PCM-Enhanced PV Panel, Ansys Fluent CFD Simulation

$160.00 $80.00 Student Discount

- In this product, we conducted a comprehensive study comparing two distinct cases1) A conventional PV panel without pCM 2) An enhanced system incorporating PCM cooling technology

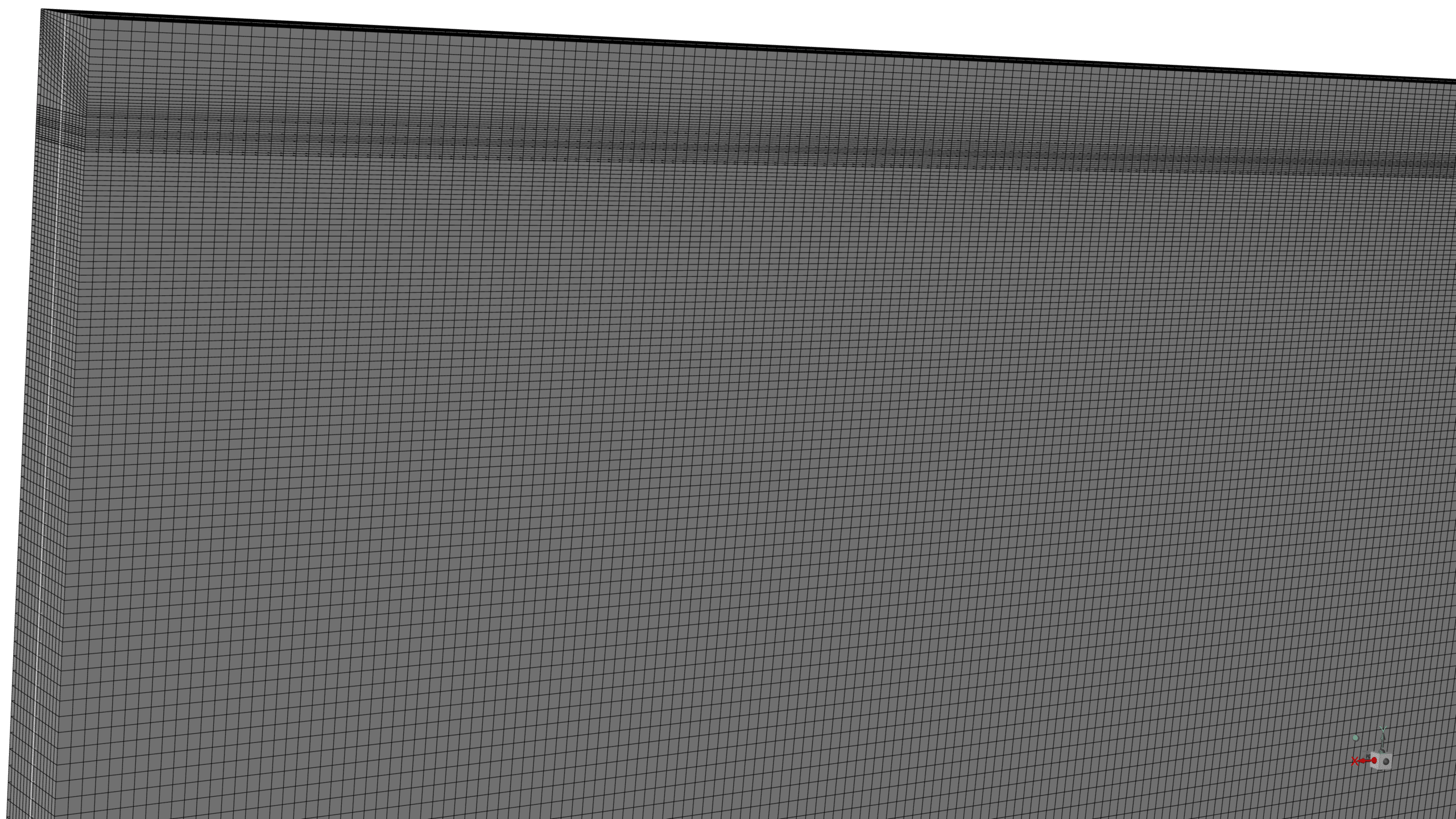

- comprehensive three-dimensional model was developed using ANSYS SpaceClaim,The computational domain was discretized using ANSYS Meshing software, employing a structured grid approach with approximately 1,000,000 elements

