NACA0012 Airfoil, Compressible Flow, Paper Validation

$240.00 $120.00 Student Discount

In this project, we intend to simulate the NACA0012 airfoil with the compressible flow around it to compare and validate the results with the results in the article.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

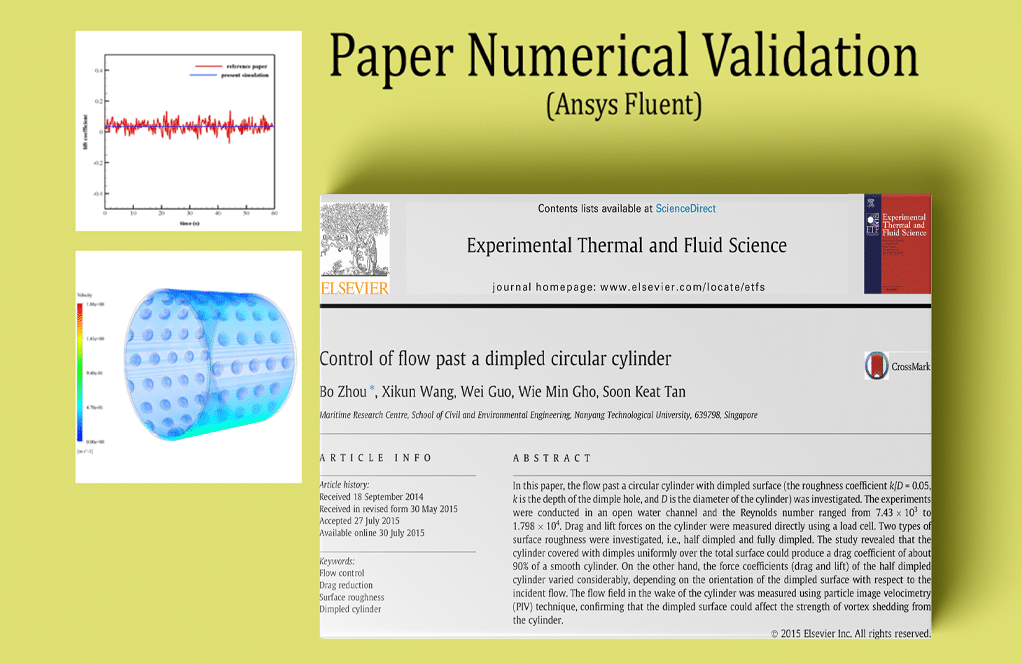

NACA0012 Airfoil (Compressible Flow), Paper Numerical Validation, ANSYS Fluent CFD Simulation training

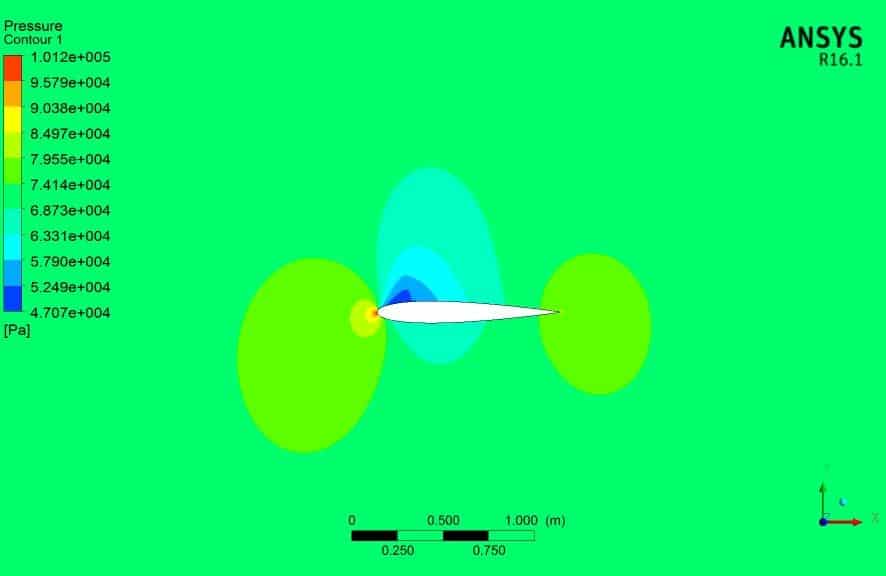

In this project, We simulated the compressible flow around the NACA0012 airfoil by Ansys Fluent Software. Then we compared the results with the results extracted from an article called this “Numerical Simulation OF VISCOUS TRANSONIC AIRFOIL FLOWS”.

