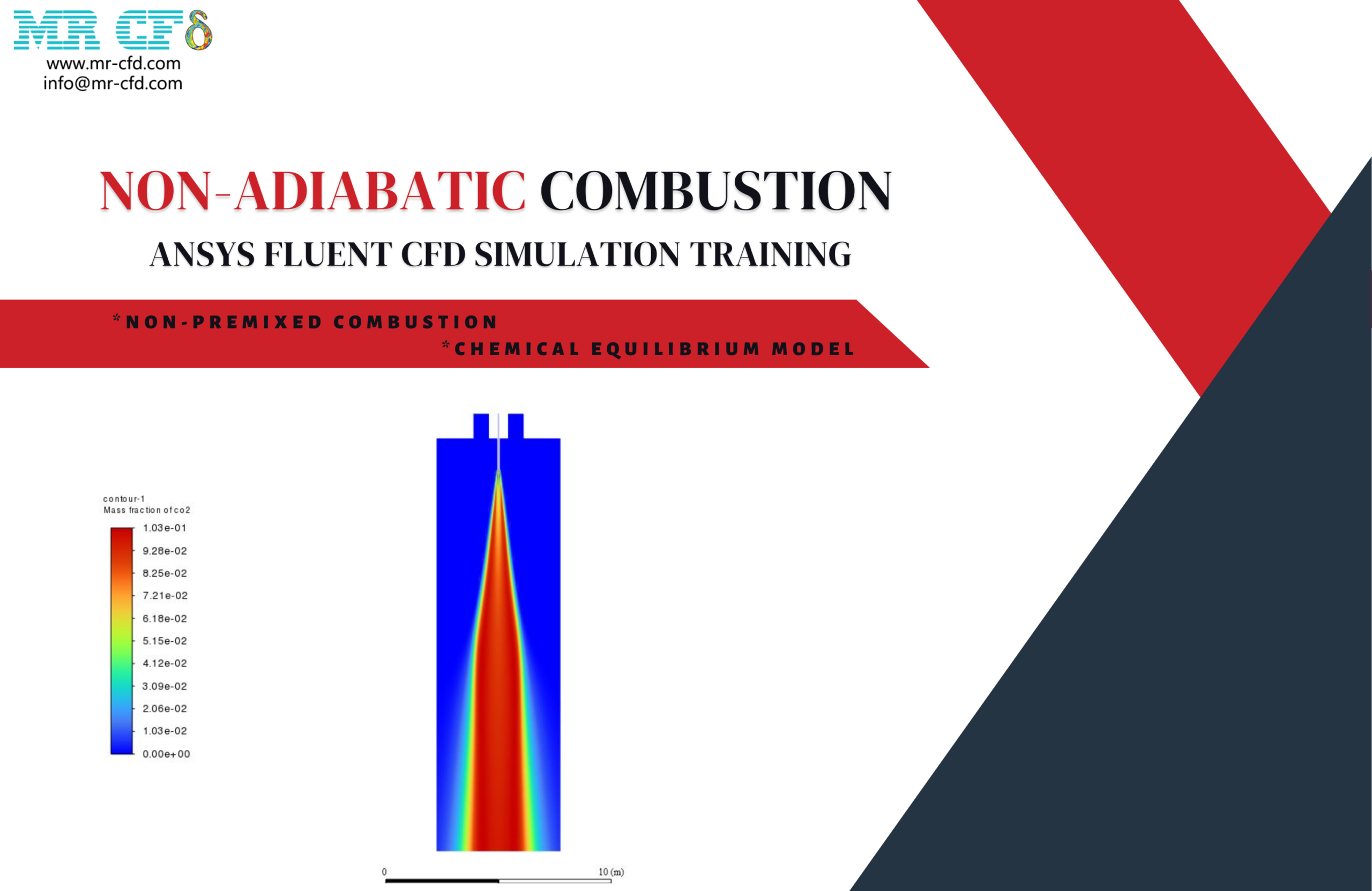

Non-Premixed Combustion, Non-Adiabatic, Chemical Equilibrium, ANSYS Fluent CFD Training

$140.00 $70.00 Student Discount

- The problem numerically simulates the non-adiabatic combustion ANSYS Fluent software.

- We design the 2-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 63280.

- We use the Non-Premixed Combustion model to define a Combustion reaction.

