Multi-Fuel Combustion Chamber CFD Simulation

$120.00 $60.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Multi-Fuel Combustion Chamber CFD Simulation, ANSYS Fluent Tutorial

Introduction

Combustion processes play a crucial role in various industries, from power generation to manufacturing. With the increasing demand for efficient and clean combustion technologies, detailed numerical modeling of reactive flows has become increasingly important. This project investigates the combustion of a multi-fuel mixture in a combustion chamber. The simulation aims to analyze the combustion process, understand the flow dynamics, and evaluate the chamber’s performance.

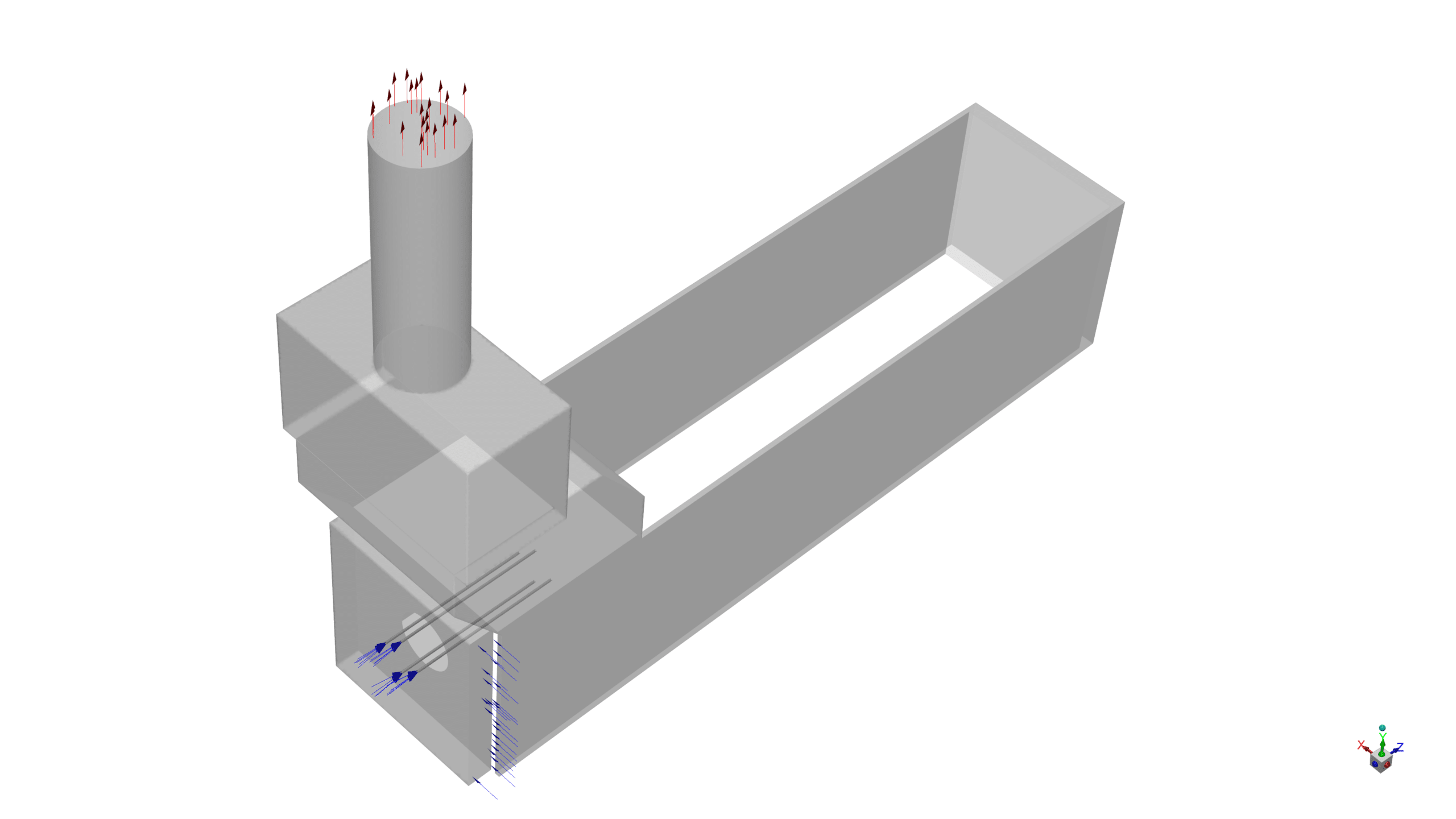

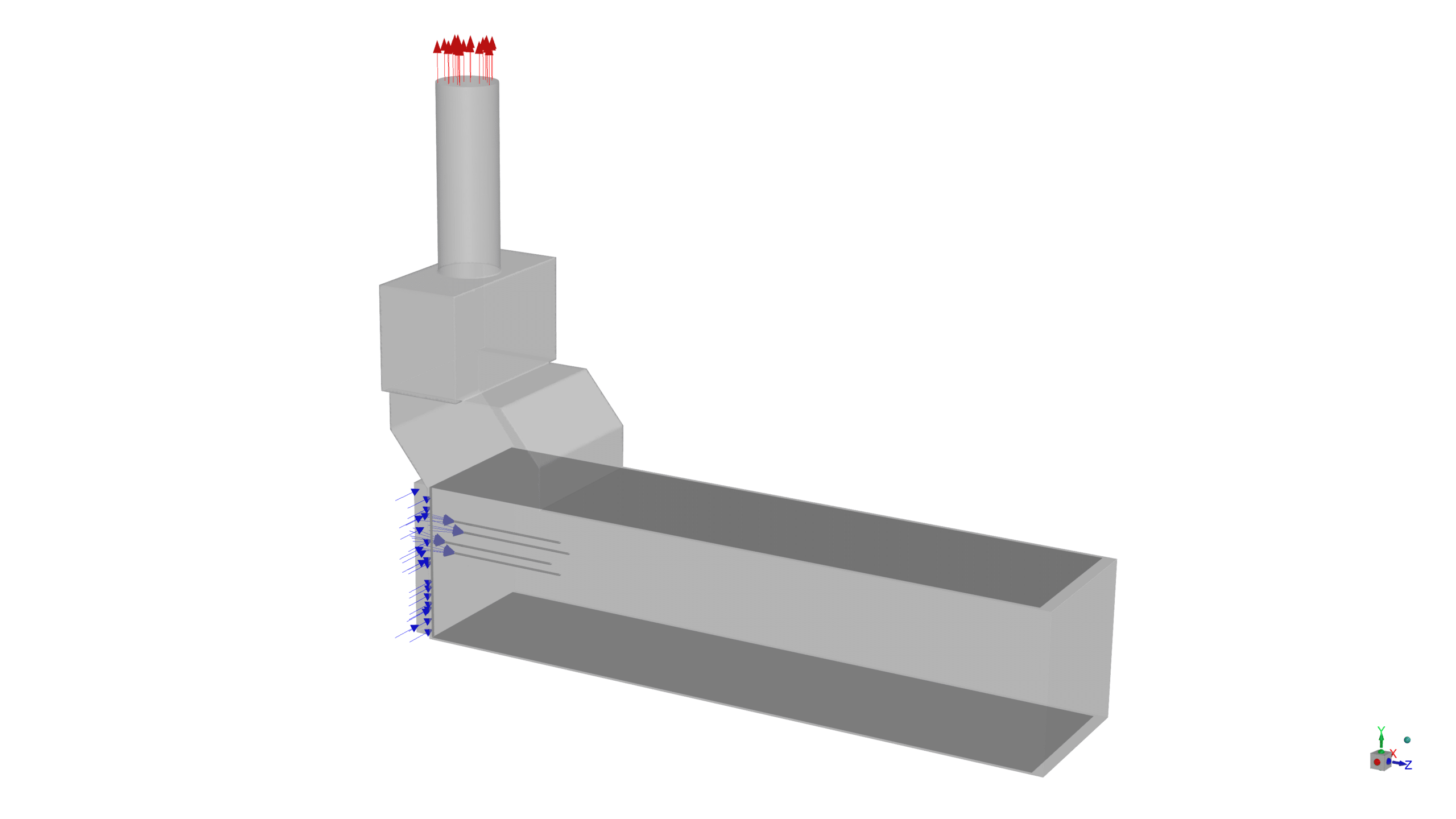

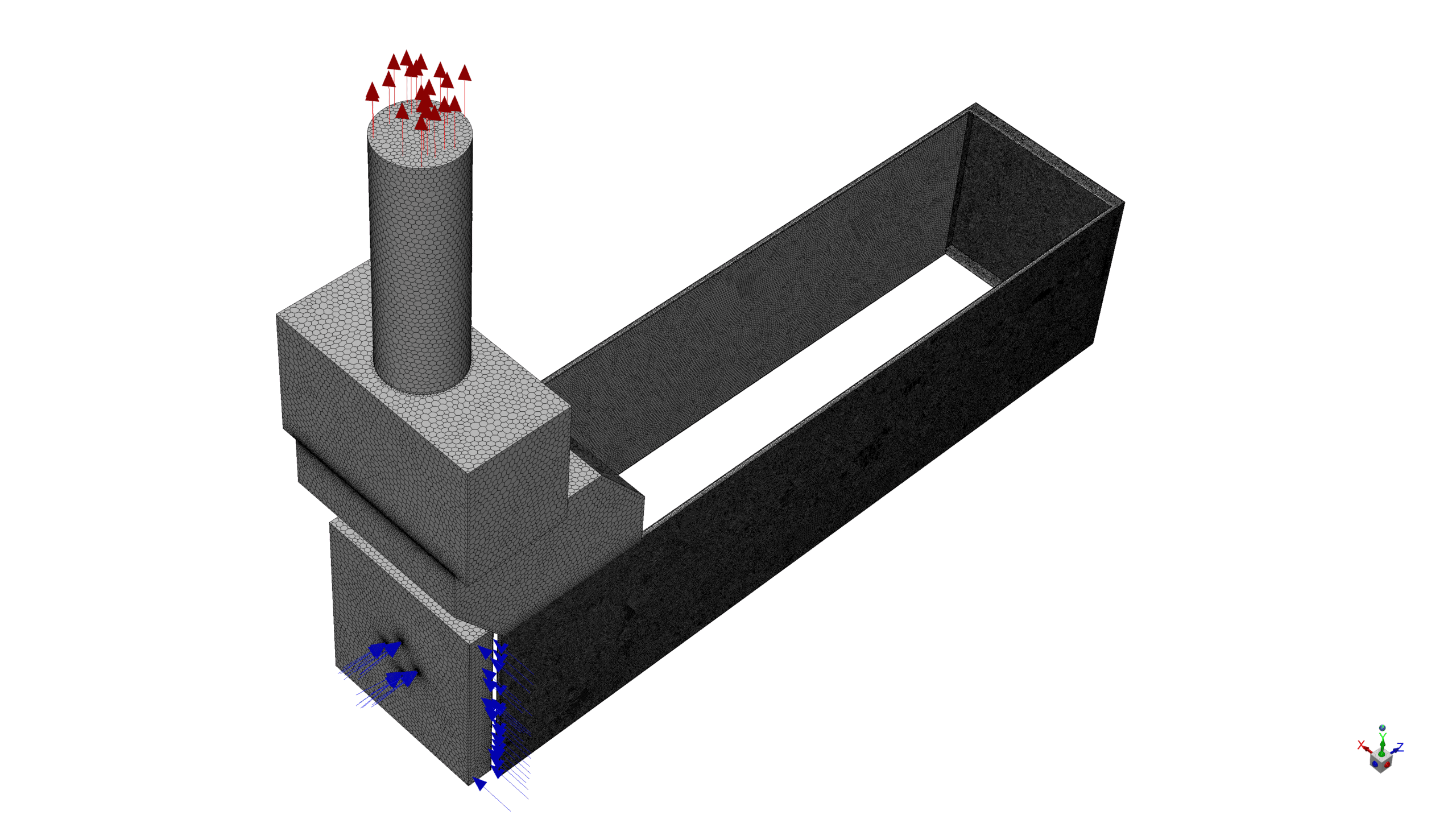

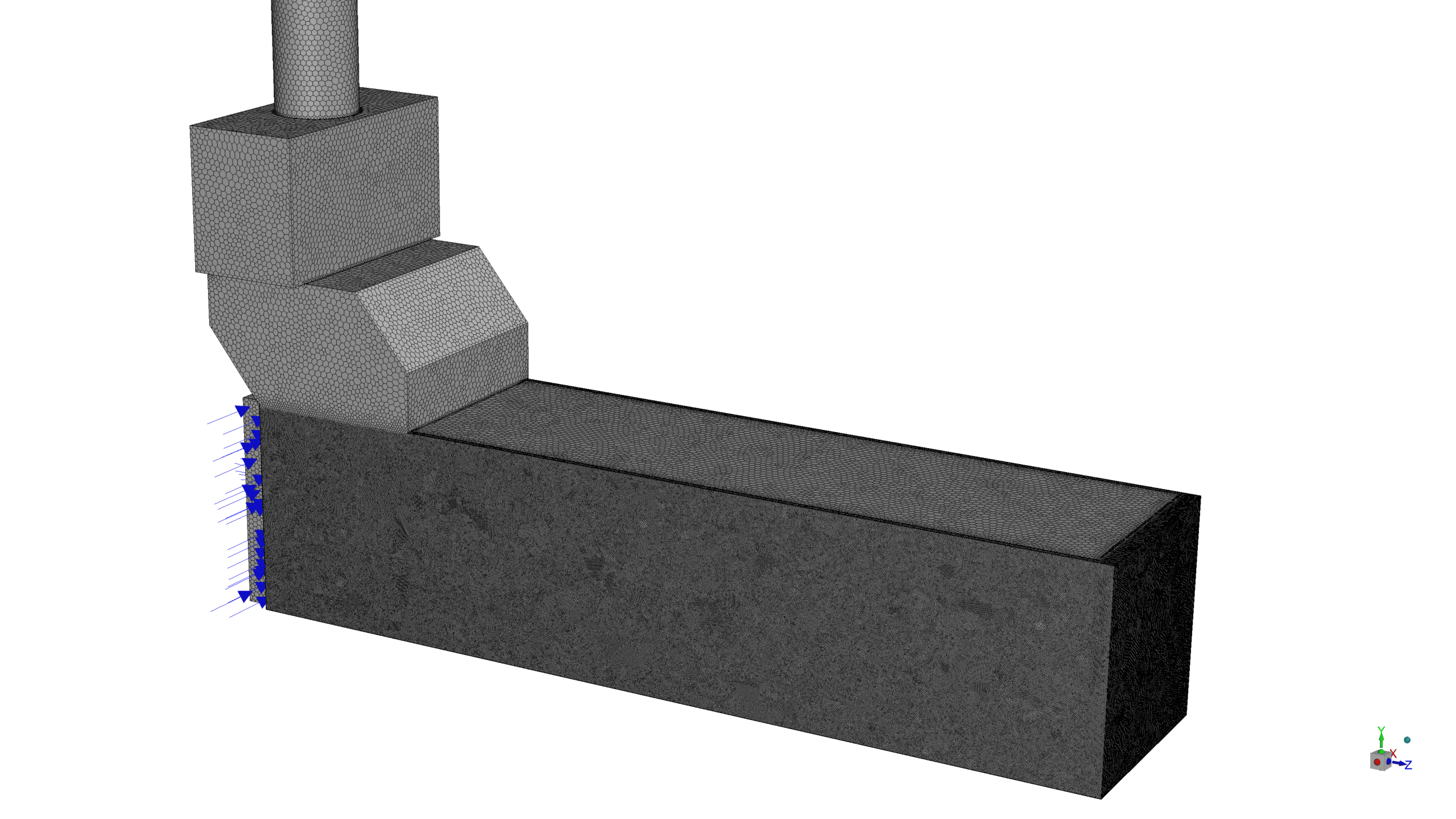

The CFD simulation was conducted using ANSYS Fluent with a focus on the steady-state solution. The combustion chamber geometry was designed in SpaceClaim and meshed in ANSYS Meshing with 3,628,838 polyhedra elements.

Methodology