Geometry & Mesh

The geometry is designed by the design modeler Software.

The meshing of this present model has been generated by ANSYS Meshing software. The mesh grid is structured, and the total cell number is 73320.

NACA0012 Airfoil CFD Simulation

To simulate the present model, several assumptions are considered, which are:

- The solver is density-based due to compressibility.

- Simulation has been done as Steady State

- We ignored the gravity effect.

The following is a summary of the steps for defining the problem and its solution:

| Models | ||

| Viscous | Spalart Allmaras | |

| Spalart Allmaras Production | Strain/Vorticity-based | |

| Boundary conditions | ||

| Fairfield | Mach Number | |

| Pressure Fairfield | 0.7

X-component of flow direction: 0.9996435 Y-component of flow direction: 0.02670036 |

|

| Airfoil Up & Airfoil Bottom | Wall | |

| Wall motion | Stationary Wall | |

| Shear Condition | No-slip condition | |

| Methods | ||

| Formulation

Flux type |

Implicit

Roe-FDS |

|

| Flow & Modified turbulent viscosity | Second-order upwind | |

| gradient | Green Gauss Node-based | |

| Initialization | ||

| Initialization methods | Standard | |

| Compute from | Far-field | |

| Material | ||

| Material properties | ||

| density | Ideal gas | |

| viscosity | Sutherland | |

| Cp | 1006.43 | |

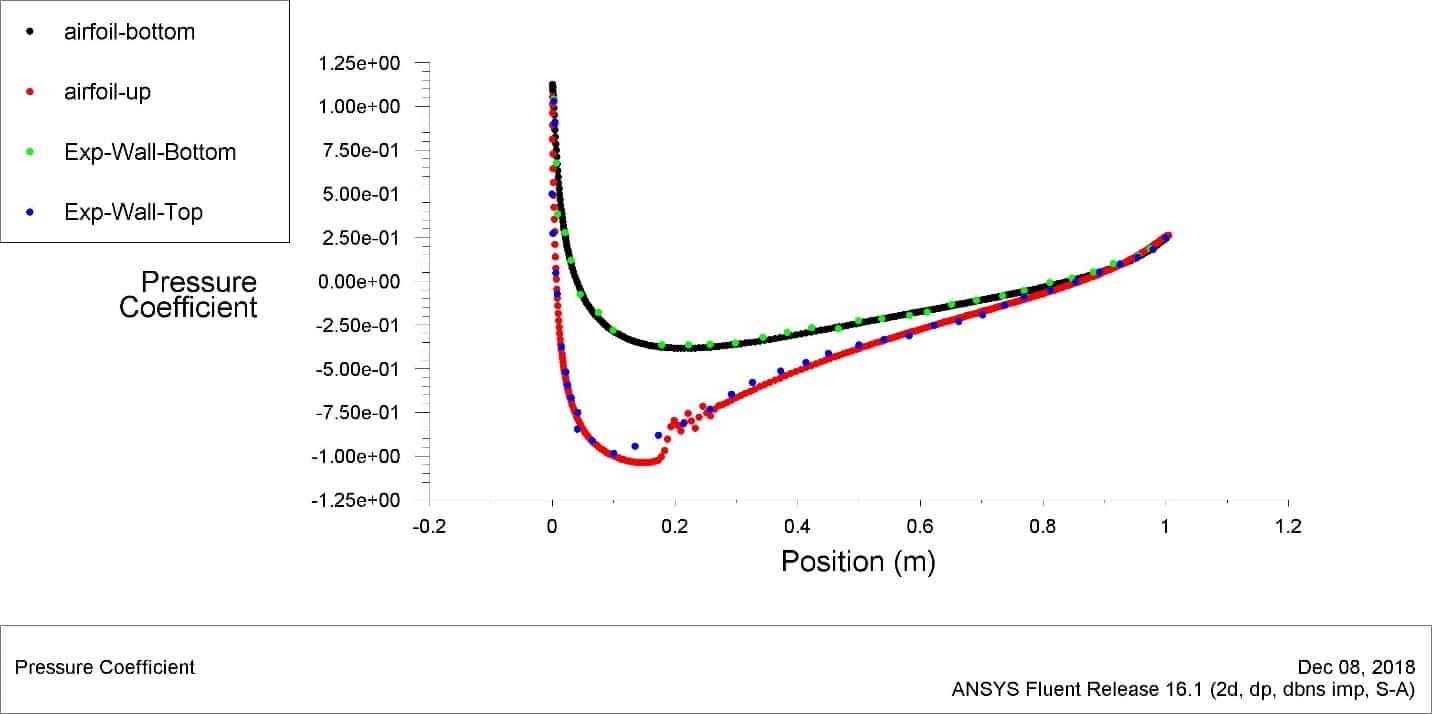

Paper Validation Results

By comparing the simulation results with the results in the article, it can be concluded that the simulation has been validated by the article.