- The Solidification and Melting model was activated to accurately capture the phase change dynamics of the PCM

- The Discrete Ordinates (DO) radiation model was implemented to account for radiative heat transfer

- Solar Ray Tracing was enabled for precise solar load calculations

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

“PCM-Enhanced PV Panel Temperature Regulation Using The Solidification and Melting model: A Comparative Numerical Study of Thermal Distribution and Phase Change Behavior”

Description

The thermal management of photovoltaic (PV) systems presents a significant challenge in solar energy technology, as PV modules can experience temperature elevations of up to 35°C above ambient conditions during peak sunlight exposure. This temperature increase substantially impacts their performance, with power output declining at approximately -0.65% per degree Celsius rise in temperature.

In this product, we conducted a comprehensive study comparing two distinct cases:

A conventional PV panel without pCM

An enhanced system incorporating PCM cooling technology

To achieve highly accurate simulation results, we implemented a sophisticated radiation modeling approach using the Solar Ray Tracing model coupled with the DO (Discrete Ordinates) radiation model in ANSYS Fluent. The simulation was geographically positioned at longitude -84.63° and latitude 13.65°, with a time zone offset of -5 UTC. This advanced modeling technique eliminated the need for simplified source terms and provided more realistic solar irradiation calculations.

The scientific community has proposed various cooling strategies to address the temperature-related efficiency losses, with passive cooling using phase change materials (PCM) emerging as a particularly promising solution. Our study focused on optimizing this approach by investigating several critical parameters:

This research contributes to the ongoing optimization efforts in PV thermal management, providing valuable insights into the effectiveness of PCM-based cooling solutions while considering real-world environmental conditions through advanced solar radiation modeling.

The photovoltaic system was modeled as a multi-layer structure consisting of the following components:

- Glass Cover Layer

- Ethylene-Vinyl-Acetate (EVA) Layer

- Silicon Solar Cells

- Second EVA Layer

- Tedlar Back Sheet

The PCM-enhanced configuration additionally included:

- RT42 Paraffin PCM

comprehensive three-dimensional model was developed using ANSYS SpaceClaim, incorporating all essential components of both the conventional and PCM-enhanced PV systems. The model included detailed representations of the PV panel layers and PCM containment structure, The computational domain was discretized using ANSYS Meshing software, employing a structured grid approach with approximately 1,000,000 elements. This mesh density was carefully selected to ensure adequate resolution of thermal gradients while maintaining computational efficiency.

Methodology

The numerical analysis was conducted using ANSYS Fluent, with specific focus on thermal performance evaluation. The simulation framework incorporated several sophisticated physical models:

The Solidification and Melting model was activated to accurately capture the phase change dynamics of the PCM

The Discrete Ordinates (DO) radiation model was implemented to account for radiative heat transfer

Solar Ray Tracing was enabled for precise solar load calculations

Momentum equations were deliberately disabled to focus computational resources on the thermal aspects of the system. The geographical parameters were set to longitude -84.63°, latitude 13.65°, and time zone UTC-5, allowing for location-specific solar radiation modeling.

Result

The numerical simulation was conducted over a period of 19,500 seconds (approximately 5.4 hours) to evaluate the thermal performance of both conventional and PCM-enhanced PV systems. The results revealed several significant findings:

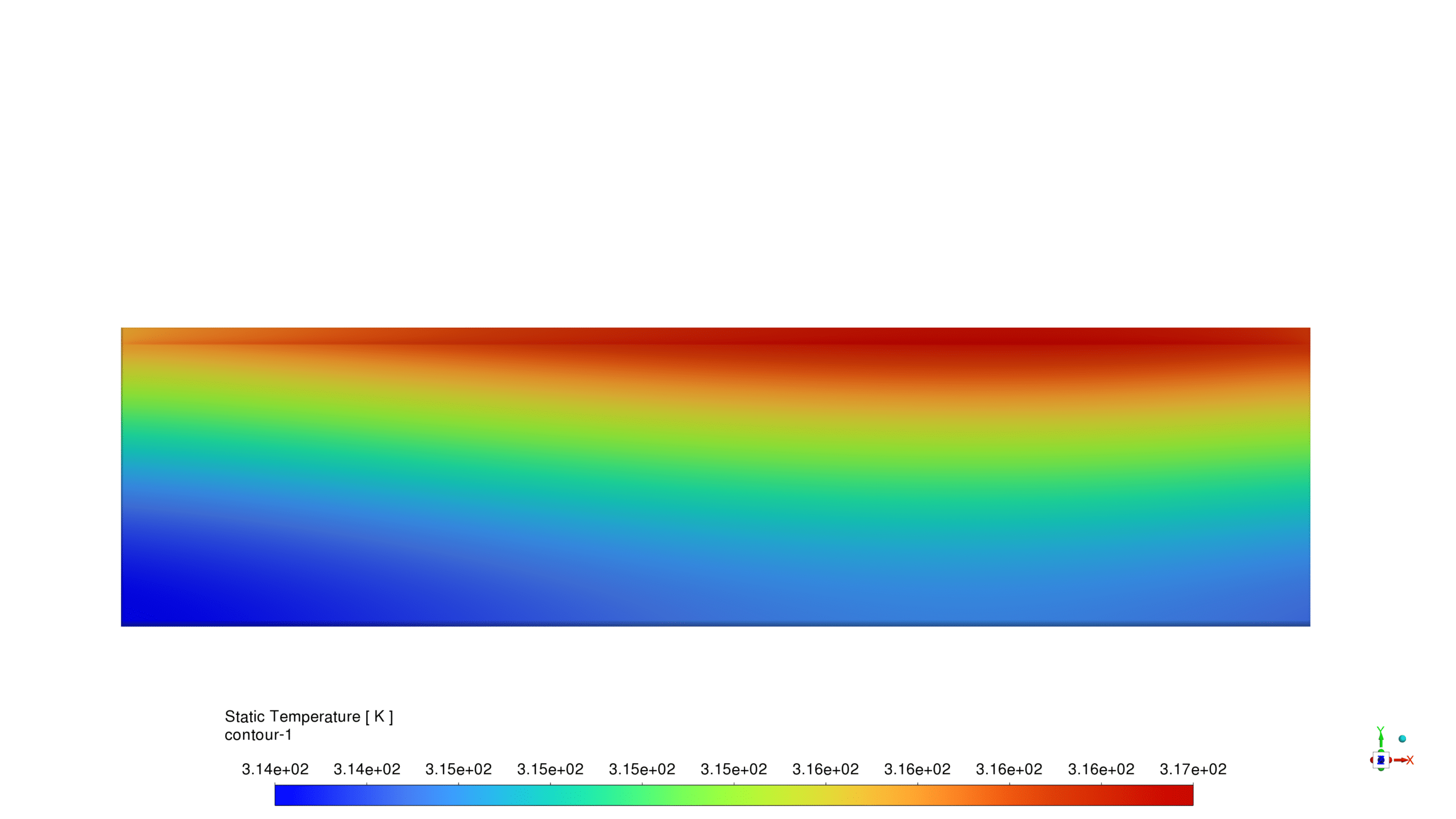

3.1 Temperature Distribution Analysis

The simulation results demonstrated distinct thermal behavior between the two configurations:

PCM-Enhanced System:

Average PV temperature: 313.25 K (40.1°C)

