Packed Bed Reactor with Radiative Quartz Spheres

$120.00 $60.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Packed Bed Reactor with Radiative Quartz Spheres CFD Simulation

Introduction

This study investigates the heat transfer and fluid dynamics within a packed bed reactor using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the complex interactions between fluid flow, heat transfer, and radiation in a cylindrical vessel filled with spherical particles. By employing advanced models for turbulence, heat transfer, and radiation, this research provides valuable insights into optimizing packed bed reactor designs for various industrial applications, such as catalytic processes, thermal energy storage, and chemical processing.

The packed bed reactor consists of a cylindrical vessel containing 14 layers of spherical particles made of quartz. These particles act as heat sources, generating a significant amount of thermal energy within the system. The study focuses on analyzing the temperature distribution, fluid flow patterns, and radiative heat transfer within the reactor, which are crucial for understanding and improving the overall performance of such systems.

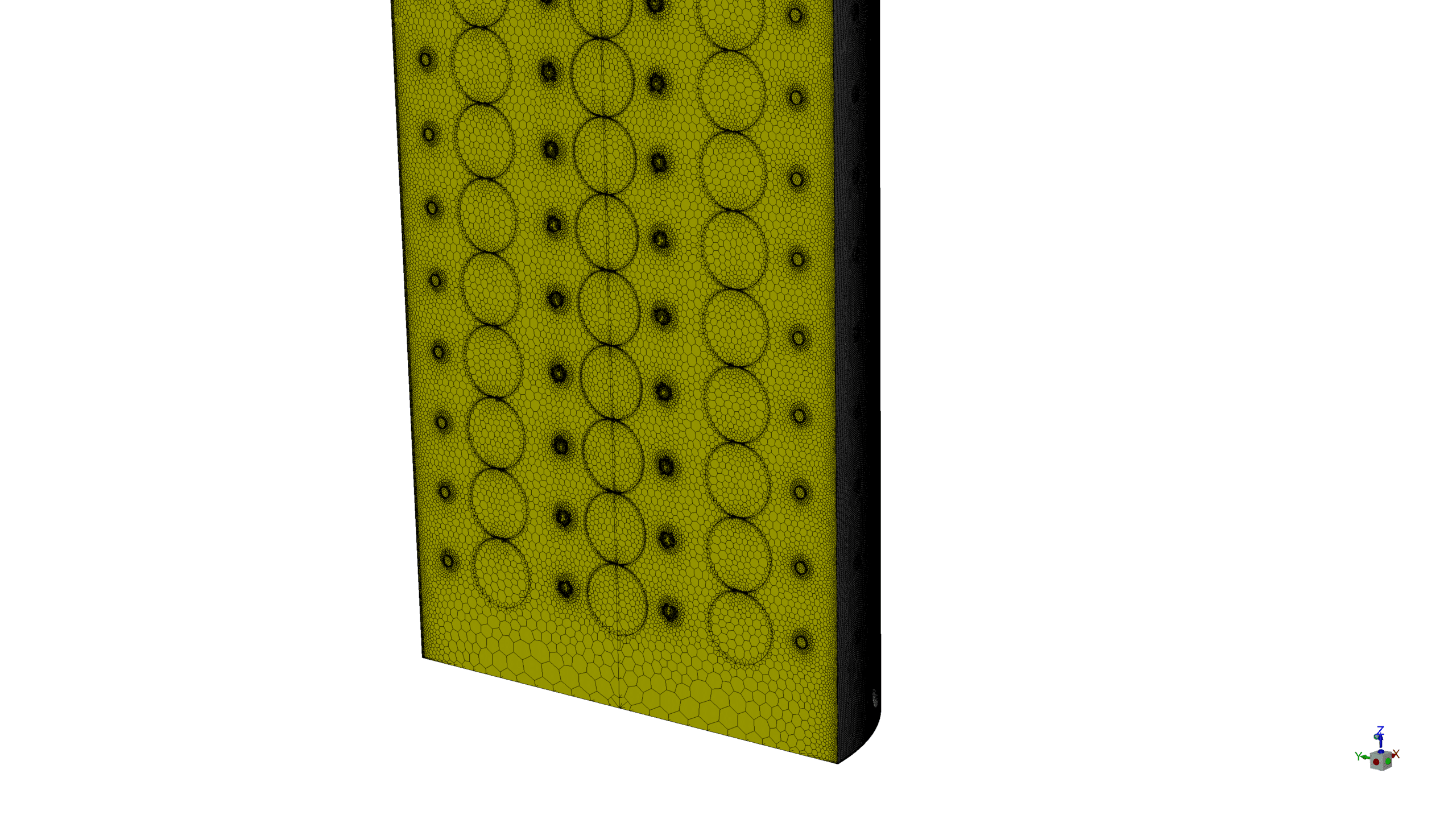

The CFD simulations were conducted using ANSYS Fluent software. The computational domain includes a cylindrical vessel with 14 layers of spherical particles. The geometry was designed using the ANSYS Design Modeler, which represents an industrial-scale packed bed reactor. The mesh was generated using ANSYS Meshing software, with approximately 4 million polyhedra elements, ensuring adequate resolution for capturing the complex flow and heat transfer phenomena around the spherical particles.

Methodology

The simulation was set up as a steady-state analysis using a pressure-based solver. The RNG k-ε model with standard wall functions was utilized for turbulence modeling, accounting for the complex flow patterns within the packed bed.

The energy equation was enabled to accurately model heat transfer within the system, which is crucial for capturing the thermal behavior of the reactor.

