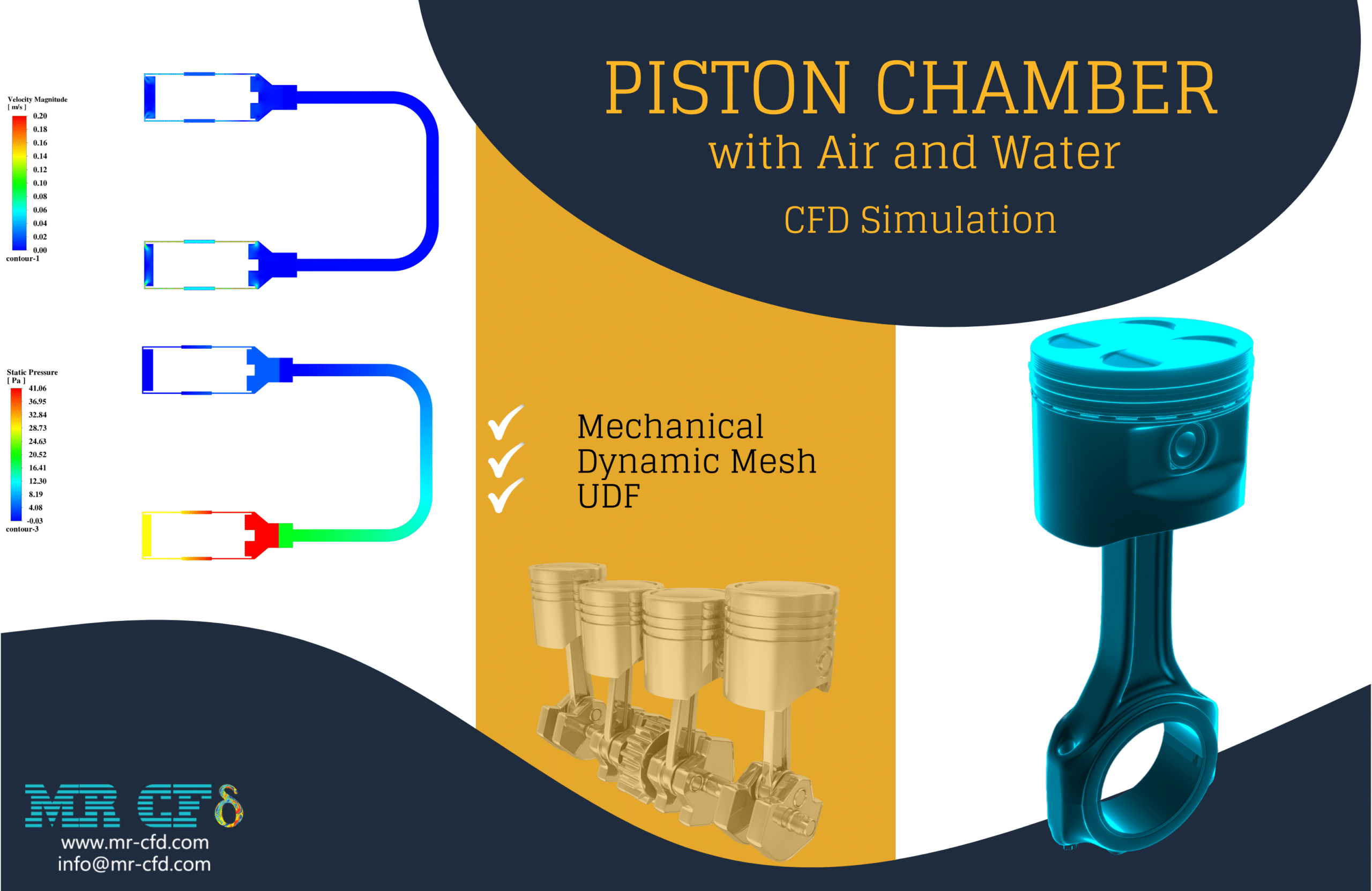

Piston Chamber with Air and Water CFD Simulation

$120.00 $60.00 Student Discount

- This study investigates the flow dynamics of air and water in a 2D piston chamber using CFD analysis in ANSYS Fluent.

