Multi-point Liquid Distributor, Ansys Fluent CFD Simulation

$120.00 $60.00 Student Discount

- This study presents a CFD analysis of a Multi-point Liquid Distributor for packed columns using ANSYS Fluent.

- We designed the 3-D symmetry model using the ANSYS Design Modeler

- We mesh the model with ANSYS Meshing software, and the element number equals 783,039.

- The Volume of Fluid (VOF) model was utilized to simulate the multiphase flow of water and air.

- A steady-state, pressure-based solver was employed for the simulation.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study presents a Computational Fluid Dynamics (CFD) analysis of a Multi-point Liquid Distributor for packed columns using ANSYS Fluent software. Liquid distributors play a crucial role in various industrial processes, including distillation, absorption, and extraction, where uniform liquid distribution is essential for optimal mass transfer and process efficiency. The simulation aims to visualize and analyze the flow patterns, velocity distribution, and phase interaction within the distributor.

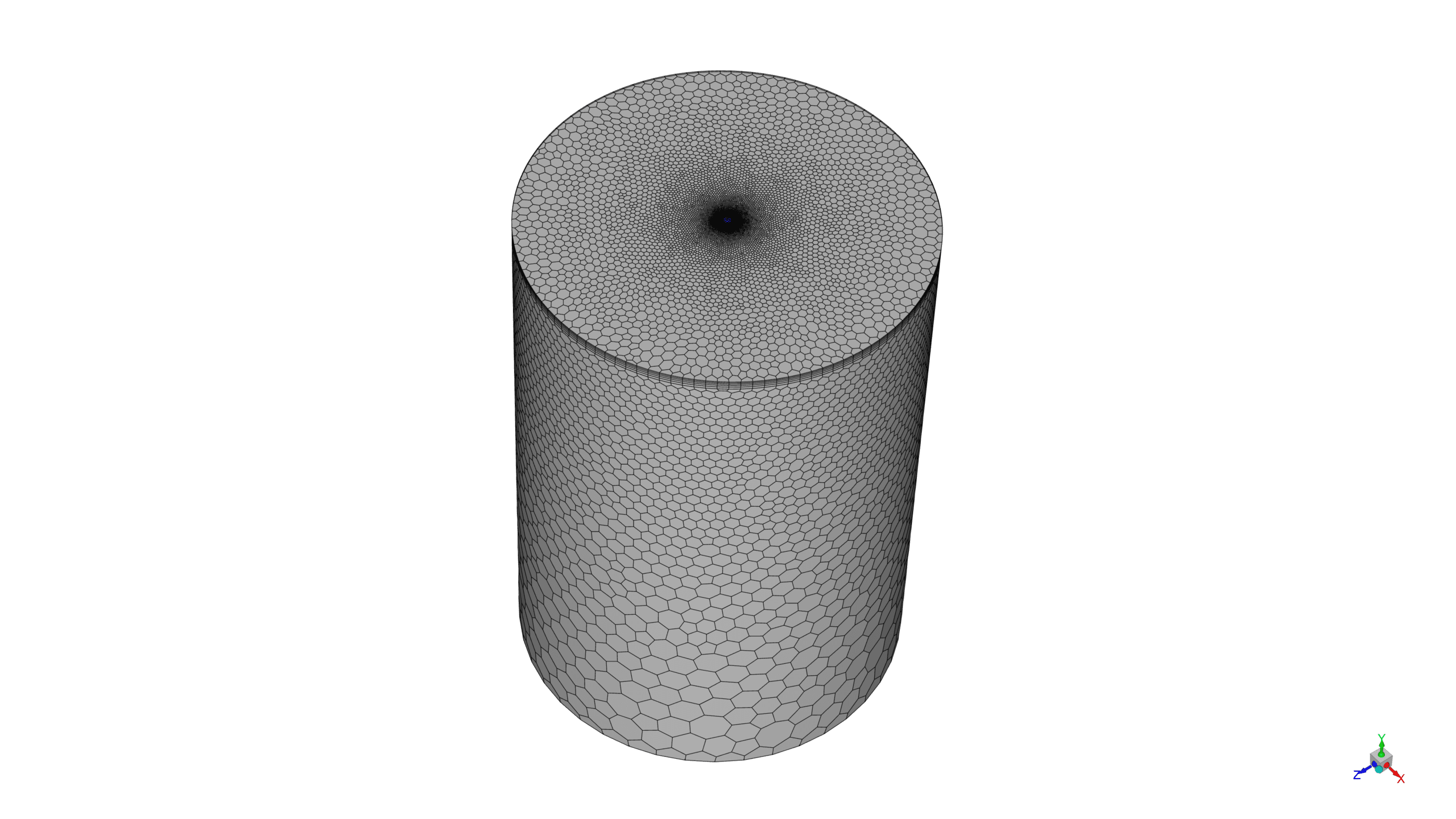

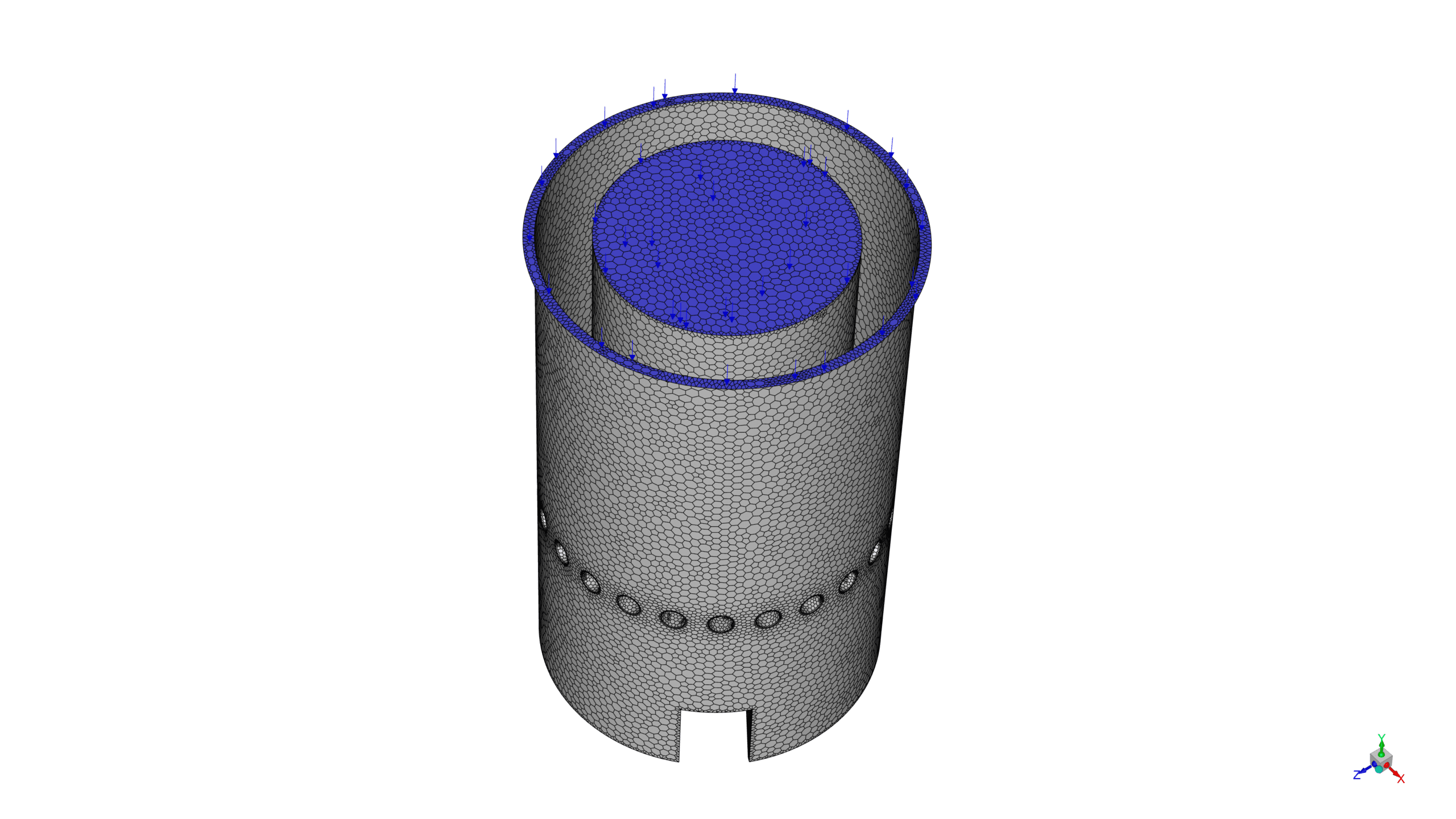

The geometry of the Multi-point Liquid Distributor was created using ANSYS Design Modeler, and the computational domain was discretized using ANSYS Meshing, resulting in 783,039 elements. This mesh density provides a balance between computational efficiency and solution accuracy.