The energy equation was enabled to track the temperature distribution within the chamber.

The Species Transport Model enabled the modeling of the chemical reactions involving the multi-fuel mixture.

Employed the Eddy-Dissipation model to account for the interaction between turbulence and chemical reactions.

Utilized the Realizable k-epsilon model with standard wall functions.

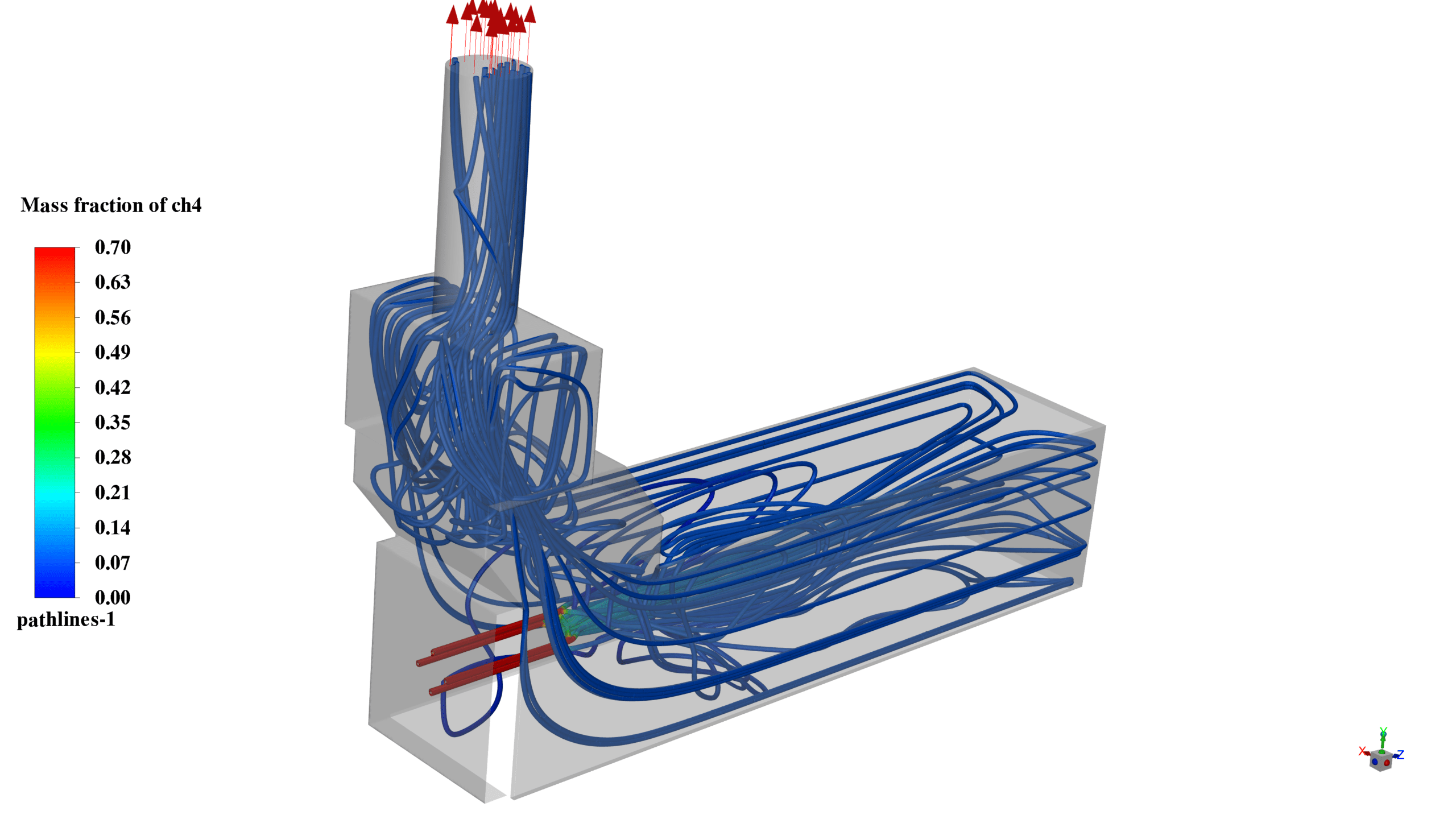

Materials: The simulation considered a mixture of nitrogen, carbon dioxide, ethylene, allene, methane, n-butane, I-butane, oxygen, and water vapor.