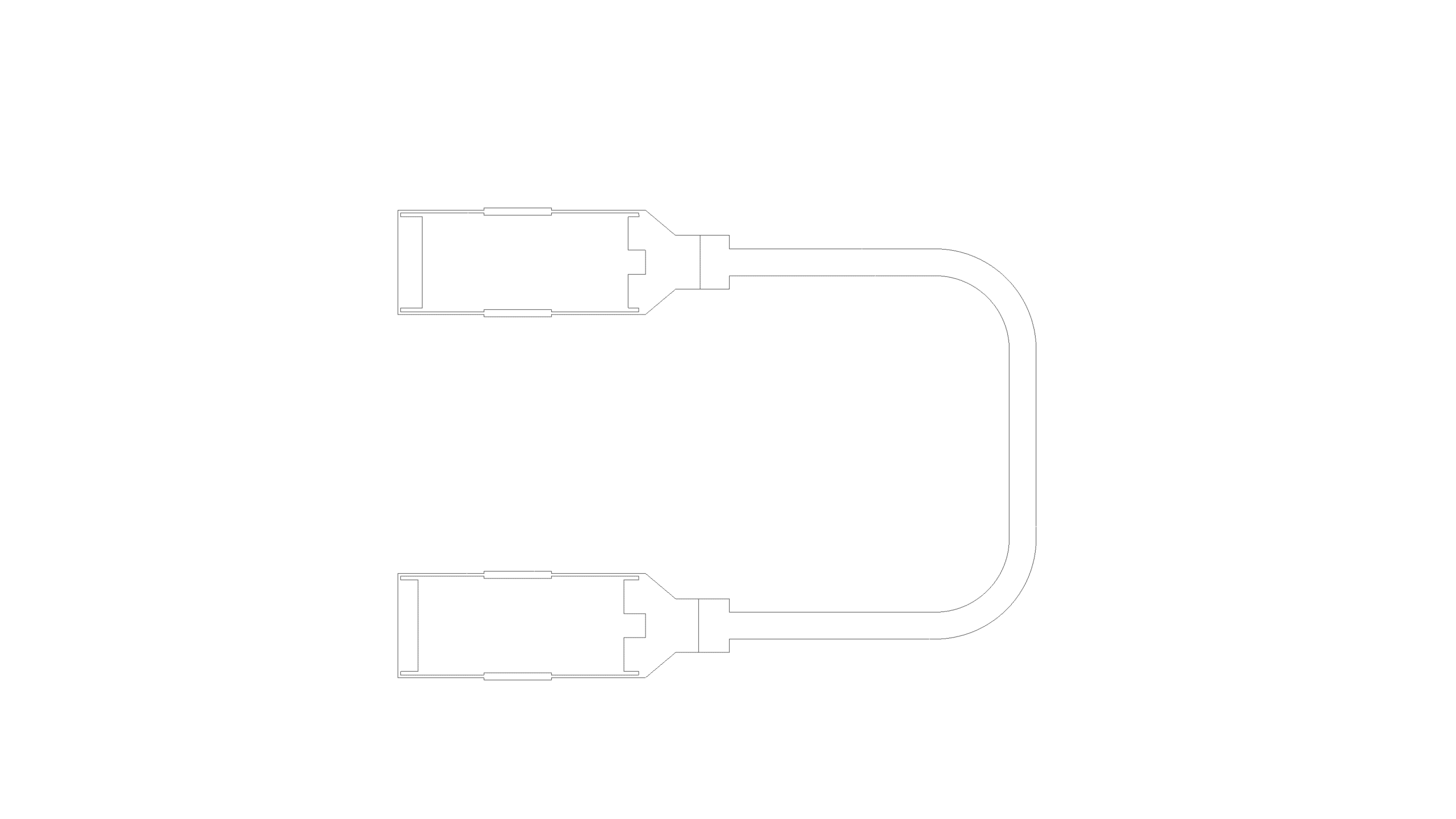

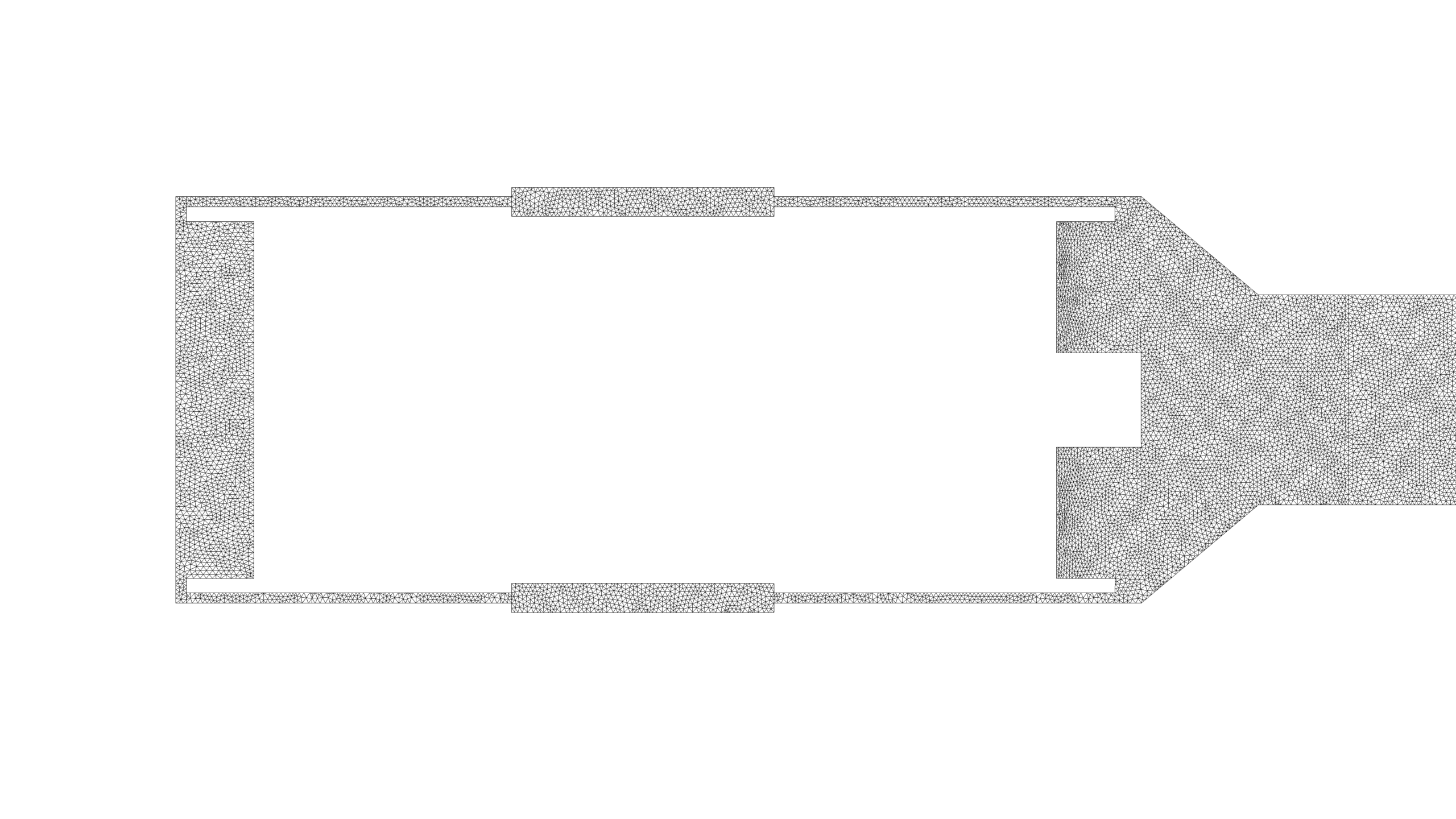

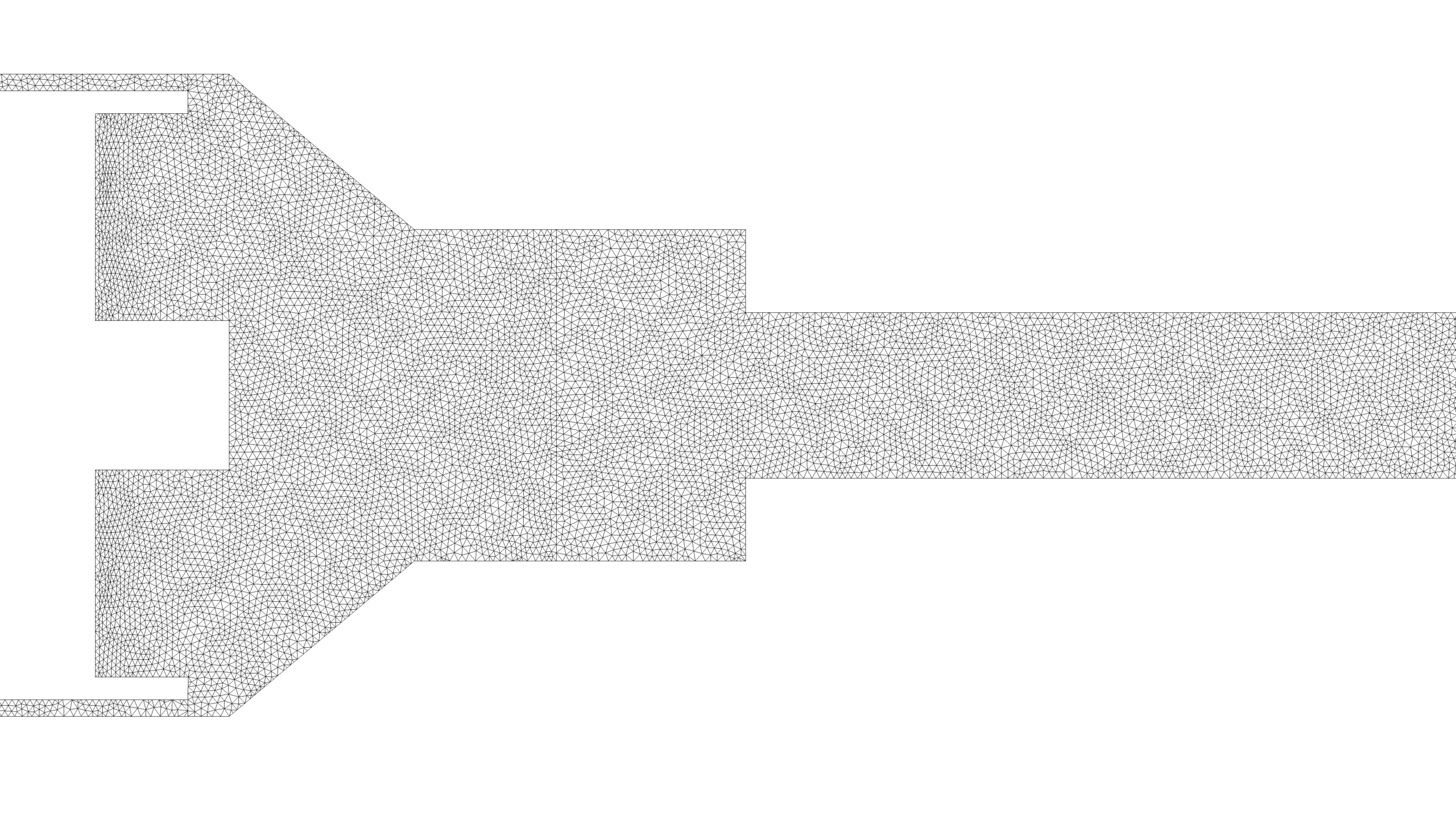

- The geometry was created in ANSYS Design Modeler and meshed using ANSYS Meshing.

