Particle Stickiness in a Bend Pipe CFD Simulation

$100.00 $50.00 Student Discount

- This report presents a simulation of the particle stickiness in a bend pipe using Discrete Phase Method (DPM).

- The geometry of the bend pipe was created using ANSYS SpaceClaim software.

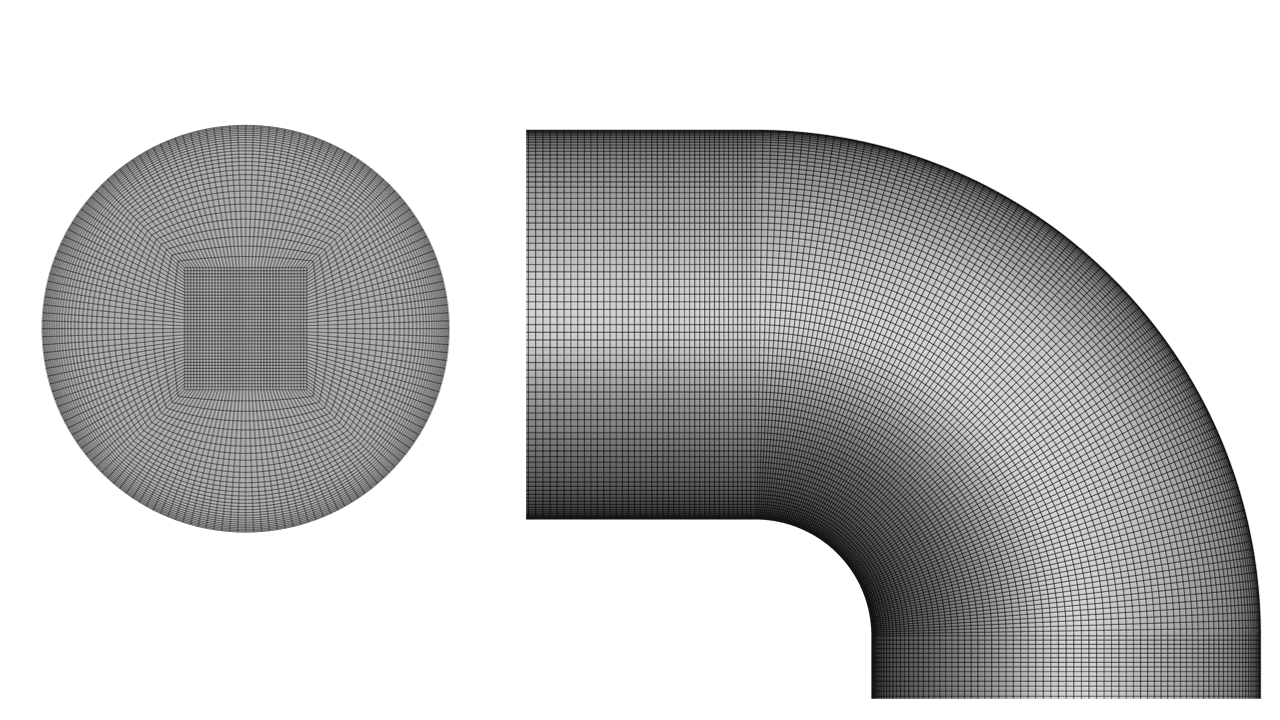

- A high-quality mesh of 1,664,000 hexahedral elements was generated using ANSYS Meshing software.

