Net Panel Displacement in Water Flow CFD Analysis, Ansys Fluent

$150.00 $75.00 Student Discount

- This study investigates the displacement of a net panel subjected to water flow using ANSYS Fluent simulation.

- The geometry of a square net panel was created using ANSYS Design Modeler.

- The computational domain was then discretized using ANSYS Meshing, resulting in over 2,339,853 elements.

- The simulation aims to analyze the net panel’s fluid-structure interaction

- The structural model utilized a Linear Elasticity submodel to simulate the net panel’s deformation

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study investigates the displacement of a net panel subjected to water flow using Computational Fluid Dynamics (CFD) simulation. Understanding the behavior of net structures in fluid environments is crucial for various applications, including aquaculture, marine engineering, and coastal protection. The simulation aims to analyze the net panel’s fluid-structure interaction, flow patterns, and structural response to underwater flow conditions.

The simulation was conducted using ANSYS Fluent, a sophisticated CFD software package. The geometry of a square net panel was created using ANSYS Design Modeler. The computational domain was then discretized using ANSYS Meshing, resulting in over 2,339,853 elements, providing a high-resolution mesh for accurate solution computation.

Methodology

The simulation setup employed a pressure-based solver in a transient state, allowing for time-dependent analysis of the flow and structural response. The SST k-Omega model was selected for turbulence modeling, offering a robust approach for capturing complex flow patterns around the net structure. The structural model utilized a Linear Elasticity submodel to simulate the net panel’s deformation. The panel material was defined as Polyethylene, with water as the working fluid.