- Six DOF Dynamic Mesh technique employed to accommodate piston movement.

- The simulation utilizes the SST k-ω turbulence model and includes the energy equation for temperature analysis.

- The transient simulation examines density variations, pressure distributions, temperature changes, and velocity profiles within the piston chamber.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

2D Piston chamber with Air and Water CFD Simulation, ANSYS Fluent Tutorial

Introduction

This study investigates the flow dynamics within a 2-dimensional piston configuration using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the complex interactions between air and water within the piston chamber, focusing on density variations, pressure distributions, temperature changes, and velocity profiles. By employing advanced models for turbulence, this research provides valuable insights into the dynamic behaviour of fluids in piston systems.

The CFD simulations were conducted using ANSYS Fluent software. The geometry, which is drawn in ANSYS Design Modeler, represents a 2-dimensional piston configuration, with the mesh generated in ANSYS Meshing, adapting to the piston movement using dynamic mesh techniques.

Methodology

For turbulence modelling, the SST k-ω model is utilized. It is known for its accuracy in predicting flow separation and performance in adverse pressure gradients.

Dynamic meshing techniques are employed to accommodate the moving piston:

Spring/Laplace/Boundary Layer mesh smoothing and remeshing method to maintain mesh quality during large deformations.

The simulation is transient, capturing the time-dependent behaviour of the fluid flow within the piston chamber.

The energy equation is enabled to solve for temperature distributions and heat transfer effects.

Results

The CFD simulations reveal significant insights into the piston flow dynamics:

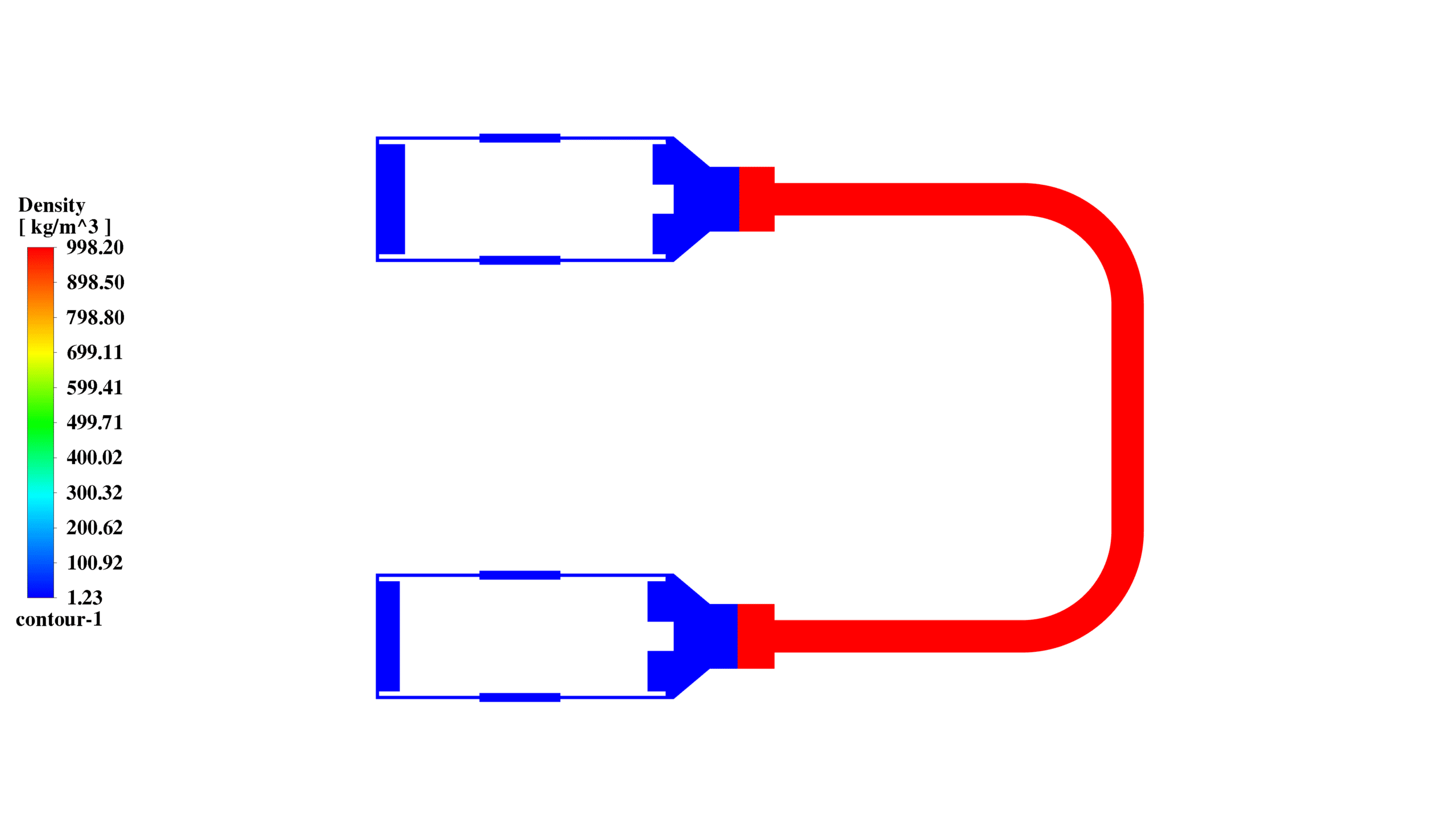

The density contour shows a clear distinction between air (blue, lower density) and water (red, higher density) regions. The maximum density observed is 998.20 kg/m³, corresponding to water, while the minimum density of 1.23 kg/m³ represents air.