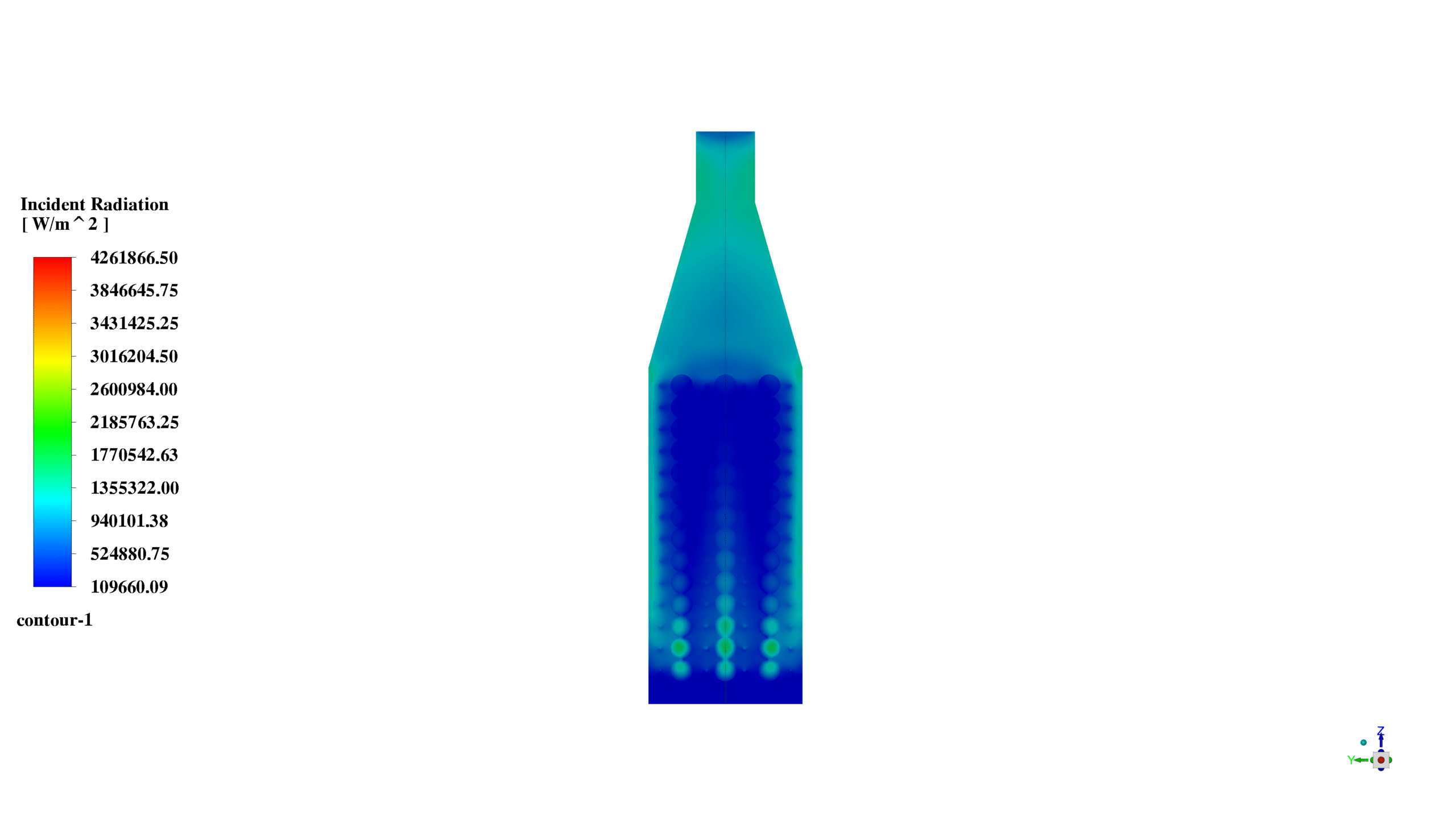

The Discrete Ordinate (DO) radiation model was activated to account for radiative heat transfer, which plays a significant role in high-temperature applications.

The spherical particles were modeled as quartz with piecewise-polynomial specific heat capacity and piecewise-linear thermal conductivity to accurately represent their thermal properties. Each sphere was defined as a volumetric heat source, simulating internal heat generation processes such as chemical reactions or electrical heating.

