Porous Medium Effects on Combustion Considering Radiation CFD Simulation

$240.00 $120.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Porous Medium Effects on Combustion Considering Radiation CFD Simulation, ANSYS Fluent Tutorial

Introduction

This study investigates the combustion process within a chamber containing a cylindrical porous medium using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the effects of the porous zone on the combustion dynamics, species distribution, and pollutant formation. By employing advanced models for turbulence, radiation, and chemical reactions, this research provides valuable insights into the complex interplay of fluid dynamics, heat transfer, and chemical kinetics in combustion systems.

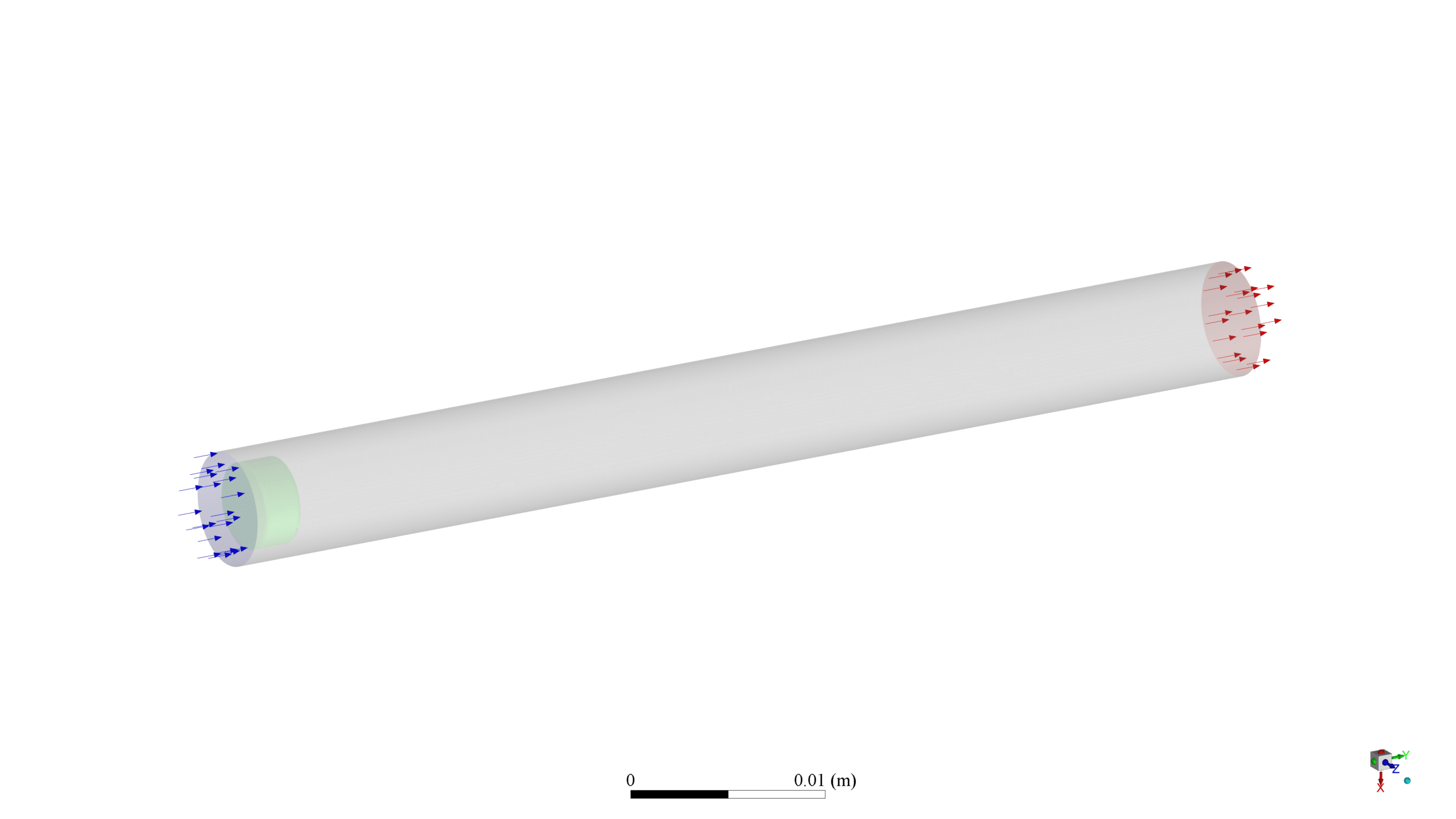

The CFD simulations were conducted using ANSYS Fluent software. The geometry was designed in ANSYS Design Modeler and meshed using ANSYS Meshing software, resulting in a high-quality mesh with 815,135 elements.

