Erosion due to Particle Flow in Elbow using DPM CFD Simulation, ANSYS Fluent

$100.00 $50.00 Student Discount

- This problem simulates Erosion due to particle flow using Ansys Fluent software.

- The 2-D geometry is designed in Design Modeler software.

- ANSYS Meshing software is used to generate the mesh; the element number equals 14,029.

- In this project, the Erosion due to particle flow is simulated using the DPM

- How the particles flow and lead to the erosion of the solid surface has been well-modeled in this project.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

The current project focuses on the numerical simulation of particle motion and erosion in an elbow-shaped pathway using Computational Fluid Dynamics (CFD). The main objectives of this project are to investigate the behavior of particles when they encounter the elbow walls, predict the flow pattern and particle distribution within this geometry, and simulate the erosion caused by particle impacts on the elbow surfaces. The simulation has been carried out using the ANSYS Fluent software and the Discrete Phase Model (DPM) module. The DPM module allows for the tracking of particle trajectories in a Lagrangian manner while considering fluid-particle interactions and modeling particle collisions with the walls. Furthermore, erosion rates and patterns are predicted based on empirical or semi-empirical erosion models, taking into account factors such as particle velocity, impact angle, and material properties. The results obtained from this simulation provide a better understanding of particle transport phenomena and erosion mechanisms in elbow-shaped ducts, which have applications in various industries. The erosion simulation results help identify the regions of the elbow that are most susceptible to erosion damage and are useful in optimizing elbow designs and selecting appropriate materials to minimize erosion effects. The findings of this study can contribute to the development of effective erosion mitigation strategies and improve the reliability, efficiency, and safety of systems involving particle-laden flows in industrial applications.

The DPM (Discrete Phase Model) module is a powerful tool in the ANSYS Fluent software that is used for simulating the behavior of particles in a fluid flow. This module allows users to track the trajectories of particles in a Lagrangian framework while considering the interactions between particles and the fluid.

