PCM based encapsulation in energy efficient buildings

$140.00 $70.00 Student Discount

- This project analyzes the thermal load of a room/building without Phase Change Materials (PCMs) and then with PCM-integrated walls.

- The energy storage capacity and liquid fraction of PCM capsules are calculated to assess their impact on thermal regulation.

- Simulations are conducted in ANSYS Fluent to evaluate heat transfer efficiency and energy savings.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This study investigates the effect of Phase Change Materials (PCM based encapsulation) on the thermal performance of a building by comparing heat loads before and after PCM integration. PCMs store and release thermal energy during phase transitions, helping to regulate indoor temperatures and reduce cooling/heating demands. By embedding PCM capsules into building walls, this project evaluates their energy storage capacity and impact on peak load reduction.

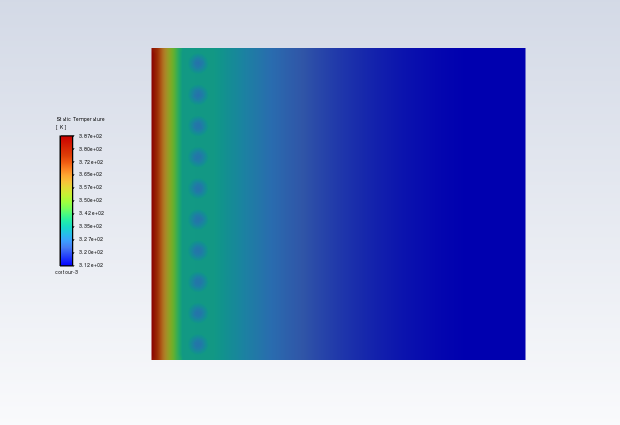

The simulation considers a standard room with predefined dimensions, material properties, and heat sources. First, the thermal load is calculated without PCMs under varying external temperature conditions. Then, PCM capsules are embedded within the walls, and their phase transition behavior is analyzed. Key parameters such as energy storage capacity and liquid fraction (indicating the phase state of PCM) are monitored over time.

Methodology

This project employs transient heat transfer simulations with the following considerations:

- Baseline Load Calculation: The room’s thermal load is determined without PCM using conduction, convection, and heat transfer models.

- PCM Implementation: PCM capsules are inserted into the walls, and their thermophysical properties (e.g., melting point, latent heat) are defined.

- Energy Storage Assessment: The heat absorption and release capacity of PCM are analyzed during charging (melting) and discharging (solidification) cycles.

- Liquid Fraction Calculation: The proportion of PCM in the liquid phase is tracked to determine its effectiveness in stabilizing indoor temperature.

Results

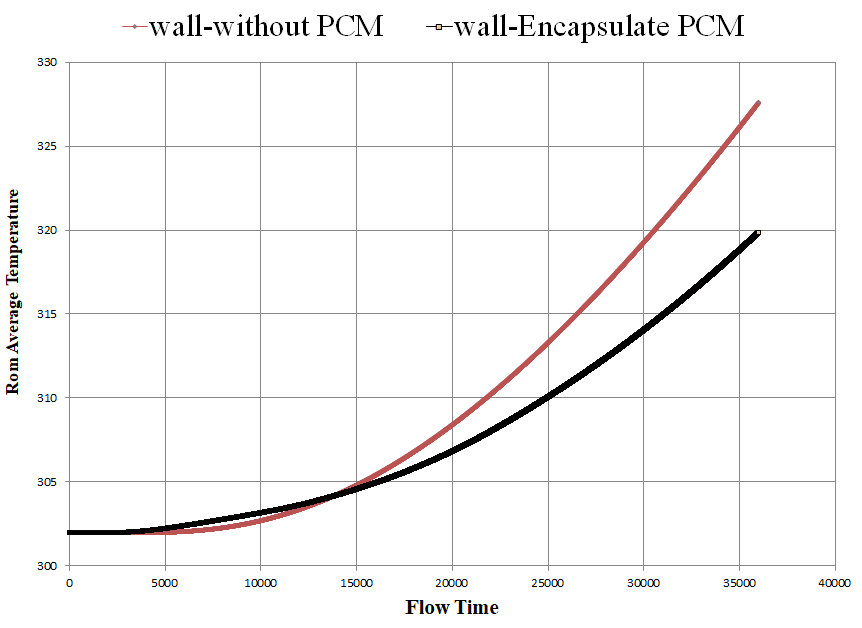

Simulations compare the thermal load before and after PCM integration, showing a reduction in peak cooling/heating demand. Energy storage capacity is quantified, demonstrating the PCM’s role in load shifting. The liquid fraction analysis reveals how efficiently the PCM transitions between phases, directly affecting heat regulation performance. The findings support the use of PCMs in building design for improved energy efficiency and indoor climate control.

The incorporation of PCM (Phase Change Material) capsules into the walls of a room led to a decrease in the average room temperature by 7.7°C compared to the scenario without PCM capsules. This result demonstrates the effectiveness of PCM capsules in improving thermal regulation within the room, as these materials are able to absorb and store heat during phase transitions, leading to reduced temperature fluctuations and enhanced thermal comfort. The findings highlight the potential of using PCM in building materials to optimize energy efficiency and create more thermally stable indoor environments.The graph of the average room temperature before and after placing PCM capsules inside the walls is shown below.

Reviews

There are no reviews yet.