PCM Components in Hot Water Tank Thermal Analysis (Load & Discharge), CFD Simulation Training

$120.00 $60.00 Student Discount

In this project, PCM components in a hot water tank are simulated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Phase Change Material (PCM) Project Description

A Phase Change Material (PCM) is a substance that releases/absorbs sufficient energy at phase transition to provide useful heat or cooling. Generally, the transition will be from one of the first two fundamental states of matter – solid and liquid – to the other.

The phase transition may also be between non-classical states of matter, such as the conformity of crystals, where the material goes from conforming to one crystalline structure to conforming to another, which may be a higher or lower energy state.

By melting and solidifying at the Phase Change Temperature (PCT), a PCM is capable of storing and releasing large amounts of energy compared to sensible heat storage.

Heat is absorbed or released when the material changes from solid to liquid and vice versa or when the internal structure of the material changes; PCMs are accordingly referred to as Latent Heat Storage (LHS) materials.

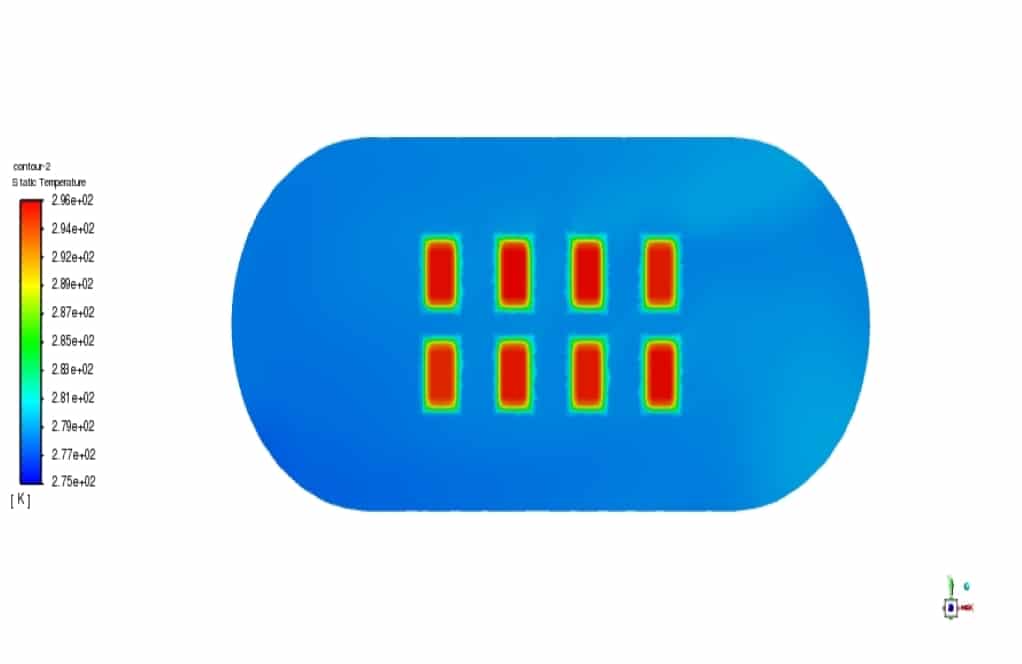

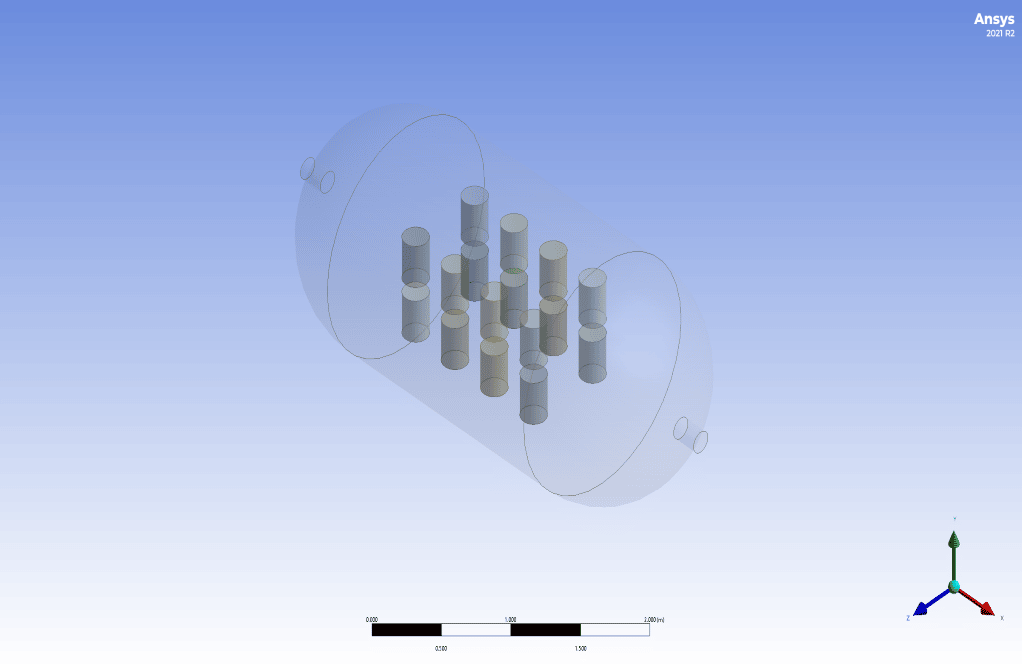

The system consists of 16 PCM capsules placed in the water tank which hot water enters the domain with a speed of 0.5 m/s and a temperature of 335 k. when PCMs are completely turned to liquid, the cold water enters the system and cools down the PCM’s. by cooling down PCM’s start to solidify.

Geometry & Mesh

The 3-D domain of this simulation has been designed in ANSYS Design Modeler. Domain has an inlet and outlet and a wall for PCMs.

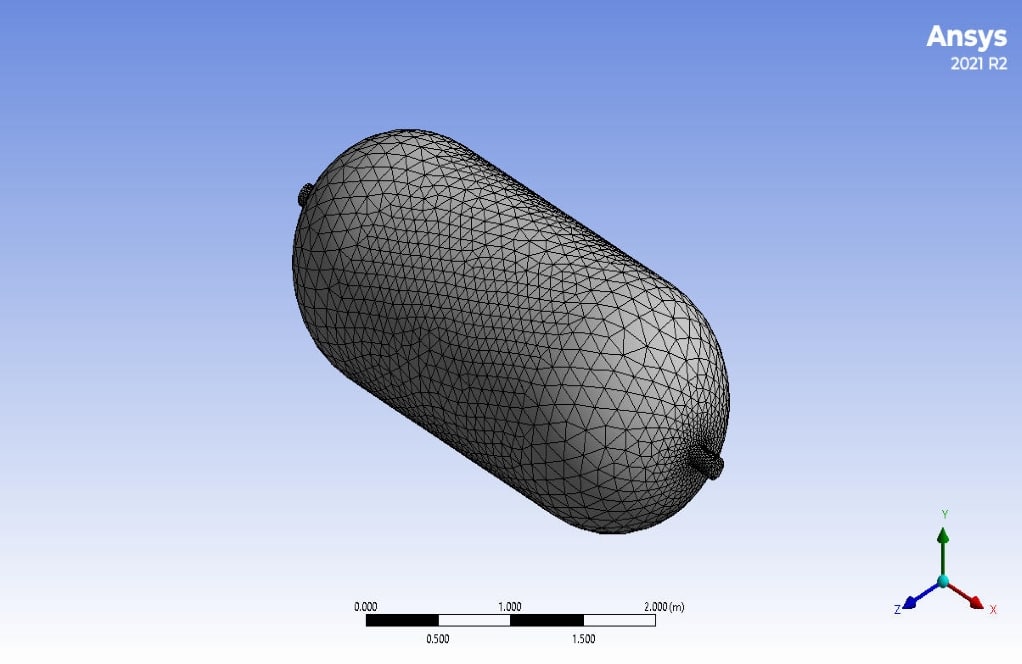

The meshing of this present model has been generated by ANSYS Meshing software. The mesh grid is unstructured, and the total cell number is 339466 elements.

Phase Change Material (PCM) CFD Simulation

To simulate the present model, several assumptions are considered, which are:

- The solver is pressure-based.

- The effect of gravity on the flow has not been considered.

- The present model is unsteady.