| Coef. | Experimental Value | CFD Value |

| CD | 0.0079 | 0.00804 |

| CL | 0.241 | 0.246 |

Jessica Hansen II –

I’m thoroughly impressed by the level of detail in the CFD simulation of the NACA0012 airfoil and its validation against experimental data. The results closely match the reference paper, reflecting the high accuracy and reliability of the training material. It’s truly commendable how the simulation captures the behavior of the transonic flow with precision. Great work!

MR CFD Support –

Thank you for your positive feedback on the NACA0012 Airfoil CFD simulation project. We are pleased that the training material met your expectations and provided you with reliable and accurate information. We strive to offer high-quality simulations that closely resemble experimental results, and we’re glad to hear that we could accomplish this for you.

Alana Wilderman –

I’m impressed with the comparison of simulation results to published data! Could you elaborate on how close the simulation results were to the experimental values?

MR CFD Support –

The validation of the CFD simulation was indeed very successful. The difference between the CFD and experimental values for the coefficient of drag, CD, was minimal: 0.0079 versus 0.00804. Similarly, for the coefficient of lift, CL, the CFD value was 0.246, being very close to the experimental value of 0.241. This indicates an excellent match between our simulation and the experimental outcomes, showcasing the fidelity of the numerical methods employed in our simulation.

Dagmar Kertzmann Sr. –

I’m thrilled with the level of detail that you covered airflow simulation over the NACA0012 airfoil. The comprehensiveness of your approach, from geometry and mesh creation to validation against the paper, is very impressive. Great job on accurately depicting and processing the computational domain which, I imagine, must be crucial for such precise simulations.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our product met your expectations. Accurate representation and meticulous processing of the computational domain are indeed crucial for the success of such compressible flow simulations; your observation is astute. We’re glad that our efforts to provide a detailed and high-fidelity simulation training have been both helpful and appreciated.

Deshawn Bogisich –

I’m truly impressed by the accuracy of the CFD values in comparison to the experimental values from the article. Great work!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation closely matched the results reported in the literature. It’s great to know that users recognize and appreciate the precision of MR CFD’s simulations. If you have any further questions or need assistance with similar projects, feel free to reach out!

Prof. Arnold Upton –

I’ve noticed the Spalart-Allmaras turbulence model was used for this simulation. Could you help me understand why this particular model was chosen over other turbulence models?

MR CFD Support –

The Spalart-Allmaras model is particularly chosen for applications like airfoil simulations because it offers robust and accurate results for boundary layer flows, which are common in aerospace scenarios involving wings and airfoils. Its performance is well-balanced between complexity and computational efficiency for capturing the behavior of the turbulent boundary layer without extensive computational cost, which can be critical for simulations focusing on aerospace applications such as the one carried out for the NACA0012 Airfoil.

Augustine Hintz III –

I was impressed with the level of detail in your simulation of the NACA0012 airfoil and its validation against the research paper. The results show a close match, proving the accuracy of your CFD model. Great work replicating such a complex aerodynamic phenomenon!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found our simulation results accurate and reflective of published research. It’s our goal to deliver detailed and reliable training material to help users understand complex aerodynamic phenomena. We appreciate your recognition of our efforts in achieving a high level of precision in our CFD simulations.

Verlie Yost Jr. –

I’m fascinated by the validation process. Could you please expand on how the validation was carried out against the numerical results in the paper?

MR CFD Support –

The validation was undertaken by meticulously comparing key performance coefficients like the coefficient of drag (CD) and the coefficient of lift (CL) obtained from the CFD simulation with the ones reported in the referenced paper. The results showed a close agreement, indicating that our simulation process accurately mirrors the published data and therefore provides reliable predictions for compressible flows over the NACA0012 airfoil.

Tillman Jacobson –

The training was nicely done, particularly in demonstrating how to validate CFD results with experimental data. It gave me confidence in using simulations for complex aerodynamic analysis.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training on NACA0012 airfoil and CFD validation techniques met your expectations and was helpful to you. If you have any further questions or need assistance with future simulations, please don’t hesitate to reach out.

