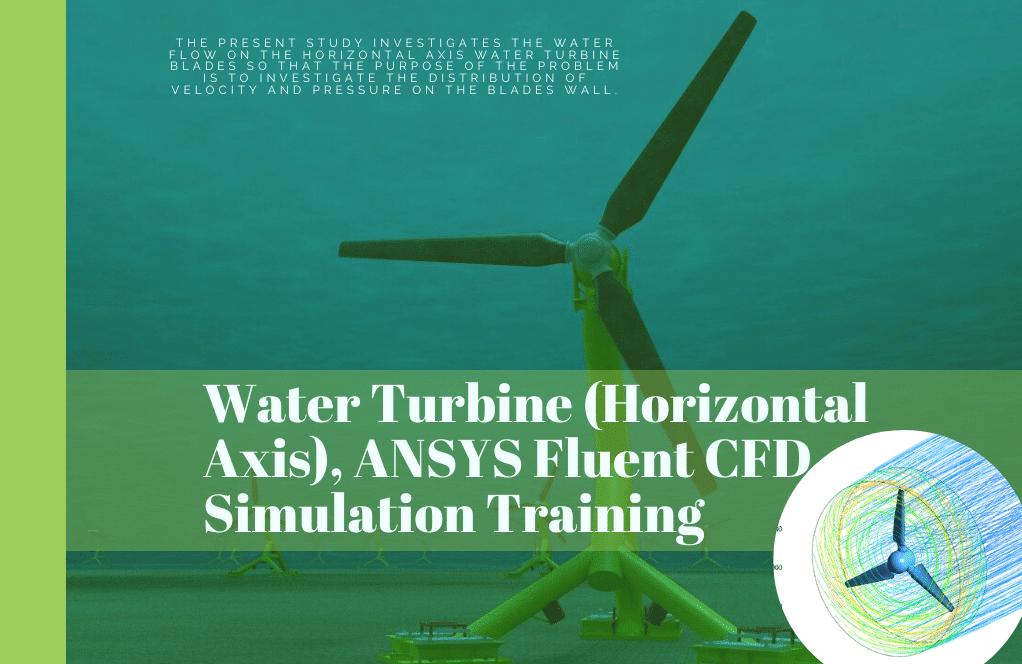

Project number 4 investigates the water flow on the Horizontal Axis WATER Turbine (HAWT) blades. The purpose of the problem is to examine the distribution of velocity and pressure on the blade wall. There are two areas around the blades, including a cylindrical area around the blades and a large area around the cylinder. The flow of water in the large outer space behaves like a normal flow, while in the cylindrical region around the blades, the rotational flow is caused by the rotational motion of the blades.

Project number 5 simulates wind turbines with a series arrangement in a wind farm. In this project, four wind turbines are designed in a row in a specific computational domain of a large field called a wind farm (turbine farm). In this way, a strong wind current at high altitudes causes the turbine blades to rotate, and by rotating the central shaft of the turbine, an electric current is generated in the generator connected to the turbine body. The wind turbines studied in this project are horizontal axis wind turbines (HAWT); Which means that the ambient wind flow is parallel with the turbine’s axis horizontally.