- We use the Non-Adiabatic energy treatment and Chemical Equilibrium.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

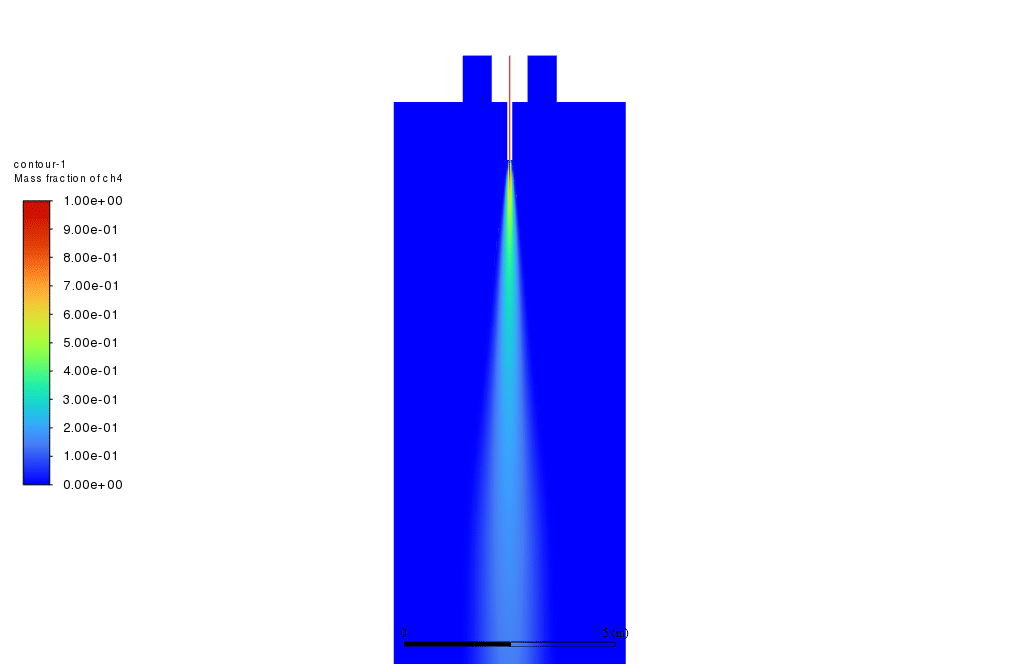

The present problem simulates the non-adiabatic combustion in a combustion chamber by ANSYS Fluent software. In the present case, it is assumed that the fuel and air enter the chamber from separate boundaries and hence are considered Non-premixed.

The geometry of the present model is two-dimensional and has been designed using Design Modeler software. We do the meshing of the present model by ANSYS Meshing software. The mesh type is Structured, and the element number is 63280.

This CFD project is the 3rd episode of the Combustion Training Course.

Non-Premixed Combustion Methodology

Non-premixed combustion model is used to model the combustion process. Non-adiabatic energy treatment along with a chemical equilibrium model is used to model the combustion process.