Results

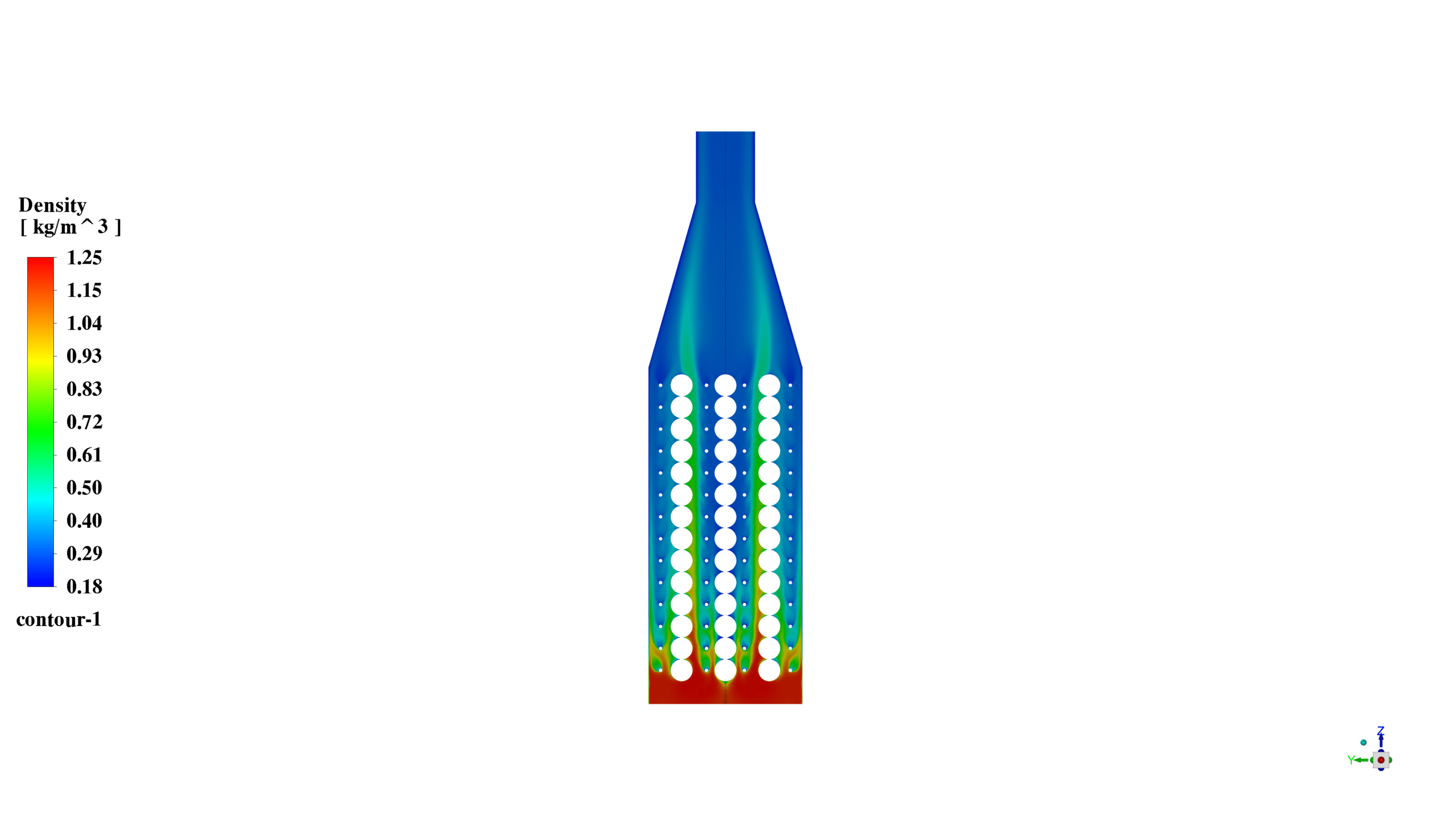

The CFD simulation provided comprehensive insights into the thermal and fluid dynamic behavior of the packed bed reactor:

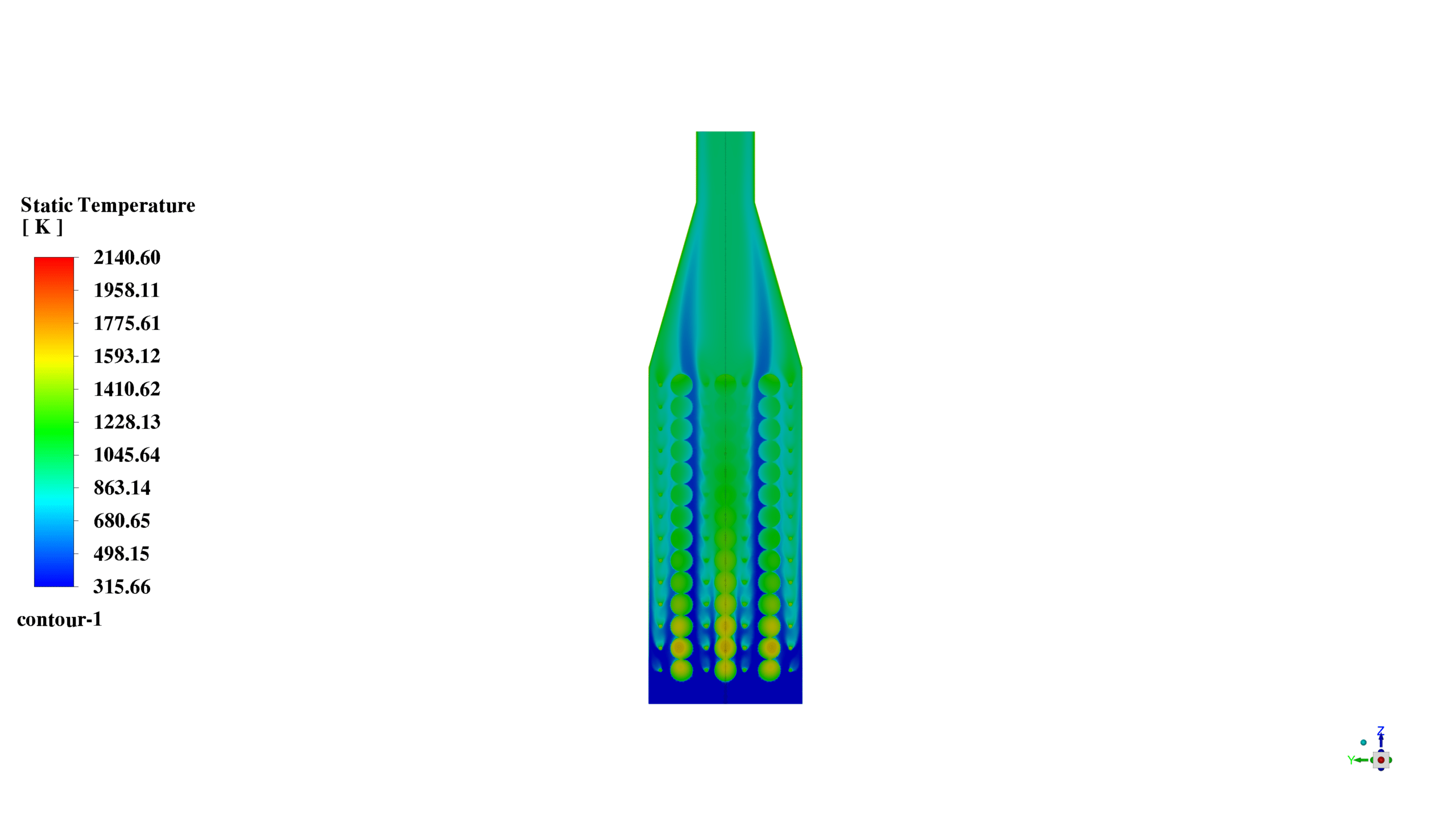

The simulation results show a significant temperature gradient within the reactor. The outlet temperature reaches 1120.819 K, indicating effective heat generation and transfer from the spherical particles to the fluid. The static temperature contour reveals that the highest temperatures are observed in the central region of the packed bed, with cooler zones near the walls and at the top of the reactor.

