Multiphase CFD Simulation of Nanofluid inside a Minichannel, ANSYS Fluent

$80.00 $40.00 Student Discount

- In this project, we aim to simulate heat transfer inside a minichannel with Al2O3 nanoparticles.

- The geometry is designed using Spaceclaim software then meshed in ANSYS Meshing with 2,850,000 hexagonal elements.

- Mixture model is used to simulate the presence of nanoparticles as second phase.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

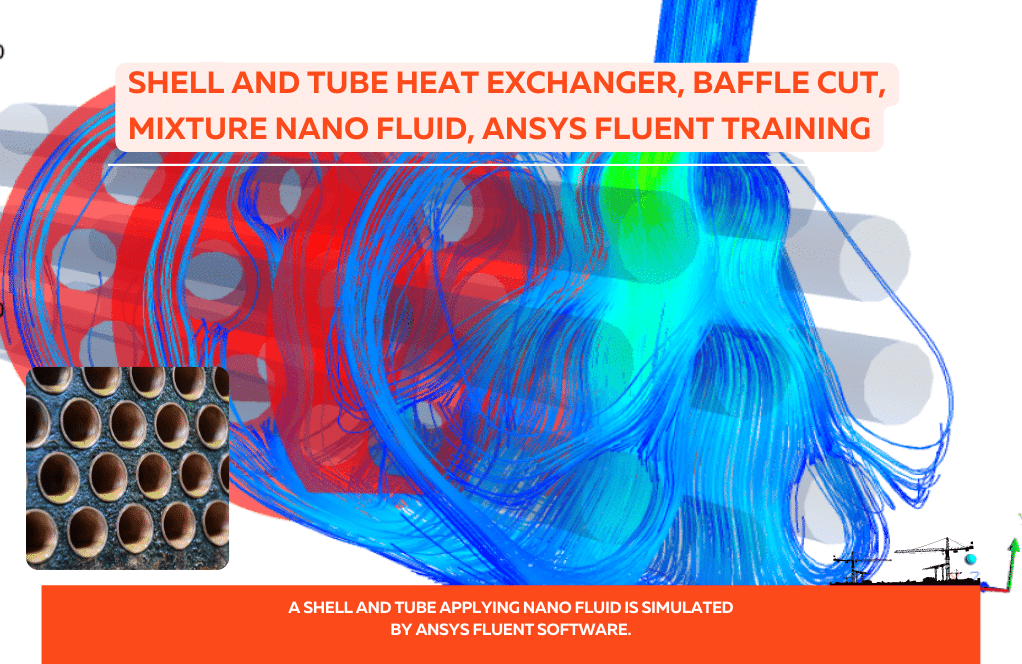

In this project, we aim to simulate heat transfer inside a minichannel with Al2O3 nanoparticles. To do so, Mixture multiphase model is used because a two-phase approach is taken. One phase is the water that carries nanoparticles and the other phase is Al2O3.

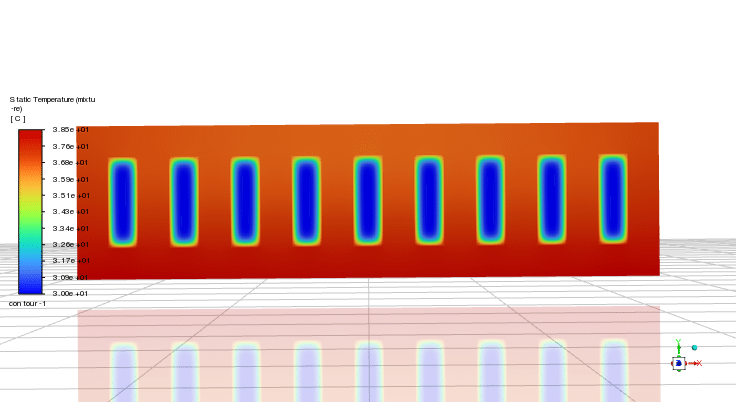

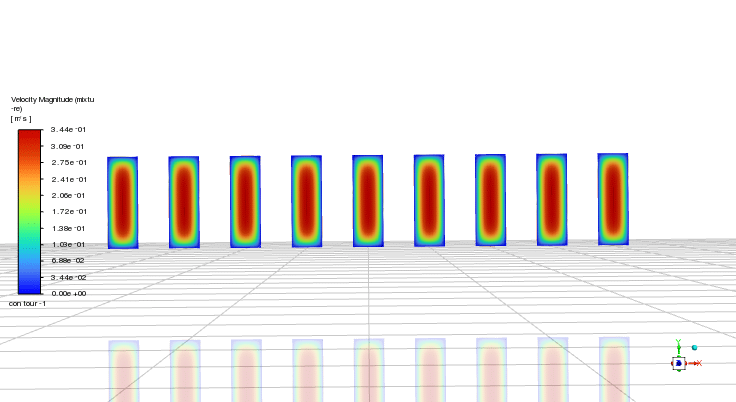

The geometry is a 9 minichannels with 30mm length and 3*1mm cross-section area. It is designed using Spaceclaim software. Then, it was meshed in ANSYS Meshing. In total, 2,850,000 hexagonal elements were generated.