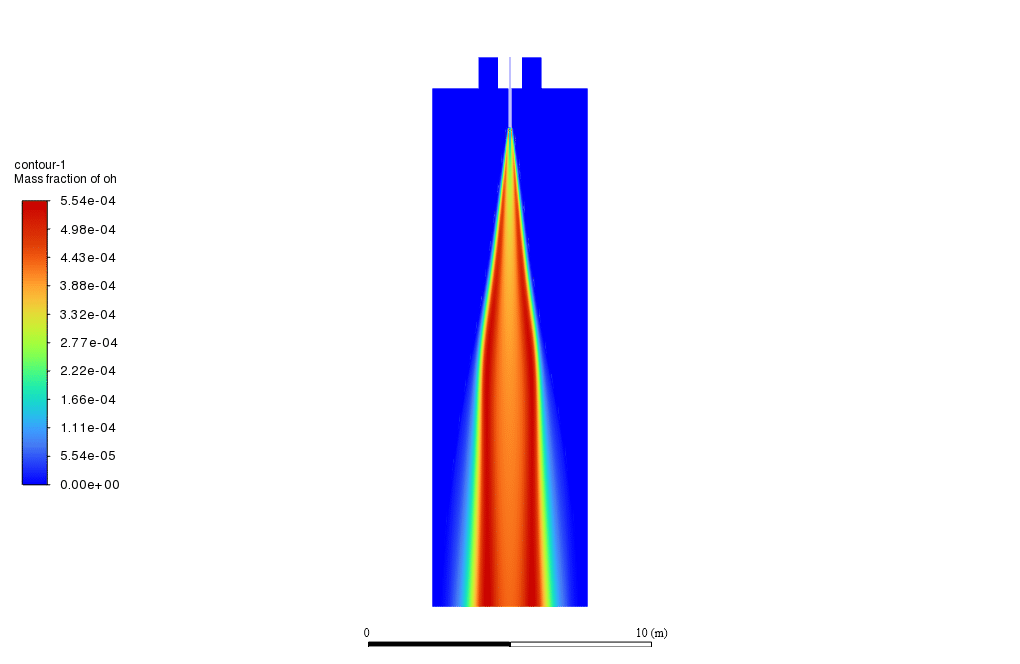

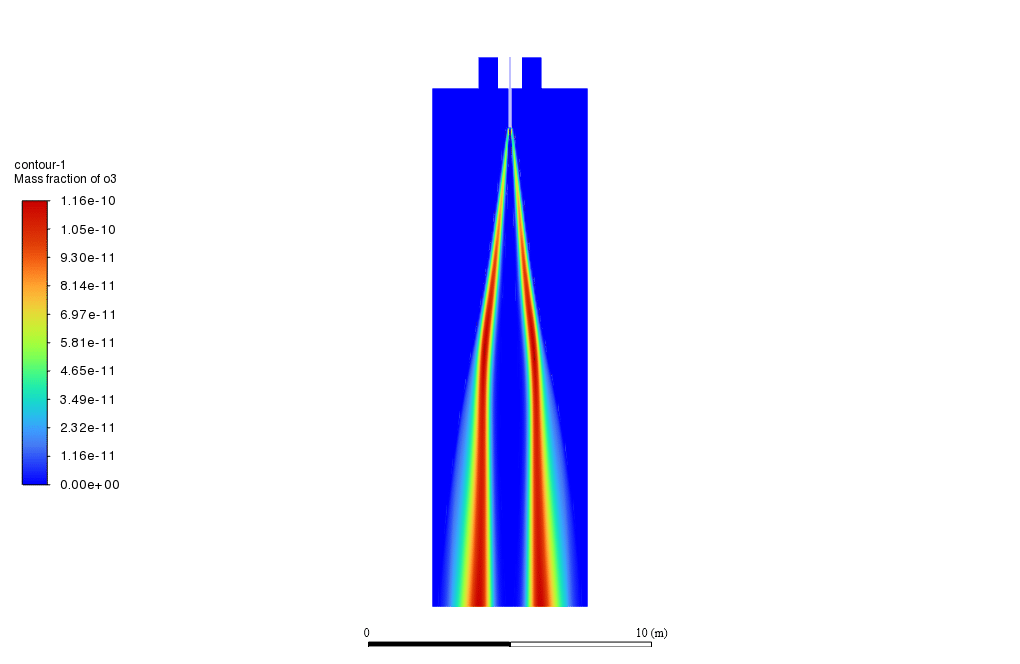

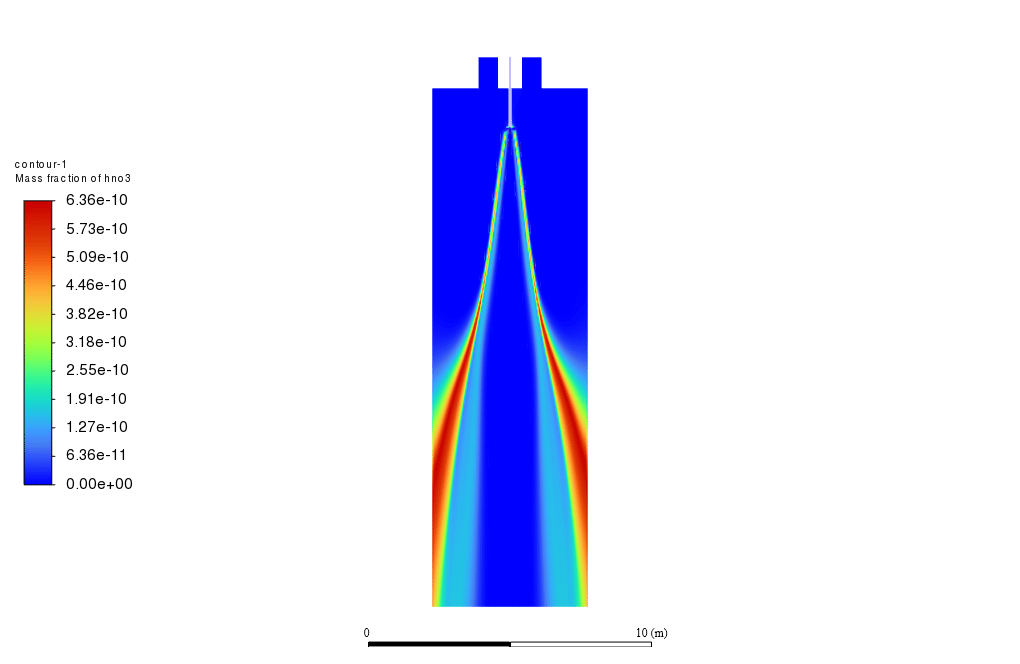

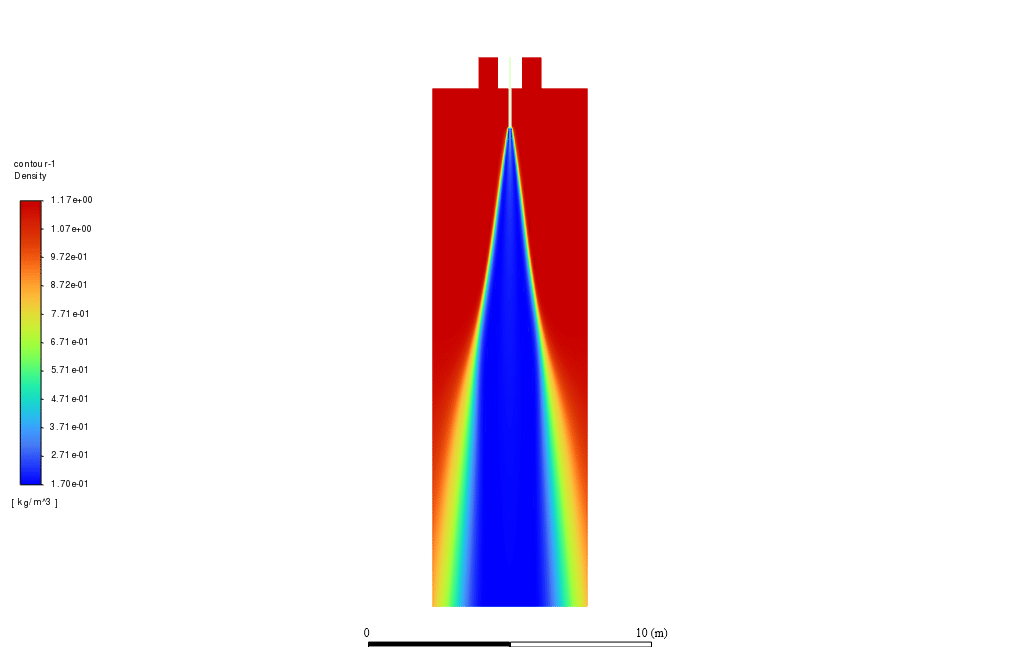

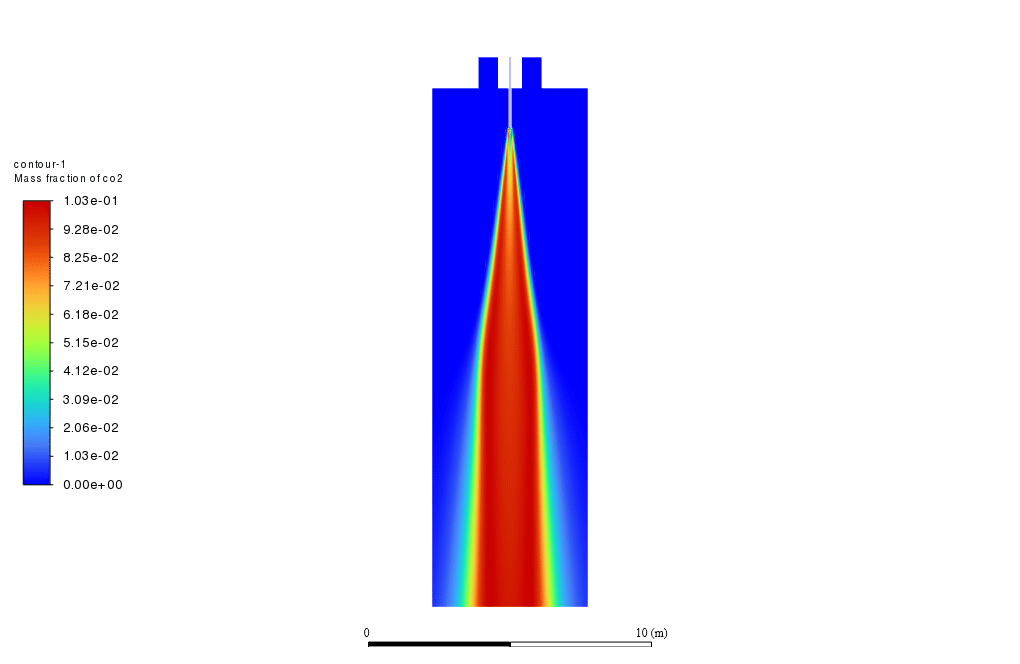

A PDF table is generated to store data related to changes in temperature, density of mixture, and different chemical species mass fractions prior to simulation to be used during the main calculations.

