Parallel Cylindrical Micro-Tubes Cooling by water flow using the VoF Model

$100.00 $50.00 Student Discount

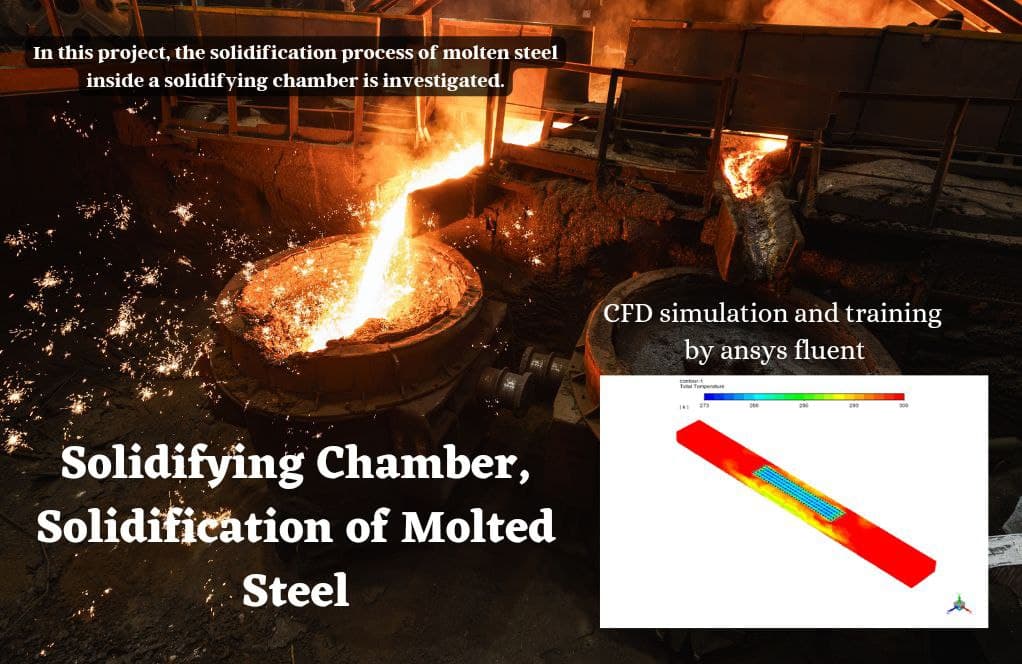

- This problem simulates Cooling of two parallel cylindrical micro-tubes using Ansys Fluent software.

- The 2-D geometry is designed in Design Modeler software.

- ANSYS Meshing software is used to generate the mesh; the element number equals 40,613.

- In this project, the Cooling by water flow is simulated using the VOF

- How water flows and reduces the temperature of the tube wall, in this project is well modeled.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

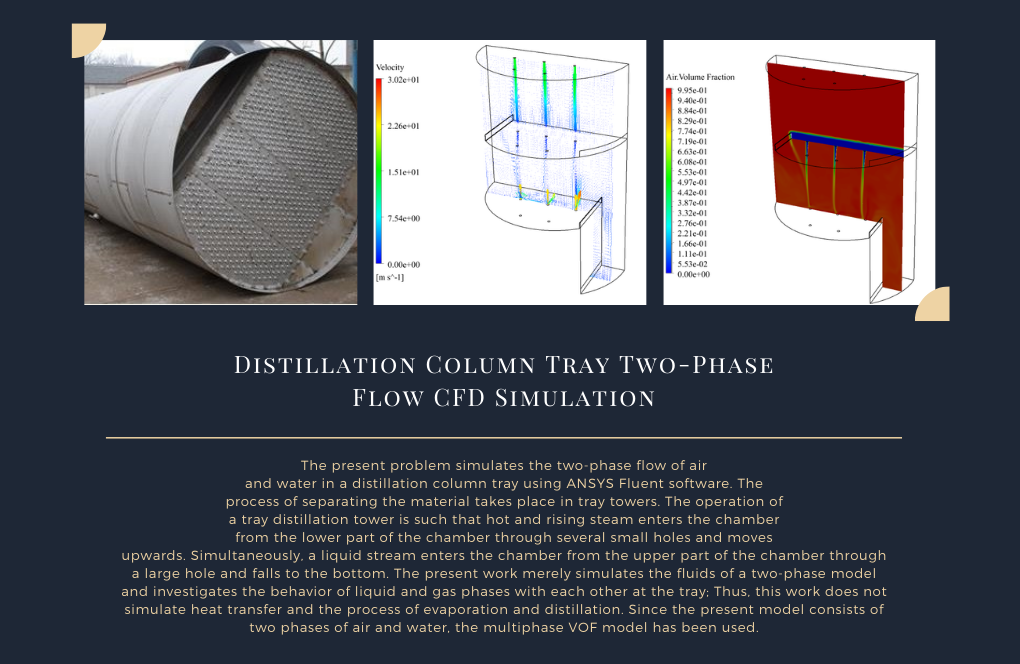

Parallel Cylindrical Micro-Tubes Cooling by water flow using the VoF Model, ANSYS Fluent