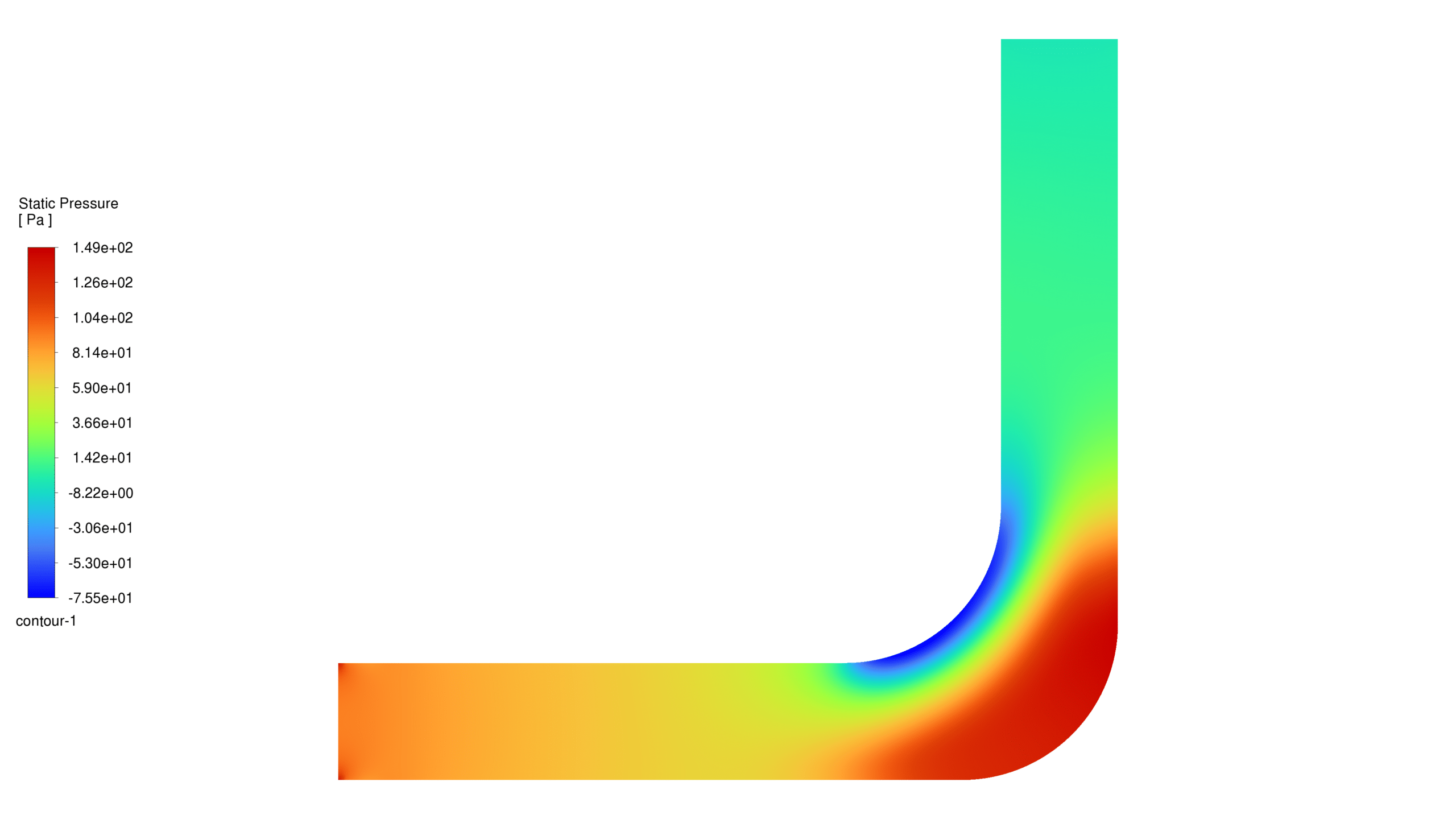

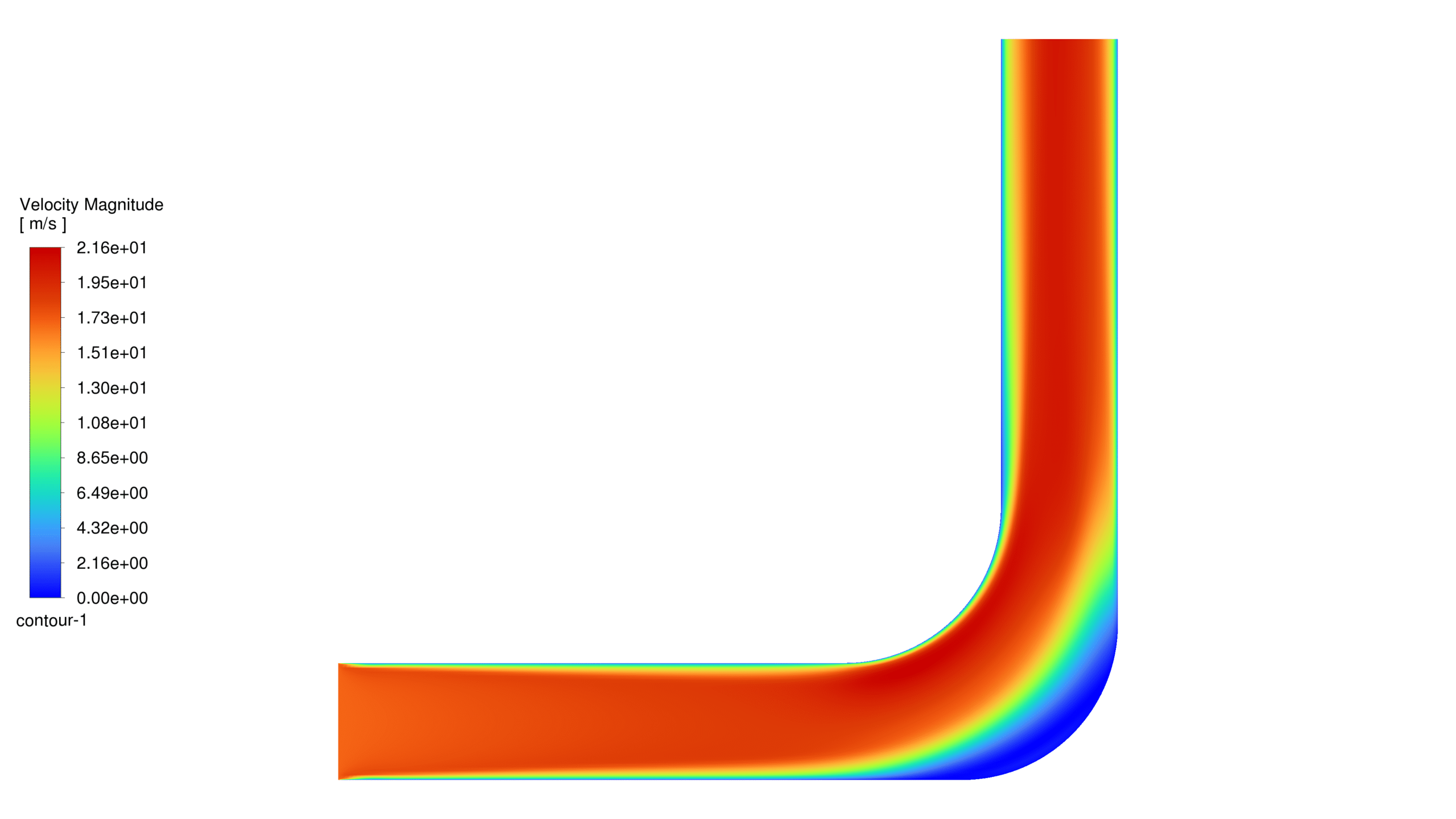

In this project, a two-dimensional elbow has been designed with a length of 0.04 meters in the x-direction and 0.038 meters in the y-direction. The width of this elbow in the straight sections is considered to be 0.006 meters. The radius of the curvature for the middle section is set to 0.008 meters. The air flow enters the elbow from the inlet with a velocity of 17 meters per second. Additionally, anthracite particles with a diameter of 0.003741 meters are introduced into the elbow from the inlet using a Lagrangian approach, with a velocity of 4 meters per second.