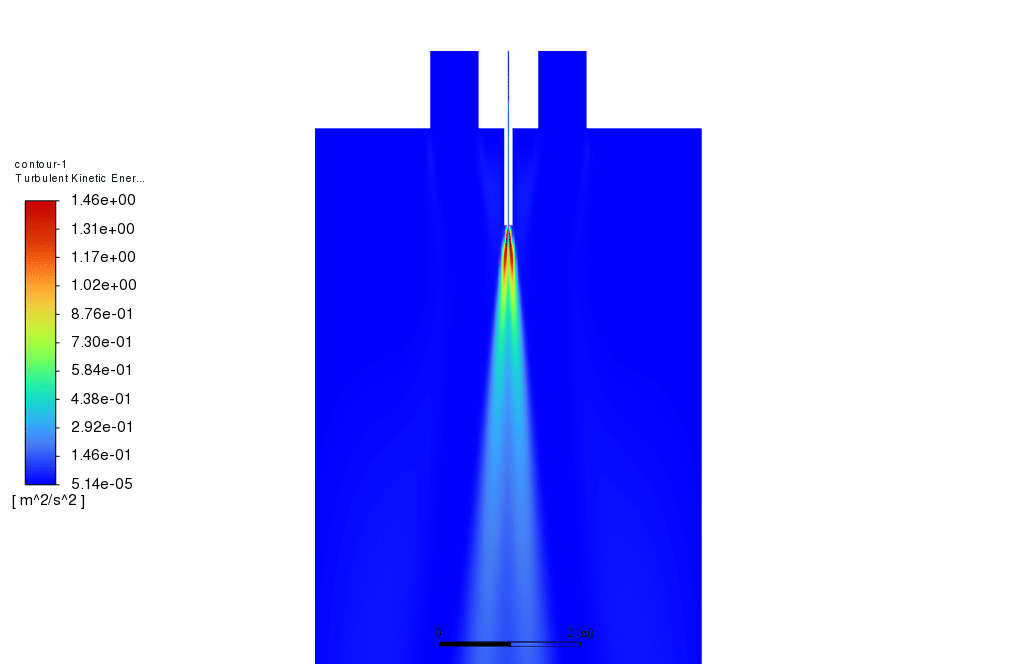

Also, the Energy equation is On to calculate the changes in temperature due to the combustion process, and the Viscous is set as the Standard k-epsilon model.