Results

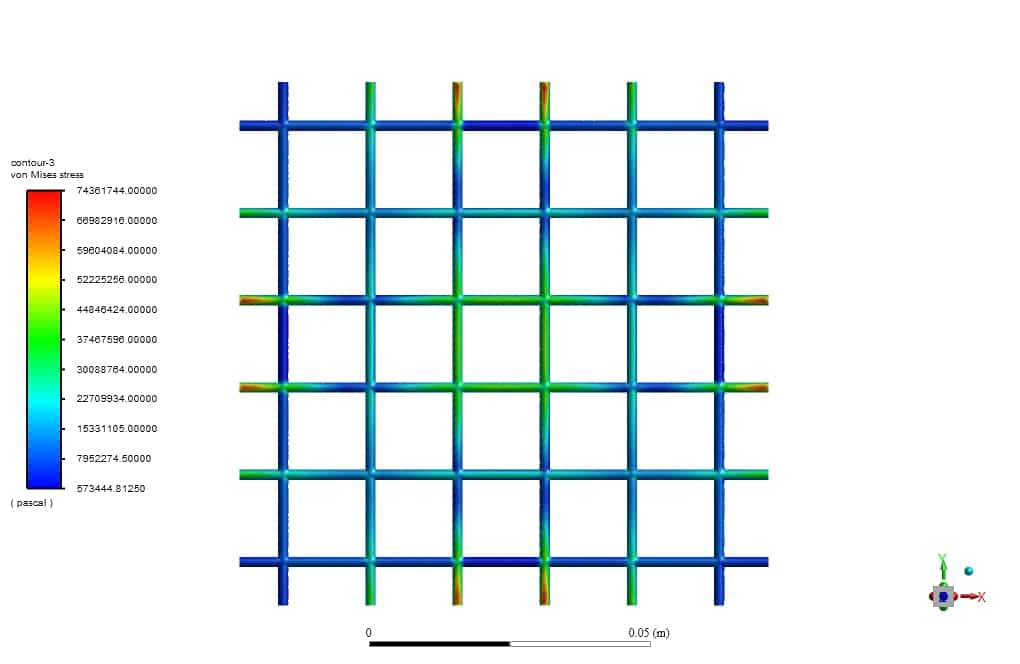

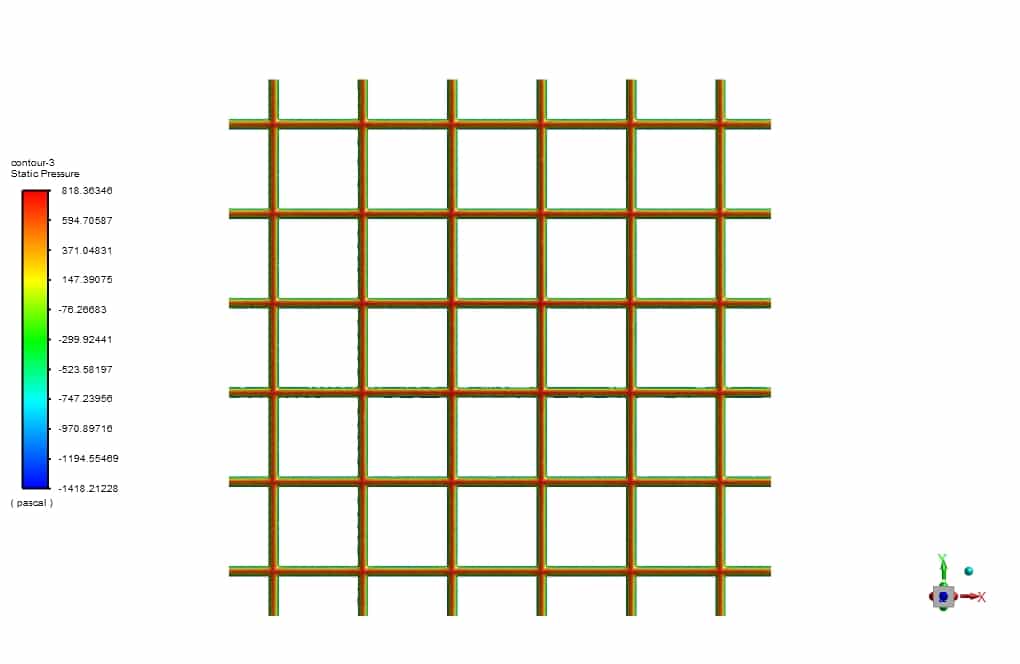

The mesh visualization demonstrates a well-structured grid of the geometry, with refined elements capturing the intricate geometry of the net structure. The simulation results provide valuable insights into the fluid-structure interaction and the panel’s response to water flow.