Results

The CFD simulation yielded valuable insights into the combustion process within the chamber. The following key results are highlighted:

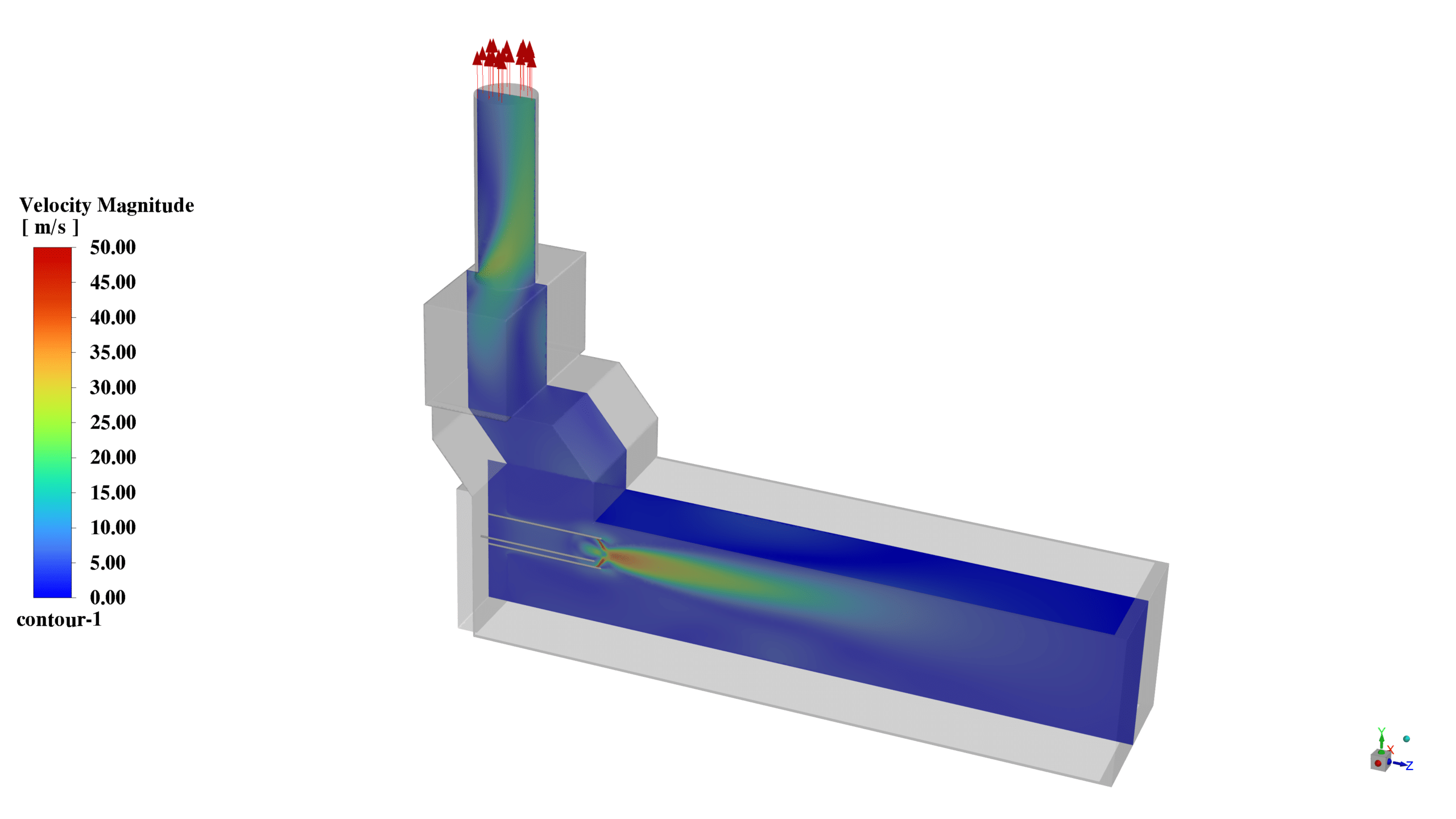

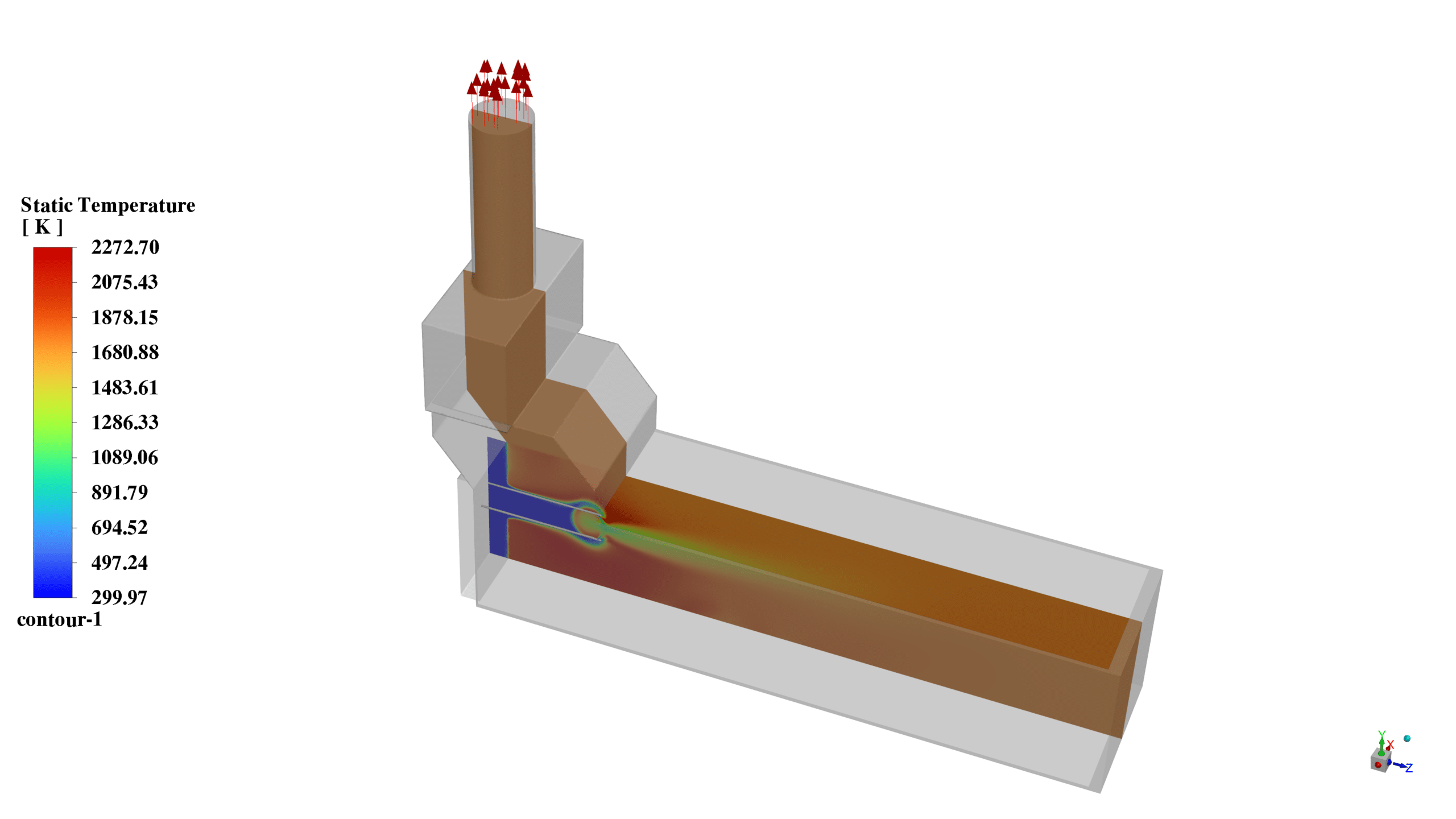