Methodology

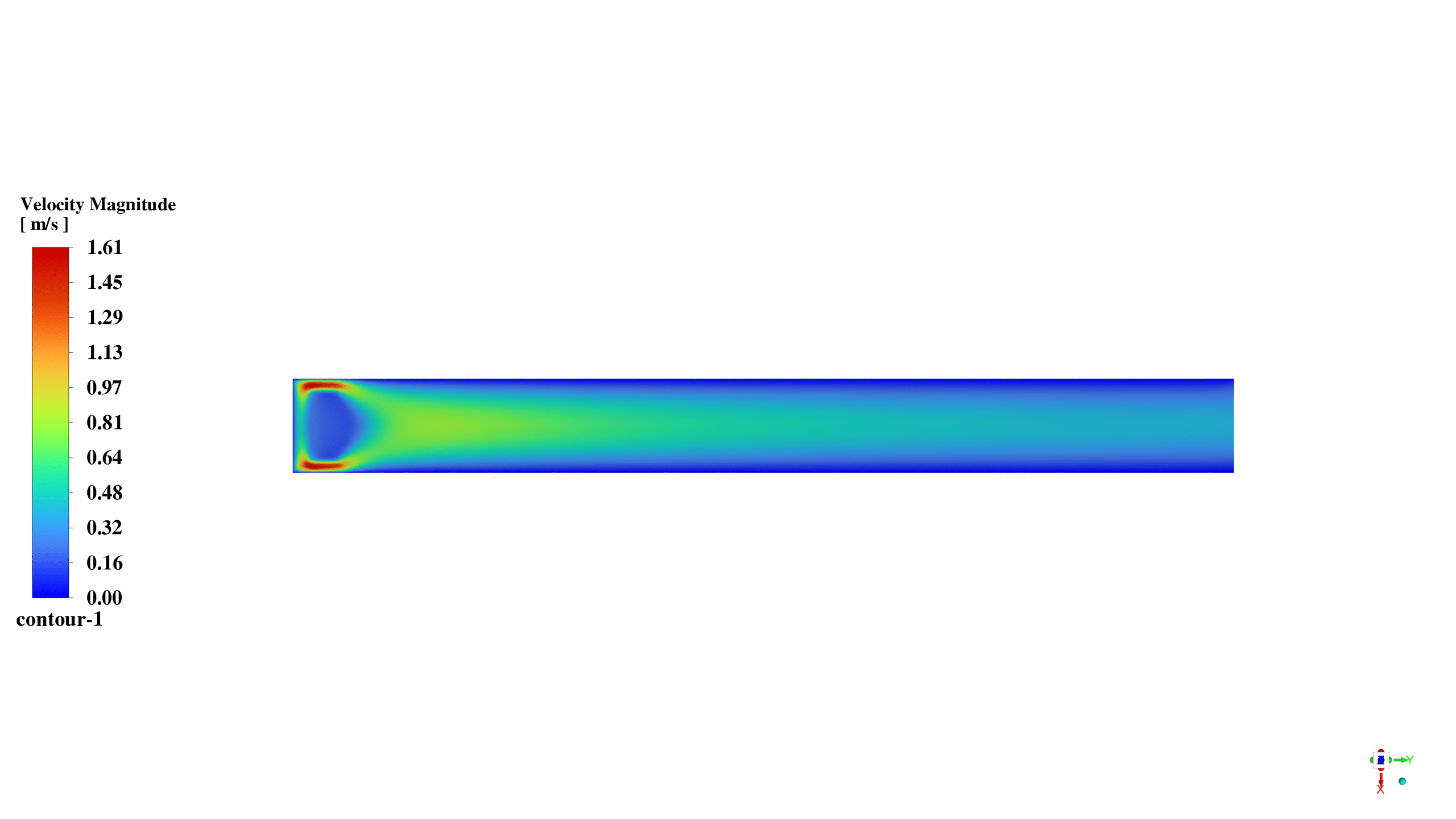

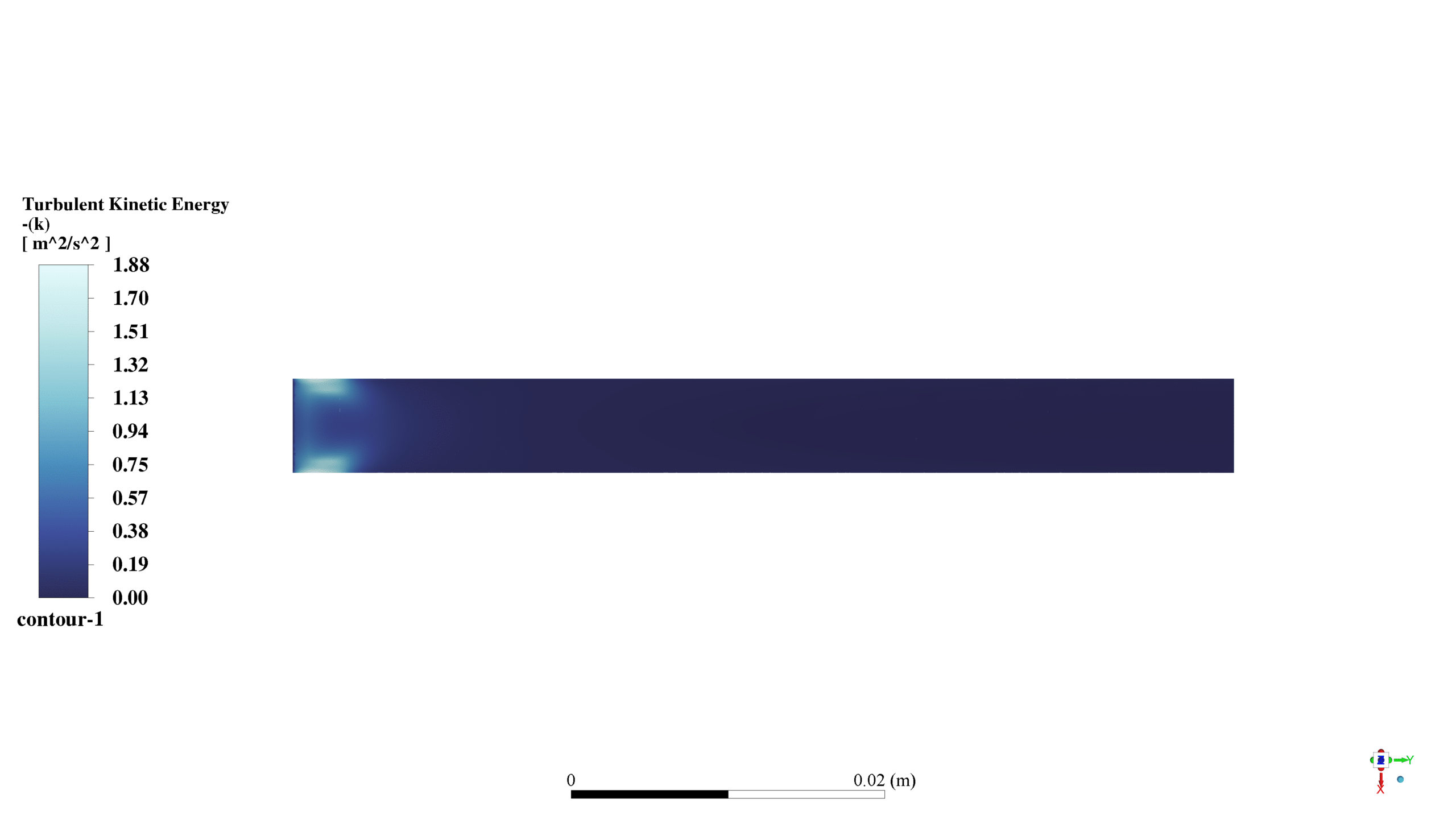

For turbulence modelling, the RNG k-ε model with standard wall function is utilized.