CFD simulation methodology

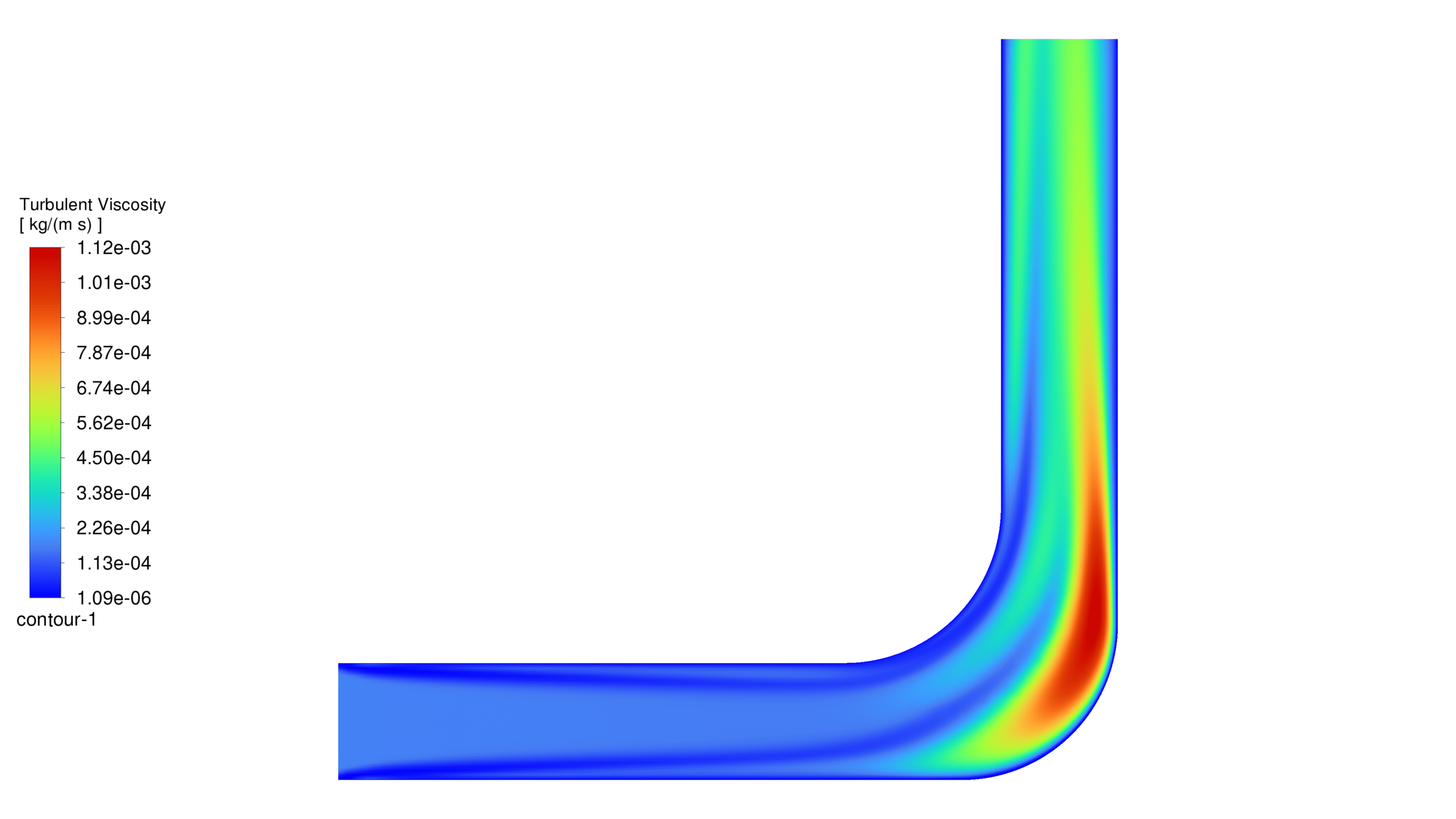

In this project, the geometry is generated in Design Modeler and meshed in ANSYS Meshing with 14029 elements. In the simulation, the effects of compressibility have been neglected; therefore, a pressure-based solver has been utilized. Furthermore, the results have been obtained for the steady-state condition, and the influence of gravity has also been disregarded. For modeling the turbulent flow, the standard k-epsilon (k-ε) model has been employed. Furthermore, in this project, the DPM (Discrete Phase Model) module has been employed for particle tracking. Within this module, the erosion model is activated to account for erosion. Additionally, an injection has been defined in which the particle type is set as inert and the material is anthracite. The boundary condition type for the discrete phase at the inlet and outlet is defined as “Escape”, while for the walls, “Reflect” is considered. Moreover, all five models, namely Generic, Finnie, McLaury, Oka, and DNV, are activated to account for erosion on the walls.