Non-Premixed Combustion Conclusion

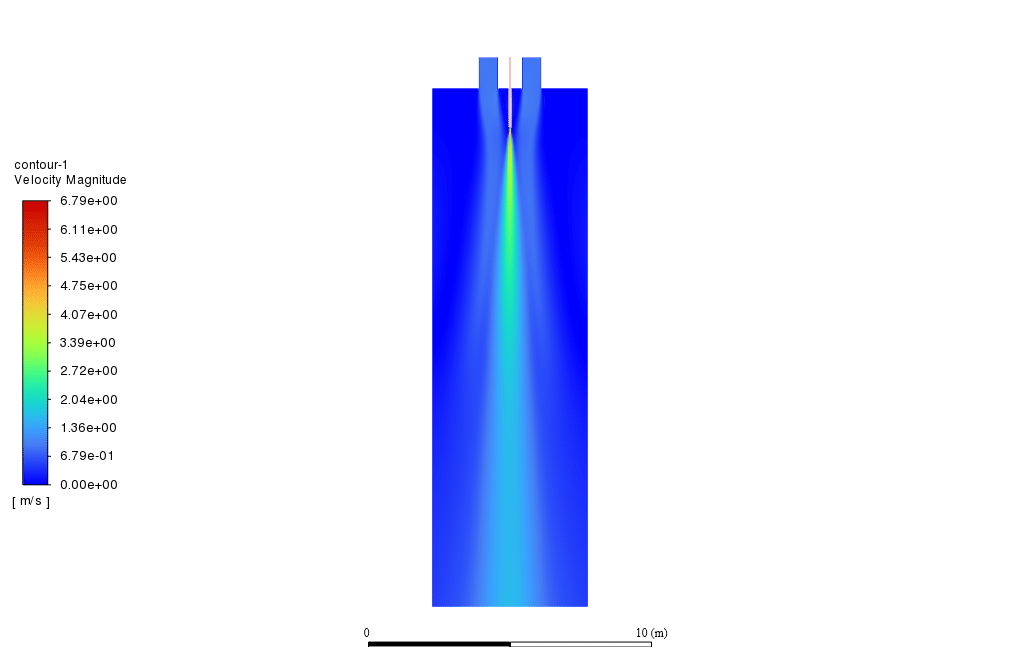

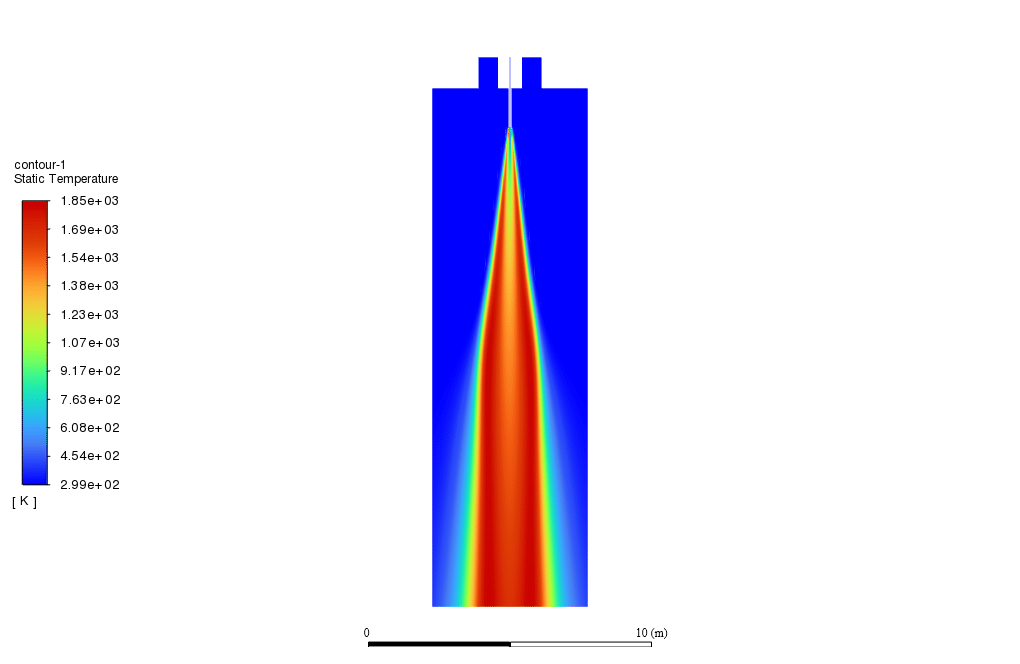

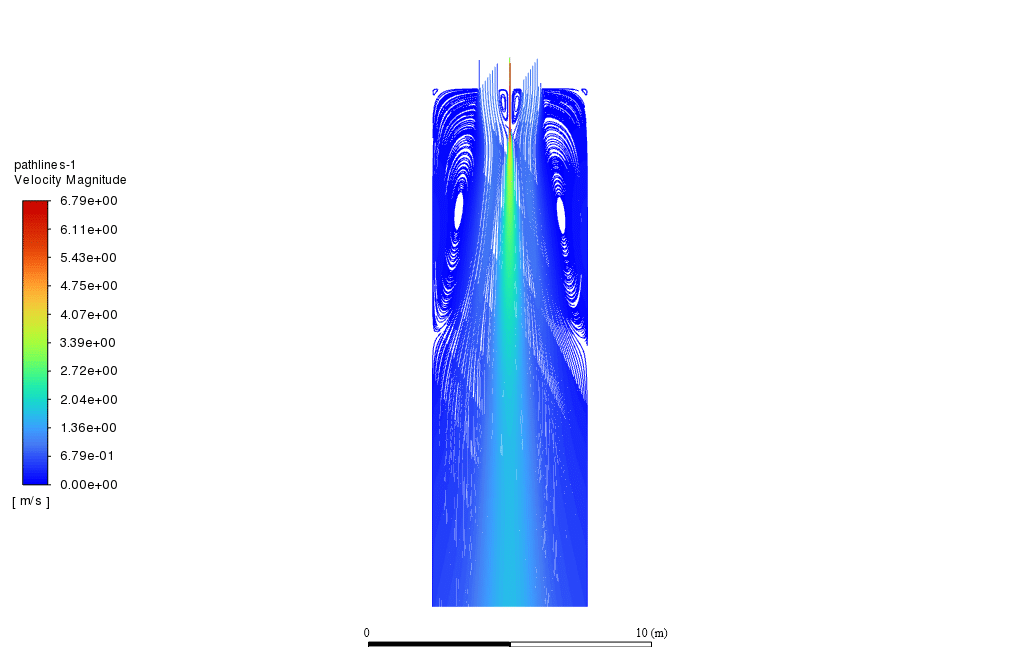

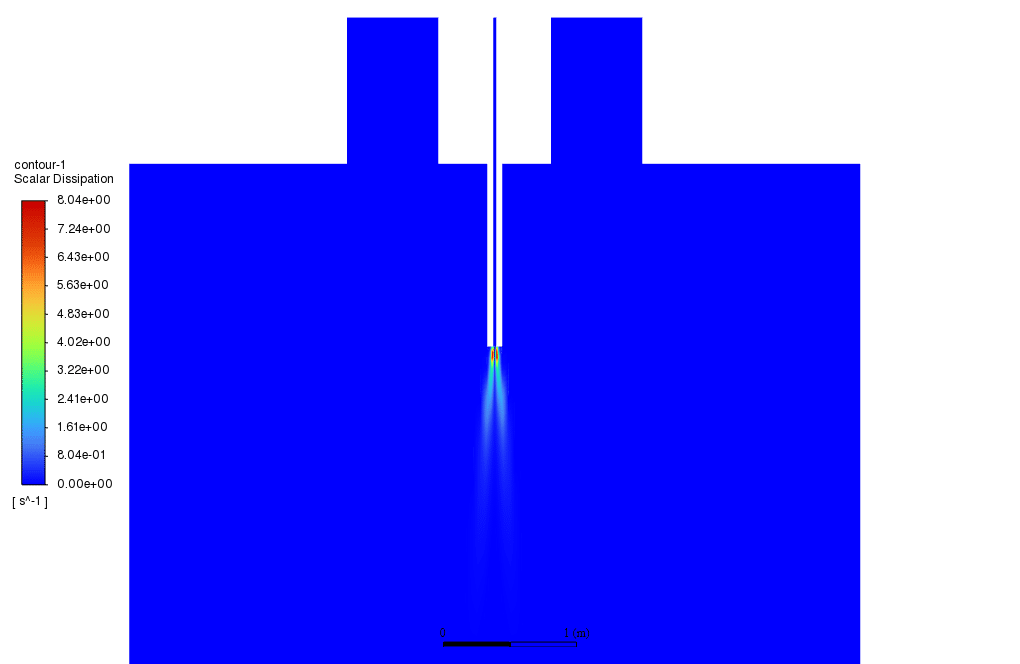

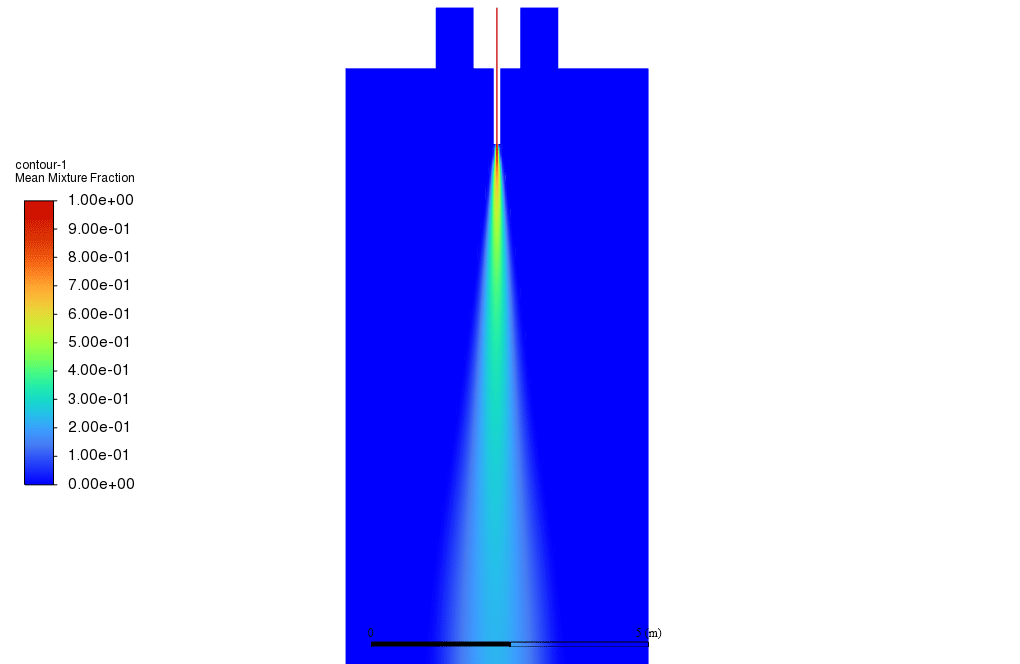

After the simulation process was finished, contours such as temperature, velocity, different species’ mass fractions, and streamlines are obtained. As shown in the temperature contour, the temperature has clearly increased in the chamber indicating that the combustion has taken place.

Also, the formed secondary flows in the chamber are shown in the streamlines. These secondary flows have the role of increasing the mixing process between fuel and air and hence enhancing the combustion process.

Dr. Salvador Erdman –

I learned a lot from the Non-Premixed Combustion training by MR CFD. The materials were well-organized and for such a complex topic, they made the learning curve much smoother!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you benefited from our Non-Premixed Combustion training. If you ever need more help or decide to take on another learning challenge, we’re here for you.

Mrs. Mable Miller DDS –

This product really clarified the combustion process for me, especially the part about the secondary flows and how they enhance combustion.

MR CFD Support –

Thank you for your feedback! We feel honored that our product helped in deepening your understanding of the non-premixed combustion process and the role of secondary flows. If you have any more questions or need further clarification, feel free to reach out.

Mr. Lafayette Kuhlman Sr. –

I’m strongly impressed by the depth of analysis your CFD training offers. The use of a non-premixed combustion model coupled with non-adiabatic and chemical equilibrium consideration provides essential insights, and the nuanced understanding of combustion within a combustion chamber. Your mention of secondary flows and their role in the mixing process was particularly illuminating. It sounds like this training is an invaluable resource for understanding complex combustion systems.