Description

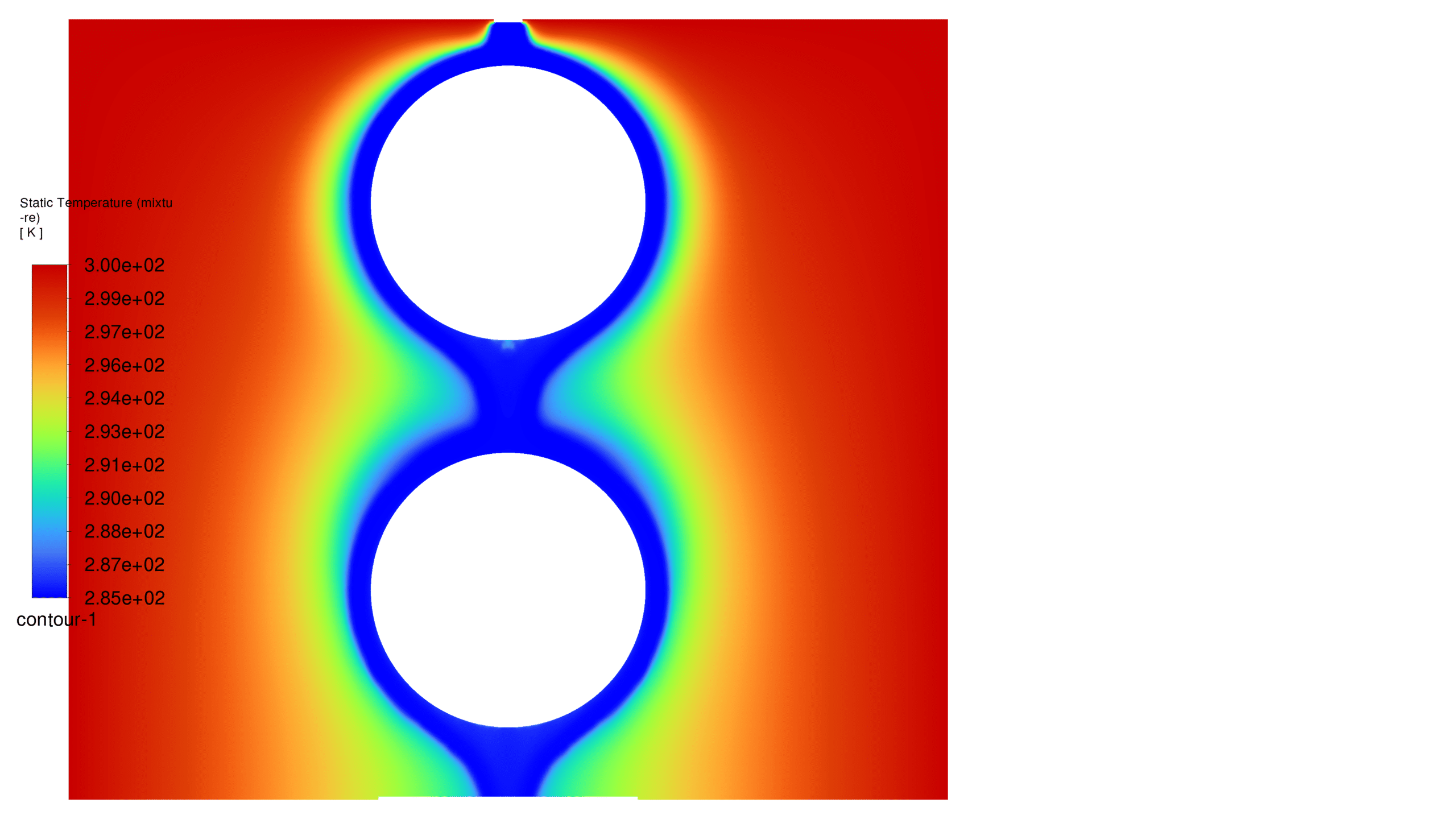

To cool cylindrical pipes, a water flow cooling system is typically employed. In this method, water is poured from above over the pipes, and as it flows downward, the heat will be taken from the pipes, reducing their temperature. The efficiency of this method depends on factors such as the water flow rate, the temperature of the incoming water, and the contact surface area between the water and the pipes. Usually, special basins or tanks are used to collect and recirculate the water to optimize water consumption. This method is a simple and effective cooling technique used in various industries.