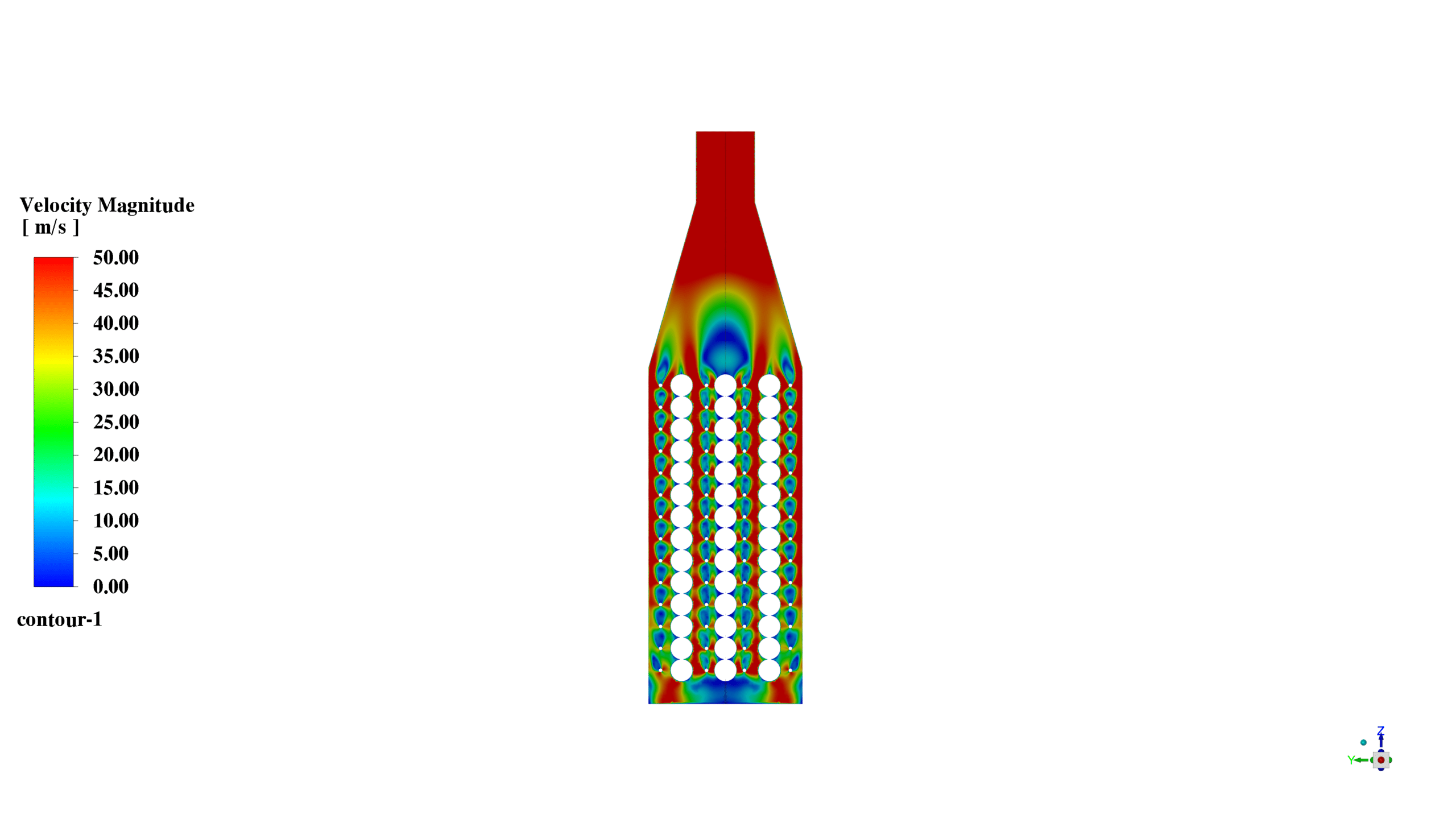

The velocity magnitude contour shows complex flow patterns within the reactor, with maximum velocities reaching 50 m/s in the narrow gaps between spheres. These high-velocity regions contribute to enhanced heat transfer between the particles and the fluid. The flow is characterized by acceleration and deceleration as the fluid navigates through the tortuous paths of the packed bed.