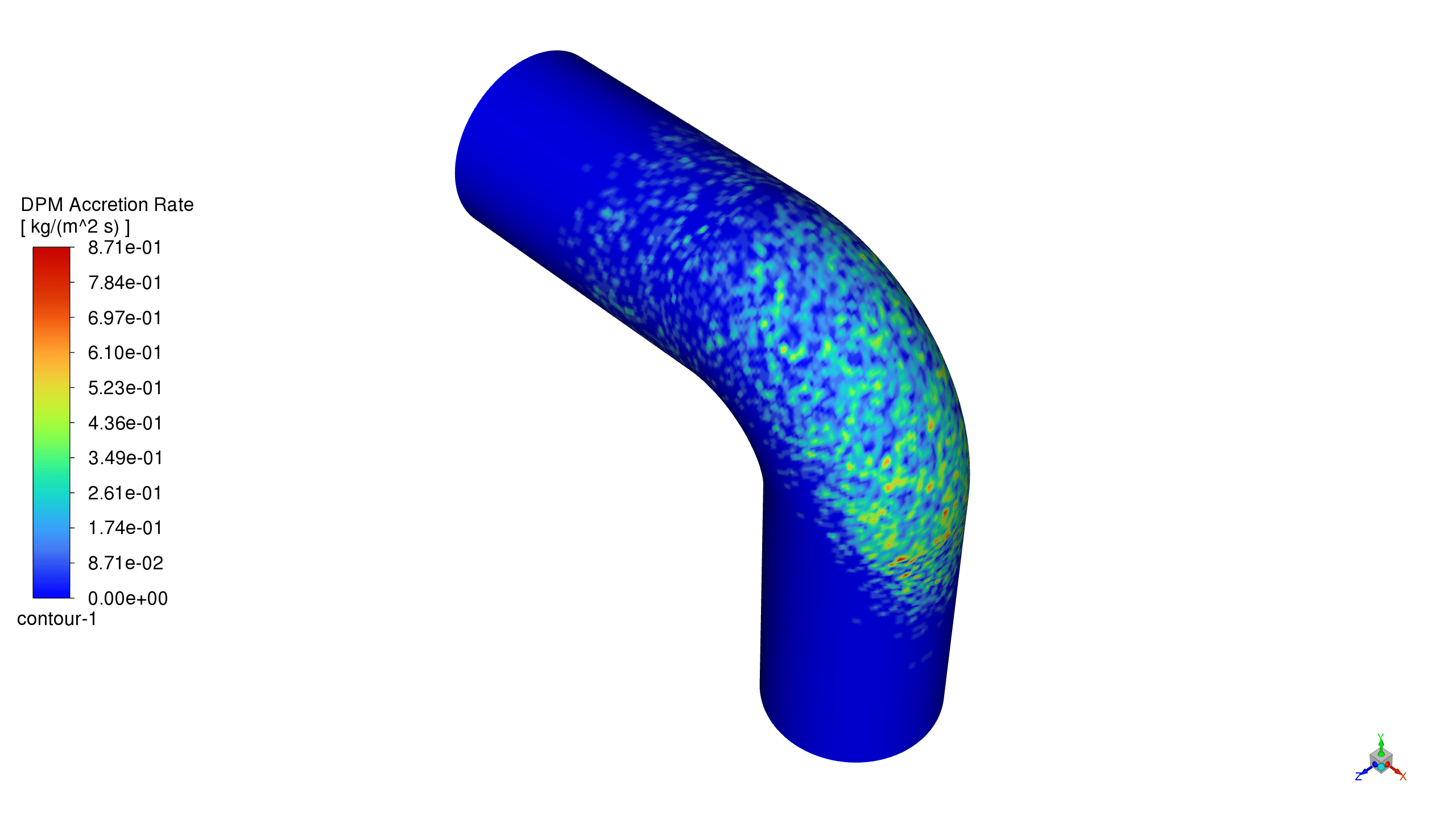

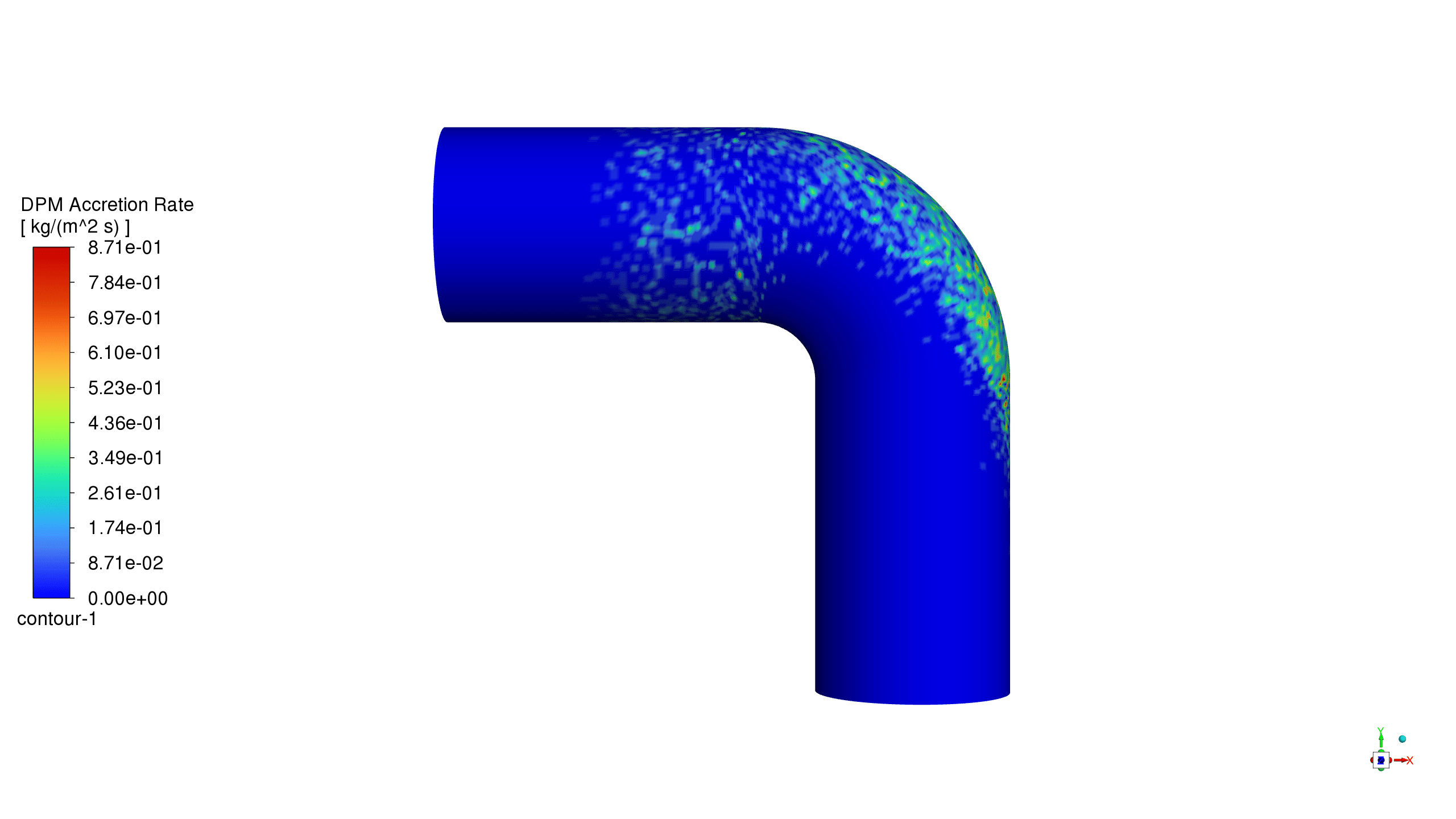

- Appropriate DPM settings were applied and the particle accretion rate was calculated on the bend pipe wall.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this simulation, steady-state particle stickiness and accretion of micrometer particles inside a bend pipe has been investigated using Discrete Phase Method in ANSYS Fluent Software.

In industrial applications, the transportation of particulate-laden fluids through piping systems is a common operation, particularly in sectors like oil and gas, chemical processing, and wastewater treatment. Understanding and predicting the behavior of particle accretion in bend pipes is critical, as accumulation can lead to blockages, reduced efficiency, and increased maintenance costs. In this study, ANSYS Fluent is employed to simulate the Discrete Phase Model (DPM) problem, focusing on identifying regions of significant particle sedimentation within a bend pipe.