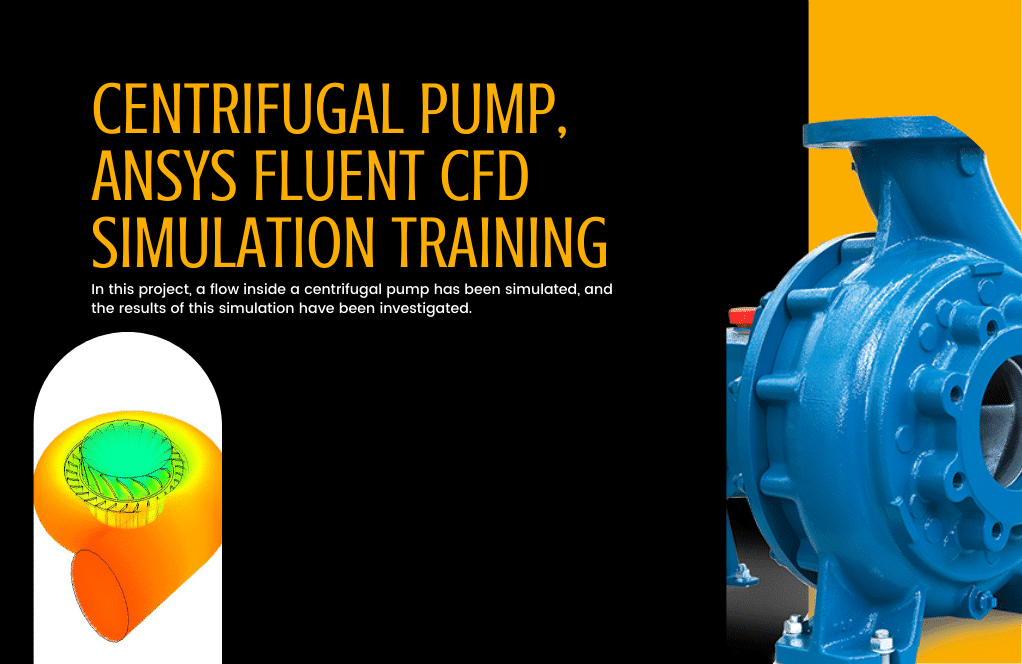

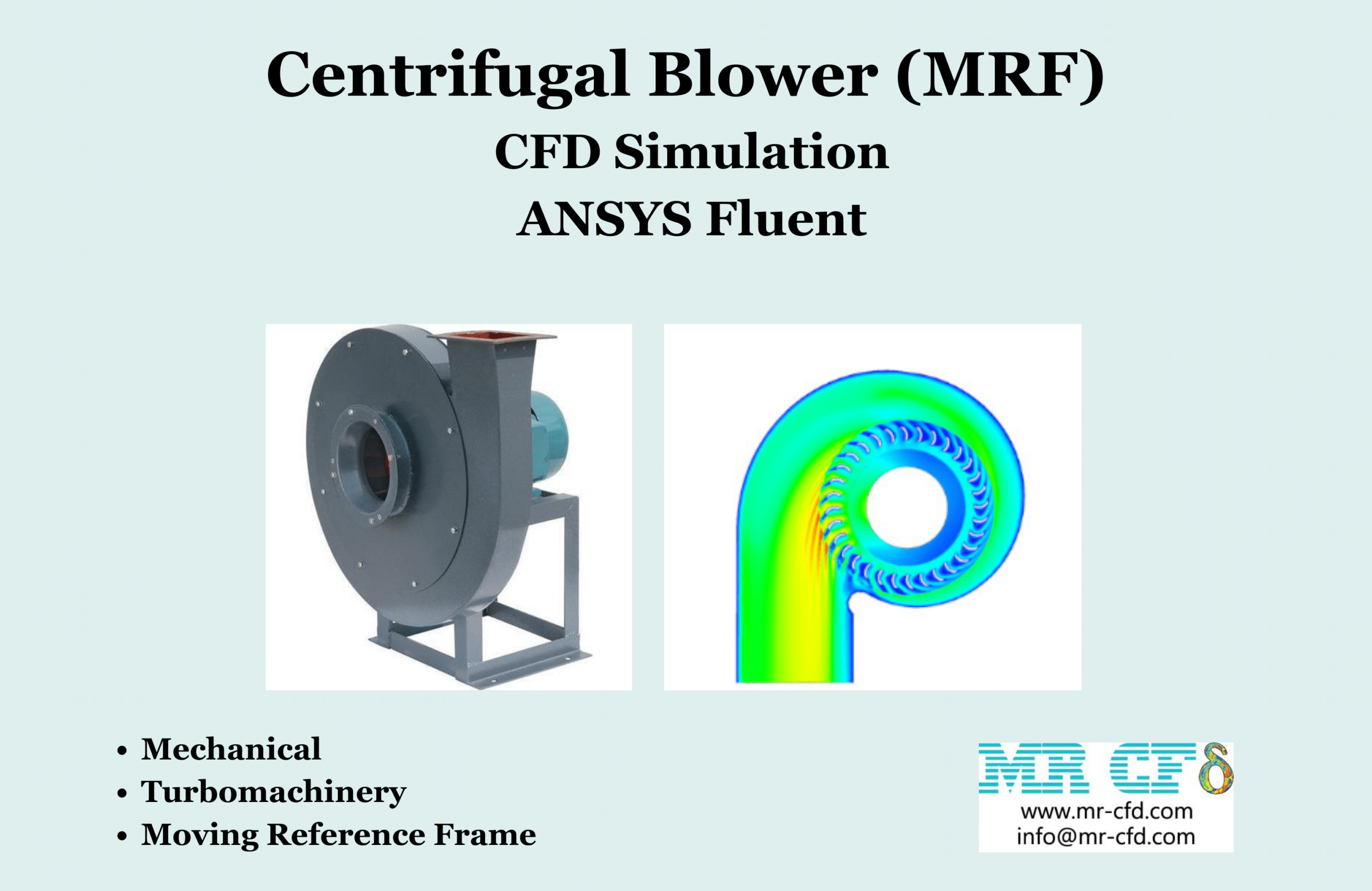

Pump (Moving Reference Frame)

Project number 6 is the flow simulation inside a centrifugal pump. Pumps are classified into two main categories: dynamic pumps and positive displacement pumps. The operation of centrifugal pumps increases the fluid pressure from the inlet to the pump’s outlet, causing the fluid to move. The force that creates this pressure is supplied by an electric motor that rotates the impeller. In this project, the pump consists of three main parts; The central blades are a solid body, and the casing around the pump is defined as the passage of fluid. A distinct central zone is defined for the fluid section so that the rotational motion of the pump blades can be applied to it.