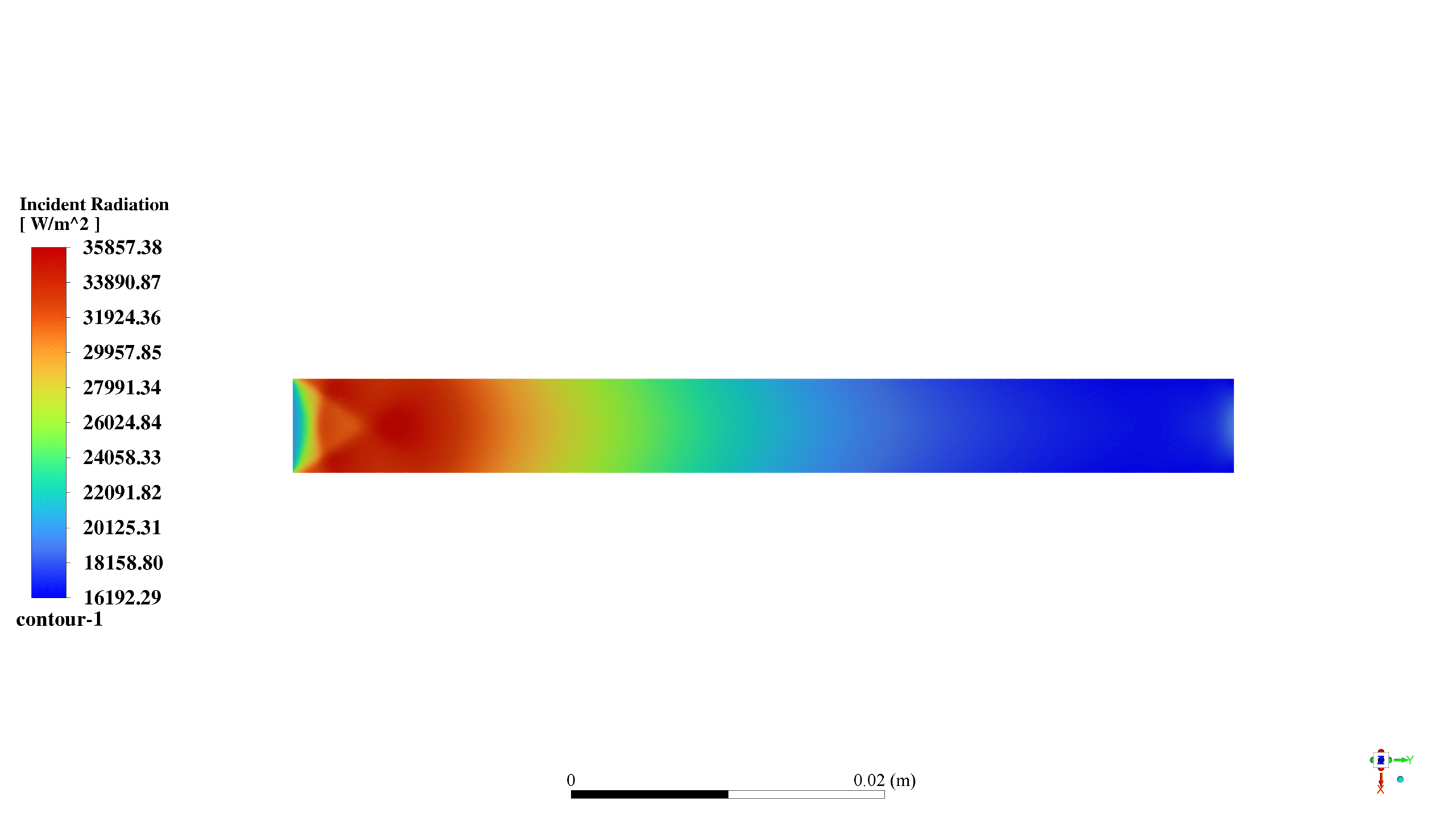

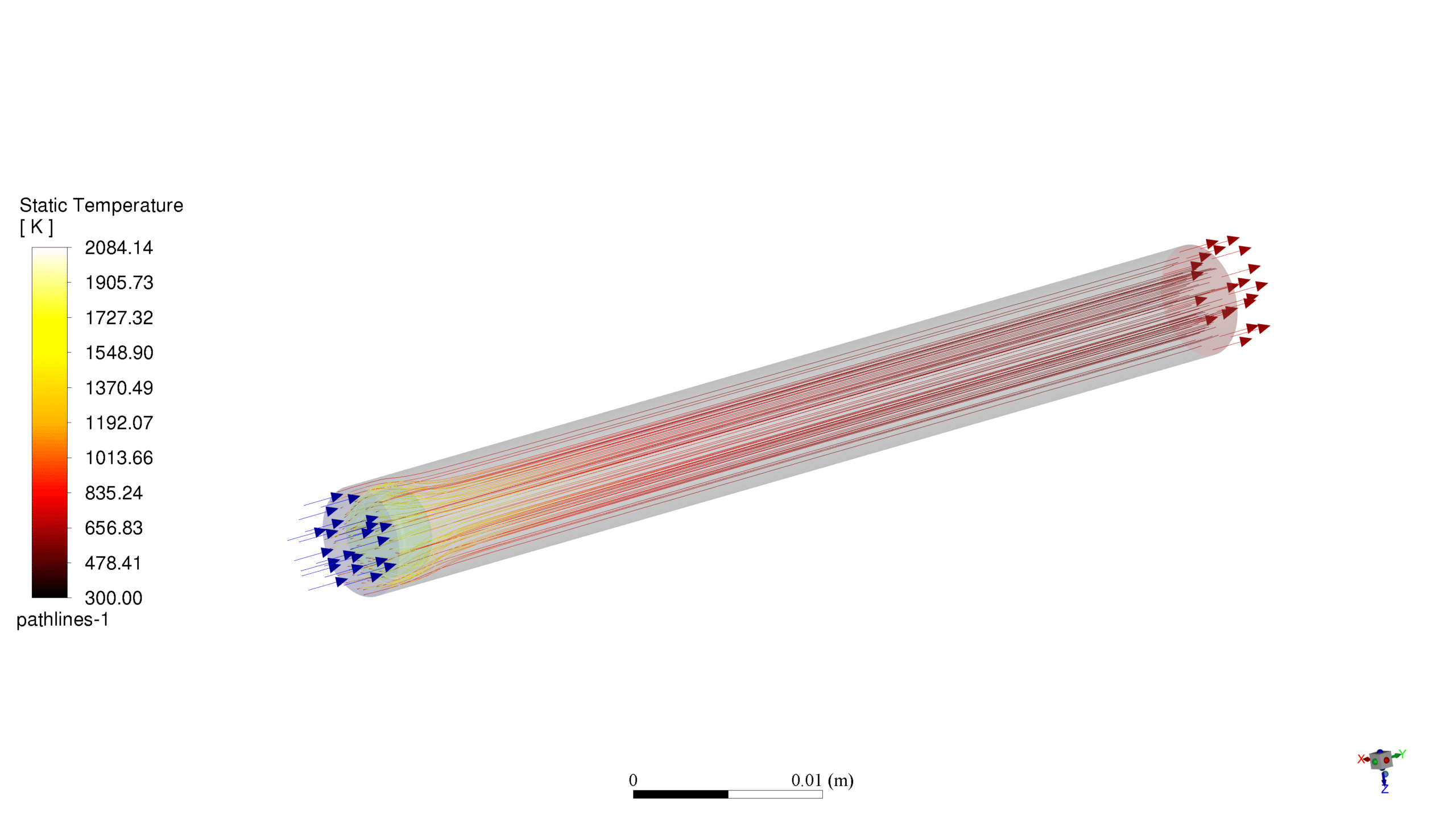

The Discrete Ordinate (DO) radiation model is implemented to account for radiative heat transfer, while the energy equation is enabled to solve for temperature distributions.