Methodology

A steady-state, pressure-based solver was employed for the simulation.

Turbulence was modeled using the Standard k-epsilon model with standard wall functions.

The Volume of Fluid (VOF) model with implicit formulation was utilized to simulate the multiphase flow of water and air.

Results

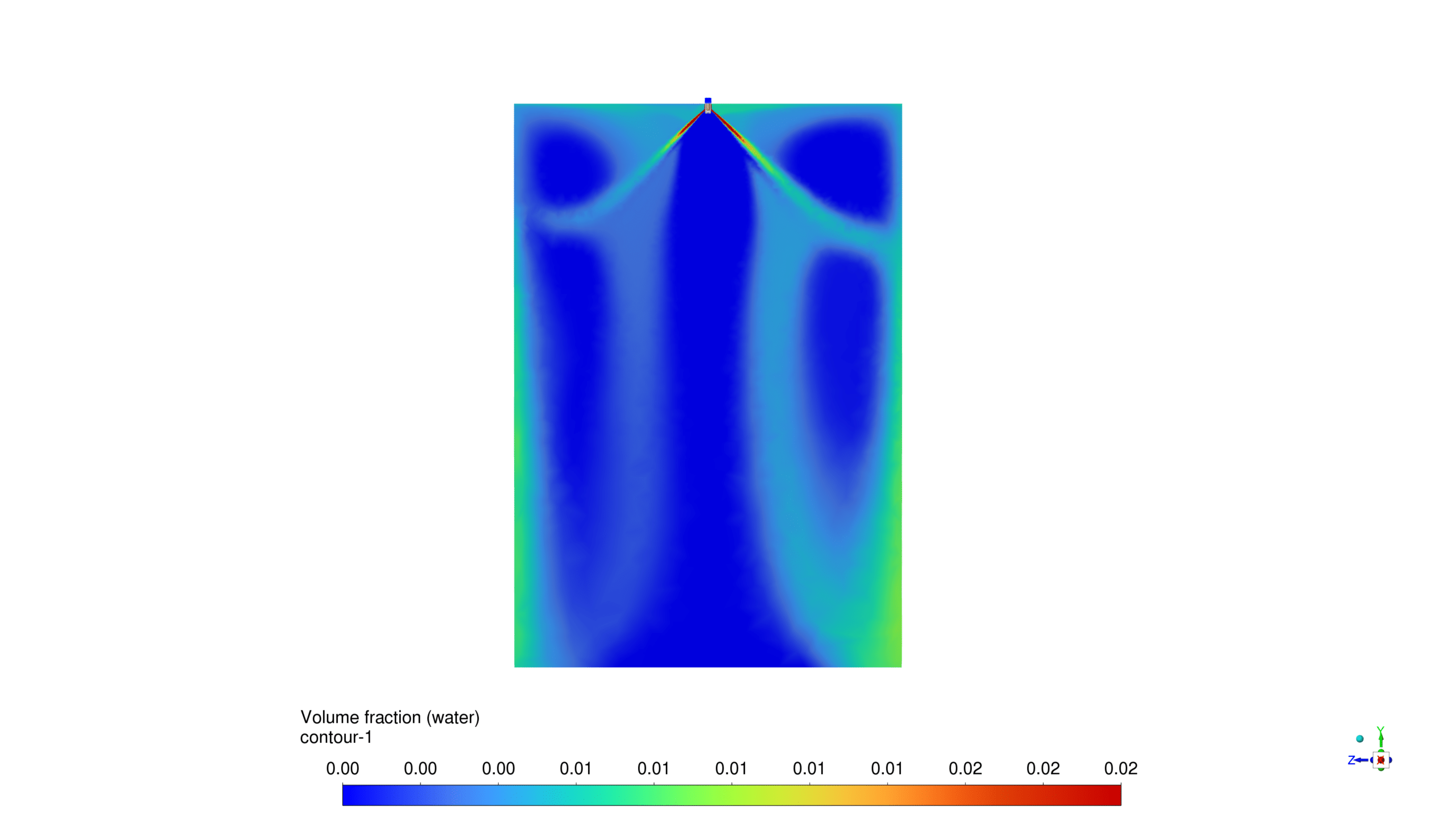

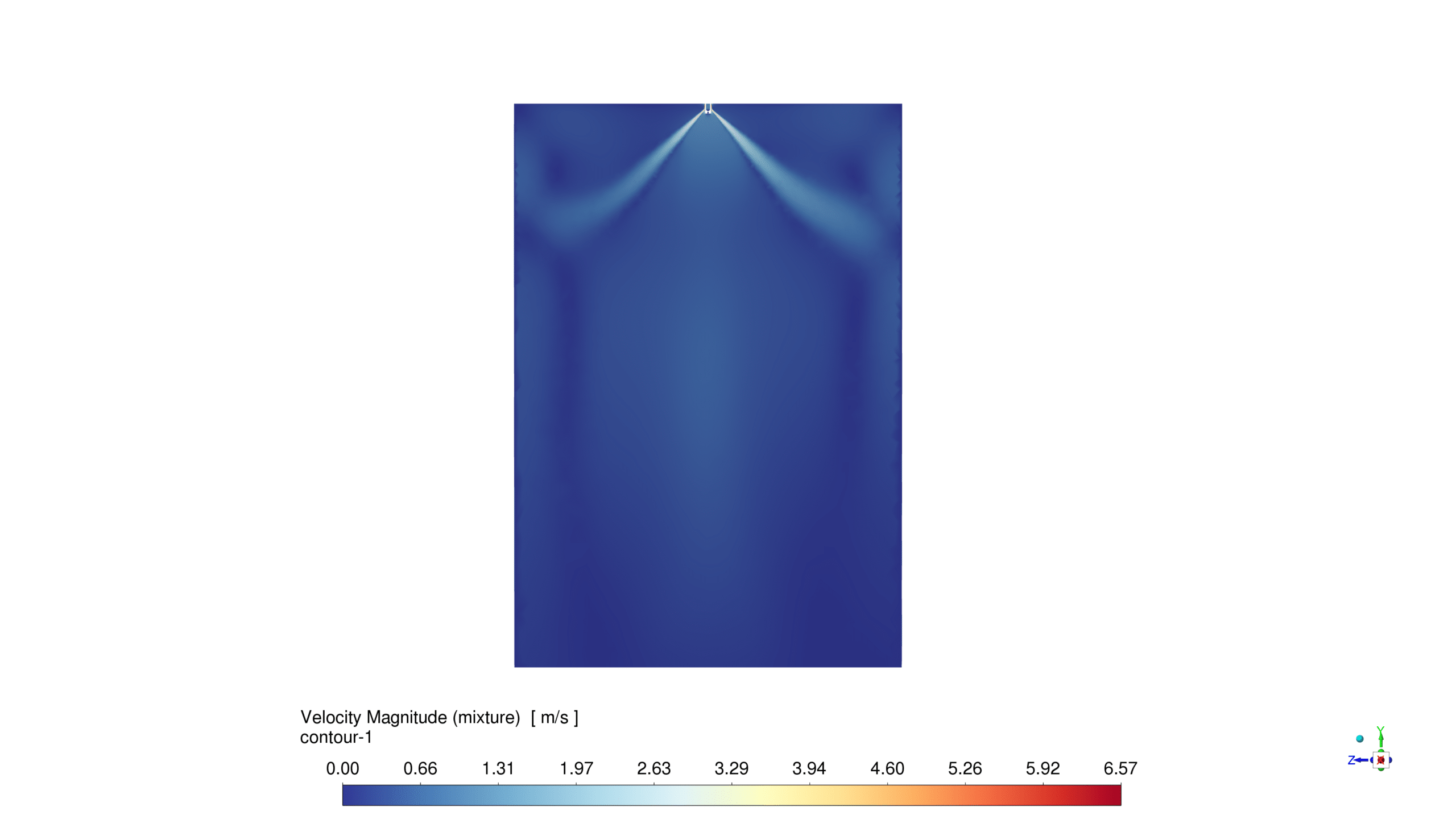

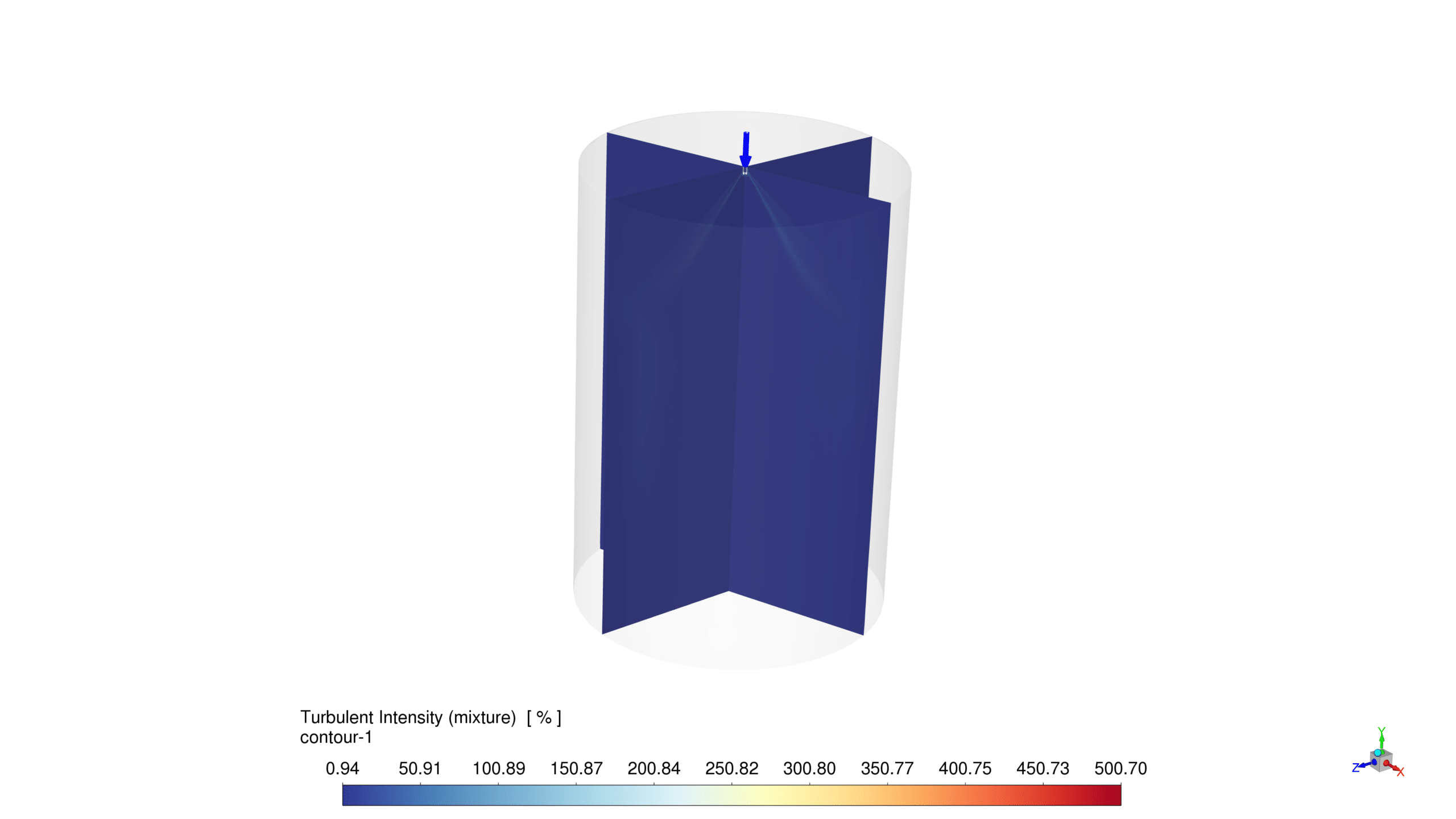

The CFD analysis of the Multi-point Liquid Distributor reveals key insights into its performance. The turbulent intensity contour shows higher turbulence near the injection point and along the flow path, indicating effective mixing. The velocity magnitude distribution demonstrates highest velocities at the injection point, gradually decreasing as the fluid spreads across the distributor, suggesting efficient liquid dispersion.