Compressor

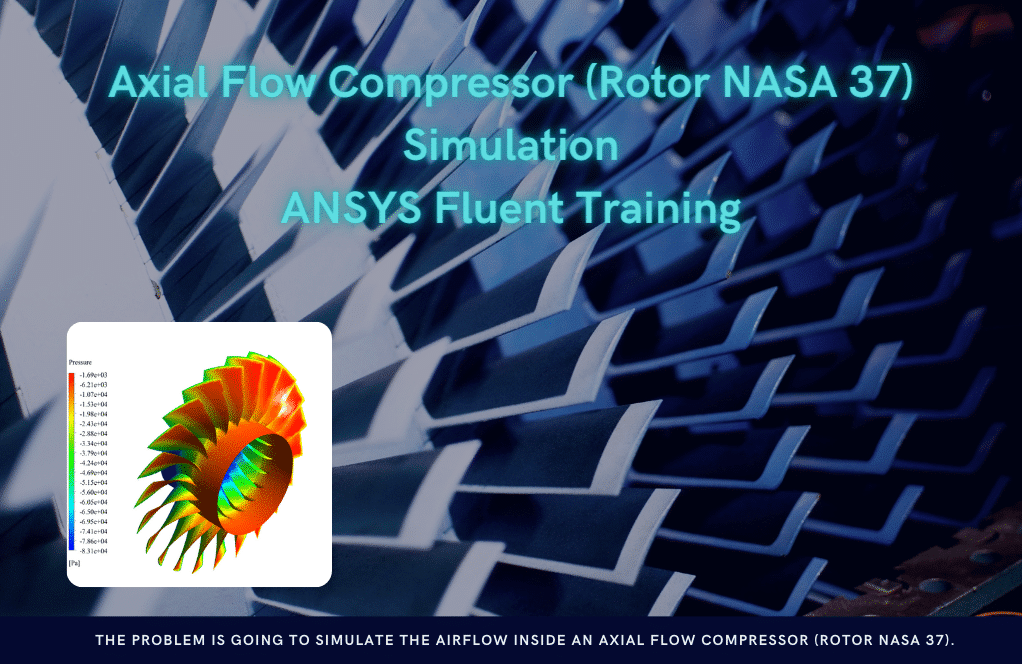

Project number 7 mi will simulate an axial flow compressor (Rotor Nasa 37). The present model consists of blades for an axial flow compressor connected to the central axis within a cylindrical area. Only one row of rotating blades is drawn on the central rotor of the compressor. This project aims to investigate the behavior of airflow and the pressure distribution around the blades after compression by the compressor.

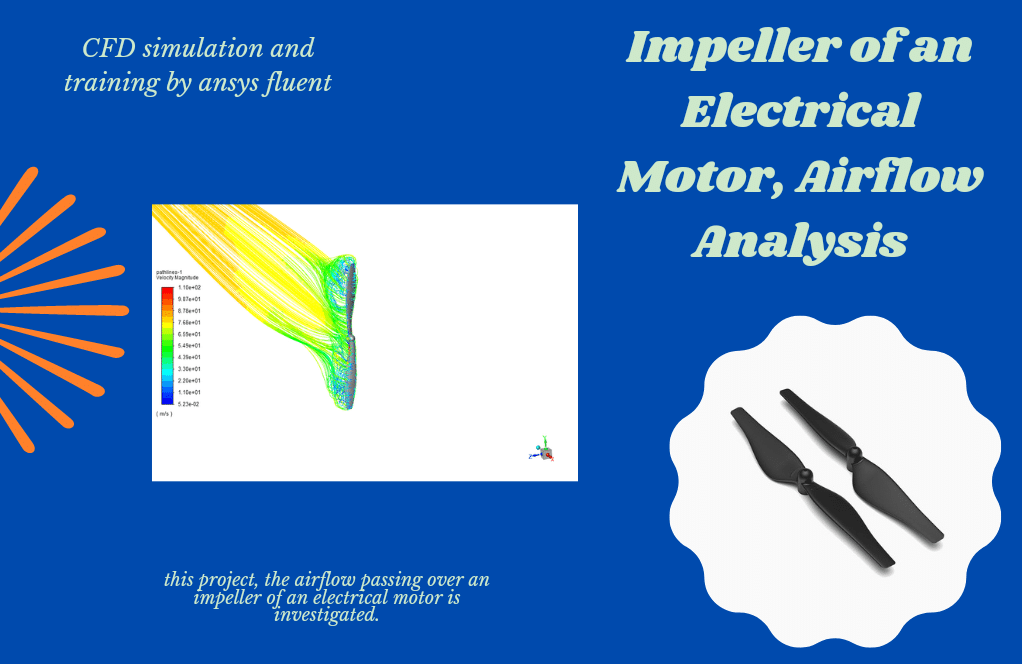

Electrical Motor (Moving Reference Frame)