Methodology

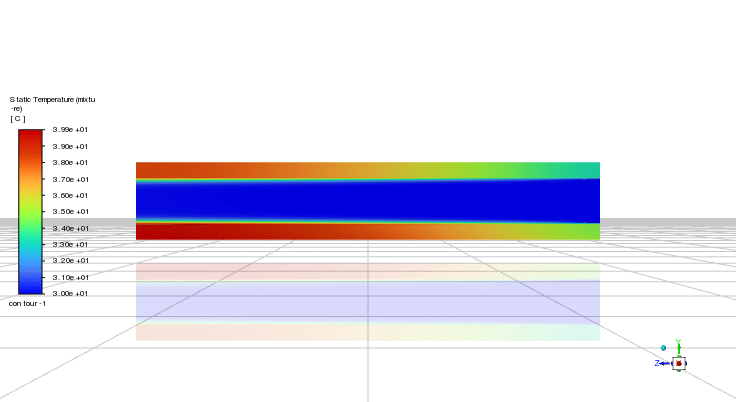

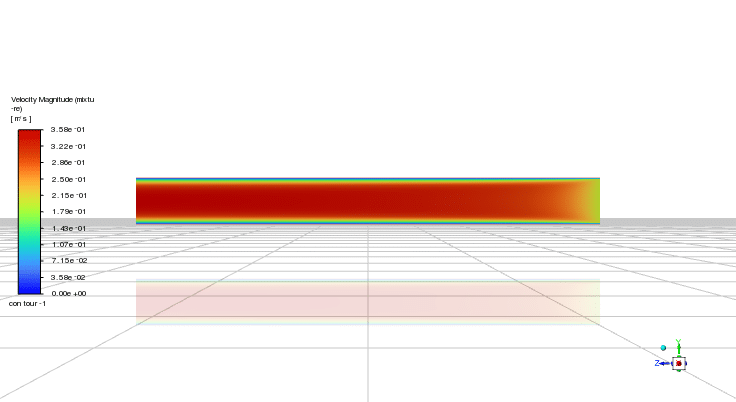

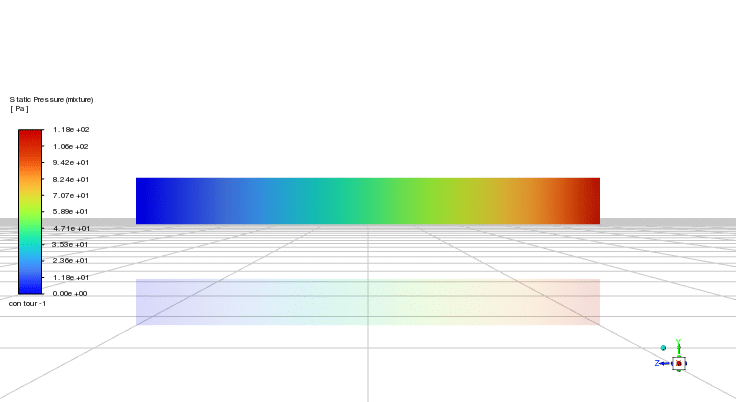

The flow in minichannels is laminar. It is because of the low Reynolds number. A heat flux of 53KW/m2 is applied from the bottom surface and all other walls are adiabatic. As mentioned earlier, Mixture multiphase model is used. Moreover, the mixture enters channels at 30°C temperature and works as a coolant.

Conclusion

After the solution process, several contours are extracted, as shown below. The nanoparticle volume fraction is 1%. The duty of nanoparticles is to increase thermal conductivity of the working fluid and enhance heat transfer. The mixture enters the channels at 30°C but leaves it at 33.6°C. It shows that the mixture gains 82.2J heat. Based on heat transfer coefficient, it is calculated as below:

h=Q/A*(Tw-Tb) = 82.2/0.00216*(4.94)=7703 W/m2.K

Reviews

There are no reviews yet.