Prof. Amparo Kris V –

The training was very well structured, and the comparison with paper validation adds a lot of credibility to the simulation process. The detail in the methods and the boundary conditions setup is impressive. The slight differences in the coefficient values seem to be within an acceptable range. Good job on thorough work!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the training and the paper validation informative and up to your expectations. Our team is committed to providing high-quality, accurate simulations, and it’s rewarding to know that our efforts are appreciated. If you have any further questions or need assistance, feel free to reach out!

Carolyne Barton –

I’m really impressed with the detailed replication of the NACA0012 airfoil study. Was it difficult to adjust the solver settings to match the conditions from the article for the validation process?

MR CFD Support –

Thank you for your kind words! It required meticulous attention to detail to adjust the solver settings to the specific conditions outlined in the paper. This process is crucial for ensuring that our CFD simulation is as accurate and representative as possible of the actual physical phenomenon.

Idell Walter –

The NACA0012 airfoil simulation was very informative, but could you tell me more about the reason for choosing the density-based solver over the pressure-based solver for this simulation?

MR CFD Support –

For the simulation of the NACA0012 airfoil, the density-based solver is chosen over the pressure-based solver because the flow is compressible and at a high speed which potentially reaches or exceeds the transonic regime. The density-based solver calculates the variables in a coupled manner which is more suitable for capturing the shock waves and accurately predicting the flow field for high-speed compressible flows.

Paolo Carter –

Fantastic resource for both beginners and experienced CFD users. The clarity in mesh details and boundary condition settings really allowed me to grasp the nuances of compressible flow simulation.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our training on NACA0012 Airfoil CFD simulation provided you with a clear understanding and was useful for people of all skill levels. Your feedback motivates us to continue delivering high-quality educational resources.

Dashawn Rohan –

The provided simulation results look very close to the experimental values. Could you share how the simulation was helpful for understanding the aerodynamics of the NACA0012 airfoil?

MR CFD Support –

Thank you for recognizing the accuracy of our simulation results! This CFD simulation helps us gain a detailed understanding of the aerodynamics of the NACA0012 airfoil in compressible flow conditions. By visualizing specific flow phenomena like shock waves and comparing numerical data like lift and drag coefficients, we can study how these parameters affect the airfoil’s performance at transonic speeds, a crucial aspect for designing efficient aerostructures. Your appreciation motivates us to keep providing quality learning materials.

Mrs. Elsa Marquardt IV –

I appreciate the work done in simulating the NACA0012 airfoil and doing validation by comparing it with existing literature. It’s impressive to see the accuracy of your CFD results compared to experimental data provided in the article.

MR CFD Support –

Thank you for acknowledging the accuracy of our CFD simulation and paper validation for the NACA0012 airfoil. We strive to provide precise and reliable simulations compared to established benchmarks in literature. Your satisfaction is paramount to us!

Gerald Balistreri –

I was really impressed with the accuracy of the simulation when compared with the results mentioned in the referenced paper. Great work!

MR CFD Support –

Thank you for your kind words! We’re pleased to hear that the accuracy of our CFD simulation for the NACA0012 airfoil met your expectations and matched closely with published results. Our team works hard to ensure our simulations are reliable and valuable to our customers. Your feedback is much appreciated!

Sonny Gibson –

I was impressed by how closely the CFD Value for CD and CL matched the Experimental Value in this training. Well done!

MR CFD Support –

Thank you so much for your kind words! We are pleased to hear that our simulation of the NACA0012 airfoil’s compressible flow and the comparison against paper validation met your expectations. Accuracy in CFD simulations is crucial, and we strive to provide detailed training that enables precise and reliable outcomes. Your positive feedback encourages us to continue delivering high-quality educational products.

Lisa Hayes –

The review thoroughly outlines how the simulation was set up and confirms a successful validation against given research. The effort put into accurately simulating the different properties and conditions is commendable. Well done!

MR CFD Support –

Thank you for your detailed feedback and recognition of the work that went into accurately setting up and validating the simulation against published research. We strive for excellence in all our training materials, and we’re glad to see that reflected in your review. If you have any further inquiries or need additional support with our products, we’re here to help.

Arne Strosin III –

The provided validation results indicate slightly different coefficients for CD and CL compared to the experimental values. Could this disparity be due to the mesh size or are there other factors that could contribute to these differences?

MR CFD Support –

The differences in the CD and CL values could indeed be a result of mesh size. Other factors that could contribute to the disparity could include numerical methods used, the accuracy of the boundary conditions applied, and physical models chosen (for instance, the turbulence model). Further mesh refinement and sensitivity analysis could help in bringing the CFD results closer to experimental data.