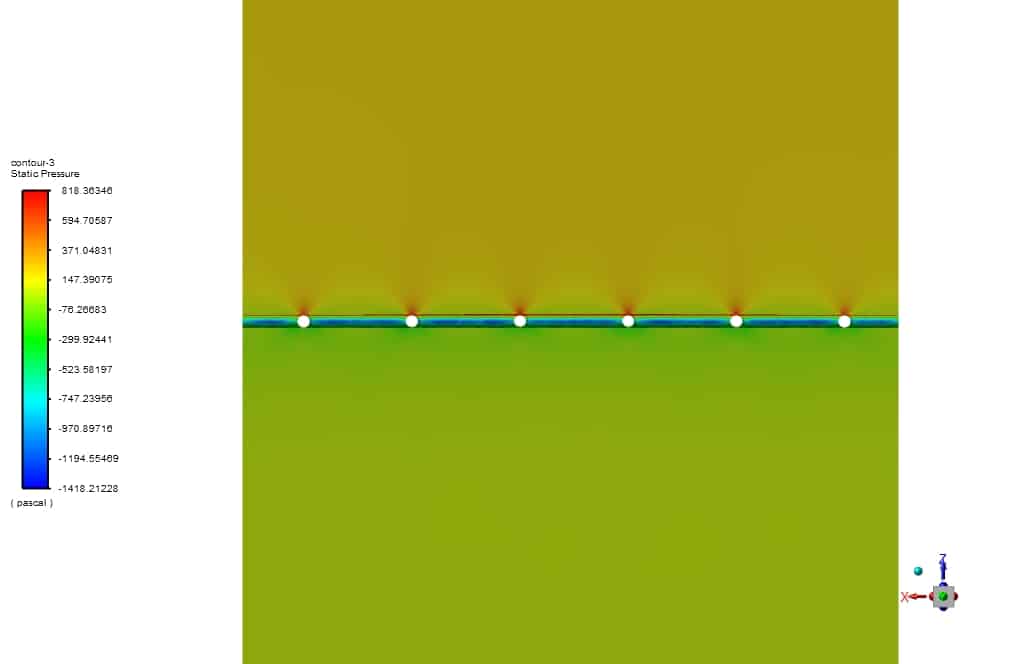

The static pressure contour reveals a complex pressure distribution across the net panel. Higher pressure zones are observed on the upstream face of the net, while lower pressure areas are evident on the downstream side. This pressure differential is the primary driver of the net’s deformation and displacement.