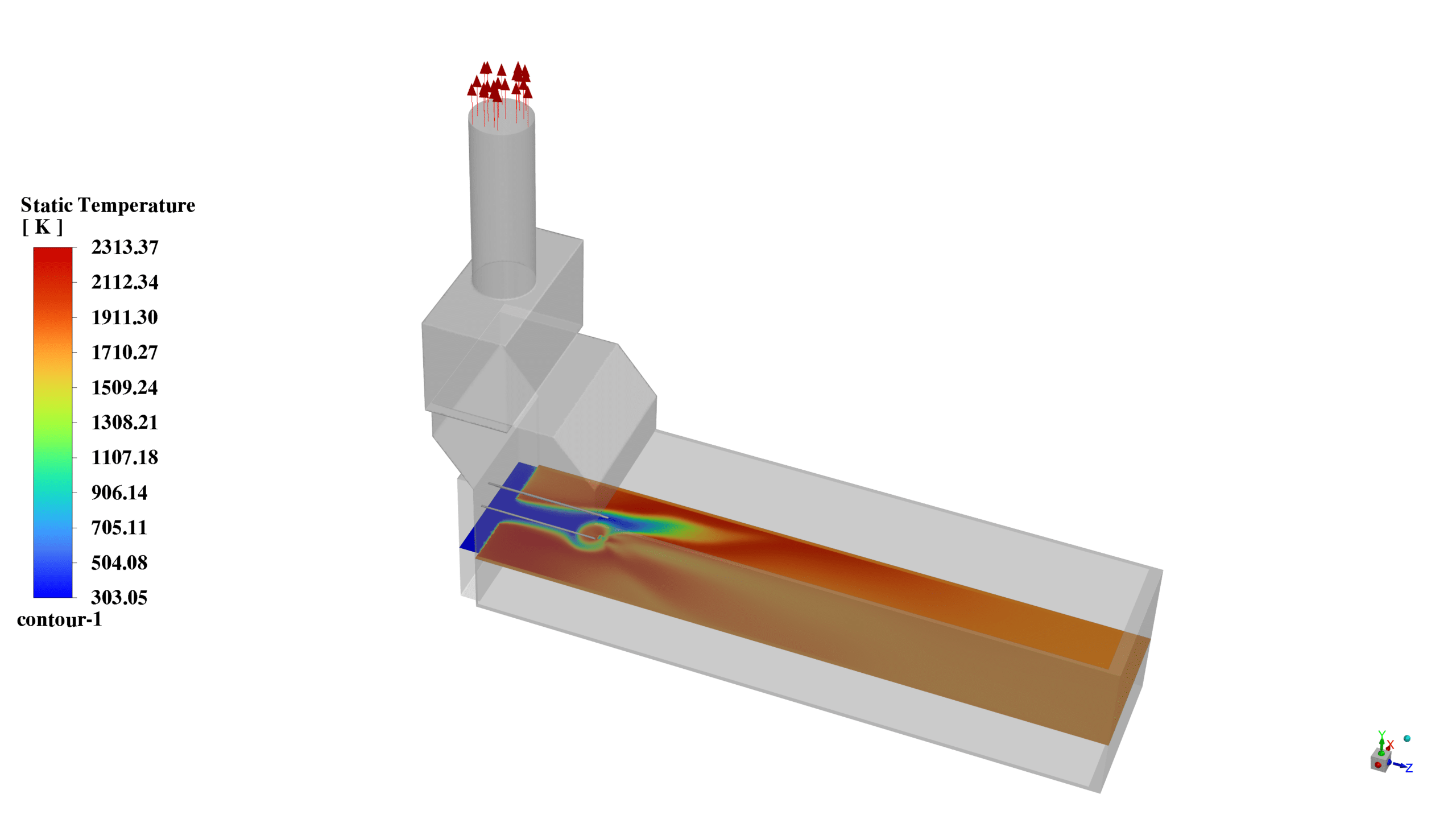

- The simulation revealed a significant temperature rise within the chamber, indicating successful combustion of the fuel mixture. The highest temperature reached approximately 2300 K.