The following summarizes the steps for defining the problem and its solution.

| Models | ||

| K-omega | Viscous model | |

| SST | K-omega Model | |

| Pressure based | Solver | |

| unsteady | Timestep | |

| On | Energy | |

| Boundary conditions | ||

| Velocity-inlet | inlet | |

| 0.5 m/s | Fluid inlet velocity | |

| 333 k | Hot water temperature | |

| 272 k | Cold water temperature | |

| Pressure outlet | outlet | |

| 0 | gage pressure | |

| wall | wall | |

| stationary wall | wall motion | |

| Non | Thermal condition | |

| wall | PCM wall | |

| stationary wall | wall motion | |

| Coupled | Thermal condition | |

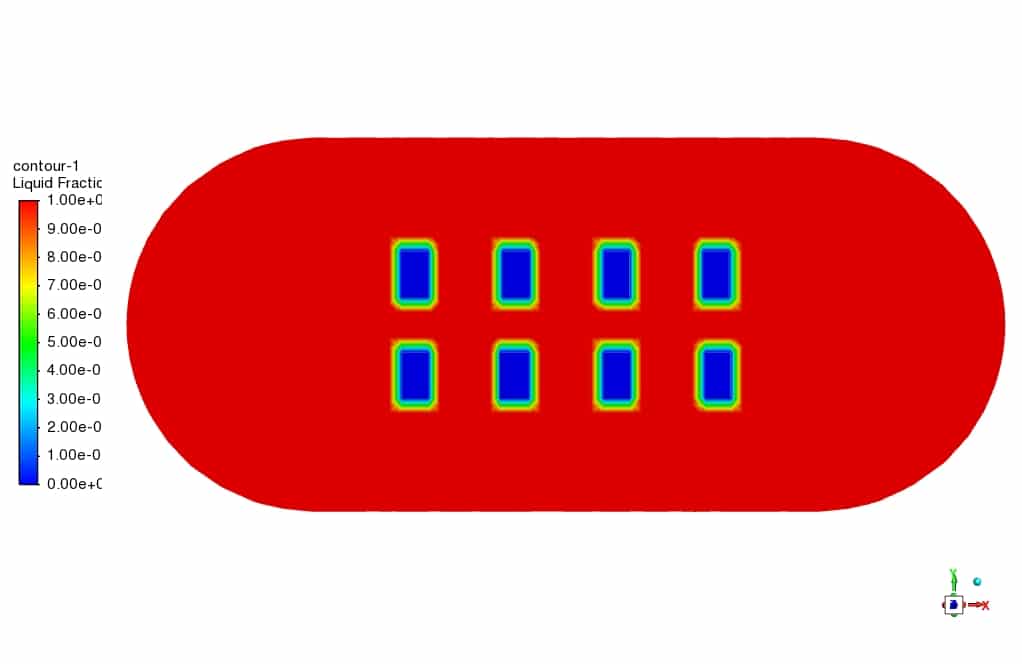

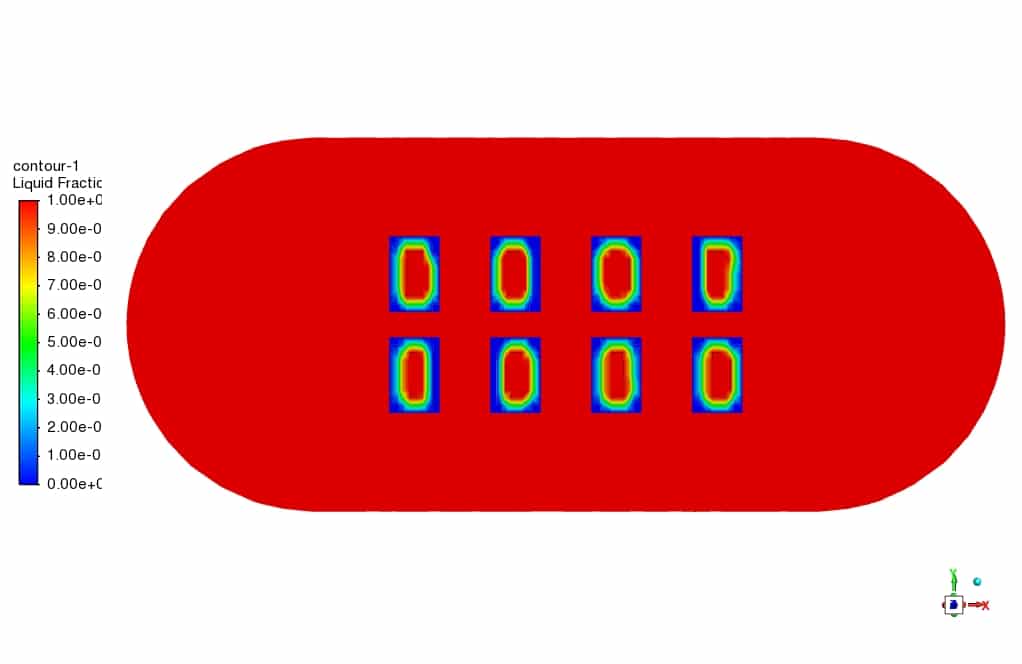

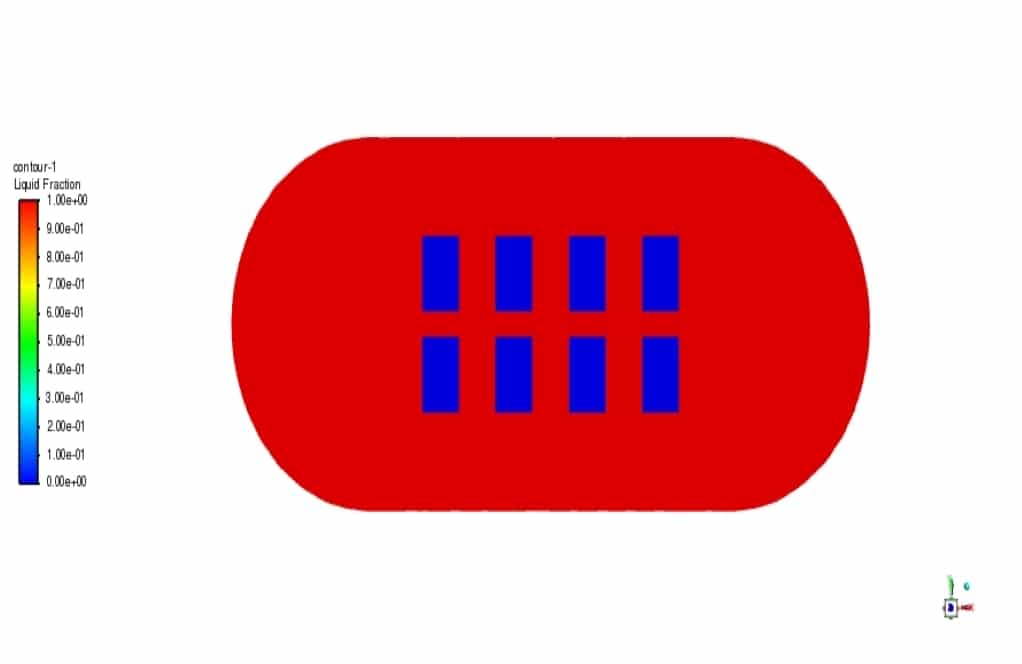

Phase Change Material (PCM) Results