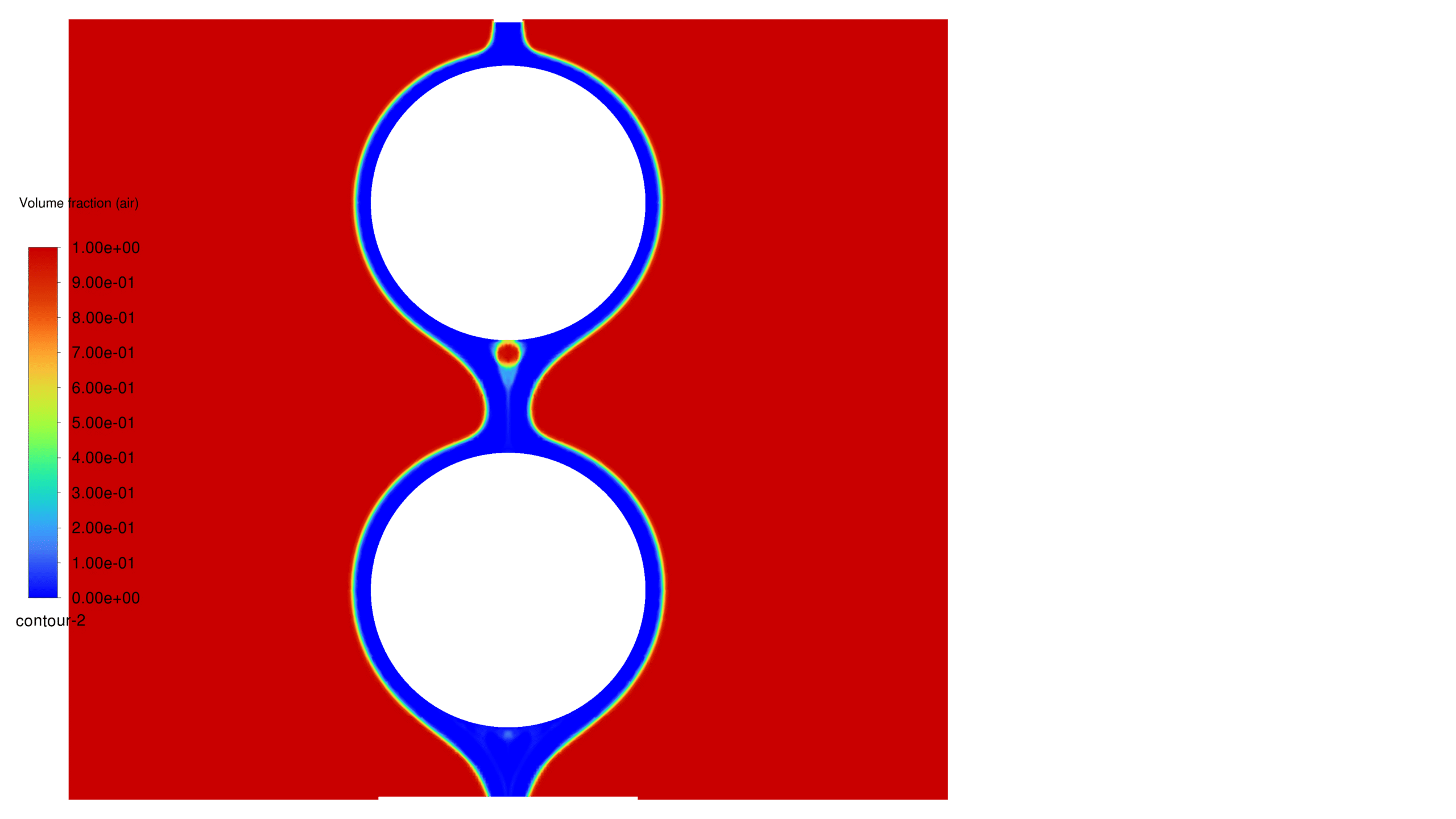

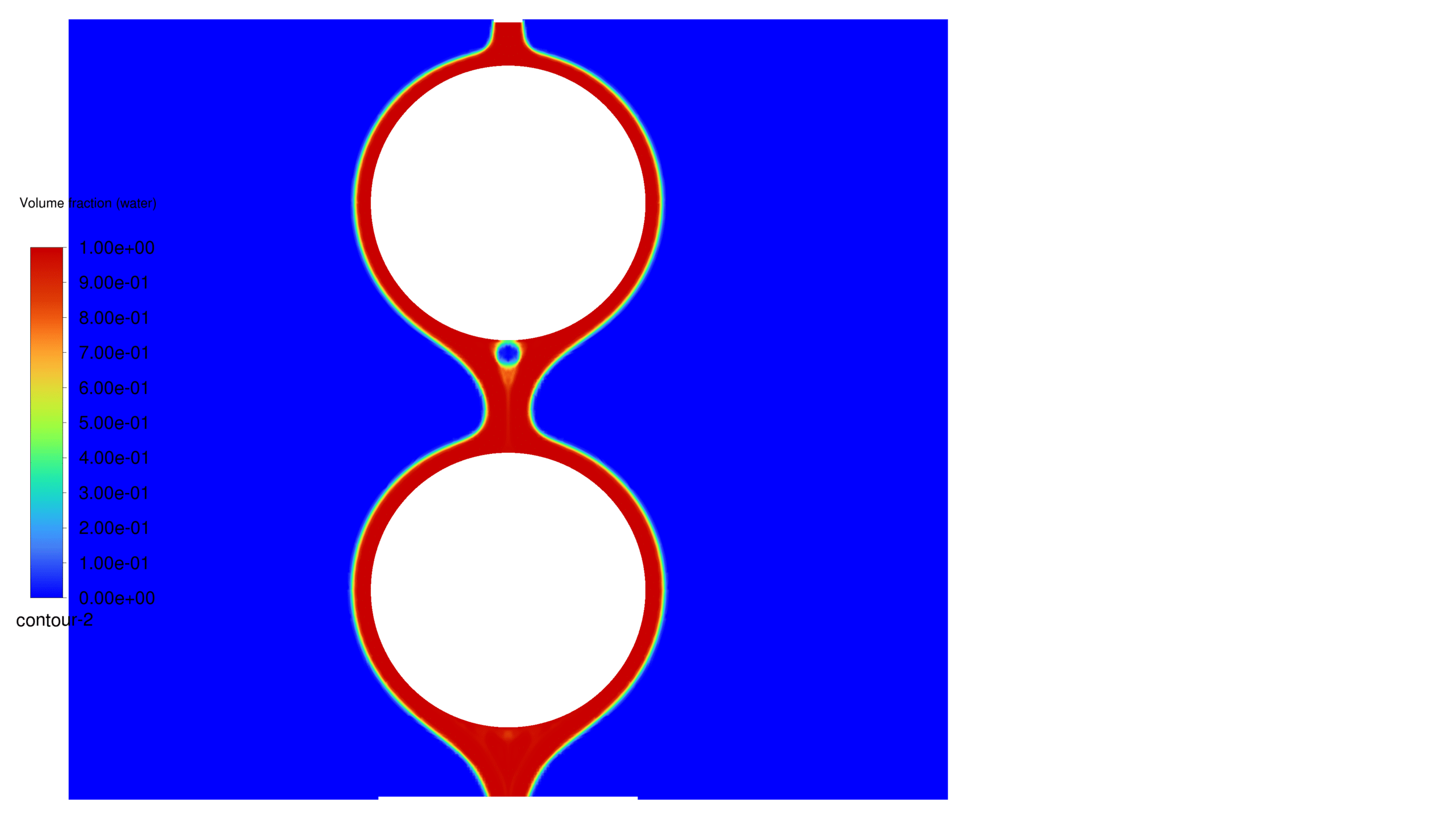

Ansys Fluent software provides the VoF model, which is a homogeneous model, for two or multi-phase flows where all phases are continuous and have a defined interface. The main goal of this model is to find this specific interface. The VoF model uses a special discretization to discretize the volume fraction equation, which makes the interface between the phases well modeled. To use this model, it must be observed that the mesh size is very small in the places where we have an interface.