The combustion process is simulated using the Species Transport model with Volumetric Reactions coupled with the Finite-Rate/No TCI Turbulence-Chemistry Interaction model. A detailed chemical mechanism comprising 17 different species and 35 reactions is imported into the software via a chemkin file to capture the complex chemistry.

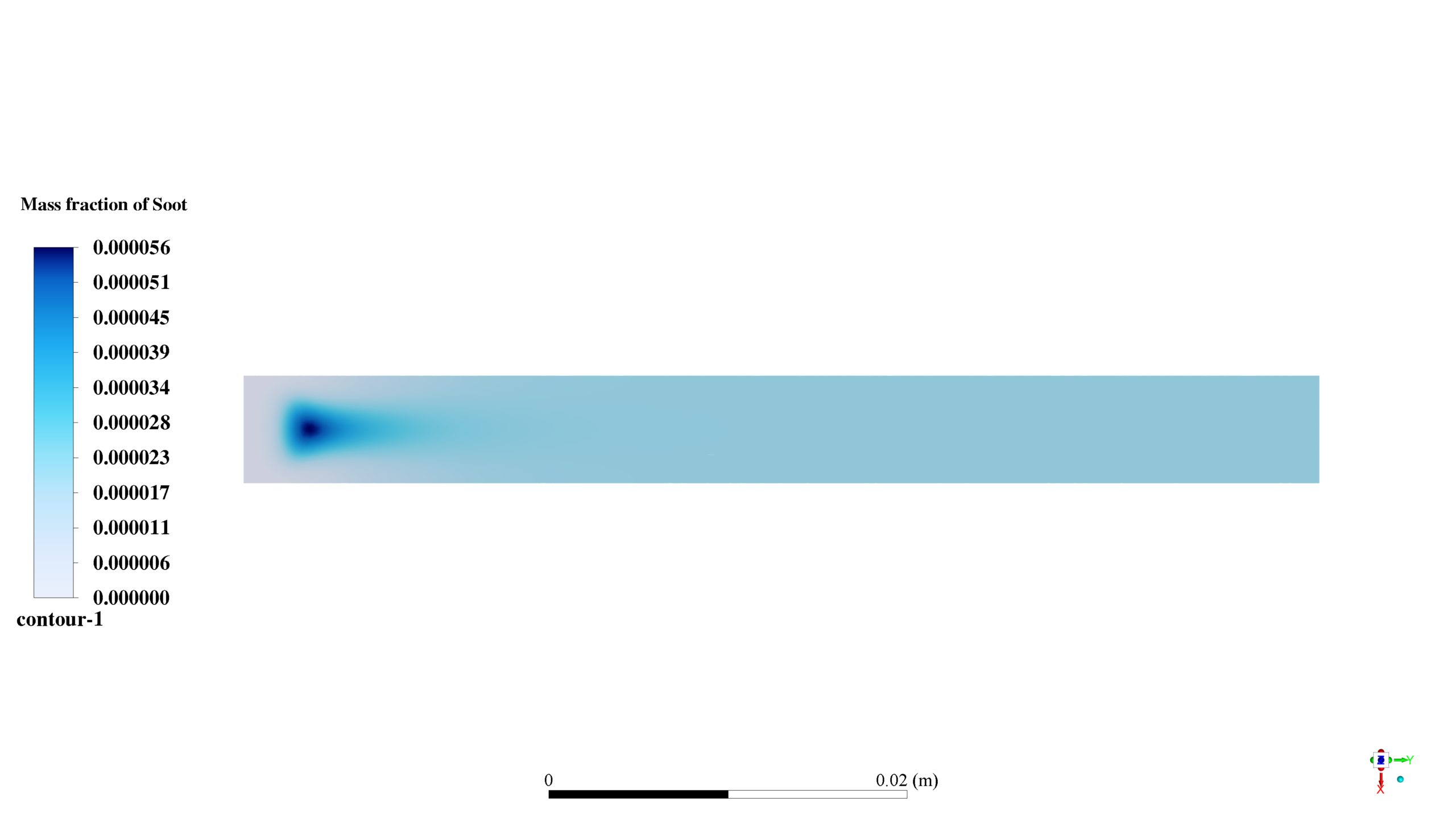

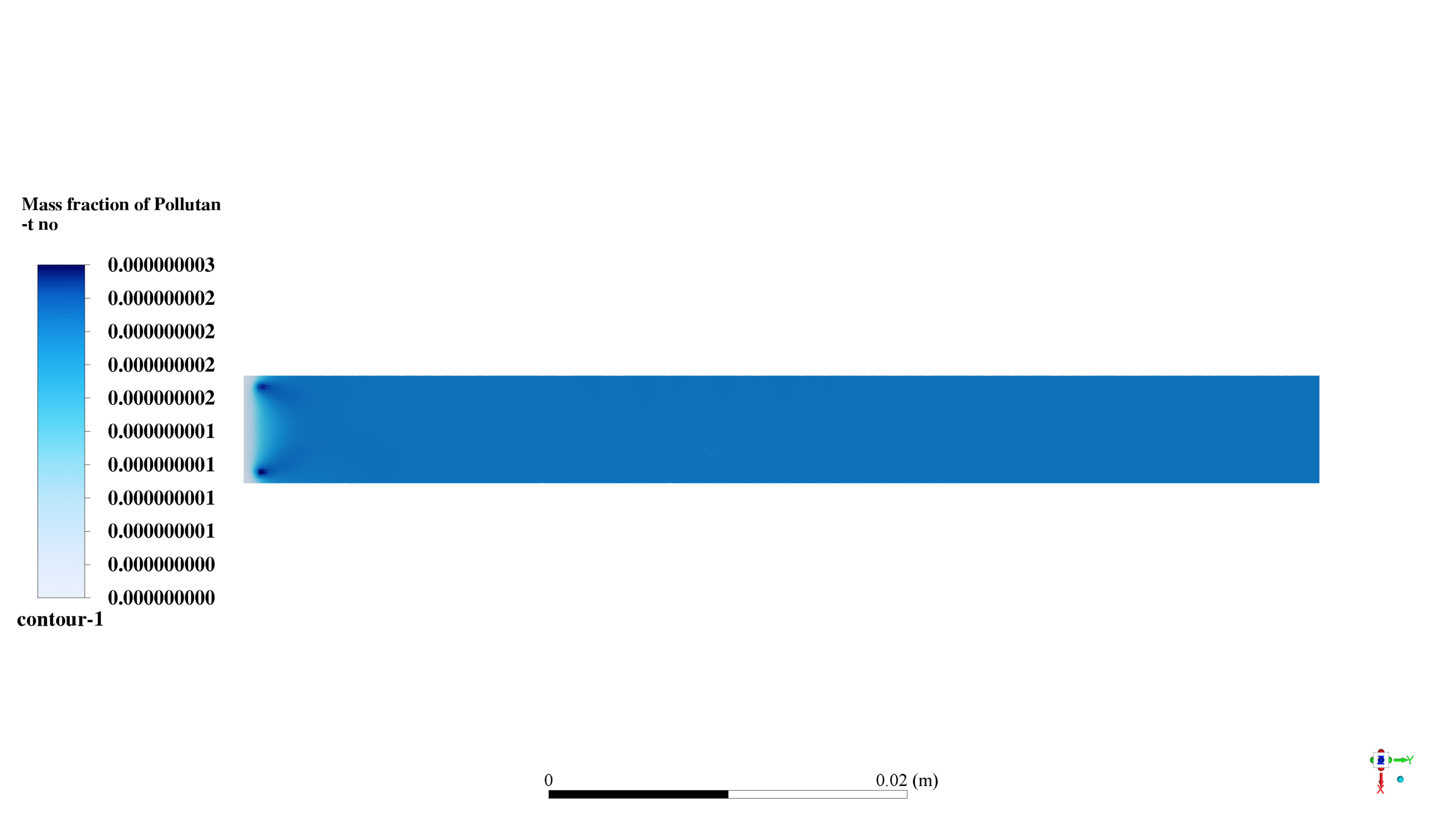