MR CFD Support –

Thank you for your enthusiastic feedback! We’re delighted to hear that the training has provided you with valuable insights into the complexities of non-premixed combustion. Our aim is to deliver comprehensive and detailed analyses that are useful for both learning and application in real-world scenarios. We are glad to have achieved that with you!

Mrs. Esta Graham Sr. –

The training material was comprehensive and very informative. I successfully applied the non-premixed combustion model to my project based on the techniques I learned.

MR CFD Support –

Thank you for sharing your positive experience with our Non-Premixed Combustion, Non-Adiabatic, Chemical Equilibrium ANSYS Fluent CFD Training. We’re thrilled to hear that the training material was beneficial for your project and that you found it to be comprehensive and informative. Your success in applying the concepts taught is the best compliment we could receive. It’s our goal to provide valuable and practical learning experiences. Keep up the great work and feel free to reach out if you have any further questions or need additional assistance.

Trycia Pfeffer –

The project looks comprehensive and well-explained. I particularly noticed the use of a PDF table. Can you clarify if users are guided on how to create or customize their own PDF table for different simulations?

MR CFD Support –

Sure! Users are provided with thorough instructions within the training material on how to generate and fine-tune PDF tables according to their specific simulation requirements and scenarios. This process typically includes setting up appropriate mixture fractions and reaction probabilities under various conditions, which are essential steps for a non-premixed combustion simulation.

Zelda Emmerich –

I found the training on non-premixed combustion quite insightful! The contours in the results showed a good grasp of chemical kinetics involved. Could you also confirm if slip walls or non-slip walls were used within the chamber?

MR CFD Support –

In the simulation of non-premixed combustion, non-slip wall boundary conditions are typically applied at the walls of the combustion chamber. This helps to simulate the friction between the chamber walls and the fluid, creating a more realistic depiction of the combustion process.

Mr. Khalid Hermann –

The training content for non-premixed combustion is very detailed and informative. The step by step simulations using ANSYS Fluent has enhanced my understanding of complex combustion phenomena. Definitely looking forward to more such in-depth courses!

MR CFD Support –

We’re thrilled to read your thoughtful review about our Non-Premixed Combustion course! It’s wonderful to know that the detail and structured approach of the training has contributed to a better grasp of combustion processes. Your eagerness for further learning motivates us to keep improving and expanding our course offerings. Thank you for choosing our training services!

Laurine Nolan –

I was really impressed by how the simulation captures the complexity of non-adiabatic combustion. The clear visualization of temperature changes and mass fractions was very educational.

MR CFD Support –

Thank you for your feedback. We are pleased to hear that the visualization in our non-adiabatic combustion simulation was educational and effective in demonstrating the complex processes involved. It’s our pleasure to provide quality learning materials that meet our customers’ expectations.

Emilia Cronin –

This training module looks extremely thorough. I’ve always been fascinated by how non-premixed combustion is simulated. The inclusion of a chemical equilibrium model must add significant accuracy to the simulation outcomes. Going forward with my projects, having such strong foundational knowledge is going to make a big difference.

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that our Non-Premixed Combustion, Non-Adiabatic, Chemical Equilibrium training module is providing you with the foundational knowledge you need for your projects. We strive to create detailed and accurate simulations to enhance understanding and application in practical scenarios. If there’s anything more we can help with in your learning journey, please let us know!

Geraldine Altenwerth –

This Non-PremixedCombustion training was incredibly clear and detailed.Once I grasped the concept of separate fuel and air entry boundaries, it all made sense. Seeing the increased temperature in the chamber was tangible proof of combustion. Streamlines showed how secondary flows aid the process! Excellent modelling and informative CFD course.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that our training on Non-Premixed Combustion has helped you understand the complexities of separate fuel and air boundaries in combustion simulations, and how secondary flows contribute to efficiency. It’s wonderful to know that you found the training clear, detailed, and useful. If you have any further queries or need more information on our training courses, feel free to reach out. Thanks again for choosing our training program!

Jeanette Davis DDS –

Marvelous detail and clarity in explaining non-premixed combustion processes. The training sounds comprehensive!

MR CFD Support –

Thank you very much for your kind words! We’re delighted to know you found clear and detailed explanations in our non-premixed combustion course. It’s our goal to provide effective educational materials, in-depth knowledge, and practical skills in CFD. Your feedback is highly valued and motivating.

Edwin Mraz –

I really appreciated the clear explanation of the non-adiabatic process and the use of chemical equilibrium in your combustion training. The concept of generating a PDF table before simulation for better efficiency was an insightful takeaway for me.

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the explanations and methodology insightful. The use of a PDF table for storing pre-computed data is indeed an important step to achieving accurate and efficient results in combustion simulations. If there’s anything more we can assist with, or another topic you’re interested in, let us know!