Nanoparticle Injection (Cone-Type) , ANSYS Fluent CFD Simulation

$120.00 $60.00 Student Discount

- This report details a nanoparticle simulation conducted using ANSYS Fluent

- The simulation geometry consists of a rectangular cuboid created in SpaceClaim

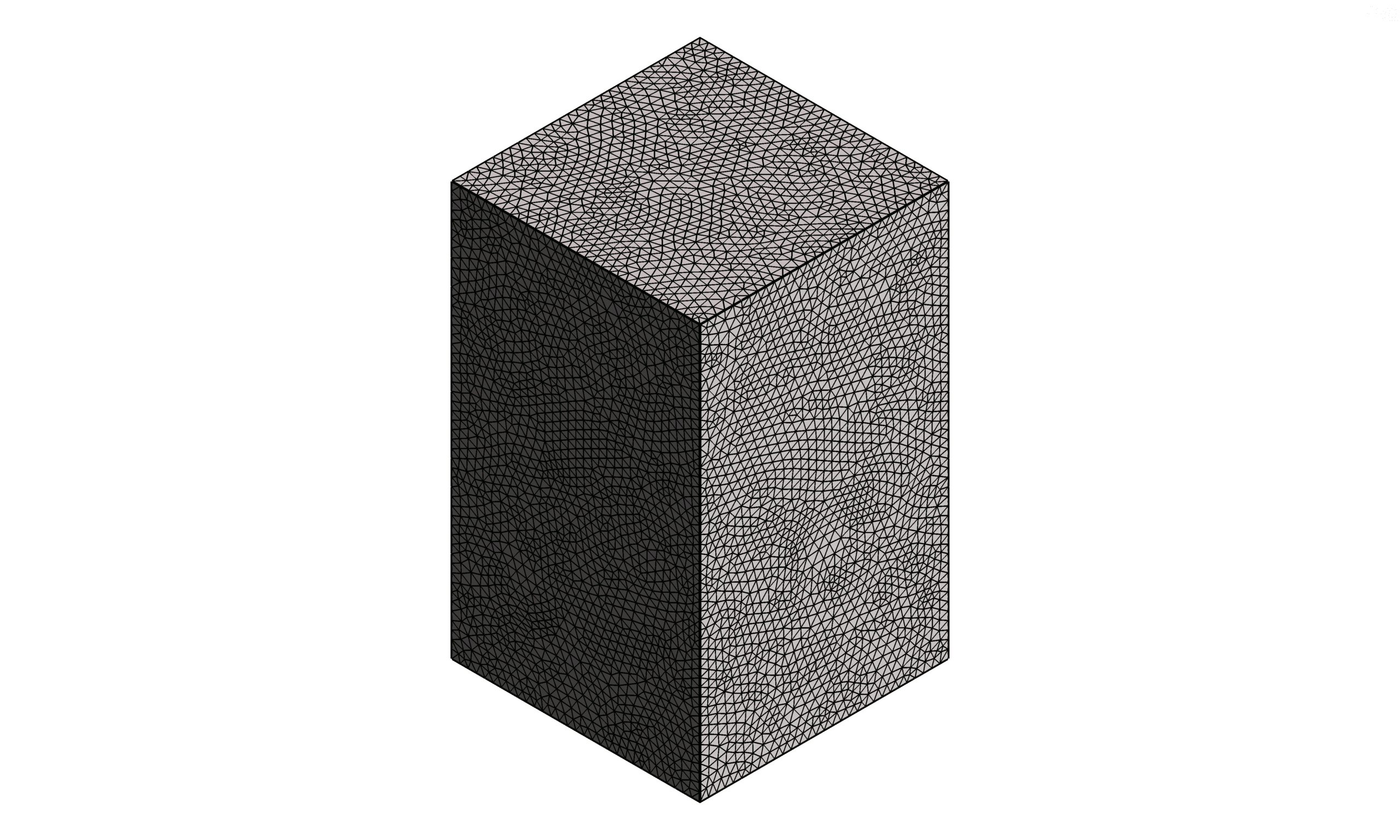

- . Meshing was performed in ANSYS Meshing, resulting in a grid of 151,294 triangular cells

- Discrete Phase Model (DPM) activated, Flow and turbulence equations deactivated

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This report details a nanoparticle simulation conducted using ANSYS Fluent. The primary focus is on the behavior of nanoparticles in a fluid environment, with particular attention to particle injection properties and simulation parameters.

The simulation geometry consists of a rectangular cuboid created in SpaceClaim. Meshing was performed in ANSYS Meshing, resulting in a grid of 151,294 triangular cells, providing a balance between accuracy and computational efficiency.