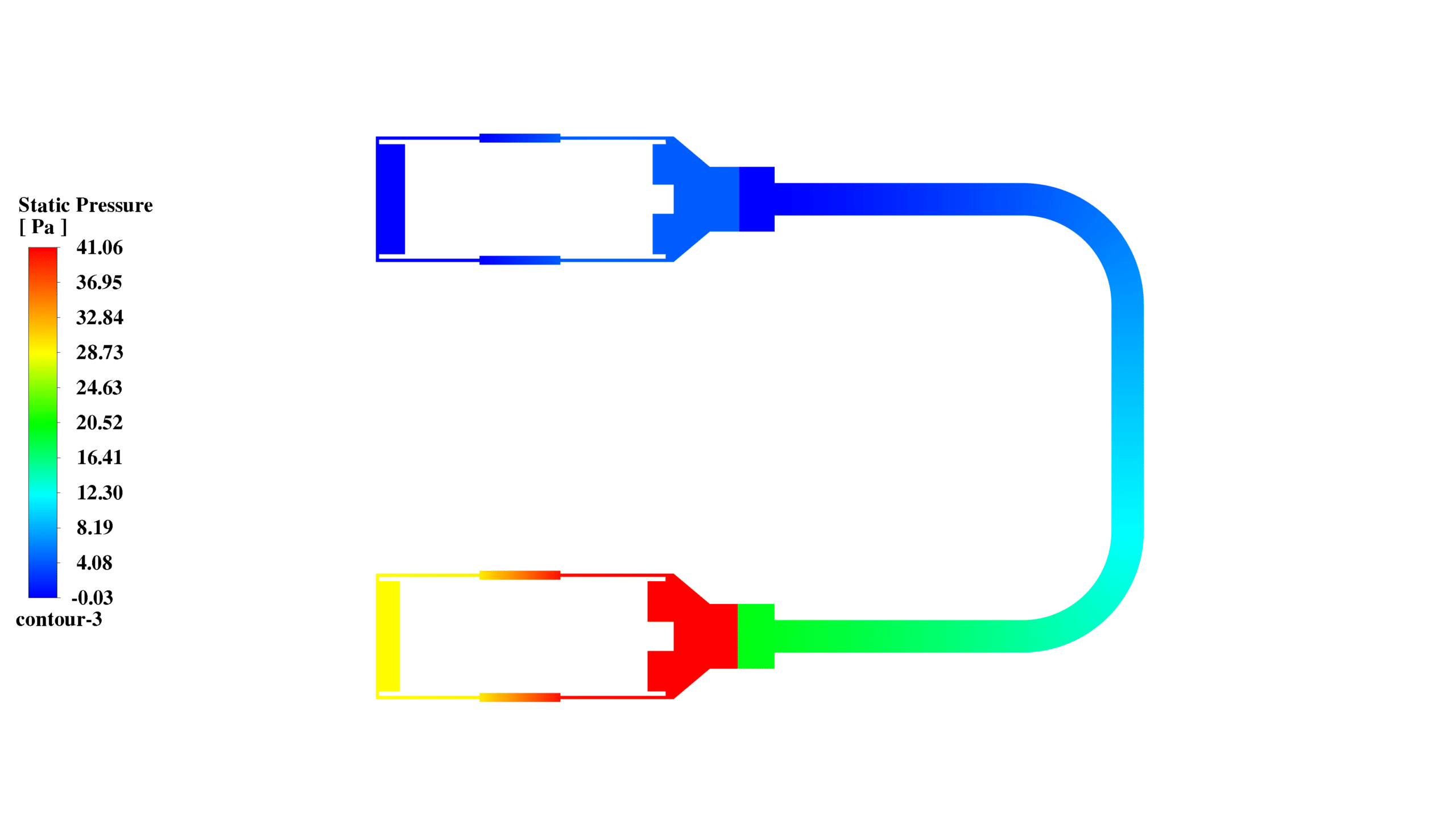

In addition, the static pressure contour indicates a maximum pressure of 41.06 Pa and a minimum of -0.03 Pa at this specific time. Higher pressures are observed in the water region and near the piston face, while lower pressures are seen in the air-filled areas.