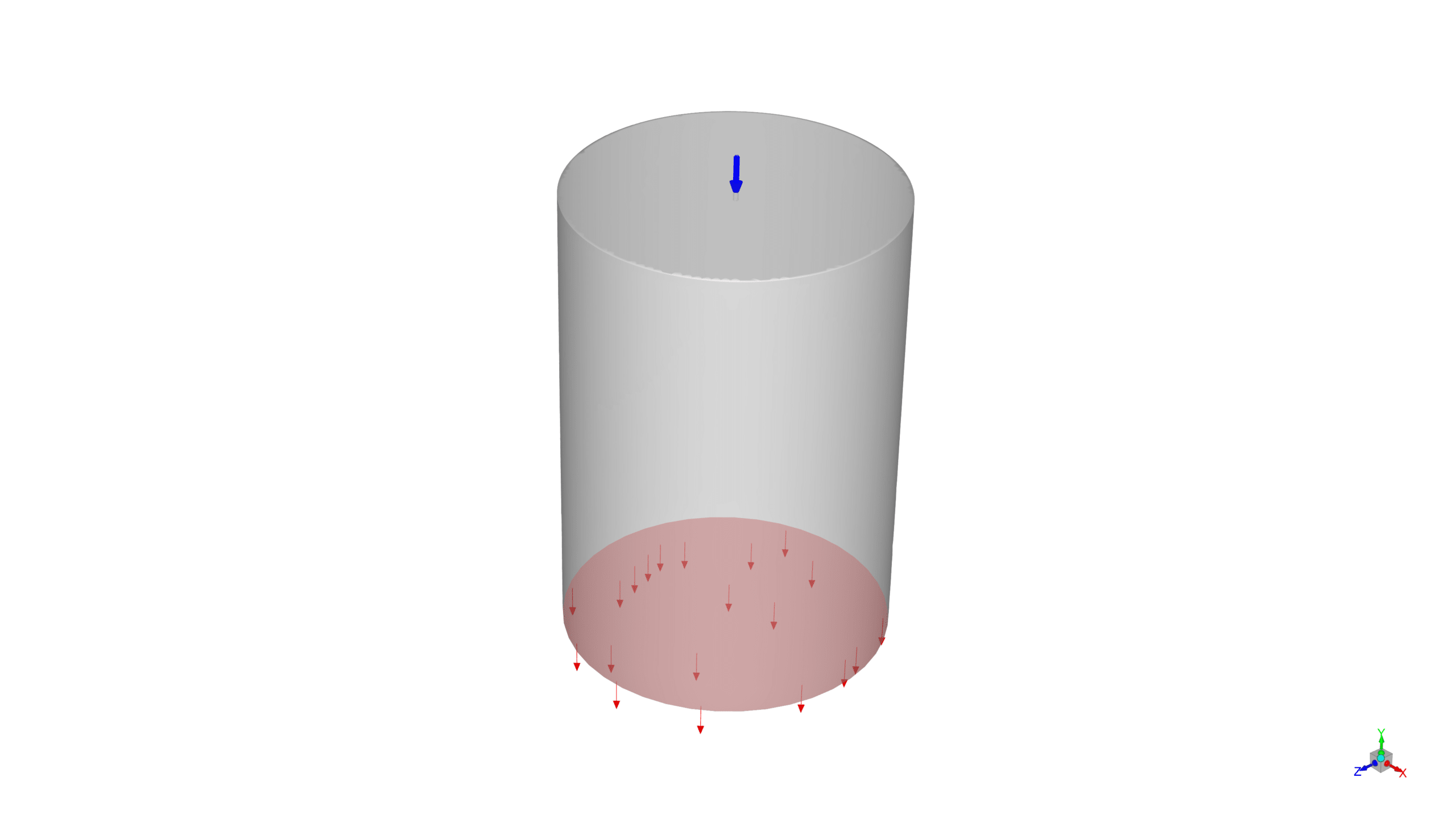

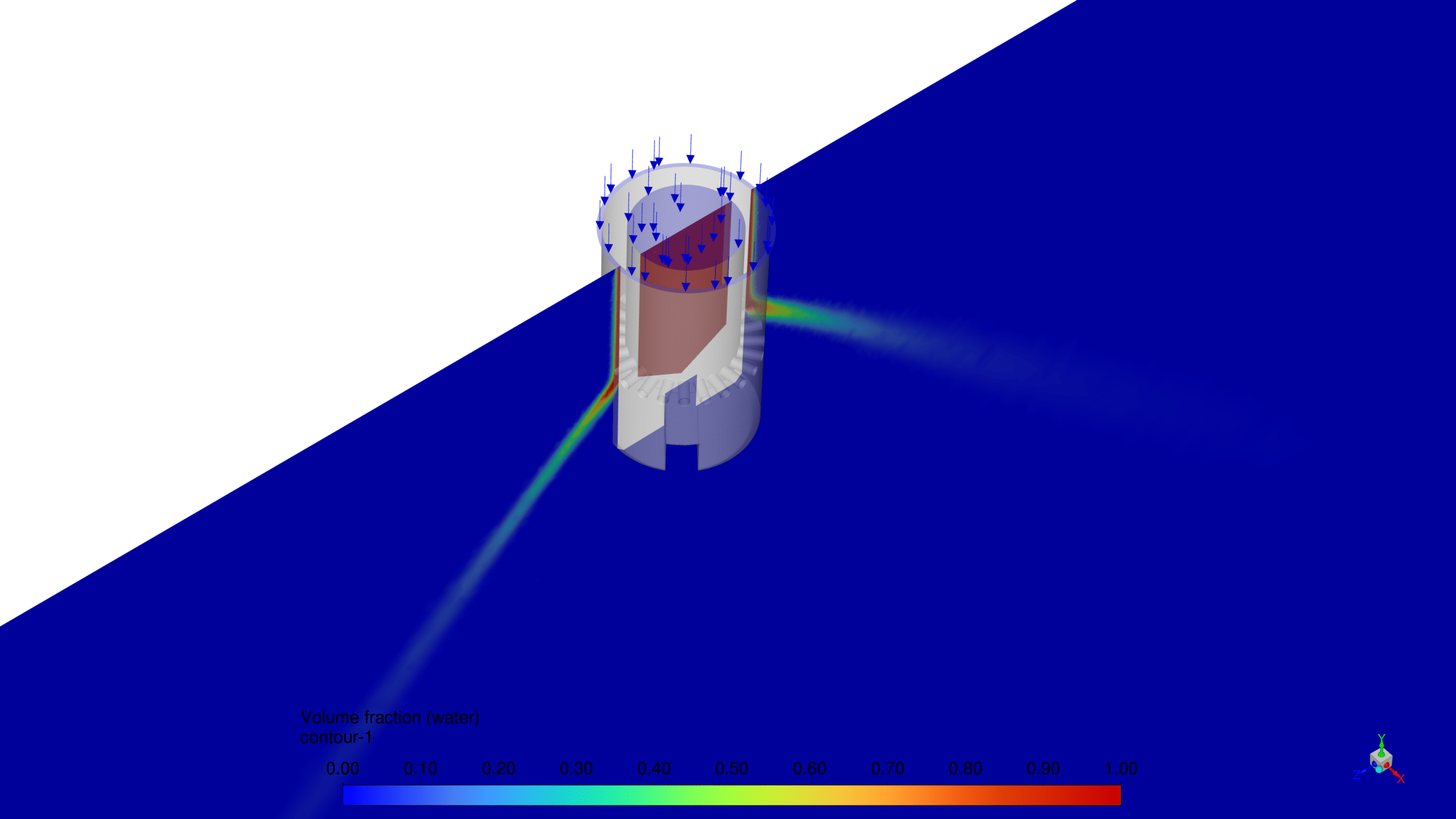

The water volume fraction contours clearly illustrate the spray pattern from the top injection point, with the liquid phase (red-orange areas) spreading radially outward, confirming the distributor’s effectiveness in achieving uniform liquid distribution.