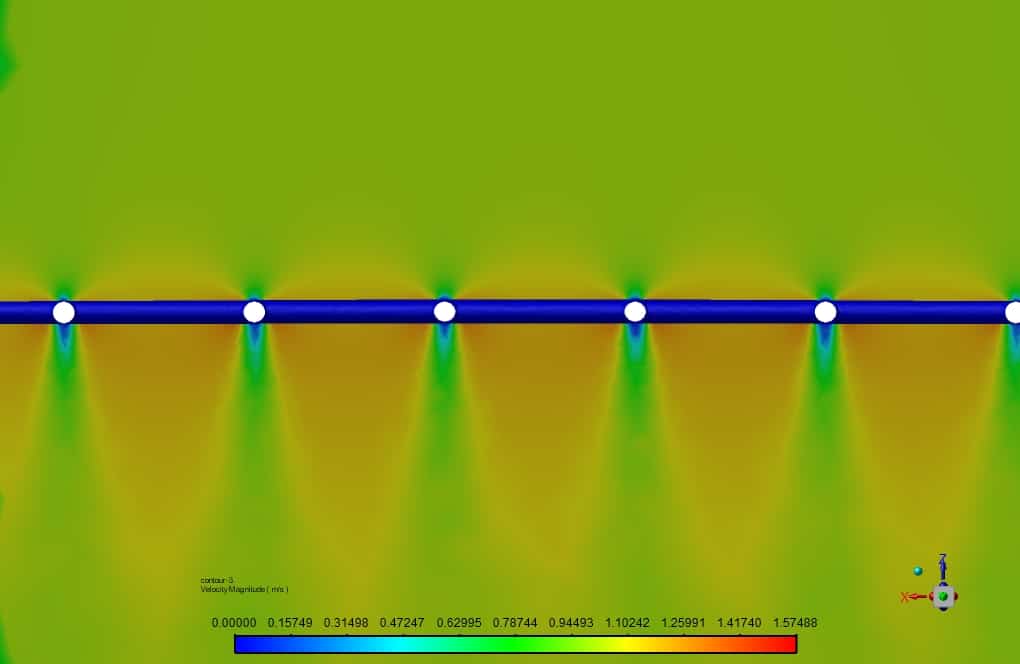

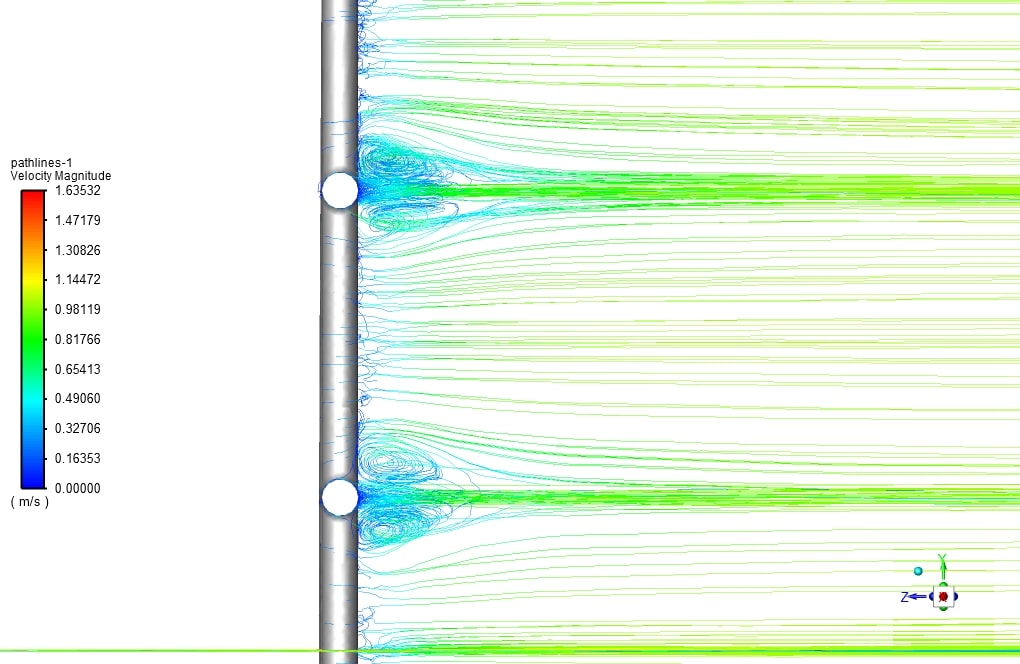

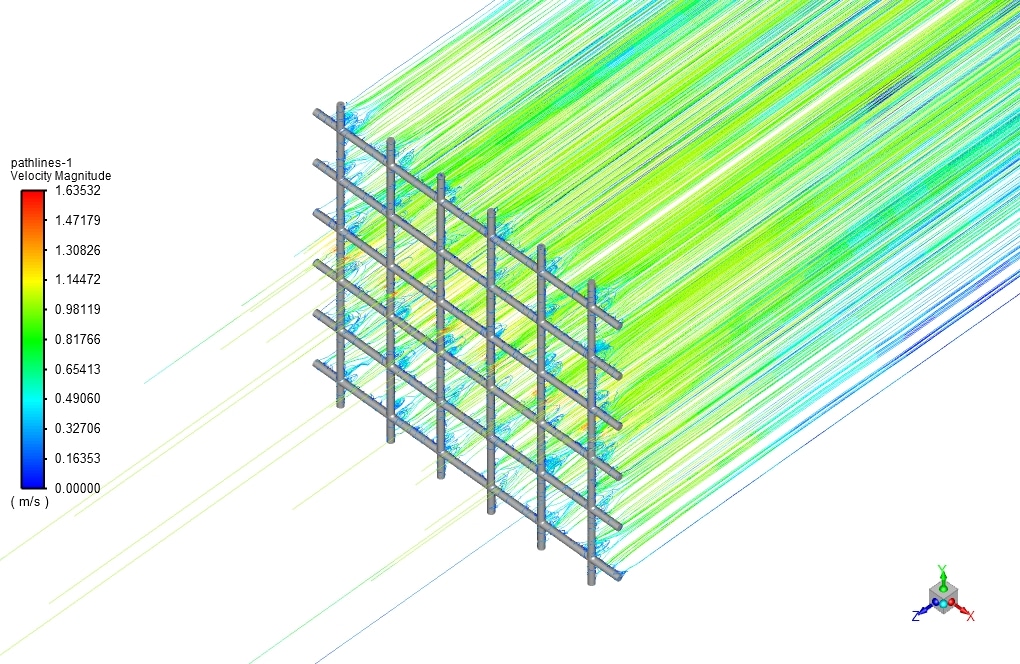

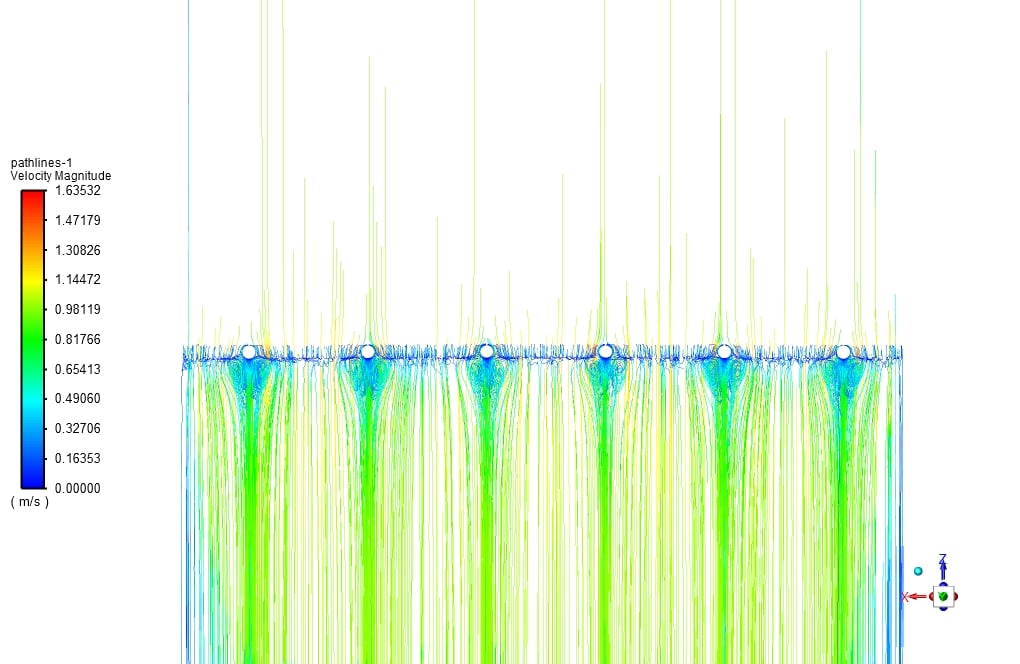

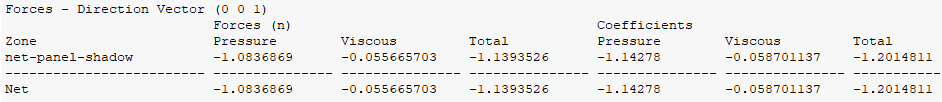

The velocity magnitude pathlines illustrate the flow behavior around and through the net panel. The pathlines show an acceleration of flow as it passes through the net openings, with areas of reduced velocity immediately downstream of the net strands. Vortex formation and flow separation are visible behind the net structure, indicating complex turbulent behavior.

The stress distribution across the geometry is visualized through the von Mises stress contour. Higher stress concentrations are observed at the intersections of the net strands and along the edges of the panel, highlighting the areas most susceptible to deformation and potential failure.