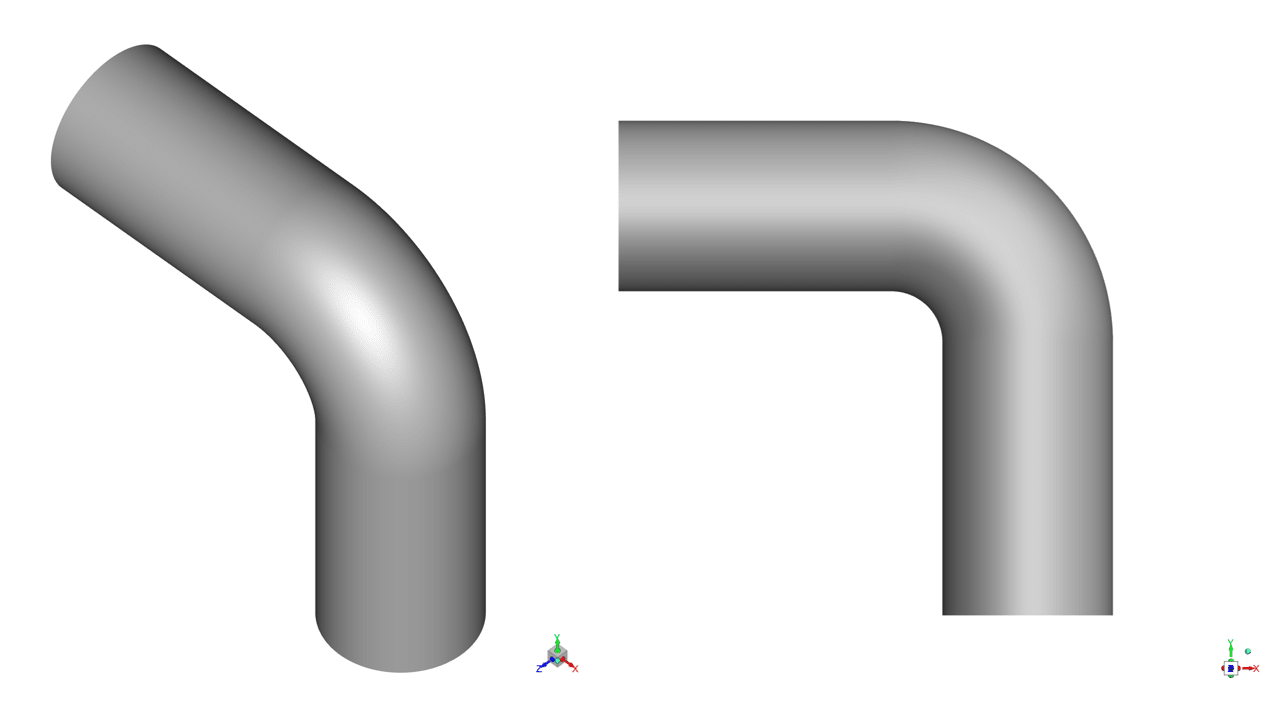

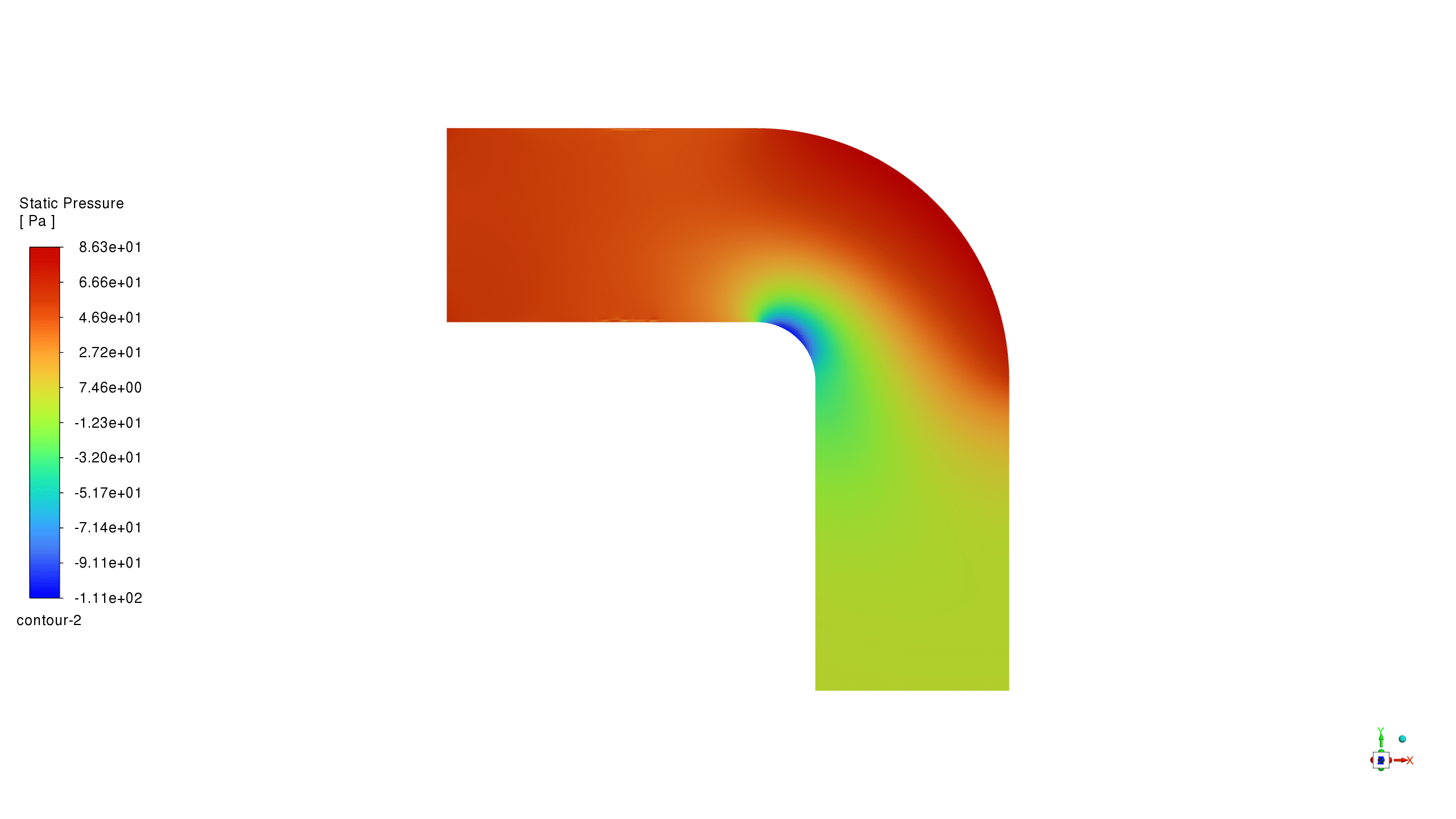

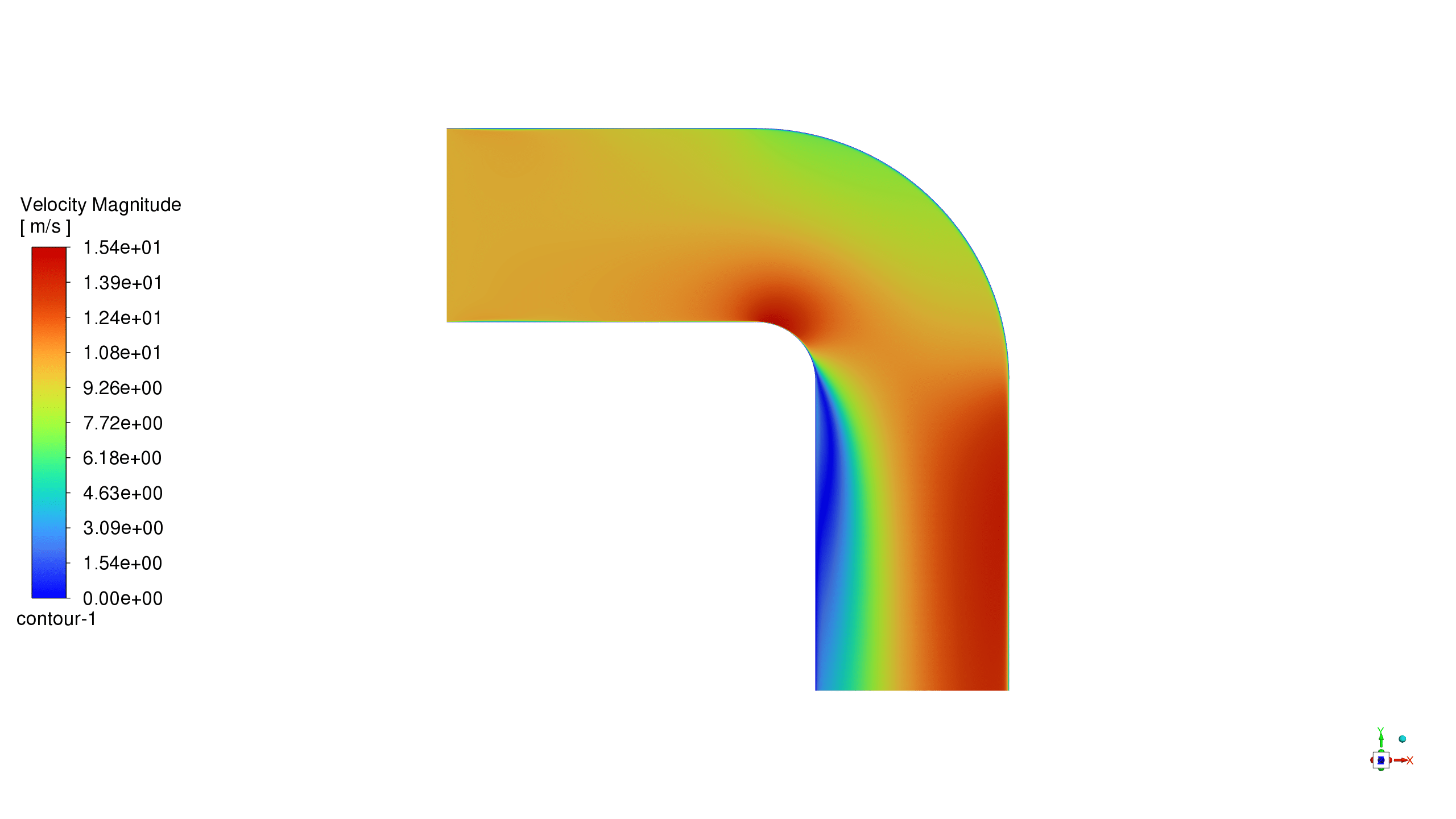

The geometry of the study comprises a 90-degree bend pipe with a diameter of 50 mm, designed using ANSYS SpaceClaim. The pipe features a centerline radius of 40 mm, ensuring a smooth curve through the bend. Tangent lines on either side of the bend extend 80 mm, forming the straight sections that connect to the bend.

ANSYS Meshing was employed to generate a high-quality mesh comprising 1,664,000 hexahedral elements. This mesh density provides sufficient resolution to accurately capture the flow dynamics, turbulence effects, and particle distribution within the domain. The structured hexahedral mesh ensures efficient computation and helps in resolving the complex multiphase flow patterns expected during the accretion process.

Methodology

A pressure-based, steady-state solver was employed to capture the equilibrium state of the particle distribution in the fluid.