Conclusion

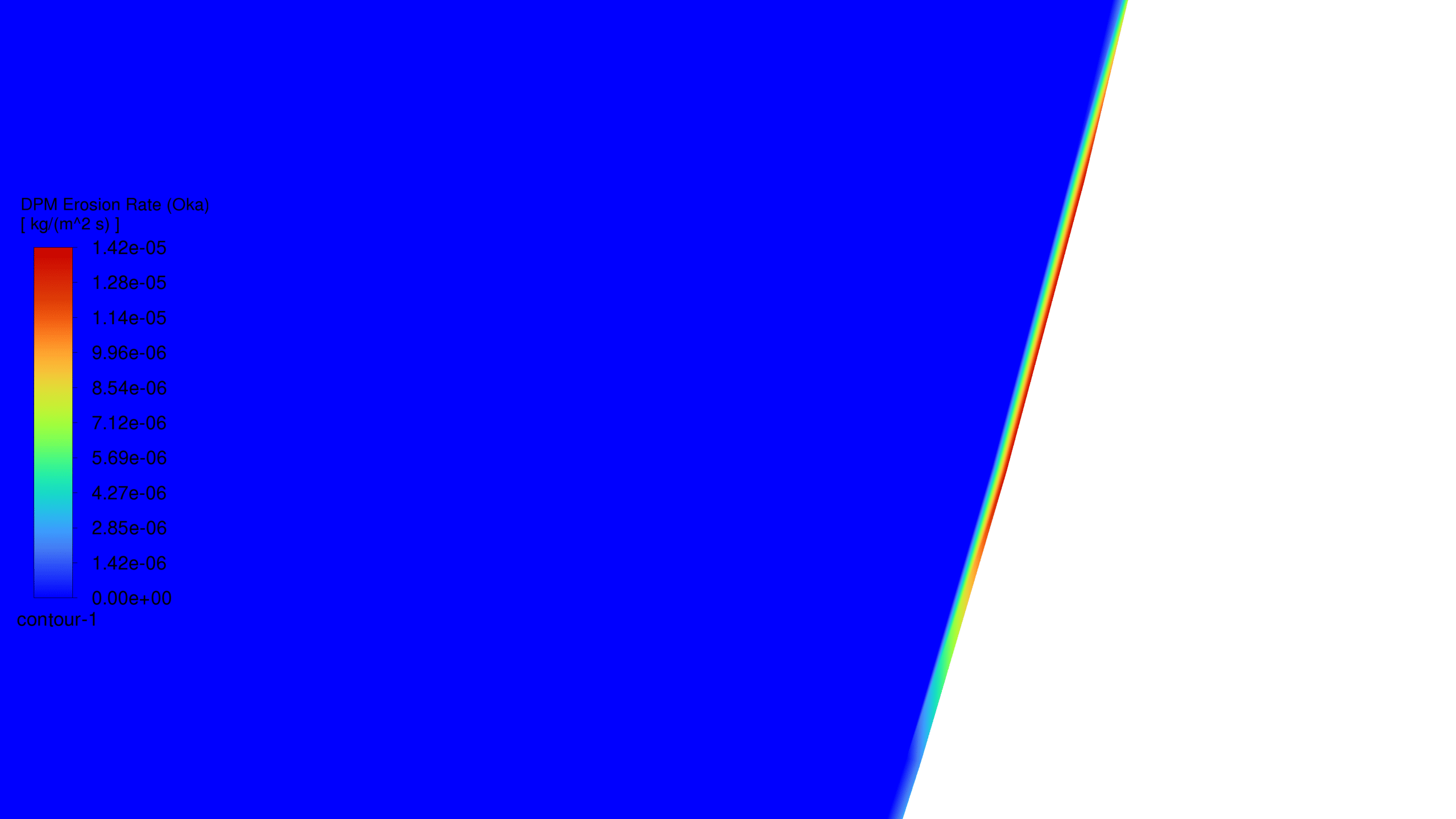

At the end of the solution process, two-dimensional contours related to pressure, velocity, viscosity and Particle Tracking were obtained. As expected, more erosion has occurred in the middle regions of the elbow due to the higher impact of the particle flow with the solid surface.

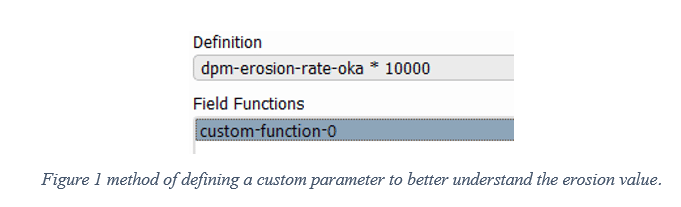

If we take a area-average of the erosion value, we see that the value of this parameter is extremely small, which is difficult to display in the report definition and contour sections due to its small magnitude. Therefore, we define a custom parameter and observe values that are 10,000 times larger. However, note that the actual value is still that extremely small value. The method of defining this custom parameter is shown in Figure 1.

Finally, the maximum erosion rate of DPM (OKA) is obtained as

; Using the custom parameter we defined, which magnifies the erosion values by a factor of 10,000, the maximum erosion rate of is displayed as 0.142 in the output results. This scaled-up value allows for better visualization and analysis of the erosion patterns while keeping in mind that the actual maximum erosion rate remains at .

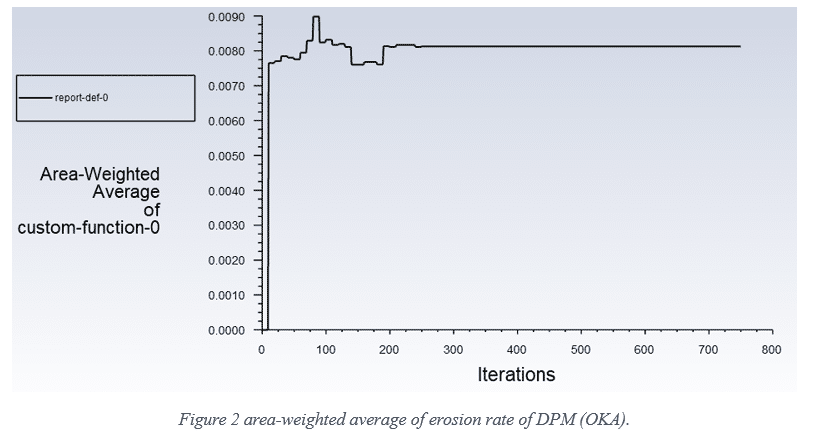

Furthermore, to better understand the erosion values, an area-weighted average has been calculated and displayed in Figure 2. This graph shows the area-weighted average erosion rate over time. The convergence of the graph indicates that the problem has reached a satisfactory level of convergence, meaning that the erosion values have stabilized and the simulation results can be considered reliable. The area-weighted average provides a comprehensive view of the erosion behavior across the entire surface, taking into account the relative sizes of different regions. This information, along with the maximum erosion rate, helps in analyzing and interpreting the erosion patterns and their significance in the context of the study.