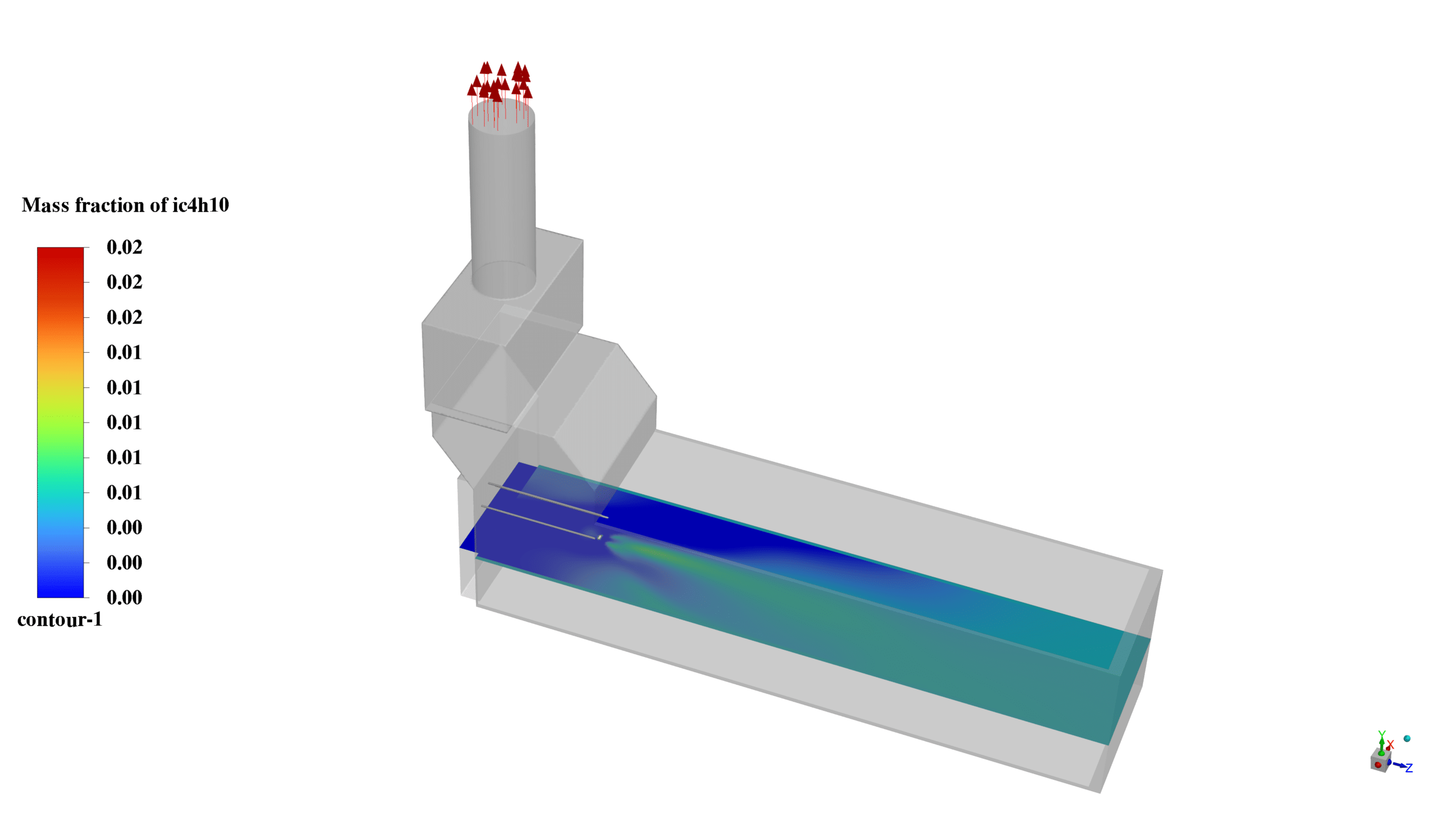

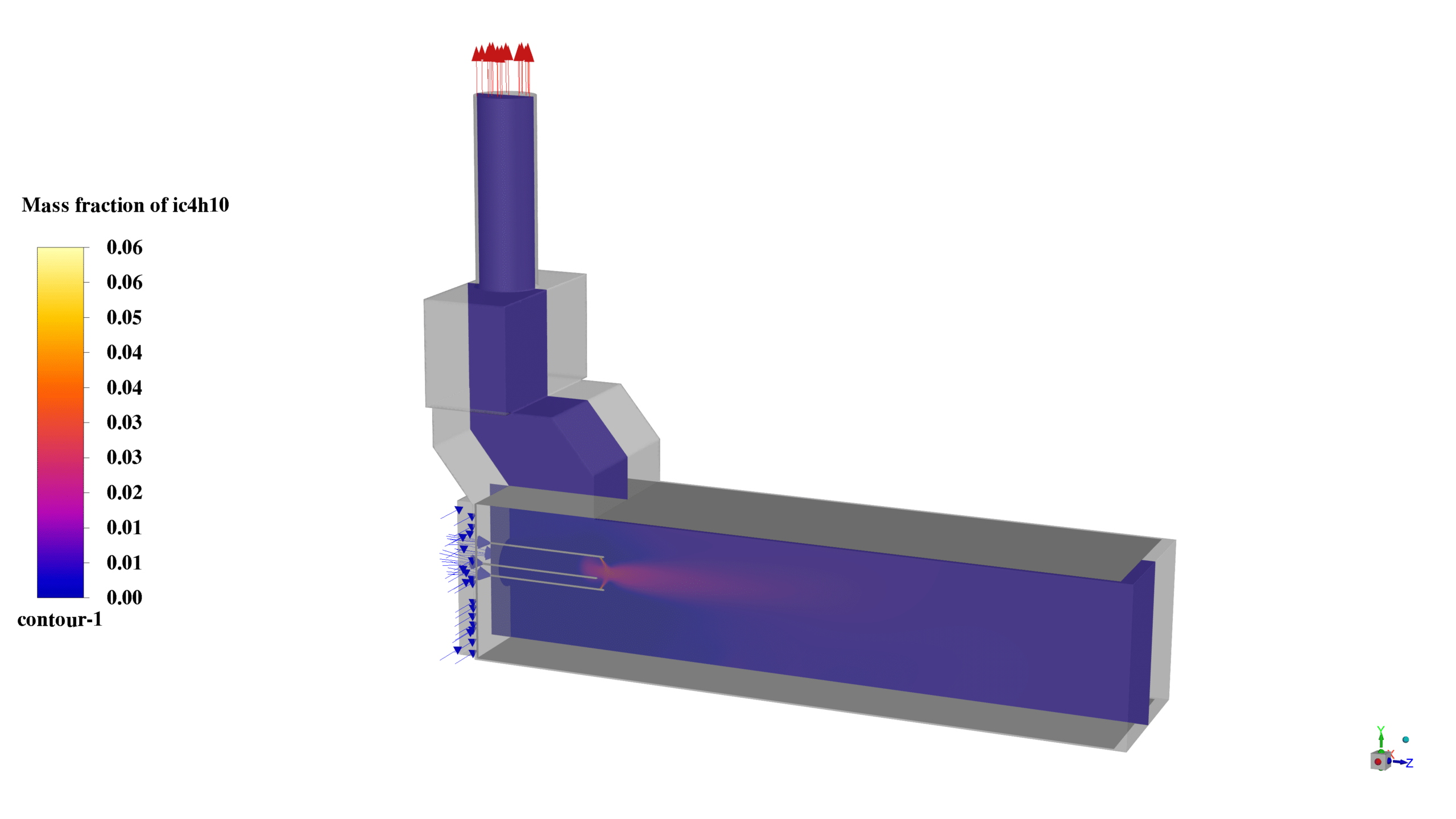

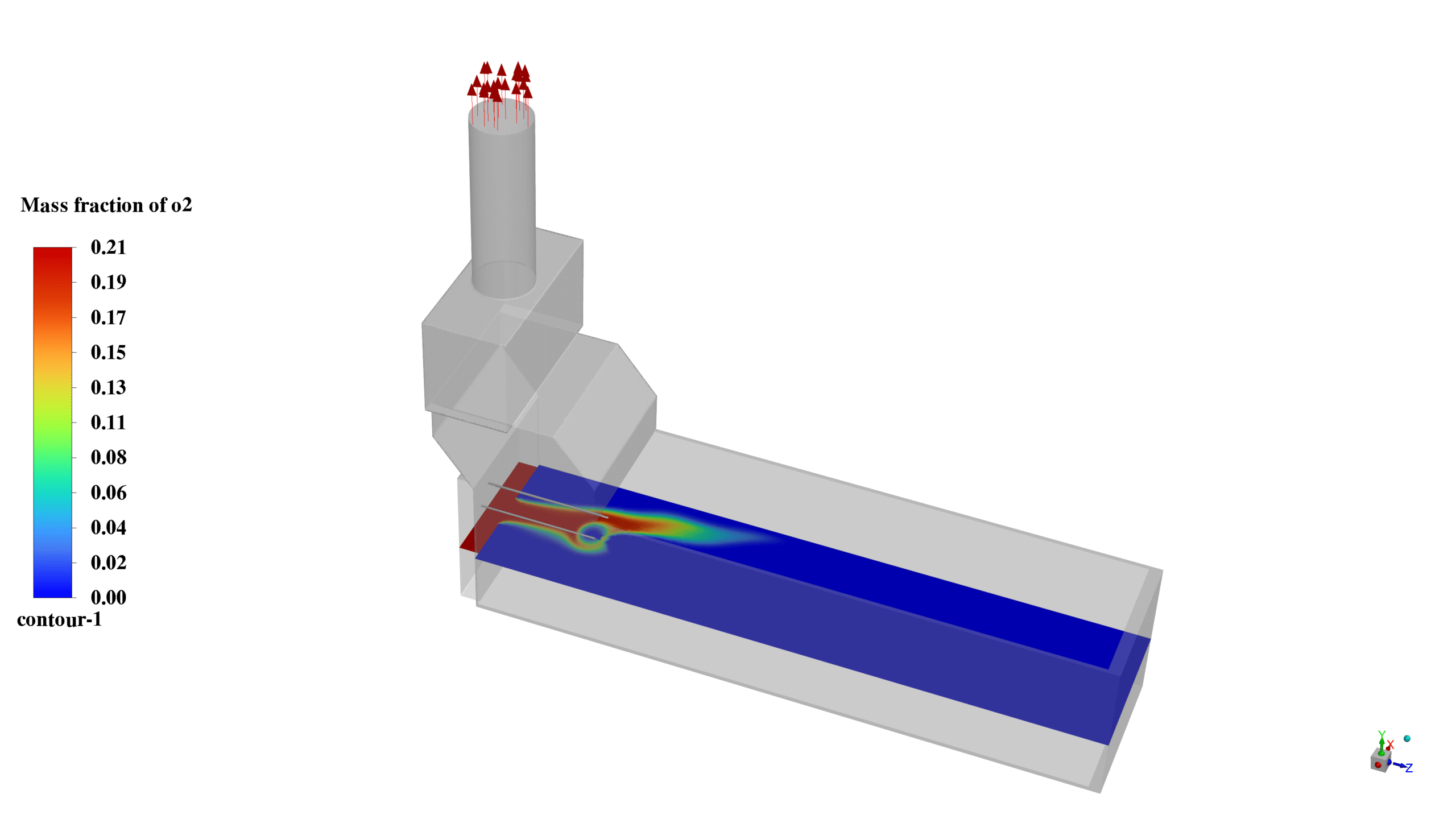

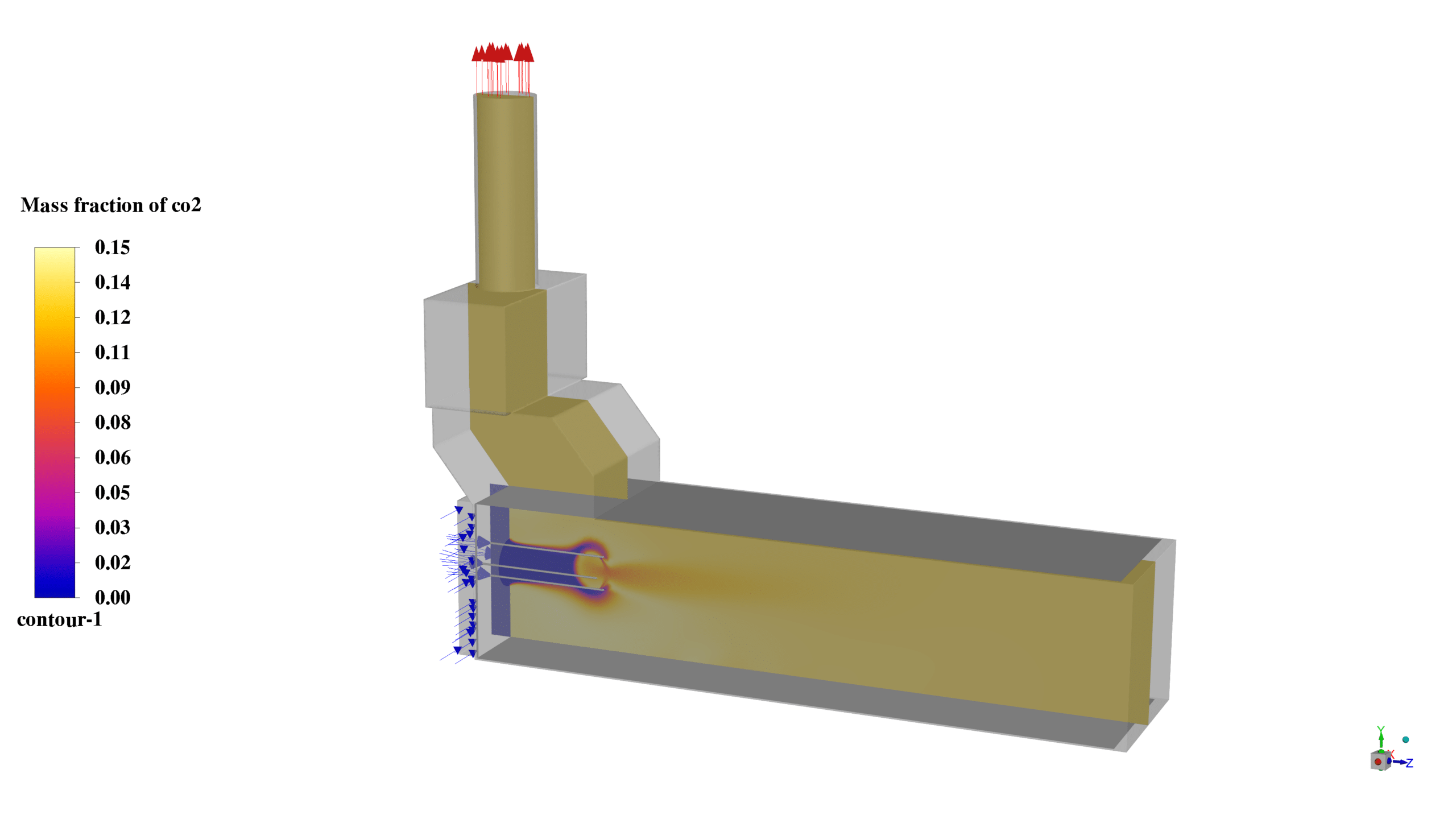

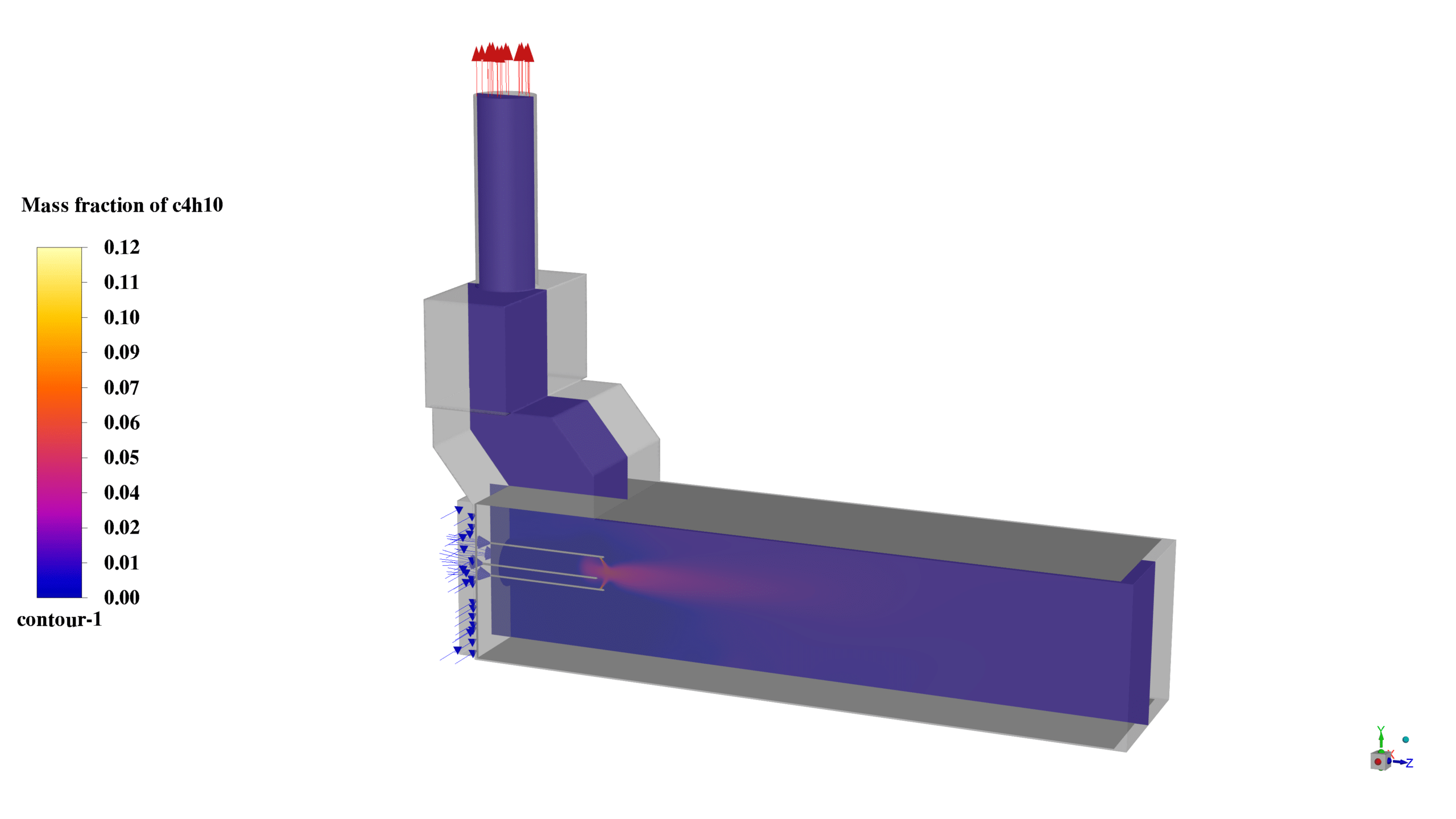

- The mass fraction distribution of different species, including CO2 and O2, provided information on the extent of fuel consumption and product formation during combustion.

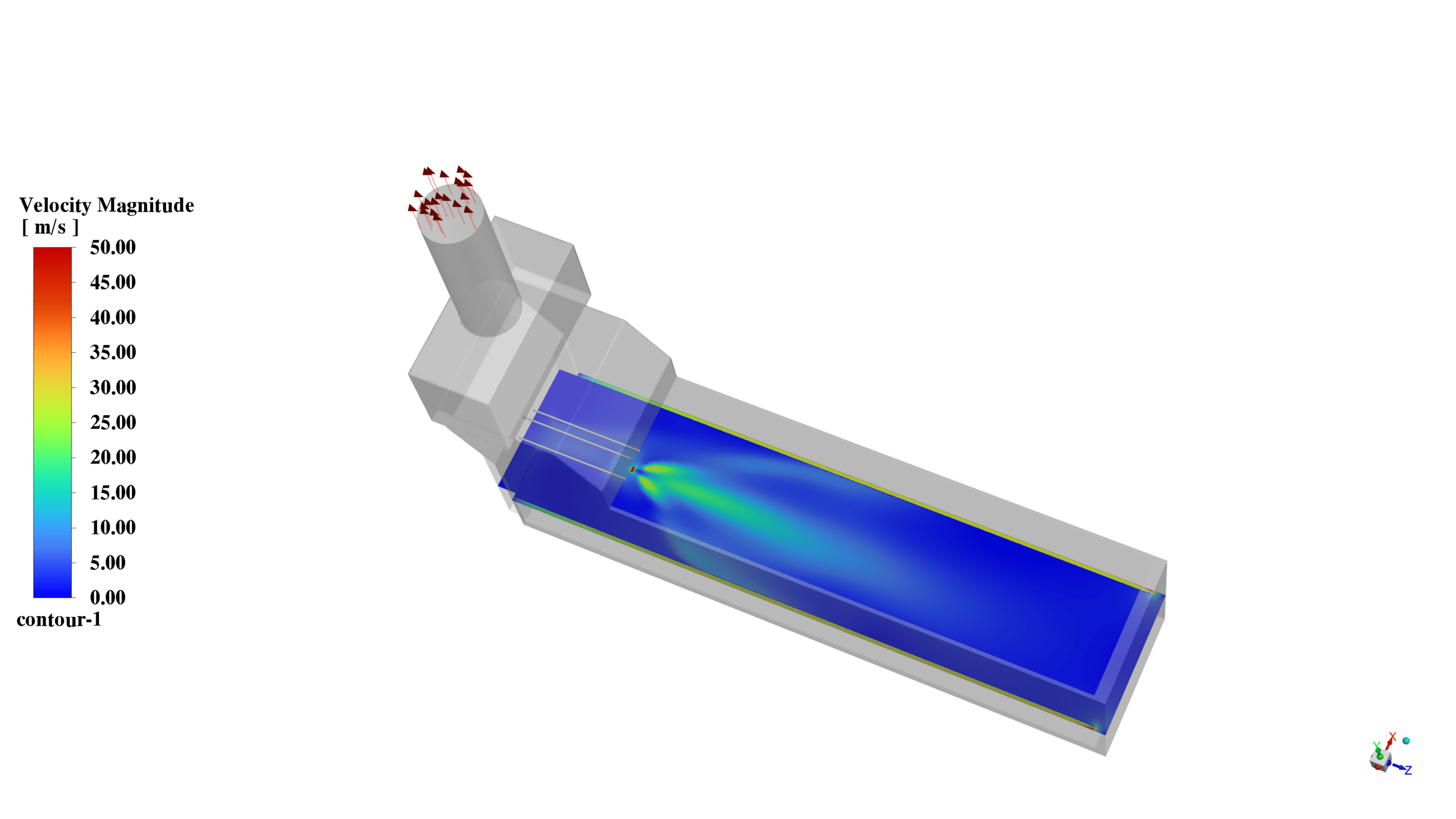

- The simulation showed the development of a complex flow pattern within the chamber, highlighting the interaction between the fuel jet, air stream, and combustion products.

- The analysis of turbulence flame speed revealed the influence of turbulent mixing on the combustion process.

The CFD simulation of the multi-fuel combustion chamber provided a comprehensive understanding of the complex interplay between fluid dynamics, heat transfer, and chemical reactions. The results demonstrated the effectiveness of the numerical model in predicting the combustion behavior and provided valuable insights for optimizing the design and operation of the chamber. Further analysis of the simulation data can be used to optimize the fuel mixture composition, chamber geometry, and operating conditions for improved combustion efficiency and reduced emissions.

Reviews

There are no reviews yet.