To predict pollutant formation, the NOx submodel is enabled, accounting for both Thermal NOx and Prompt NOx pathways. Additionally, the Soot submodel employing the Moss-Brookes model is activated, with the Fenmore-Jones model chosen for soot oxidation.

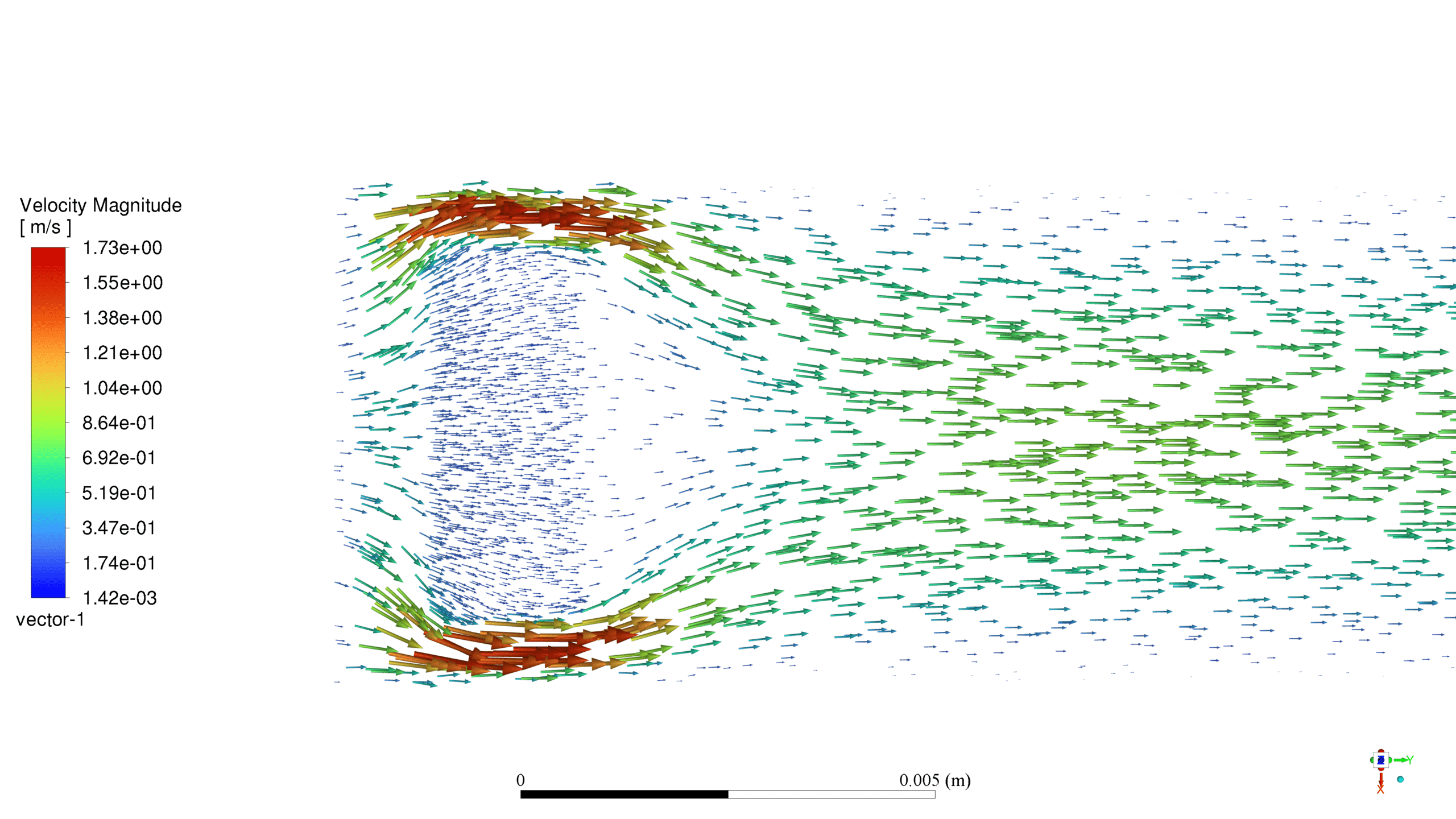

The porous medium is represented by a cylindrical zone near the inlet boundary condition, with a fluid porosity of 0.5.