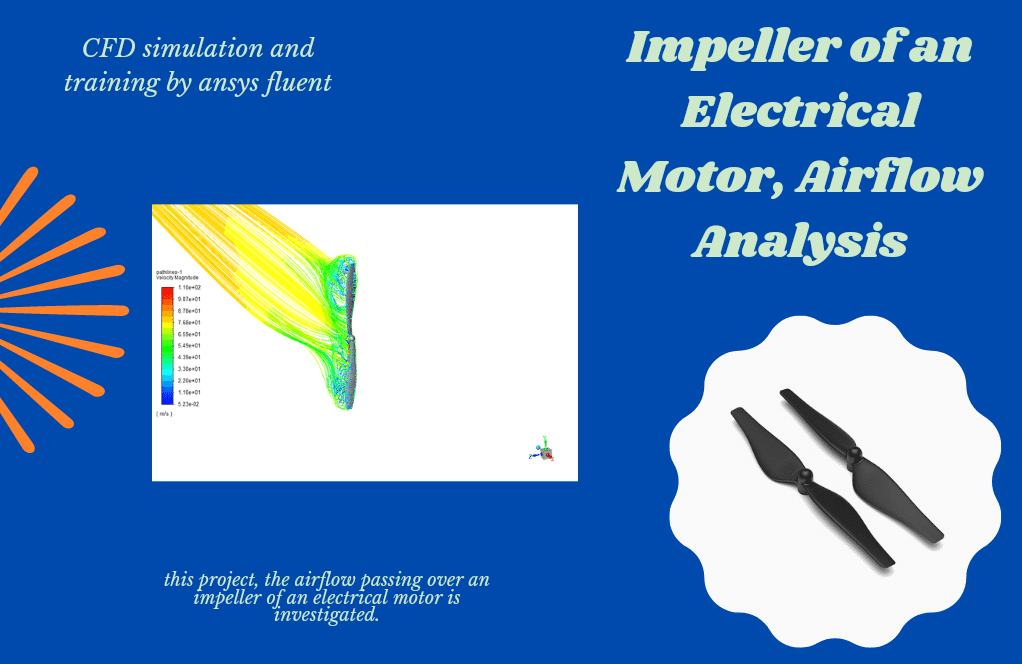

In project number 8, the airflow passing over an impeller is investigated. The airflow enters the computational domain with 80m/s, and the impeller rotates at 1000rpm. A Realizable k-epsilon model is exploited to solve turbulent flow equations. It should be noted that the MRF (frame motion) option has been activated to model the rotation of the impeller.

Mixer Tank

In industry, mixing is an operation that involves manipulating heterogeneous materials with the intent to make them more homogeneous. Industrial Mixer is a machine that blends, homogenizes, and mixes different materials into a single substance. In project number 9, a mixer tank is modeled, and the effect of its rotating impeller on the mixing procedure is investigated. The simulation uses the VOF model for the three phases of air, water, and salt. The k-epsilon model is applied for solving the turbulent flow inside the tank. MRF model is also used to model the rotation of the impeller.

Brake Disk (Moving Reference Frame)

In project number 10, the heat conduction of a Brake Disk system is modeled and simulated. The disk revolves at the speed of 20rad/s, and a braking pad is set to contact the disk. This frictional contact will heat generation inside the disk and the pad. The heat produced in the contact region will be dissipated based on the heat conduction formula. The energy and laminar model is activated. Also, the MRF model (frame motion) is activated to model the rotational motion of the disk. A UDF is implemented to account for the radial heat flux.

Mr. Jedediah Hartmann –

How does this package handle the simulation of heat transfer in rotating machinery?

MR CFD Support –

This package includes the energy equation to simulate heat transfer in rotating machinery. This allows for the accurate simulation of the temperature distribution and the impact of heat transfer on the performance of the machinery.

Gwendolyn Smith I –

How does this package handle the simulation of turbulence in the flow?

MR CFD Support –

This package includes advanced turbulence models to accurately simulate the turbulent flow in rotating machinery. These models can capture the complex flow patterns and the impact of turbulence on the performance of the machinery.

Roxanne Jast Sr. –

Can this package be used to simulate the performance of axial fans?

.

MR CFD Support –

Absolutely, one of the exercises included in this package focuses specifically on the simulation of axial fans. The MRF methodology is well-suited for such simulations as it can accurately capture the rotational motion of the fan blades

Marjolaine Gerhold MD –

Can this package be used to simulate the performance of hydro turbines?

MR CFD Support –

Yes, one of the exercises included in this package focuses specifically on the simulation of hydro turbines. The MRF methodology is ideal for such simulations as it can accurately capture the rotational motion of the turbine runner.