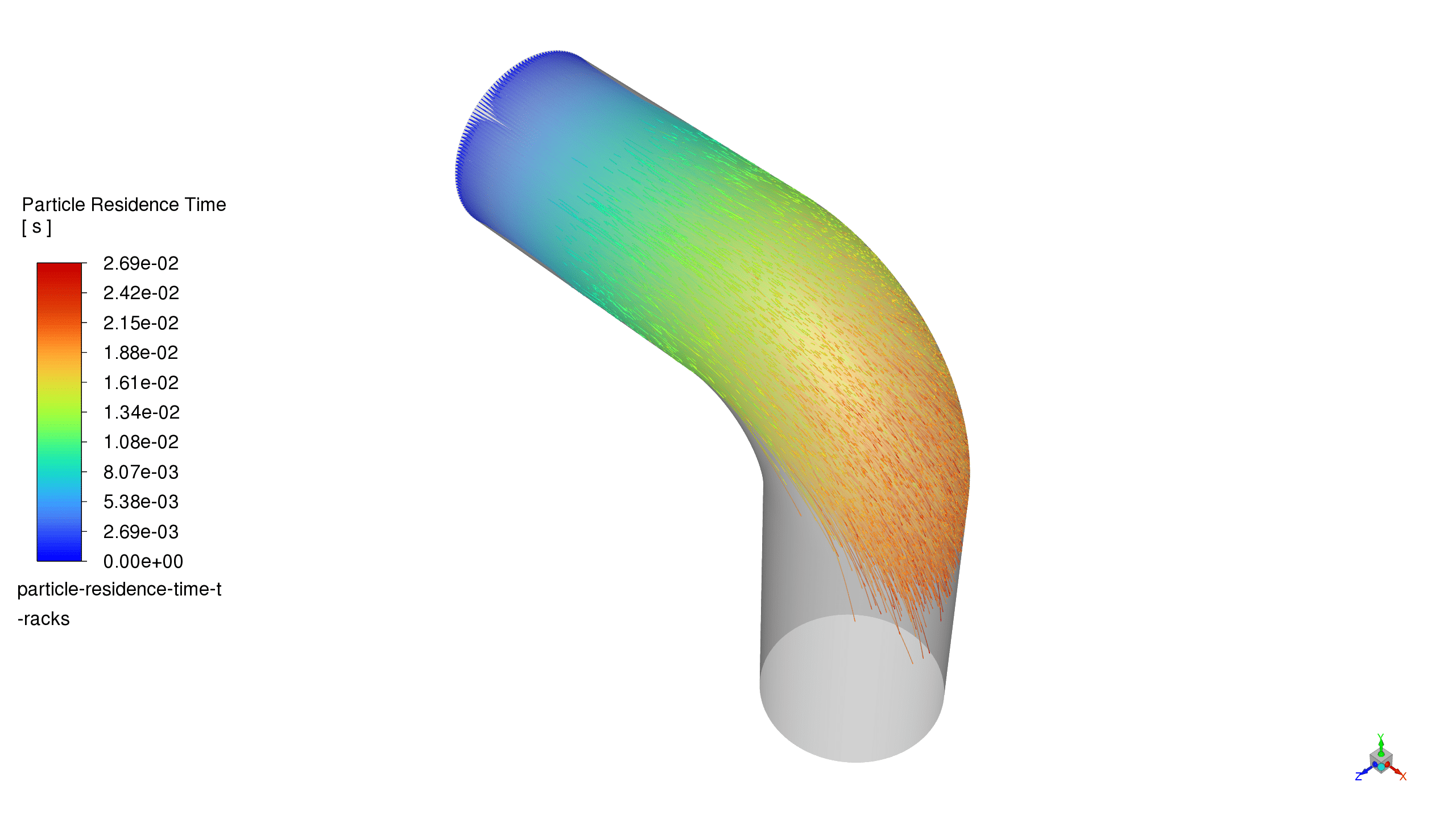

The Realizable k-epsilon turbulence model was adopted for this simulation due to its effectiveness in capturing the complex flow characteristics that arise in bend pipes. A suitable wall function was implemented to ensure accurate resolution of the near-wall region, which is essential for capturing the detailed interactions between fluid flow and particle dynamics near the pipe surface. Additionally, appropriate forces and models related to particle dynamics, and accretion model were considered to enhance the accuracy of the Discrete Phase Model (DPM) settings used in the analysis.

Results and Conclusion

The simulation results indicate that particle accretion predominantly occurs on the outer radius of the bend wall within the pipe with a maximum accretion rate on the bend pipe wall of 0.871 (kg/m^2 s). This accumulation pattern is attributed to the centrifugal forces acting on the particles as the fluid navigates the curved section, causing them to migrate towards the outer wall. The increased likelihood of particle impact, combined with the Particle stickiness of the particle, enhances deposition in this region, highlighting the critical nature of bend design in piping systems. Understanding these accretion dynamics, including the role of particle stickiness, is essential for predicting and mitigating potential blockages or wear in industrial applications where particulate transport is involved. This insight aids in the optimization of pipe geometry and the development of maintenance strategies.

Reviews

There are no reviews yet.