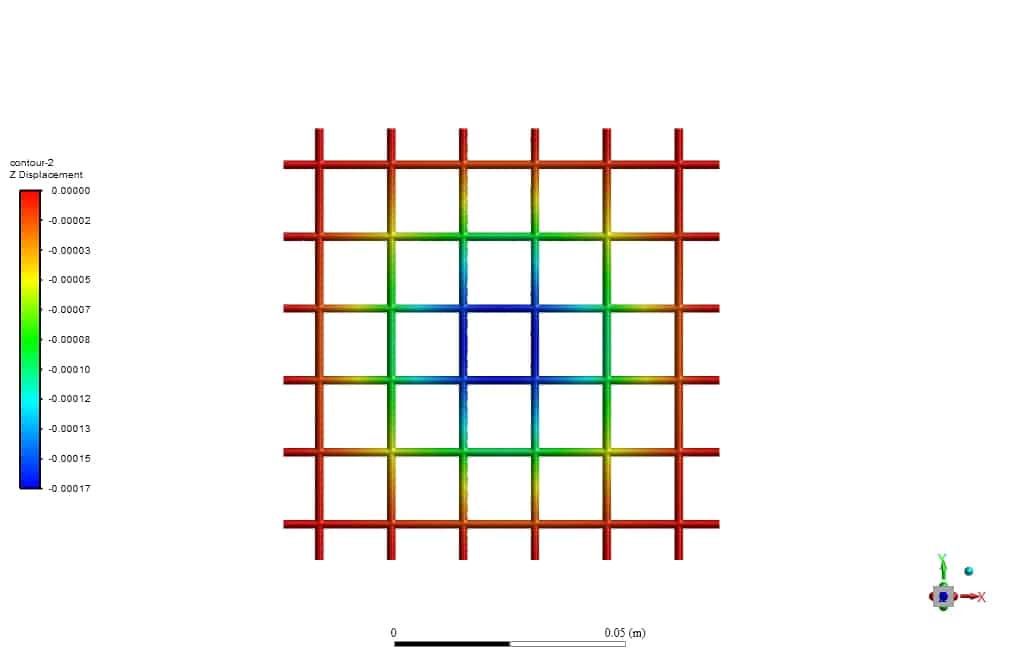

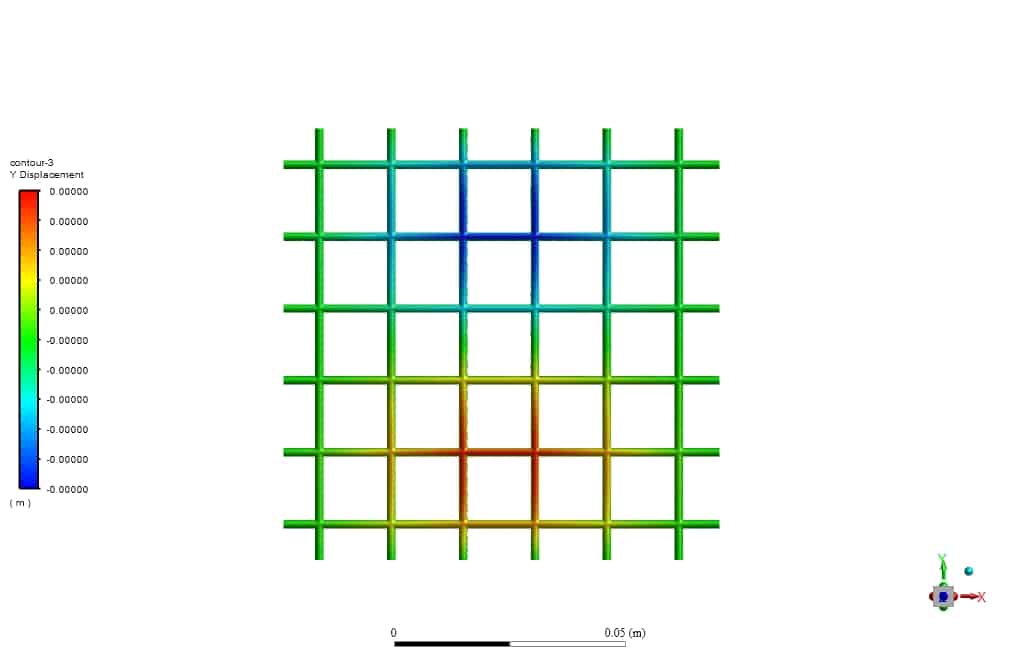

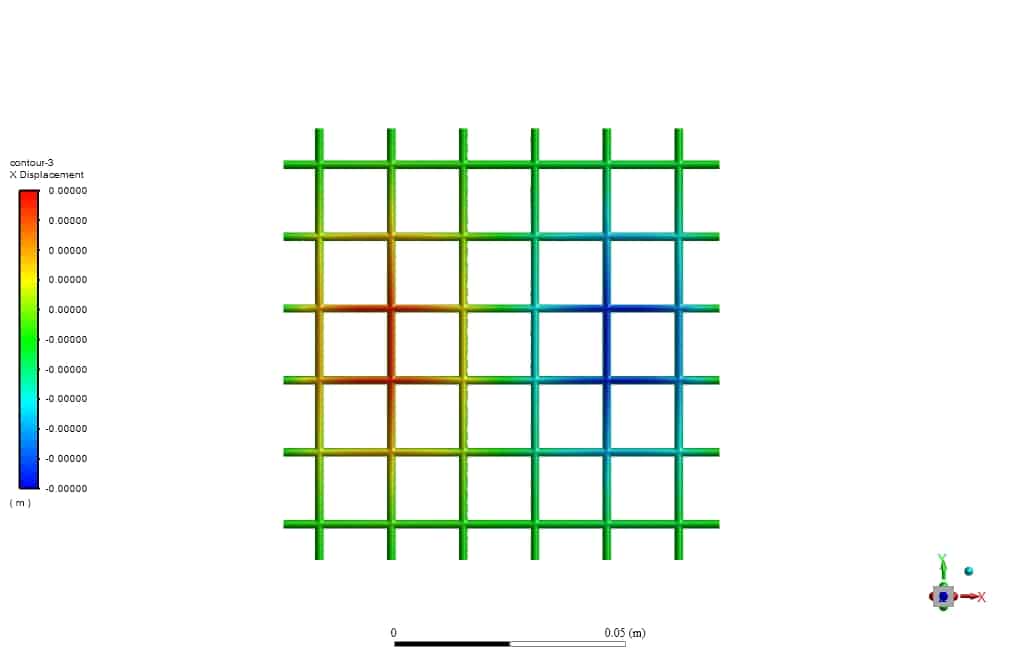

The displacement contours in the X, Y, and Z directions provide a comprehensive view of the net panel’s deformation under water flow. The X-displacement shows the panel’s deflection in the flow direction, with maximum displacement at the center of the panel. The Y and Z displacement contours reveal the out-of-plane deformation, indicating a complex three-dimensional response of the net structure to the fluid forces.