Simulation Setup in ANSYS Fluent:

The simulation was configured in ANSYS Fluent with the following key settings:

Discrete Phase Model (DPM) activated

Flow and turbulence equations deactivated

Gravity enabled: 9.81 m/s² in the negative y-direction

Standard initialization used

Initial velocity: 1 m/s in the y-direction, 0 m/s in other directions

Nanoparticle Injection Properties The injection properties were set as follows:

| Property | Value |

| Injection Type | cone |

| Number of Streams | 100 |

| Particle Type | Inert |

| Material | anthracite |

| Diameter Distribution | rosin-rammler |

| Cone Type | solid-cone |

| X-Axis | 0 |

| Y-Axis | 1 |

| Z-Axis | 0 |

| Velocity Magnitude [m/s] | 10 |

| Cone Angle [deg] | 20 |

| Outer Radius [m] | 0.002 |

| Total Flow Rate [kg/s] | 0.001 |

| Min. Diameter [m] | 1e-09 |

| Max. Diameter [m] | 1e-08 |

| Mean Diameter [m] | 5e-08 |

| Spread Parameter | 3.5 |

| Number of Diameters | 10 |

Nanoparticle Size Configuration To accurately simulate nanoparticles, an additional step was necessary:

The default minimum particle diameter in Fluent’s GUI is 1e-8 m.

To model true nanoparticles, the following command was executed in the Fluent console: /define/models/dpm/options> set-minimum-particle-diameter

This command allowed setting the minimum particle diameter to 1e-10 m, enabling the simulation of particles at the nanoscale.

Simulation Time and Type The simulation was set up as a transient analysis, allowing for the observation of nanoparticle behavior over time.