More uniform temperature distribution across the panel

Temperature contours showing effective heat absorption by PCM layer

Lower peak temperatures due to PCM thermal buffering effect

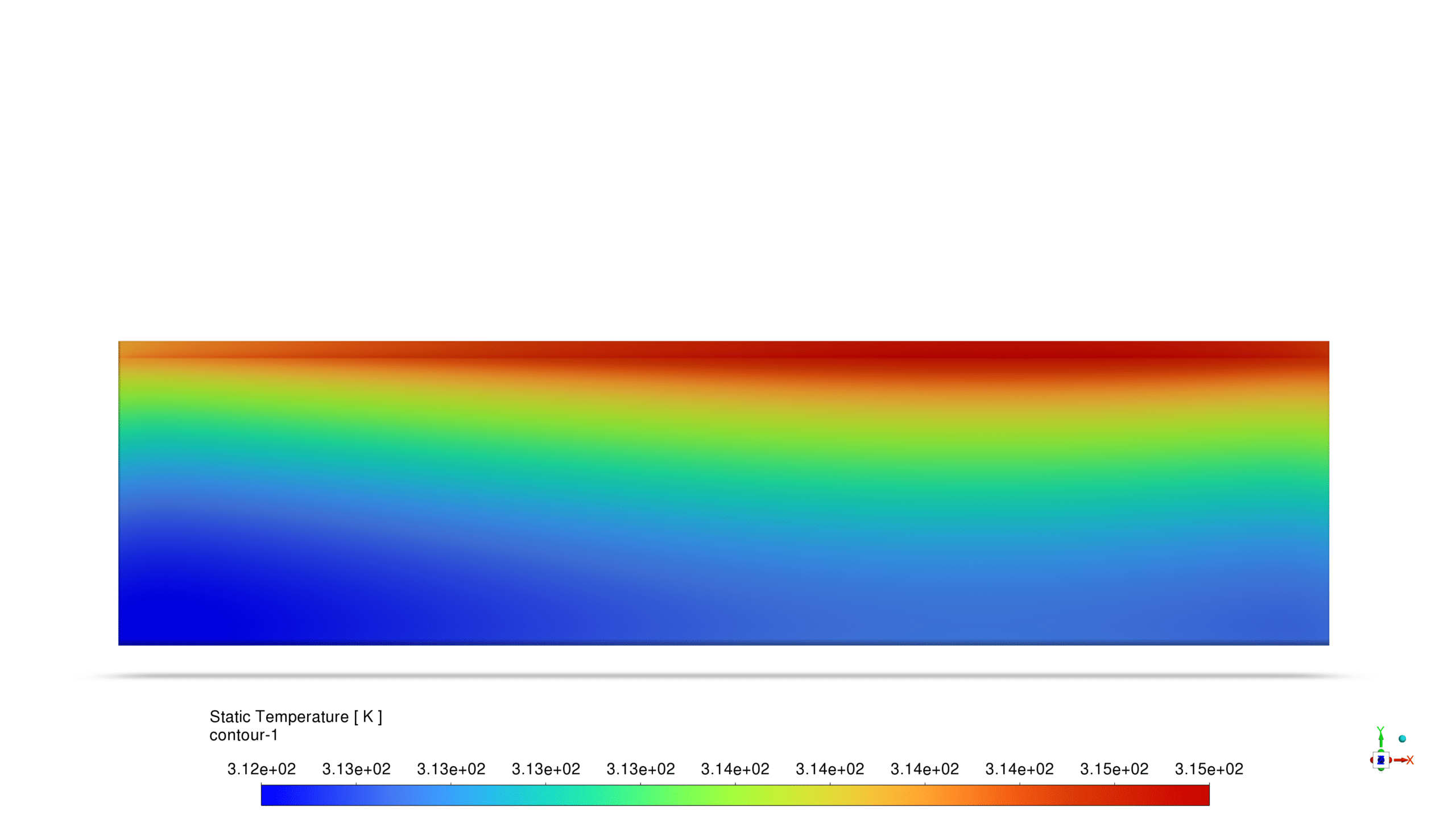

Conventional System (Without PCM):

Average PV temperature: 315.06 K (41.91°C)