Results

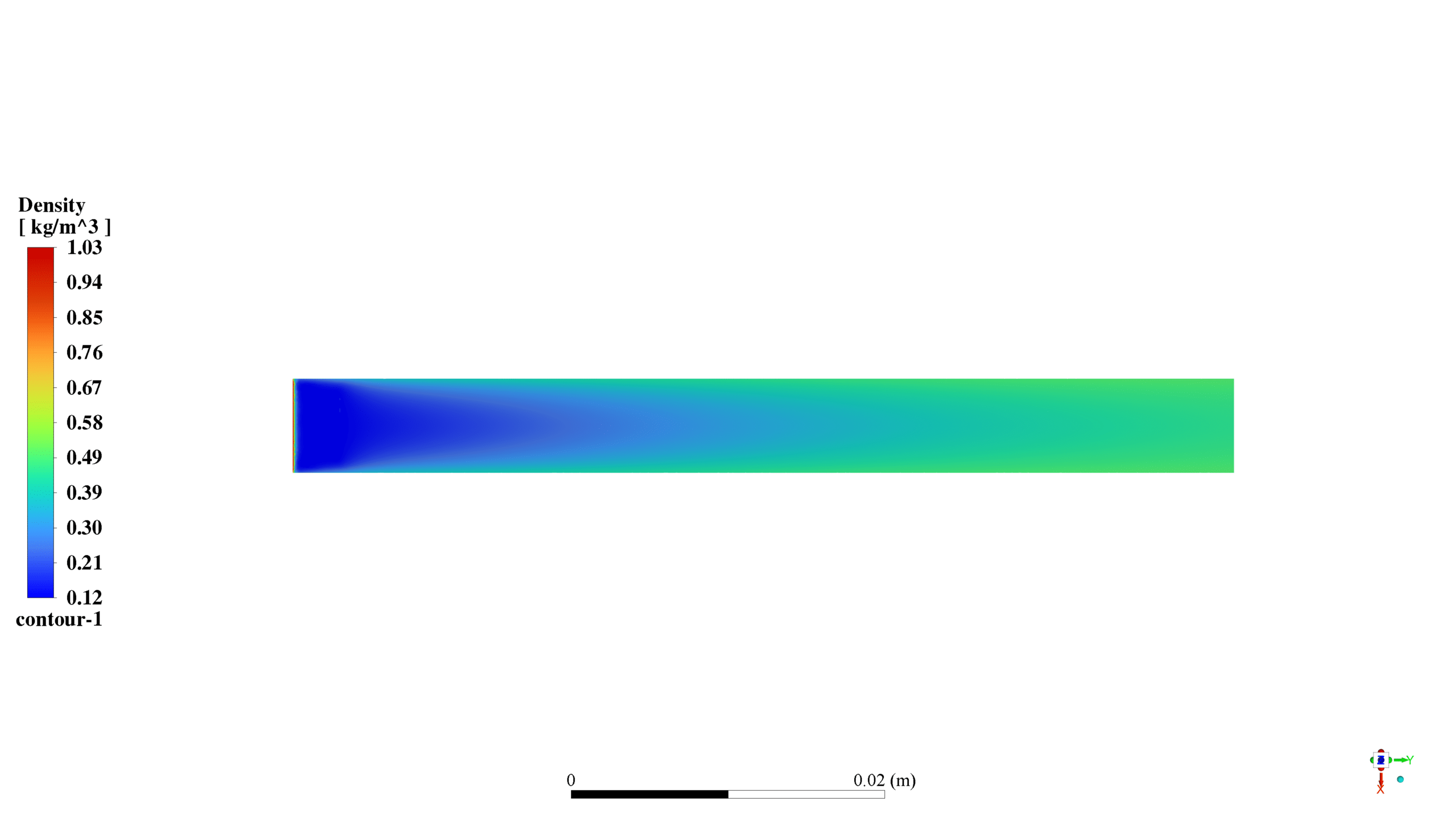

The CFD simulations reveal significant insights into the combustion process:

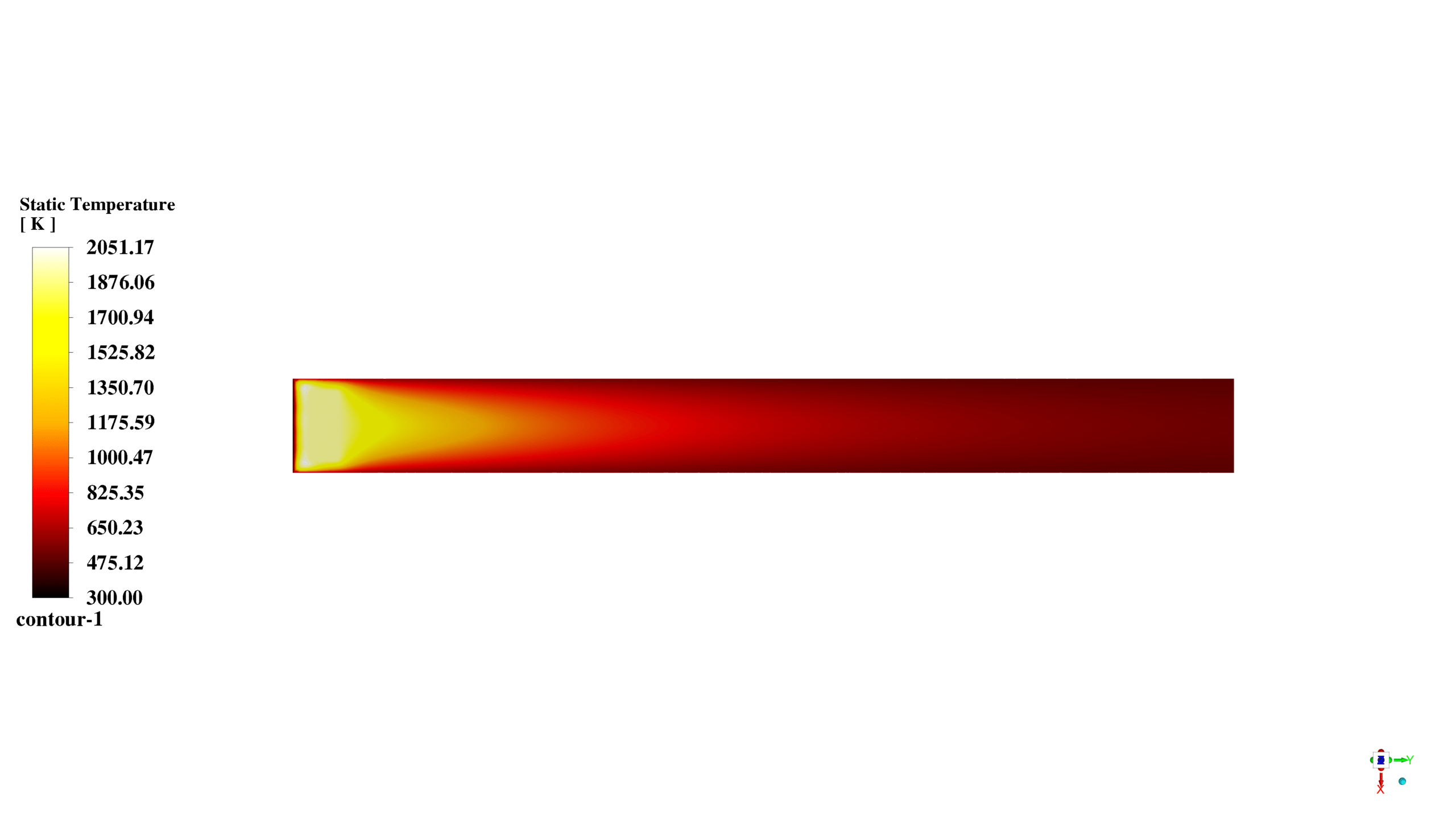

The velocity magnitude contour shows a maximum velocity of 1.61 m/s near the inlet, with flow deceleration along the chamber length. In addition, the static temperature contour indicates a maximum temperature of 2051.17 K in the reaction zone, gradually decreasing towards the outlet.

The incident radiation contour displays a maximum value of 35,857.38 W/m^2 near the inlet, decreasing towards the outlet, indicating significant radiative heat transfer in the combustion zone.