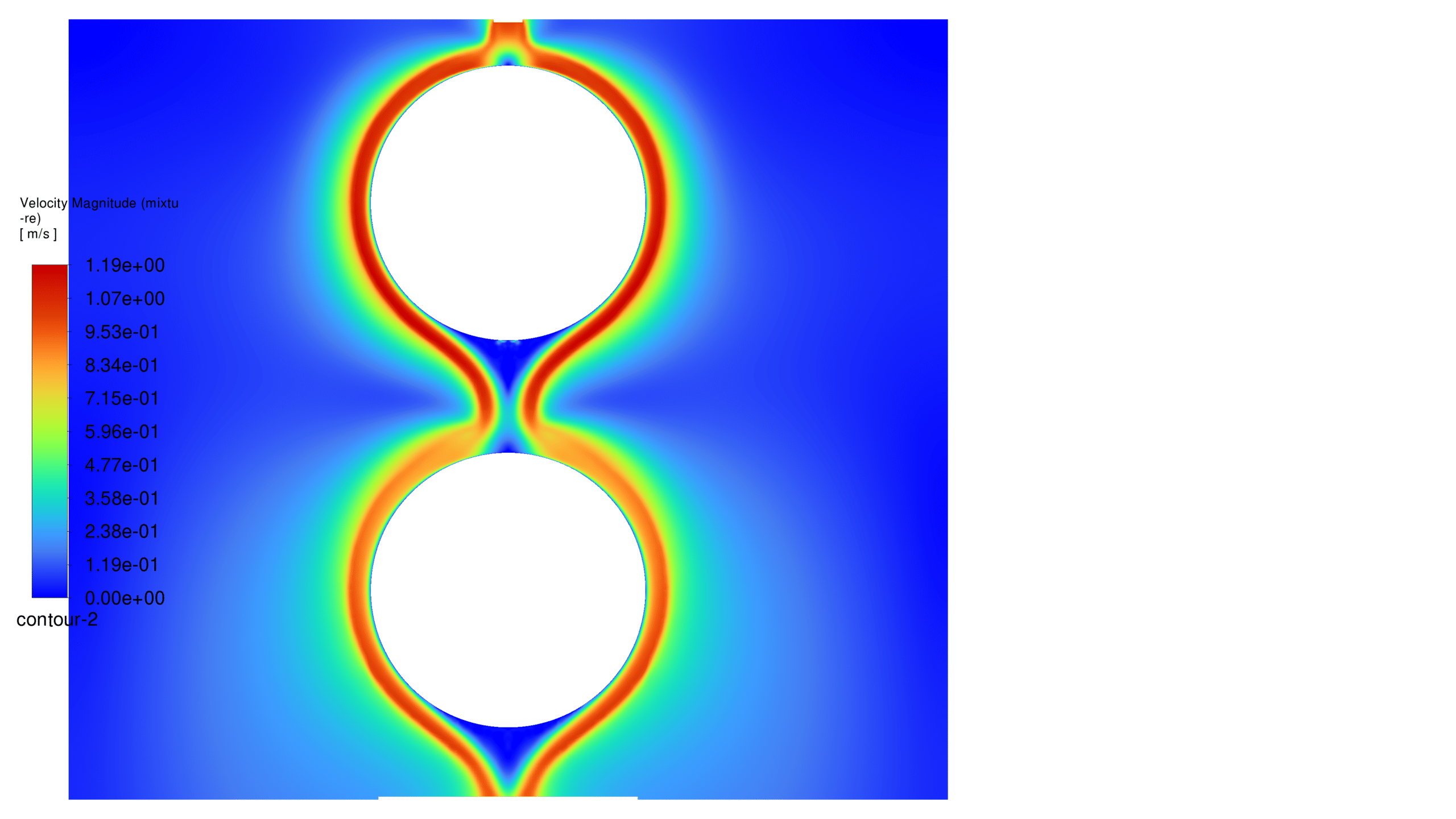

In this project, how the water flows over two tubes, and the cooling of the water flow at two different inlet velocities, is well modeled. A water inlet of 2 mm and an outlet of 18 mm are provided in the tank with dimensions of 6.1 cm x 5.41 cm. And two cylindrical tubes are placed in the middle of this tank, whose diameter is 0.9525 cm. For simplicity, the project is solved in one plane of the real shape, i.e. in two dimensions. Also, since the project is symmetrical, we solve half of it and generalize to the other half. For two cases where the inlet water velocity is 1 and 2 m/s, the project is solved, the temperature difference on the walls is obtained and the flow pattern is displayed.