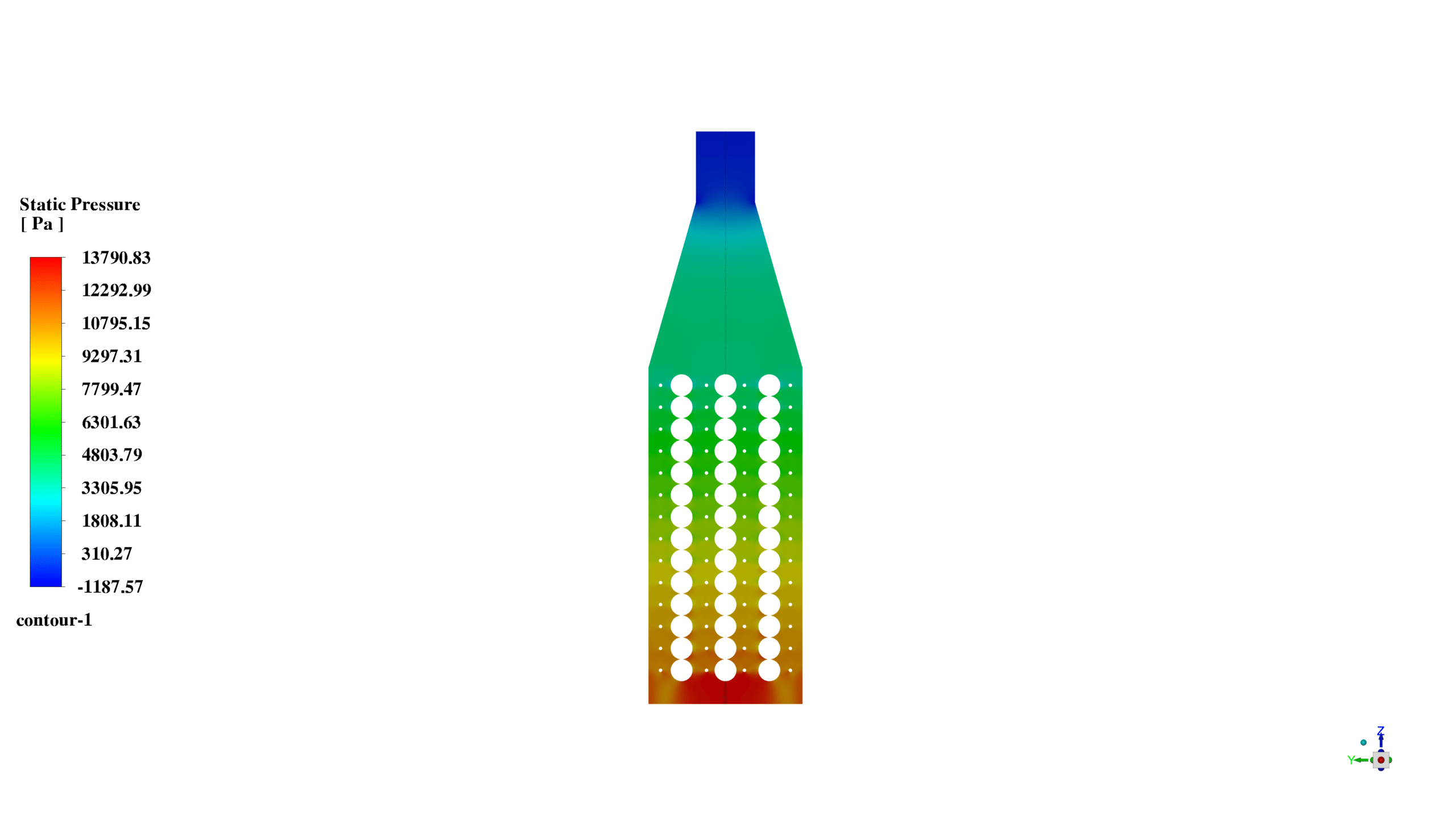

The static pressure contour indicates a pressure gradient from the bottom to the top of the reactor, which is typical for packed bed systems. This pressure drop is a result of the flow resistance caused by the spherical particles and plays a crucial role in determining the overall performance of the reactor.

The incident radiation contour demonstrates the importance of radiative heat transfer in the system. The highest radiation intensities are observed near the heat-generating spheres, with values reaching up to 4,261,866.50 W/m². This radiative heat transfer contributes significantly to the overall temperature distribution within the reactor.