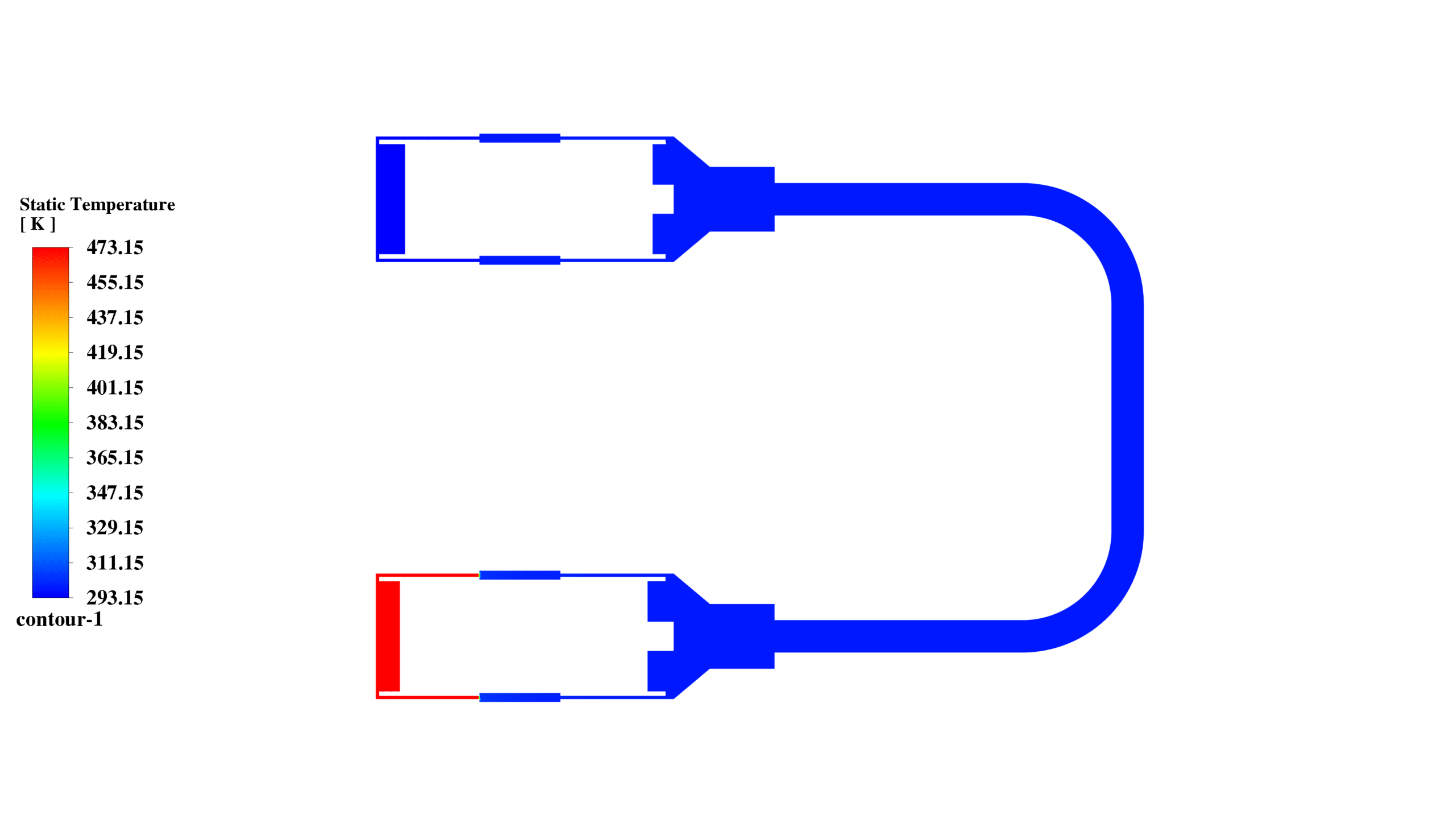

The static temperature contour shows a temperature range from 293.15 K to 473.15 K. Higher temperatures are observed in specific regions due to compression or friction effects.