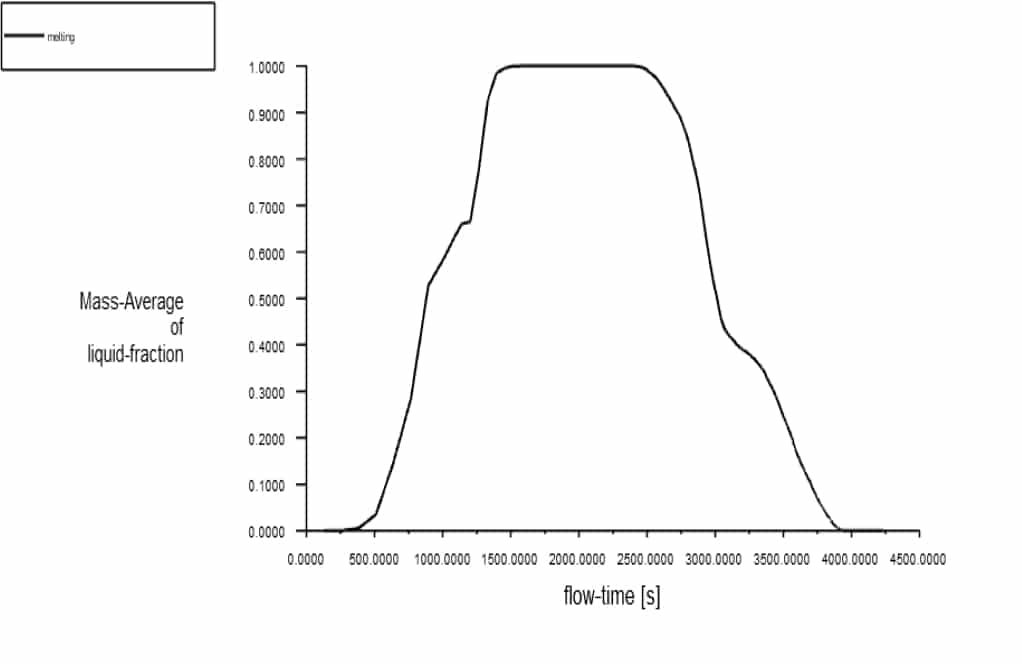

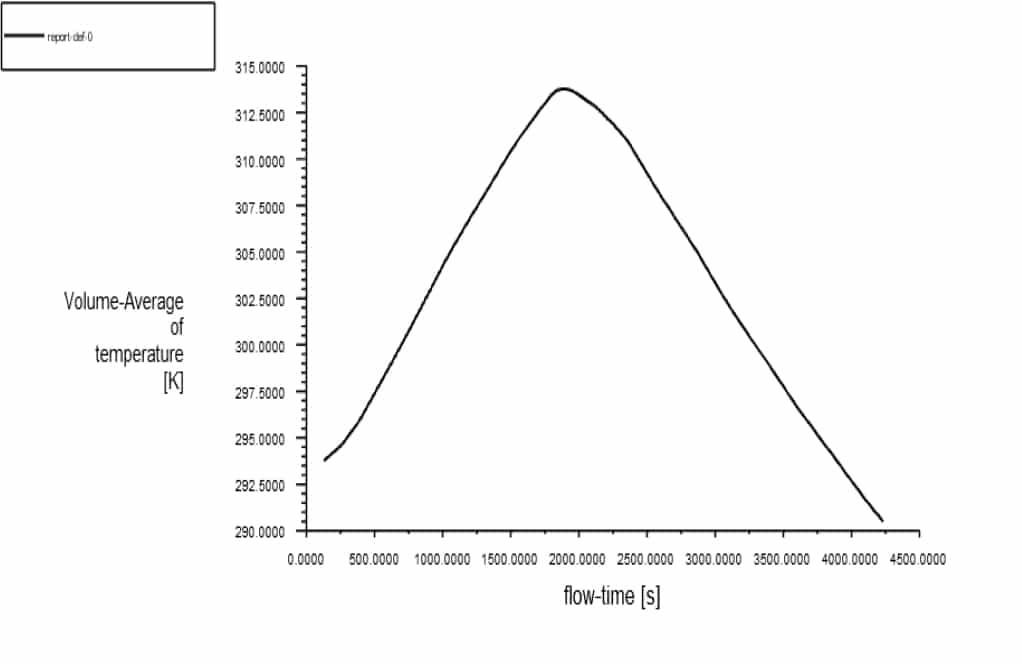

The first instance, according to the graph of the average temperature of the environment and PCMs, shows that with the entry of hot water, the temperature of the environment increases, which causes the average temperature of the PCMs to increase and shows the process of melting in 343 seconds.