CFD simulation methodology

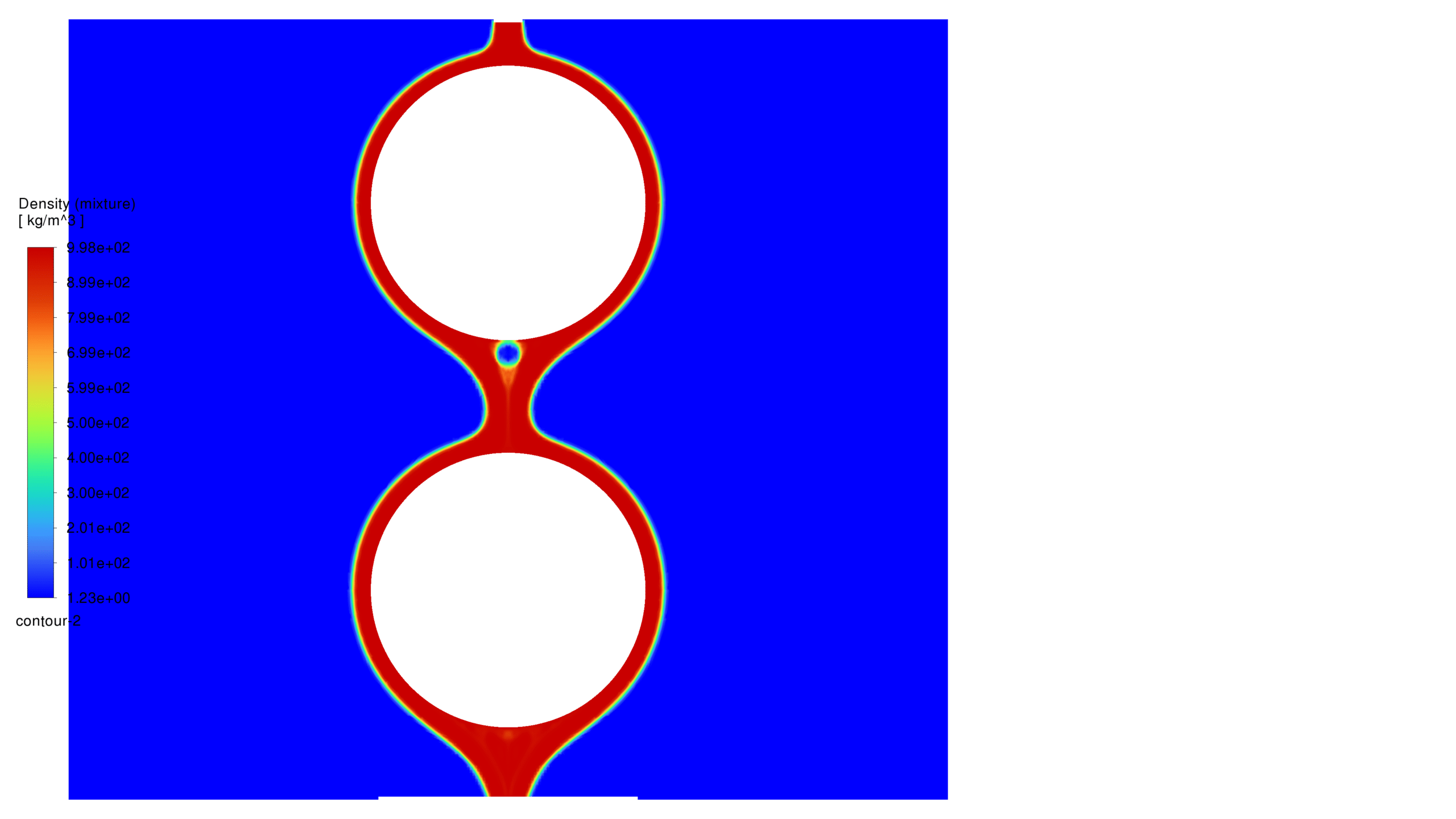

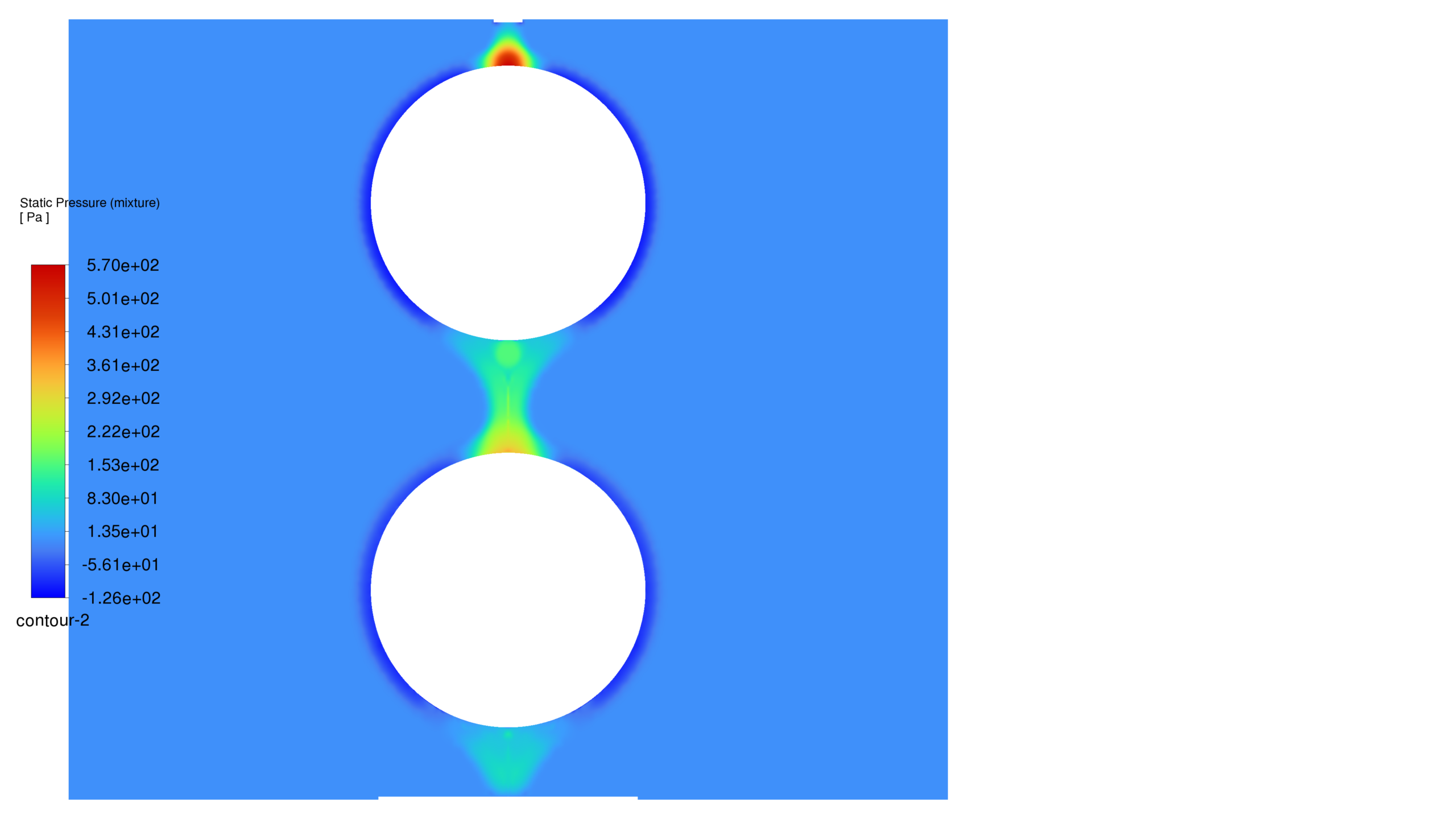

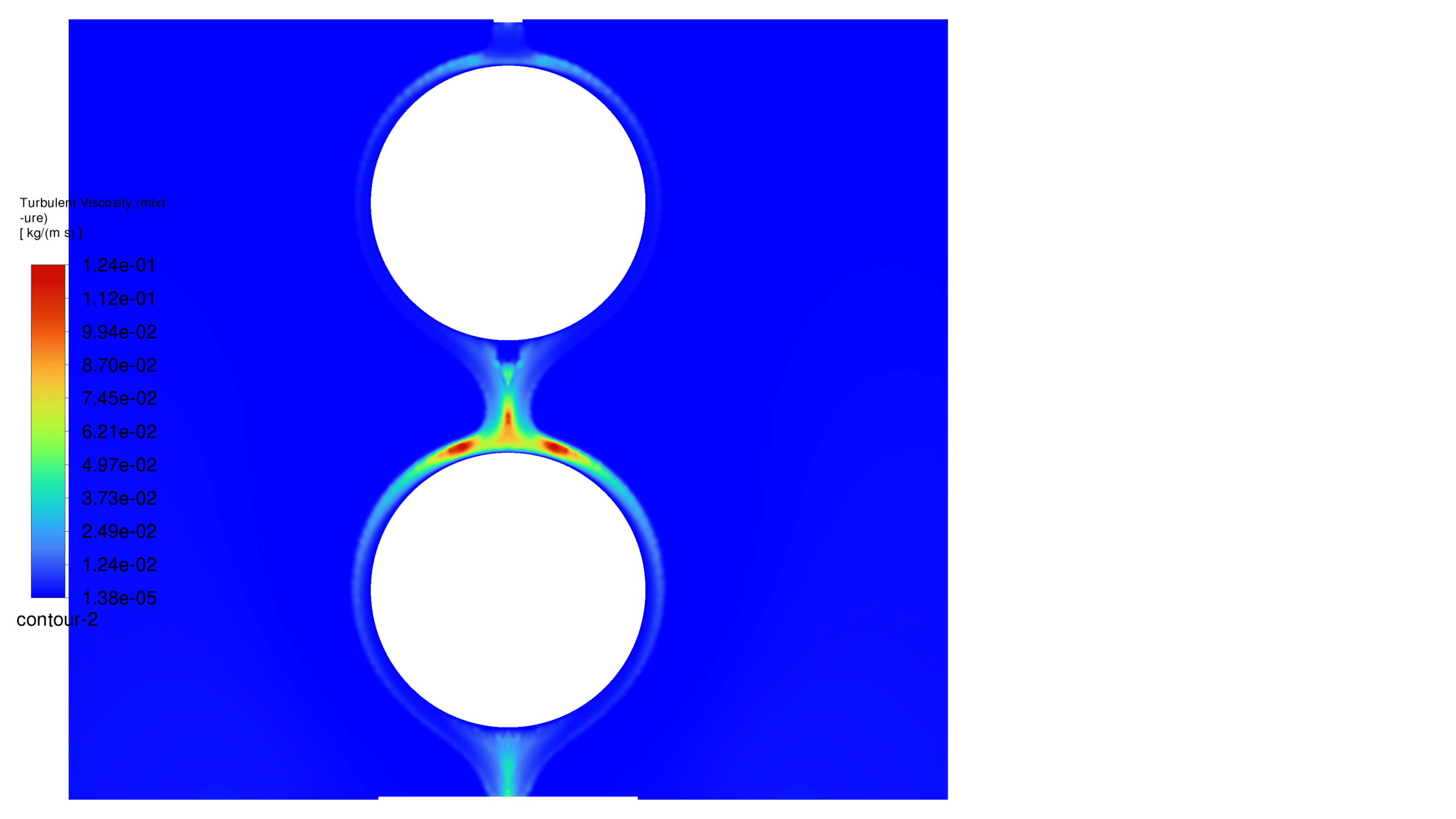

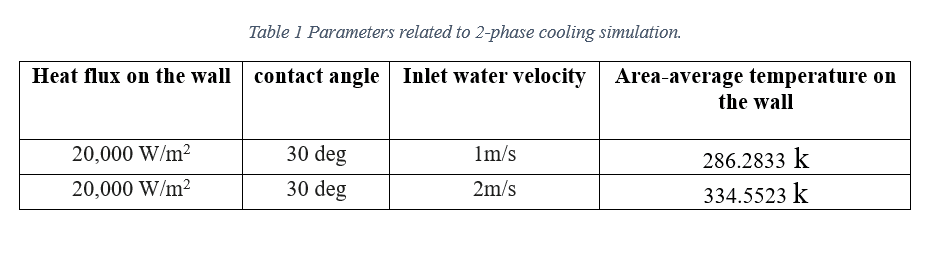

In this project, the geometry is generated in Design Modeler and meshed in ANSYS Meshing with 40613 elements. For simulation, VOF multiphase flow model has been used. The project is two-phase and the phases are air and water. For the initial conditions, it is considered that the entire tank containing the tubes contains air and as soon as the solution starts, water flows from the corresponding inlet. It should be noted that the simulation is done transiently. In this project, gravity is active and has