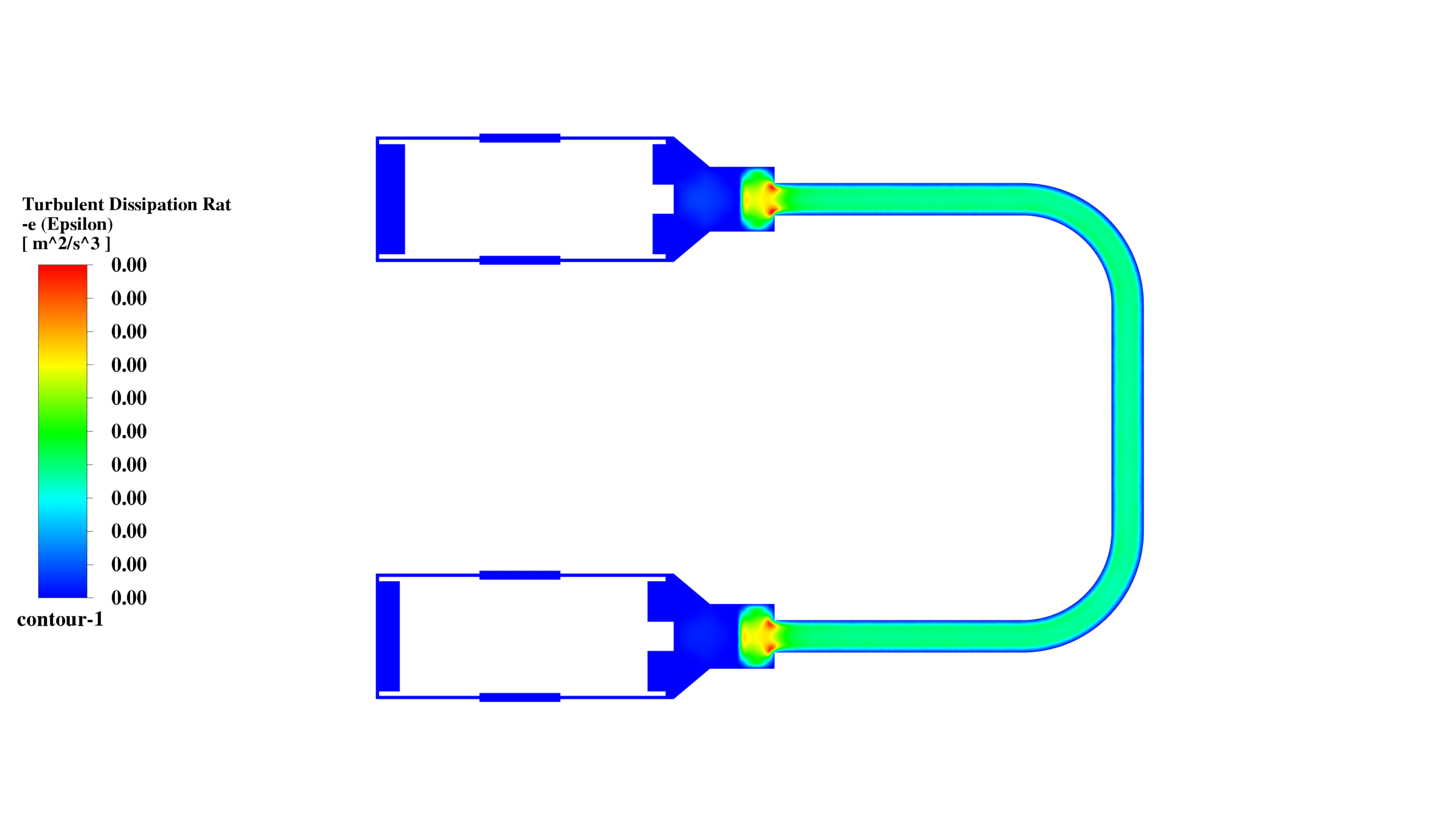

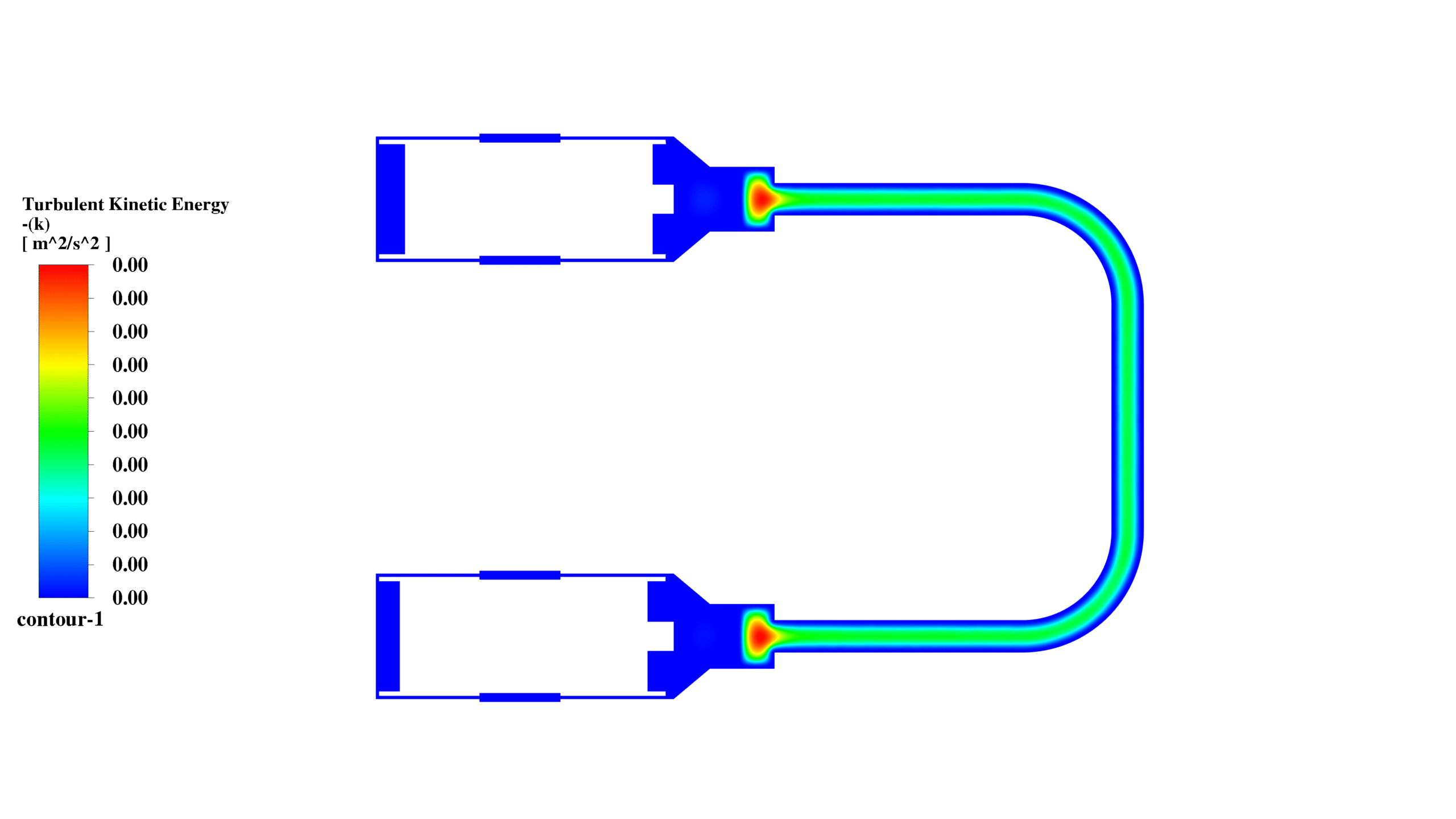

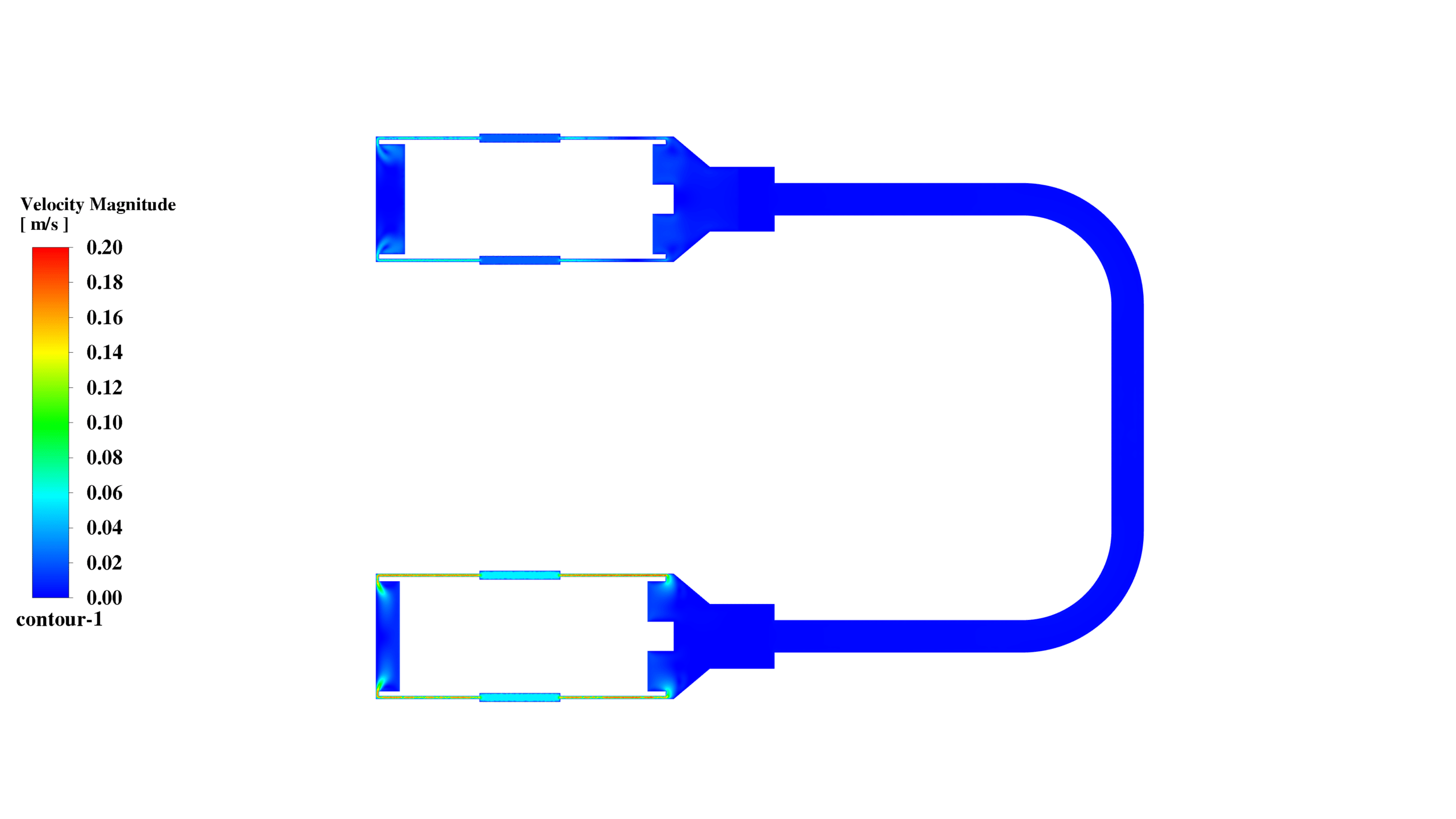

The velocity magnitude contour displays a maximum velocity of 0.20 m/s. Higher velocities are observed near the piston face and in regions where the flow is constricted. Furthermore, the turbulent kinetic energy and turbulent dissipation rate contours highlight areas of intense turbulence, particularly near the piston face and in regions of fluid interaction.

The simulation results demonstrate the complex interactions between air and water in the piston system. The density stratification, pressure variations, and velocity profiles provide insights into the fluid behaviour during piston movement. The temperature distribution suggests potential areas of heat generation or transfer within the system.

Reviews

There are no reviews yet.