Higher temperature gradients observed

Less uniform temperature distribution

Temperature difference of 1.81 K compared to PCM-enhanced system

3.2 PCM Phase Change Behavior

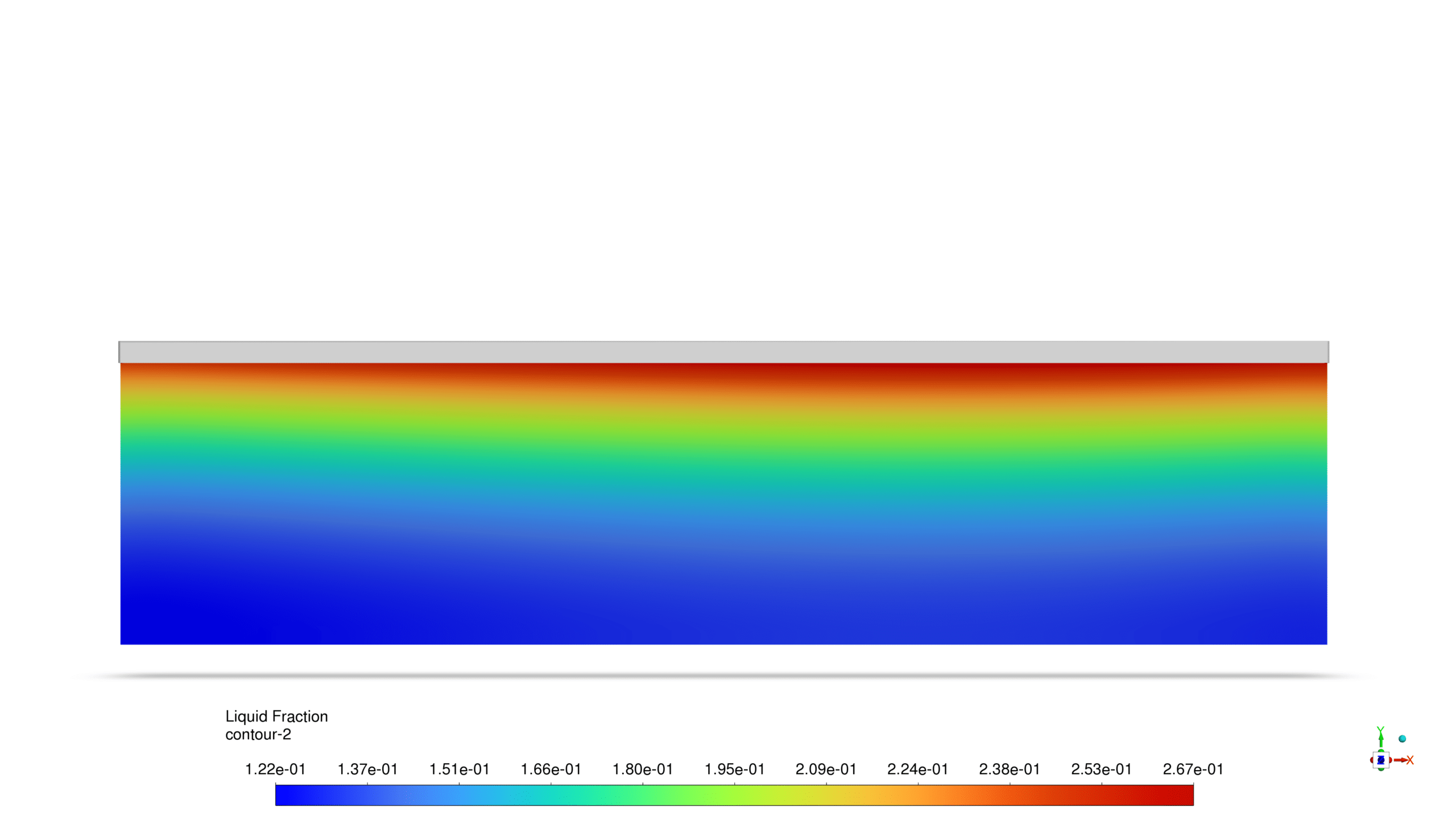

The liquid fraction contours reveal the PCM’s phase transition characteristics:

Gradual melting pattern from top to bottom

Liquid fraction varying from 0.122 to 0.267

Progressive phase change indicating effective thermal energy storage

3.3 Thermal Performance Comparison

The temperature contour plots illustrate:

More uniform thermal gradients in the PCM-enhanced system

Reduced maximum temperatures in the PCM-cooled configuration

Enhanced heat dissipation through the PCM layer

Temperature range of 312-317 K in the PCM case versus 312-315 K in the conventional case

3.4 System Efficiency Impact

The temperature reduction of 1.81 K achieved by the PCM system translates to:

Approximately 1.18% improvement in electrical efficiency (based on the typical -0.65%/°C temperature coefficient)

More stable operating conditions

Reduced thermal stress on PV components

Enhanced long-term reliability potential

These results demonstrate that the PCM cooling system effectively moderates PV panel temperature, providing a measurable improvement in thermal management compared to the conventional configuration. The phase change process acts as a thermal buffer, absorbing excess heat during peak solar radiation periods and maintaining more favorable operating temperatures.

Reviews

There are no reviews yet.