a y-component. It is evident that to take temperature considerations into account, the energy equation is active. It is assumed that the walls of the tubes have a constant heat flux equal to 20,000 W/m2. And the thickness of these walls is 0.002 m. It should be noted that the contact angle between air and water is considered to be 30 degrees, which means that the walls can be considered hydrophilic.

Conclusion

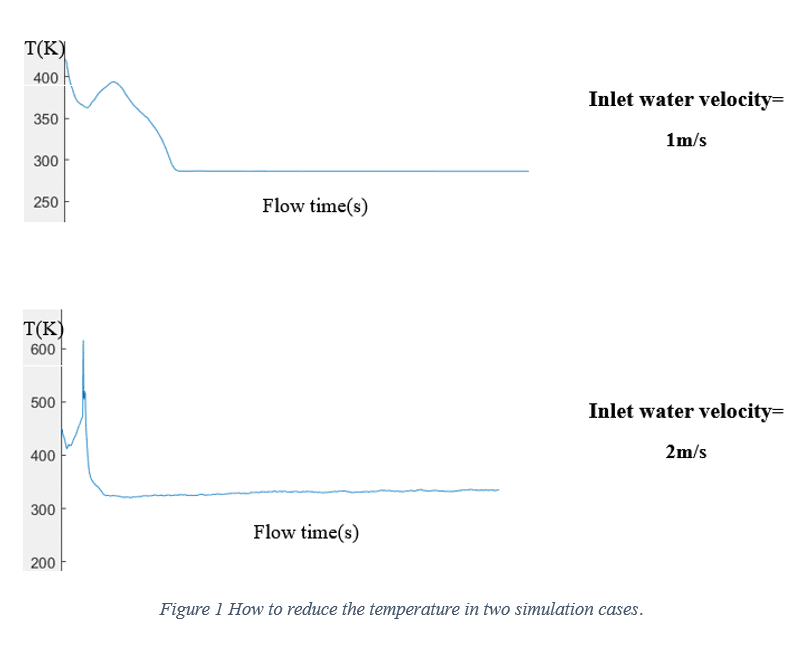

At the end of the solution process, two-dimensional contours related to pressure, velocity, viscosity, density, water volume fraction, air volume fraction and static temperature were obtained for each case. The parameters related to this simulation are listed in Table 1. It is also shown in Figure 1 how the temperature of the walls decreases for each case. As it is clear from the graphs, for the conditions prevailing in this project, water with a lower speed can do better cooling. Of course, as can be seen from the graphs in Figure 1, higher inlet velocities provide cooling in less time. The reason for this is that higher velocity brings more convection.

Finally, for a better understanding, an animation of how the temperature drops and how the water flows on the tubes have been prepared. By comparing these two situations, you will fully understand how the water flow leads to the cooling of the tubes.

Reviews

There are no reviews yet.