By completing this project, you will be able to thoroughly understand the concept of erosion.

Carmen Krajcik –

Is the erosion in the elbow modeled dynamically to impact the fluid flow as the simulation progresses, or is it simply recorded as where the most erosion would occur over time without changing the flow?

MR CFD Support –

The erosion within the elbow is not modeled dynamically to impact the fluid flow during the simulation. It is rather recorded to determine regions where the most erosion would likely occur over time. The mechanical impact on the elbow structure and consequent change in fluid flow patterns are typically not part of the steady-state DPM analysis.

Leatha Kiehn –

The review presents a thorough layout, but could you elaborate on how erosion on the elbow surface was measured or predicted in ANSYS Fluent?

MR CFD Support –

In ANSYS Fluent, erosion is often predicted by tracking the particles’ trajectories and estimating the impact wear on the surface due to collisions. Parameters like particle mass flow rate, velocity, angle of impact, and material properties of both particle and surface are considered in an erosion rate calculation that’s usually based on empirical models. The reported erosion value can be derived using Fluent’s DPM erosion models, which can be enabled in the simulation setup.

Claire Leannon DVM –

The description mentions neglecting gravity’s effect; how does that influence the results related to particle deposition and erosion inside the elbow?

MR CFD Support –

When gravity is neglected in the simulation, the deposition and erosion patterns observed will be solely due to the momentum of the particles within the flowing air rather than any settling or vertical movements that gravity would cause. This assumption is often made when the primary focus is on understanding the impact dynamics and erosion due to the flow direction and pipe geometry, particularly when particles are small and likely to be carried along with the fluid stream.

Hazel Williamson –

I’m interested in the erosion aspect of this simulation. How accurately does the DPM method predict the erosion pattern in the elbow over time?

MR CFD Support –

The DPM (Discrete Phase Model) used in ANSYS Fluent is effective for predicting erosion patterns as it simulates the interaction between the particles and the elbow surface. Specifically, the model calculates the impact of particles, including their velocity and trajectory, on the surface. Over time, by monitoring the frequency and intensity of these collisions, ANSYS Fluent can estimate erosion rates and patterns. The accuracy depends on the quality of the mesh, the chosen boundary conditions, and the physical properties assigned to both the particles and the continuous phase. However, for a more detailed prediction of erosion, additional experimental validation might be necessary.

Ian Langworth –

I learned a lot from the particle flow in elbow erosion CFD simulation tutorial, but I’m curious about the erosion prediction. How is the erosion rate calculated or estimated in this simulation?

MR CFD Support –

The erosion rate in the simulation is estimated using a combination intrinsic to DPM and empirical models that calculate the impact wear caused by the particles upon collision with the elbow surfaces. Parameters affecting this rate include particle size, velocity, material, angle of impact, and the current status of the wall surface. Fluent provides specific models, like the Oka erosion model, to predict this phenomenon based on these factors.

Demarco O’Kon –

I’m curious, what type of particles does the DPM in this simulation handle, and are there any limitations on particle size or material properties?

MR CFD Support –

The DPM in this simulation can handle a wide range of particles, as long as they are discrete, separate phases from the primary fluid. However, certain conditions apply, such as particle size being much less than the flow’s characteristic length scale. For this model, there is no mention of specific limitations on particle size or material properties beyond a defined diameter of 0.003741 m for the particles. The simulation handles inert particles, which means the particles do not react chemically with the fluid and their material properties remain constant.

Jessie Olson –

Really impressed with the application of the DPM model here. It provided a clear visualization of flow trajectory and erosion patterns inside the elbow which can be extremely valuable for industrial applications!

MR CFD Support –

Thank you for your positive feedback! We are glad to hear that our training material was able to provide a clear and helpful visualization of the particle flow and erosion process. It’s our goal to create useful and practical CFD simulation content. If you have any further questions or need more training, please don’t hesitate to reach out.

Willie Klocko DVM –

I found the provided velocity and initialization parameters helpful in understanding input setup. Could you elaborate on how you address the rebound or accumulation of particles at the impact locations?

MR CFD Support –

In sections where particles impact the wall, we apply a ‘reflect’ boundary condition which allows for the simulation of particle rebound. Additionally, if particle accumulation or erosion effects need to be accounted for, a user-defined function (UDF) can be implemented to capture the erosion rate of the surface material over time due to these particle collisions.