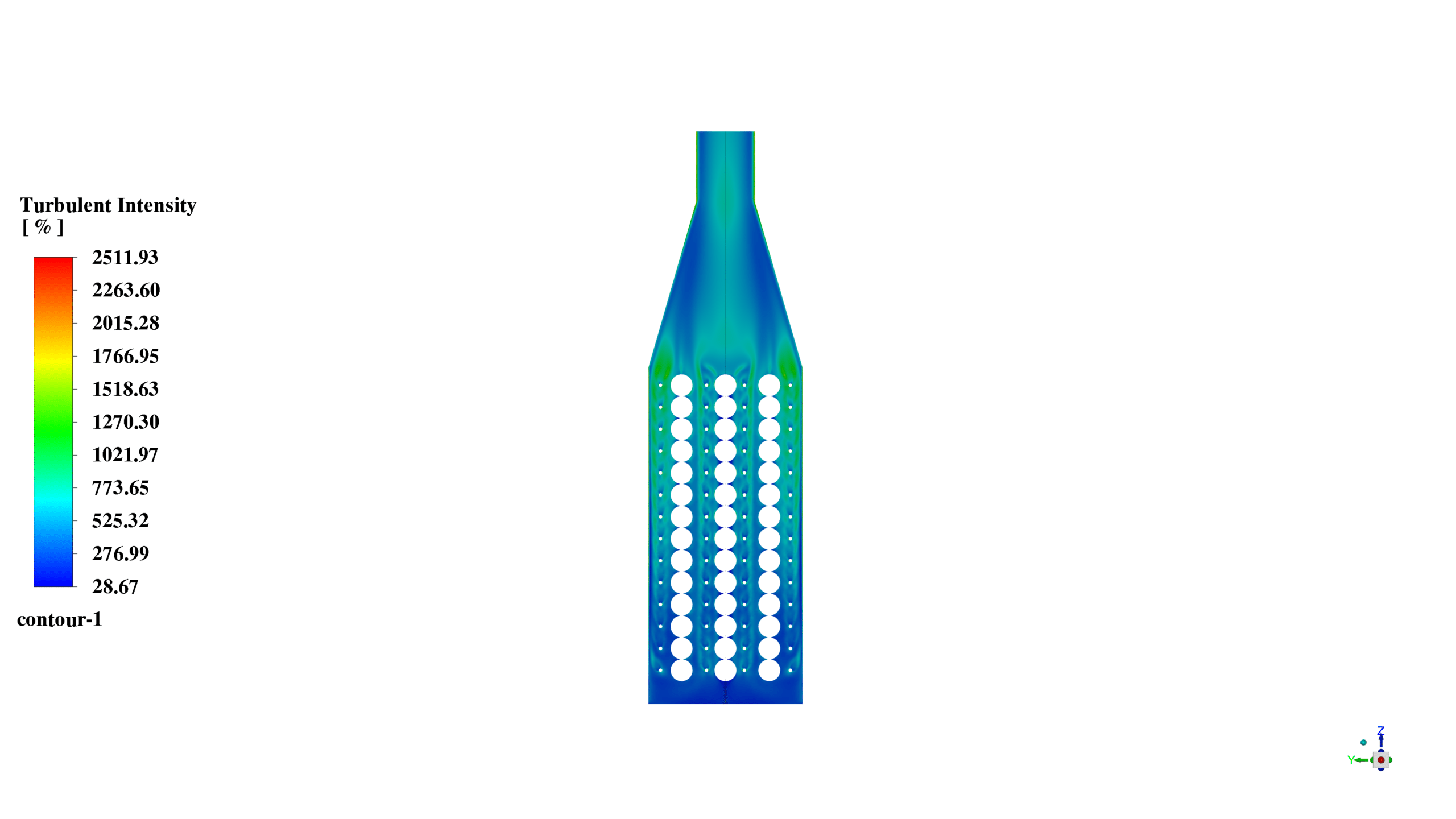

The turbulent intensity contour reveals areas of high turbulence, particularly in the spaces between spheres and near the reactor walls. The maximum turbulent intensity reaches 2511.93%, indicating highly turbulent flow conditions that enhance mixing and heat transfer.

The simulation results demonstrate the complex interplay between fluid flow, heat transfer, and radiation in the packed bed reactor. The temperature gradients and flow patterns highlight areas of efficient heat transfer as well as potential zones for optimization. The high outlet temperature of 1120.819 K suggests that the reactor is effective in transferring heat from the spherical particles to the fluid.

Reviews

There are no reviews yet.