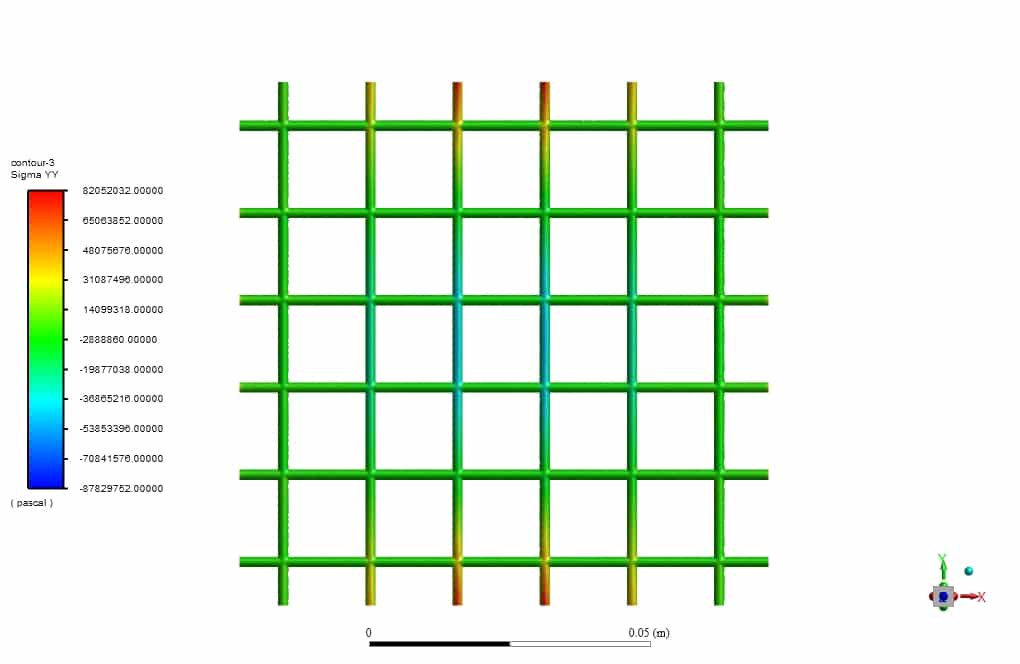

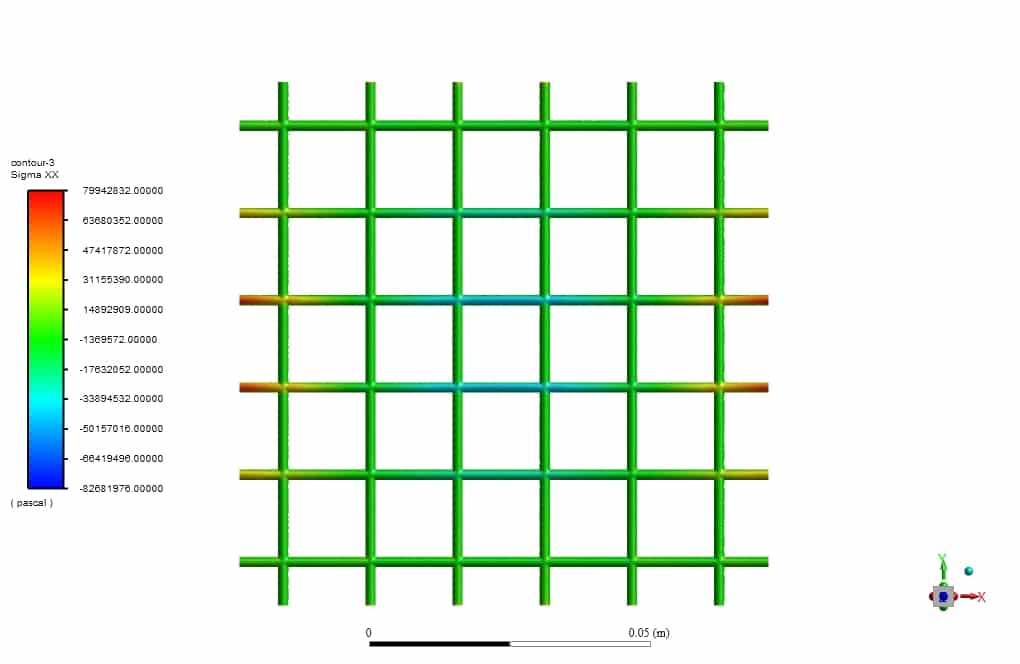

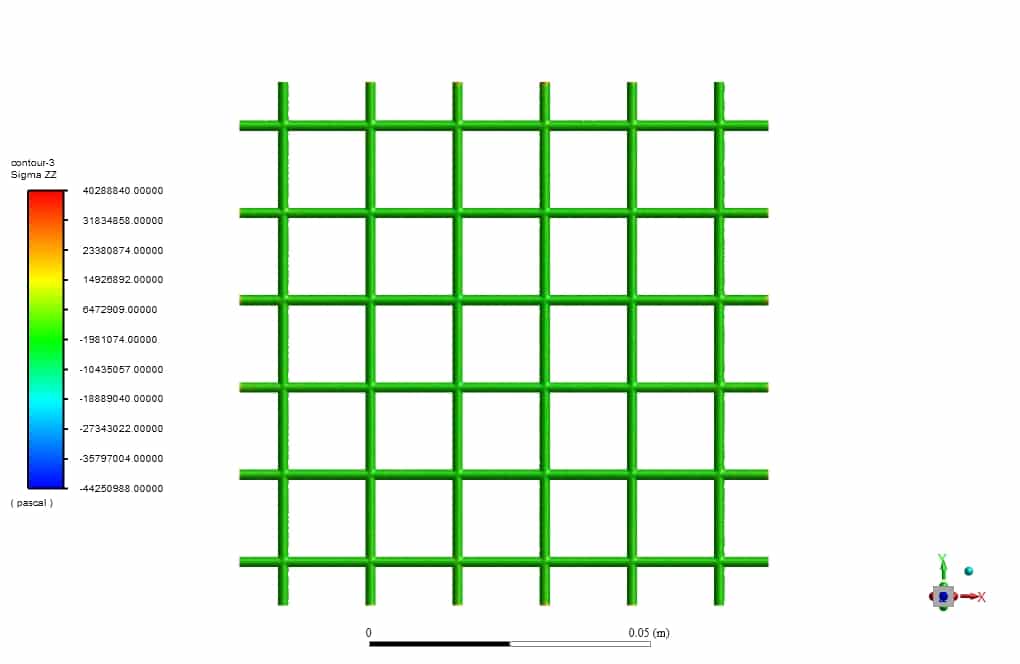

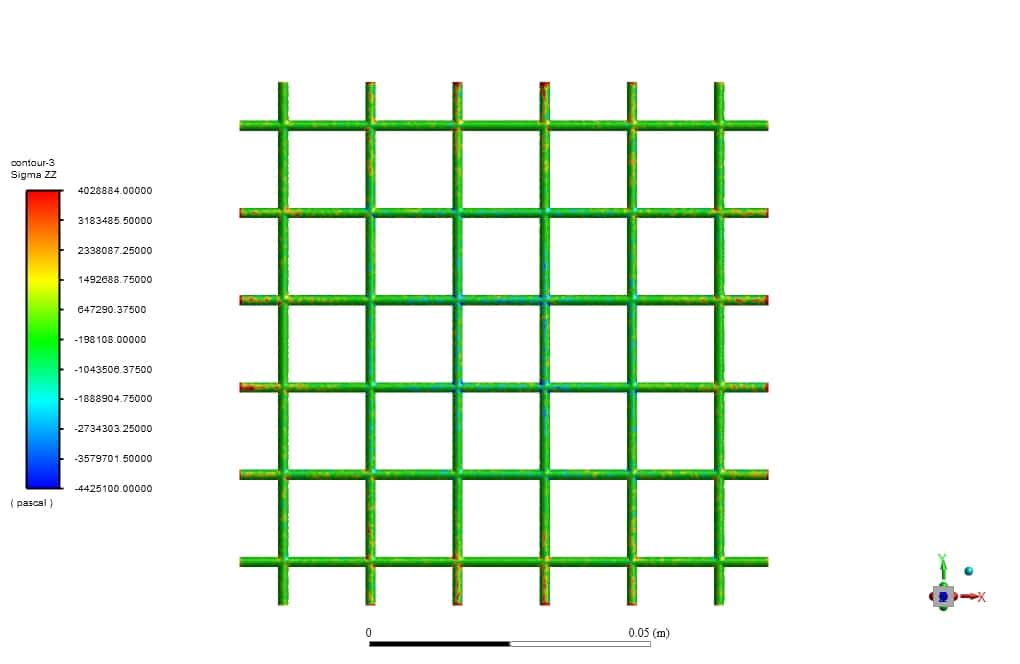

The sigma XX, YY, and ZZ contours depict the normal stresses in the respective directions, offering insight into the internal forces experienced by the net material. These stress distributions are crucial for assessing the structural integrity and potential failure modes of the net panel.

The detailed flow visualization around individual net strands shows the formation of wake regions and small-scale vortices, which contribute to the overall drag force on the structure. This microscale flow behavior is essential for understanding the macroscale response of the entire net panel.

Reviews

There are no reviews yet.