Simulation Results

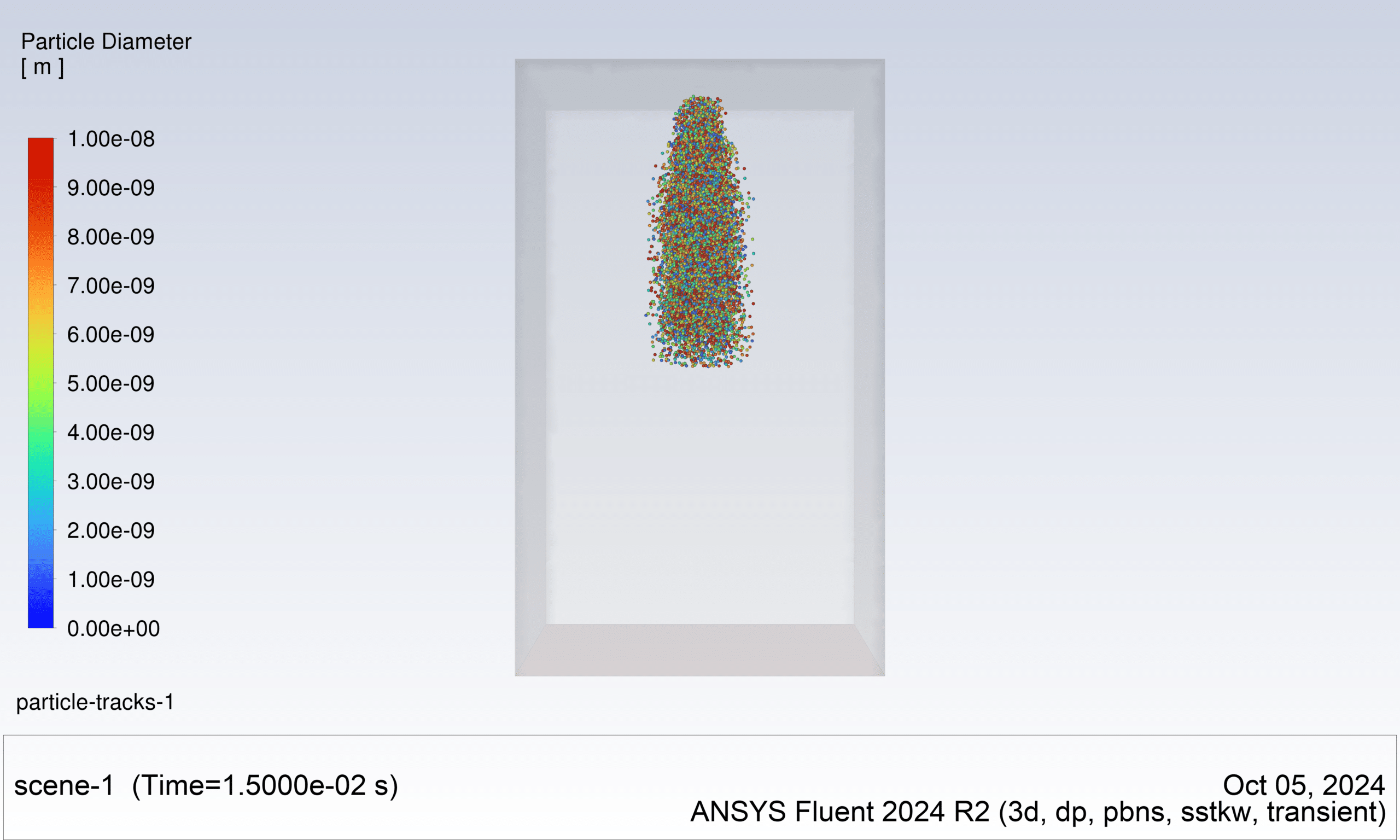

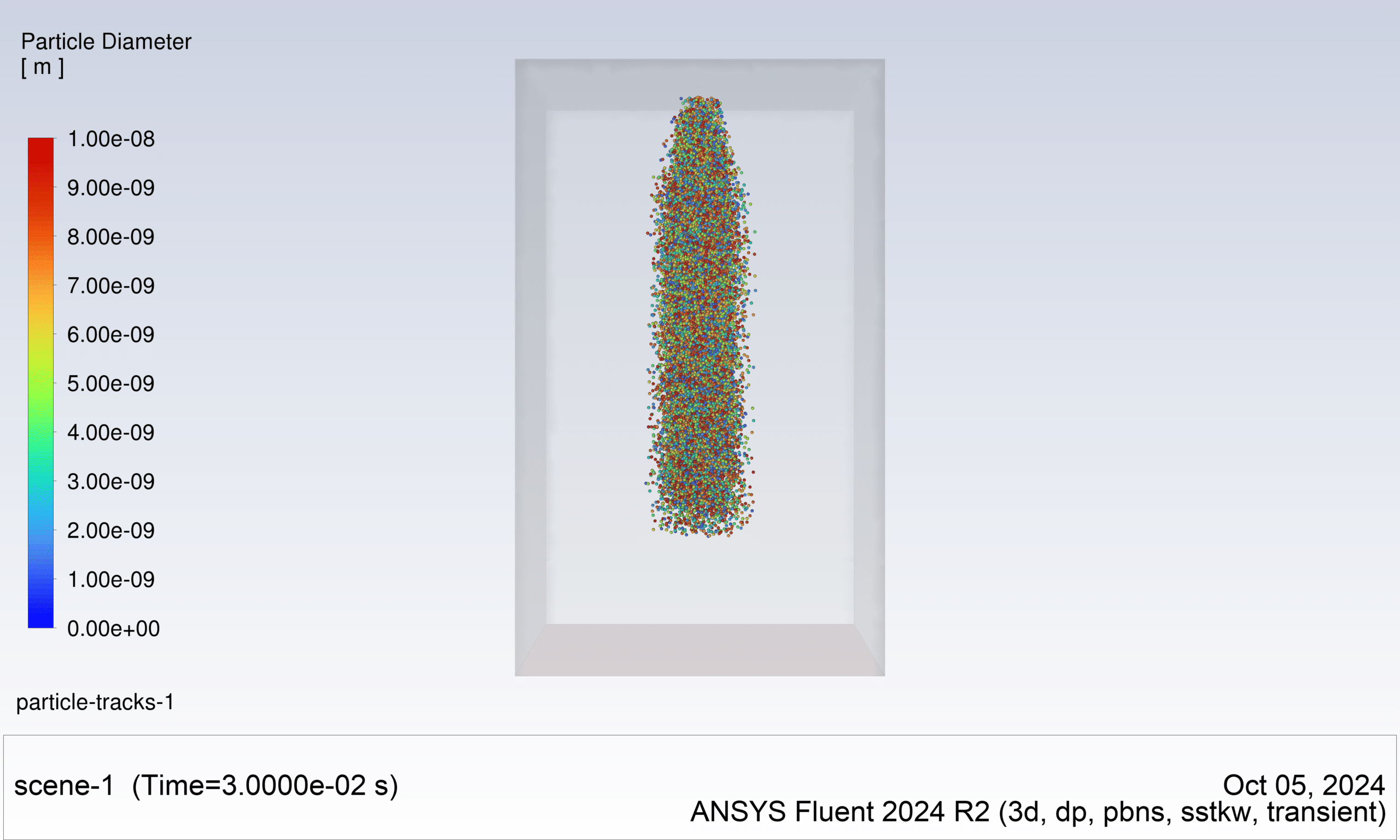

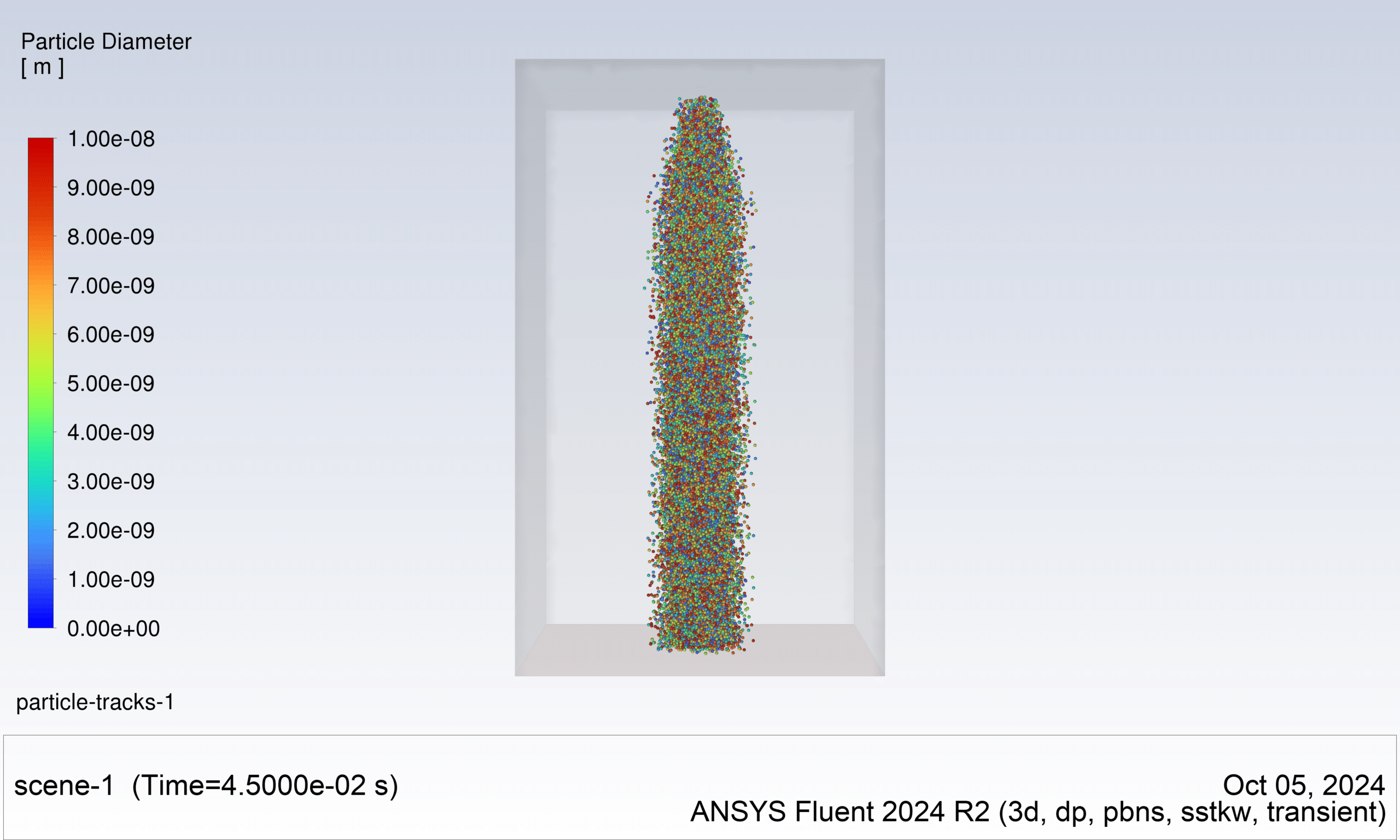

Figure 3 shows the particle diameter distribution at different time steps (1.5e-02 s, 3.0e-02 s, and 4.5e-02 s). This series of images illustrates the evolution of particle dispersion over time. The particles appear to spread out from the injection point, forming a cone-shaped distribution that expands as time progresses.

At 1.5e-02 s, the particles are concentrated near the injection point. By 3.0e-02 s, they have dispersed further, and at 4.5e-02 s, the particles have spread even more, occupying a larger volume of the simulation domain.

The color variation in the particles represents different particle diameters, as specified by the Rosin-Rammler distribution used in the injection setup.

This simulation provides insights into the behavior of anthracite particles injected into a confined space, showing how they disperse over time under the influence of gravity and initial injection parameters.

Conclusion:

This setup allows for a detailed simulation of nanoparticle injection and dispersion in a fluid environment. The use of the console command to set a smaller minimum particle diameter enables the study of true nanoparticle behavior, which is crucial for applications in nanotechnology and fluid dynamics at the nanoscale.

Reviews

There are no reviews yet.