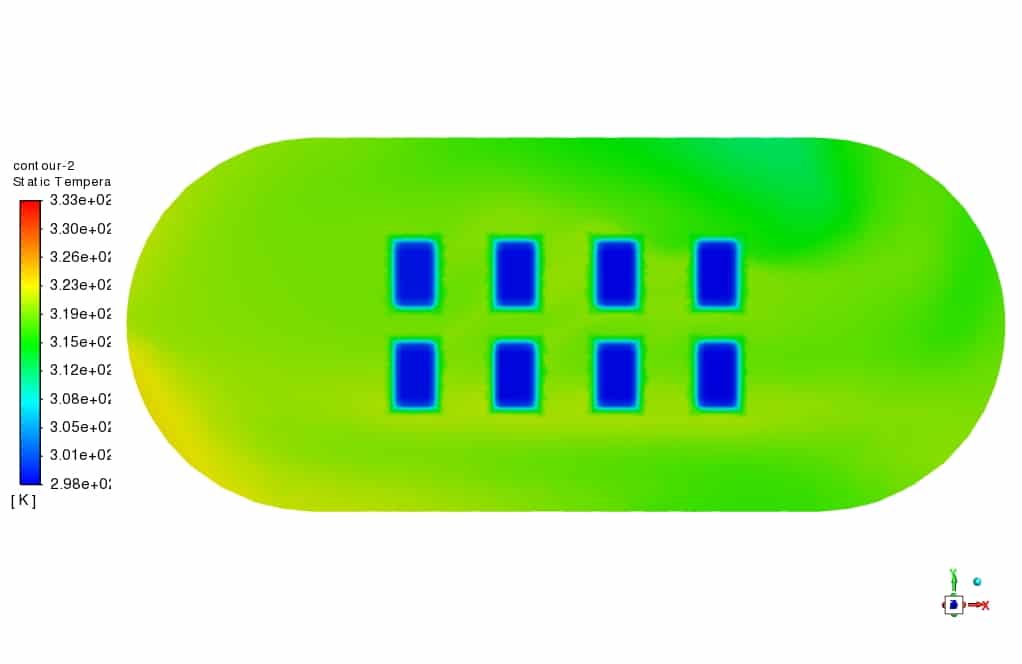

Gives. After 1500 seconds, all the PCMs are completely melted, and cold-water flows into the domain, the effects of which are evident in the average temperature diagram and causes the average temperature of the domain to decrease. PCMs release the stored heat slowly, and their average temperature decreases at a slower rate.

After 500 seconds after entering the cold water, the PCMs start to solidify, and in 4500 seconds, they are completely solidified.

Delbert Hermiston –

The simulation concept is intriguing! The intricate balance of heat transfer and phase change really highlights the potential for efficient energy storage. Looking forward to see how this research can be translated into practical applications for thermal management systems.

MR CFD Support –

Thank you! We’re thrilled to hear that you find the simulation concept enlightening and appreciate the potential of PCMs in energy storage. Indeed, these results could pave the way for advancements in thermal management applications. We’re excited to explore how this research can offer practical solutions. Stay tuned for further developments in this area, and thank you for taking the time to review our work!

Ethan Lebsack –

The explanation on PCM utilization in the hot water tank was enlightening. I’ve gained valuable insights on energy conservation techniques.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the training enlightening and insightful. It’s great to know that our materials on Phase Change Material applications are enabling an understanding of innovative energy conservation techniques.

Ms. Christiana Russel –

The training was extremely insightful for understanding PCM behavior in hot water tanks. The detailed steps provided make the complex process of heat exchange and phase transition very approachable. Kudos to the MR CFD team for such a useful and practical learning module.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the PCM training module both insightful and useful for understanding thermal analysis in applications like hot water tanks. Your recognition is greatly appreciated, and we look forward to continuing to provide valuable learning experiences. If there’s anything else we can assist you with, please let us know.

Lauriane Lesch –

I was impressed by the thoroughness of the phase change material simulation. The detailed steps from hot water increase to PCM melting and the final PCM solidification were particularly insightful. The graphical temperature data seems to have added to the clarity of the results. Can I have access to these graphs for a deeper understanding?

MR CFD Support –

Thank you for your compliment on the thoroughness of the phase change material (PCM) simulation. We’re glad to hear that the detailed steps and the inclusion of graphical temperature data enhanced the clarity of the results. Unfortunately, as a text-based AI, I don’t have access to graph representations or external content. However, you can typically view such graphs and detailed simulation results within the learning materials provided with the training, such as simulation result files or within the course platform if online access is available.

Jeremy Dicki II –

I’m thoroughly impressed with how the PCM components interact with temperature changes. The results seem to indicate efficient energy storage and release. Outstanding simulation setup!

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that you’re impressed with the PCM simulation and the detailed analysis of thermal energy storage. We appreciate your recognition of our meticulous setup efforts. If you need further information or assistance with similar simulations, feel free to reach out to us.

Cecilia Cummerata –

I was thoroughly impressed with the details and results of the PCM Components in Hot Water Tank Thermal Analysis CFD Simulation! The intricate balance of melting and solidifying PCMs to regulate temperature is very promising for energy storage solutions. Keep up the excellent work!