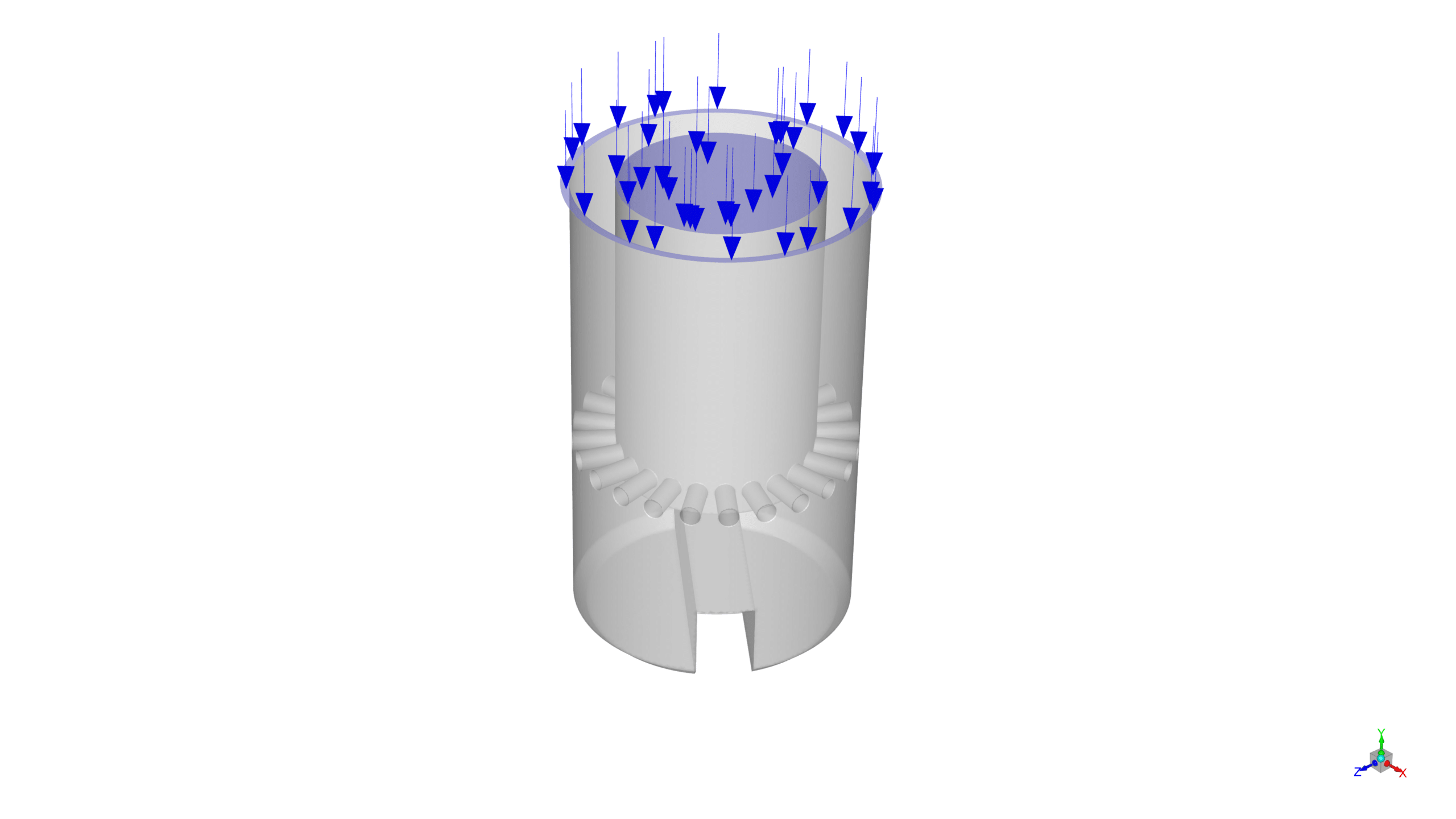

The 3D visualizations provide a comprehensive view of the distributor’s design and flow patterns. Multiple injection points at the top, represented by blue arrows, ensure even liquid distribution across the entire cross-section.

The cylindrical vessel features outlet holes at the bottom, likely for uniform liquid discharge onto the packed bed below. The mesh structure, as seen in the last two images, is well-refined with hexahedral elements, denser near critical areas such as injection points and distributor walls, ensuring accurate capture of flow features.

In conclusion, the CFD analysis demonstrates that the Multi-point Liquid Distributor effectively achieves its primary function of uniform liquid distribution. The design promotes efficient liquid spreading, appropriate turbulence levels for mixing, and even velocity distribution.

These characteristics make the distributor well-suited for applications in packed columns where uniform liquid distribution is crucial for optimal mass transfer and process efficiency. Future studies could explore parametric variations in operating conditions or geometric modifications to further optimize the distributor’s performance.

Reviews

There are no reviews yet.