MR CFD Support –

We really appreciate your enthusiasm and the time you took to elaborate on our PCM Components in Hot Water Tank Thermal Analysis. We’re delighted to see that you recognize the potential of this application for energy storage. Thank you so much for your compliment!

Rickey Hill –

The CFD training on PCM components was fantastic! It was so helpful to see the graphical data and understand the melting and solidification process of the PCM within the hot water tank. The step-by-step explanation of the simulation setup really clarified the interactions at play.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the simulation data and detailed walkthrough enhanced your understanding of the PCM’s thermal behaviors. If you have any further questions or need additional information, feel free to reach out!

Adan Lemke –

This product taught me so much about thermal analysis. Seeing the PCMs react to temperature changes was fascinating. The graphs and the results were clear and precise. I initially had concerns about understanding PCM behavior in a hot water tank, but this simulation made the process very accessible. Excellent work!

MR CFD Support –

We appreciate your kind words and are thrilled to hear that our PCM Components in Hot Water Tank Thermal Analysis simulation was instrumental in increasing your understanding of PCM behavior. Thank you for taking the time to share your positive experience. We strive to provide clear and intuitive learning materials, and it’s rewarding to know we’ve achieved this with you. If you have any further questions or need additional learning resources, please do not hesitate to reach out.

Jeremie Smitham –

I’m impressed with how PCMs can store and release heat. Great for efficient energy use!

MR CFD Support –

Thank you for your kind words! We’re pleased to know that the elaborative teaches about the potential and efficiency of PCM in energy storage. Your appreciation is highly valued, and we are glad you found the learning material insightful.

Aurelie Quigley –

I used this PCM analysis training for my university project and the results look really promising. Great on incorporating critical aspects like PCM melting and solidification!

MR CFD Support –

Thank you for the positive feedback! We’re thrilled to hear the training proved beneficial for your university project and that the complex phenomena of PCM phase change were well represented. If there’s more we can assist with in future studies, don’t hesitate to reach out!

Verlie Spinka –

Fantastic learning material! The concept was explained very well with the practical simulation of PCMs in a hot water tank. I was able to understand the melting and solidification process clearly thanks to the accurate modeling and detailed solution steps.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our training on PCM components in a hot water tank CFD simulation was helpful and informative. If you have any further questions or need assistance with other topics, feel free to reach out. Happy learning!

Caden Quigley –

This tutorial covers a wonderful application of PCMs in water tanks. The step by step explanation and background theory enhanced my understanding of latent heat storage. I especially appreciated the detailed analysis of the melting and solidification process!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial was informative and enhanced your understanding of latent heat storage systems. If you have any further insights or inquiries, don’t hesitate to reach out!

Prof. Brennan Schuster –

The simulation of PCM in a hot water tank is exceptional. The detail provided in thermal analysis shows a thorough understanding of the heat transfer processes involved, especially during the loading and discharge cycles when the PCM transitions from solid to liquid and back. This training product shows strong practical application of CFD principles in developing energy efficient systems.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you found the detail in the thermal analysis of PCM to be thorough and practically useful. We take pride in providing high-quality training products that effectively convey the principles and applications of CFD. Your appreciation means a lot to us!

Prof. Pinkie Rath –

The explanation of PCM component behavior in thermal simulation was enlightening! The visual representation of melting and solidification processes added depth to my understanding. Great job on creating vivid simulations and provide practical analysis.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the visual aspects of the PCM thermal simulation were beneficial in enhancing your understanding. Our team strives to provide high-quality educational material that is both informative and engaging. If you have any further questions or need additional information, please do not hesitate to ask.

Dr. Orville Schinner –

The PCM components simulation seems incredibly detailed. The application of hot and cold water for the charge and discharge process was fascinating, and it’s impressive how all the steps, including the mesh specifications and boundary conditions, were clearly outlined. Overall, it was highly educational to understand the principles of energy storage and heat transfer in practical scenarios through this CFD simulation training project.

MR CFD Support –

We greatly appreciate your positive feedback on our PCM Components CFD Simulation Training. It’s rewarding to hear that you found the simulation detailed and educational, especially regarding the charge and discharge processes using PCM. Your understanding and acknowledgement of the effort put into crafting a clear and instructive simulation are most encouraging for our team. Thank you for choosing our training project, and we hope it proves valuable in your future endeavors!

Mrs. Rachelle Stark –

The explanation of PCM components seems efficient for system thermal regulation. I appreciated learning how they absorb and release energy during phase transitions. Observing the outcome of coupling a latent heat storage mechanism with a dynamic water temperature in a tank has provided valuable insight into energy management for heating systems. Excellent practical and theoretical application throughout the course!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the course was able to provide you both practical and theoretical understanding of PCM components and their role in thermal energy management. If you have any further questions or need more insight into any other aspect, we’re here to help!

Otho Harber II –

The product provides a thorough understanding of PCMs in a hot water tank system. The incorporation of various temperatures for different stages of the PCM cycle is appreciated.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our product was able to provide you with a comprehensive understanding of the PCM system and its thermal processes in a hot water tank system.

Rylan Armstrong –

The PCM components in a hot water tank work beautifully! The gradual phase transition and the latent heat storage both during the melting and solidification stages are easily seen, providing insight into the material’s ability to store and release energy. It’s impressive to see the precise timings of the phase changes in the simulation.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our simulation model provided clear insights into the behavior of PCM components. It’s wonderful that the timing of the phase changes was helpful for your understanding. If you have any further inquiries or need more information, please feel free to reach out.

Adella Dicki –

I appreciate the detailed analysis from the unsteady CFD simulation, particularly the temperature profiles during the PCM melting and solidification stages. Well executed!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you appreciated the level of detail and analysis in our CFD simulation training on PCM components in a hot water tank. It’s great to know that the information on temperature profiles during the phase change processes provided valuable insights. If you have any more questions or need further assistance, feel free to reach out.

Mr. Dane Kunde –

I couldn’t be happier with what I’ve learned from the PCM Components in Hot Water Tank Thermal Analysis training. The detailed explanation of the PCM behavior and the simulation process truly opened my eyes to the potential of incorporating PCM in energy-efficient designs. It was absolutely fascinating to see the melting and solidification processes simulated accurately. Thanks for such an illuminating experience!

MR CFD Support –

Thank you so much for your kind words. We’re really glad to hear that our training has provided you with valuable insights into PCM components and their practical applications. We always strive to offer detailed and accurate simulations to enhance understanding and application in real-world scenarios. If you ever have any questions or need further assistance, feel free to reach out. We appreciate your feedback!

Dr. Taya Kirlin Sr. –

The utilization of PCM in hot water tanks is fascinating! The detailed temperature analysis indicating the melting and solidification process within the specified timeframe was particularly enlightening.

MR CFD Support –

Thank you for your feedback! We are delighted to hear that you found the phase change behavior in our PCM thermal analysis within the hot water tank simulation enlightening. Accurate temperature analysis is crucial for understanding the thermal dynamics of PCMs, and we strive to ensure our training materials help our clients grasp such complex processes. Your compliment is highly appreciated!

Ms. Lucy Wolff –

This course really enhanced my understanding of thermal analysis involving PCM in hot water tanks. Seeing the phase transition from solid to liquid and back was fascinating and quite informative. The visual representations were particularly helpful in grasping the underlying concepts.

MR CFD Support –

We’re thrilled to hear that our PCM Components in Hot Water Tank Thermal Analysis CFD Simulation Training was both informative and visually engaging for you. Thank you for taking the time to share your experiences with the course material. Your feedback is greatly appreciated!

Hadley Schimmel IV –

Absolutely fascinating simulation on PCM components in a hot water tank. The detailed analysis of how PCMs absorb and release energy during phase changes, as well as the results displaying the time-based phase change effects, were highly educational. Well done!

MR CFD Support –

Thank you for your kind words! We’re thrilled to know that the simulation on PCM components has provided you with educational insights and that you found the analysis detailed and interesting. If you have any further questions or need more information, don’t hesitate to reach out to us.

Jaime Moore –

The provided CFD training material on PCM in hot water tanks was thoroughly informative. I particularly appreciated the inclusion of phase change and latent heat, which offered an in-depth understanding of PCM behavior during thermal processes.

MR CFD Support –

Thank you for your positive feedback! We are delighted to know that our training material contributed to your understanding of PCM behavior in thermal processes. It’s great to hear that the content was informative and helpful. If you have any further questions or need more information, please feel free to reach out to us.