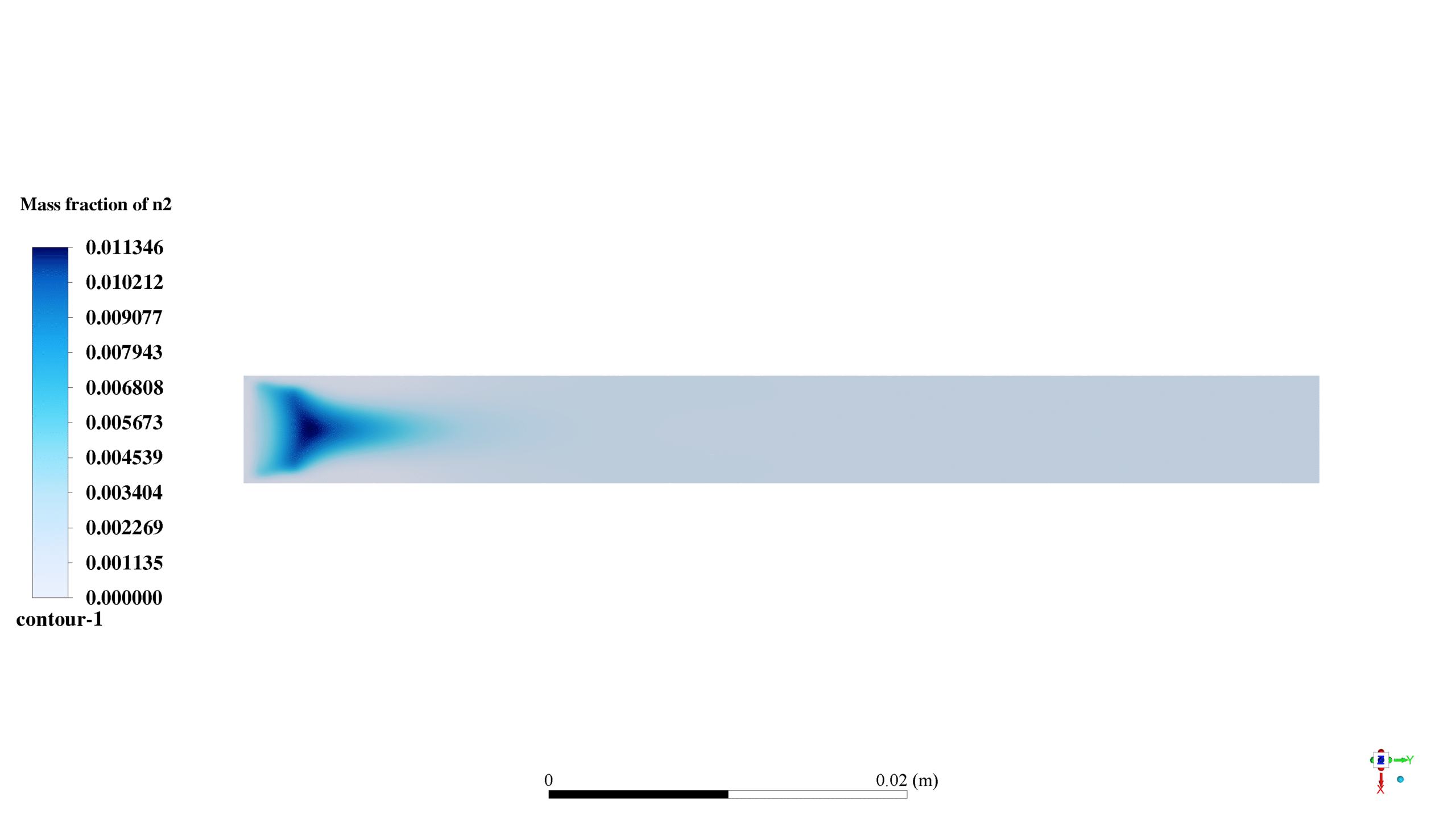

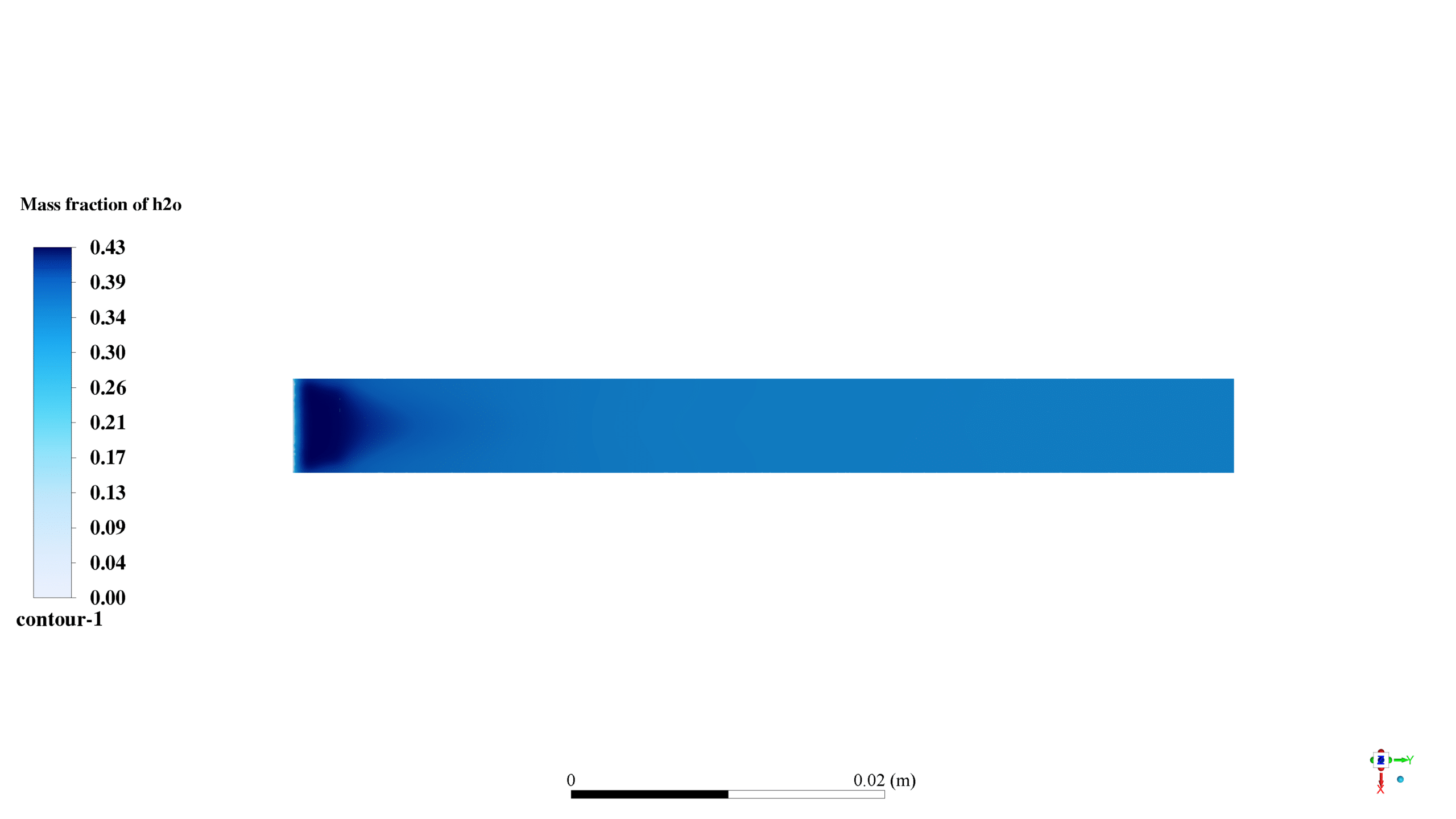

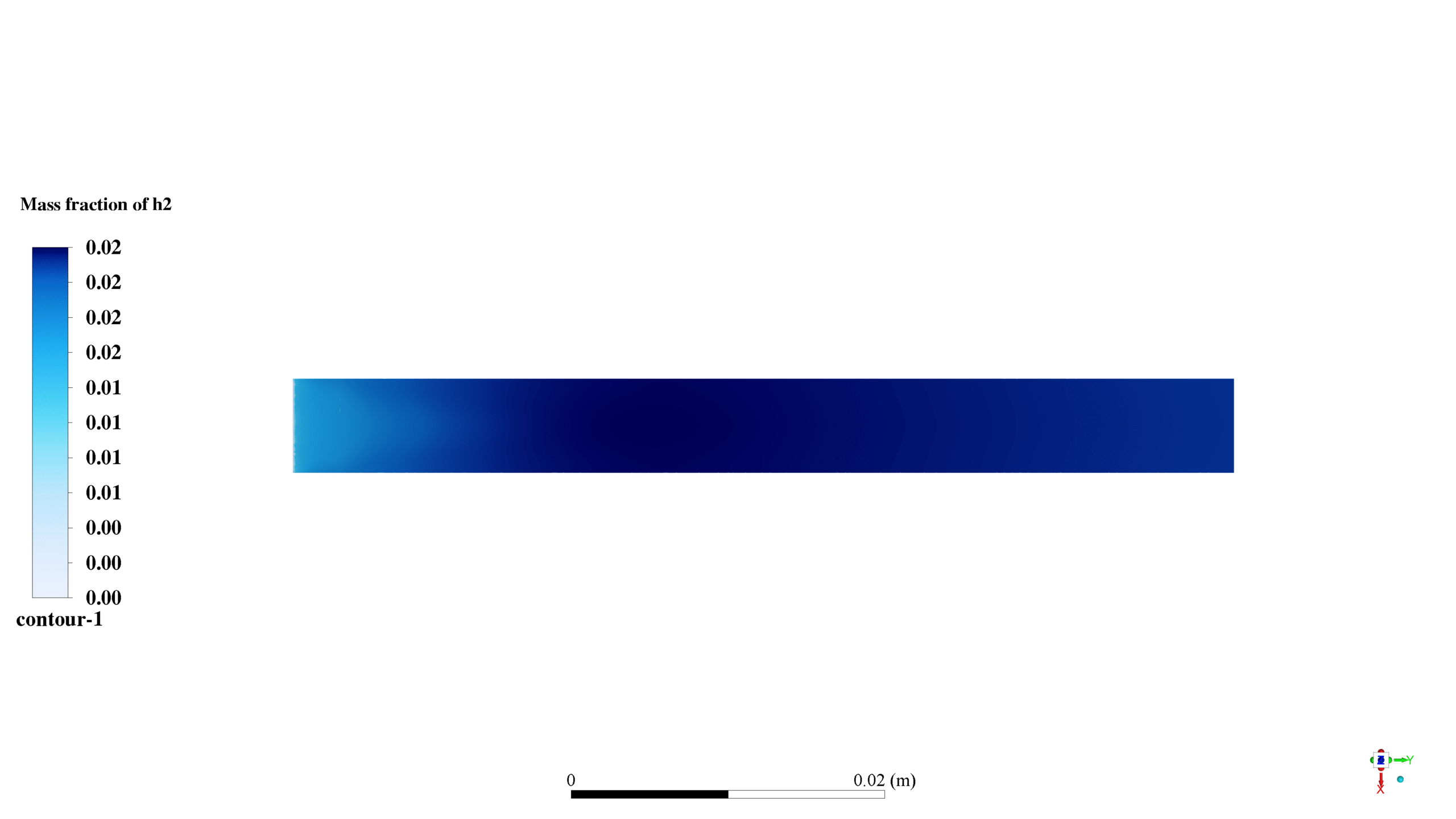

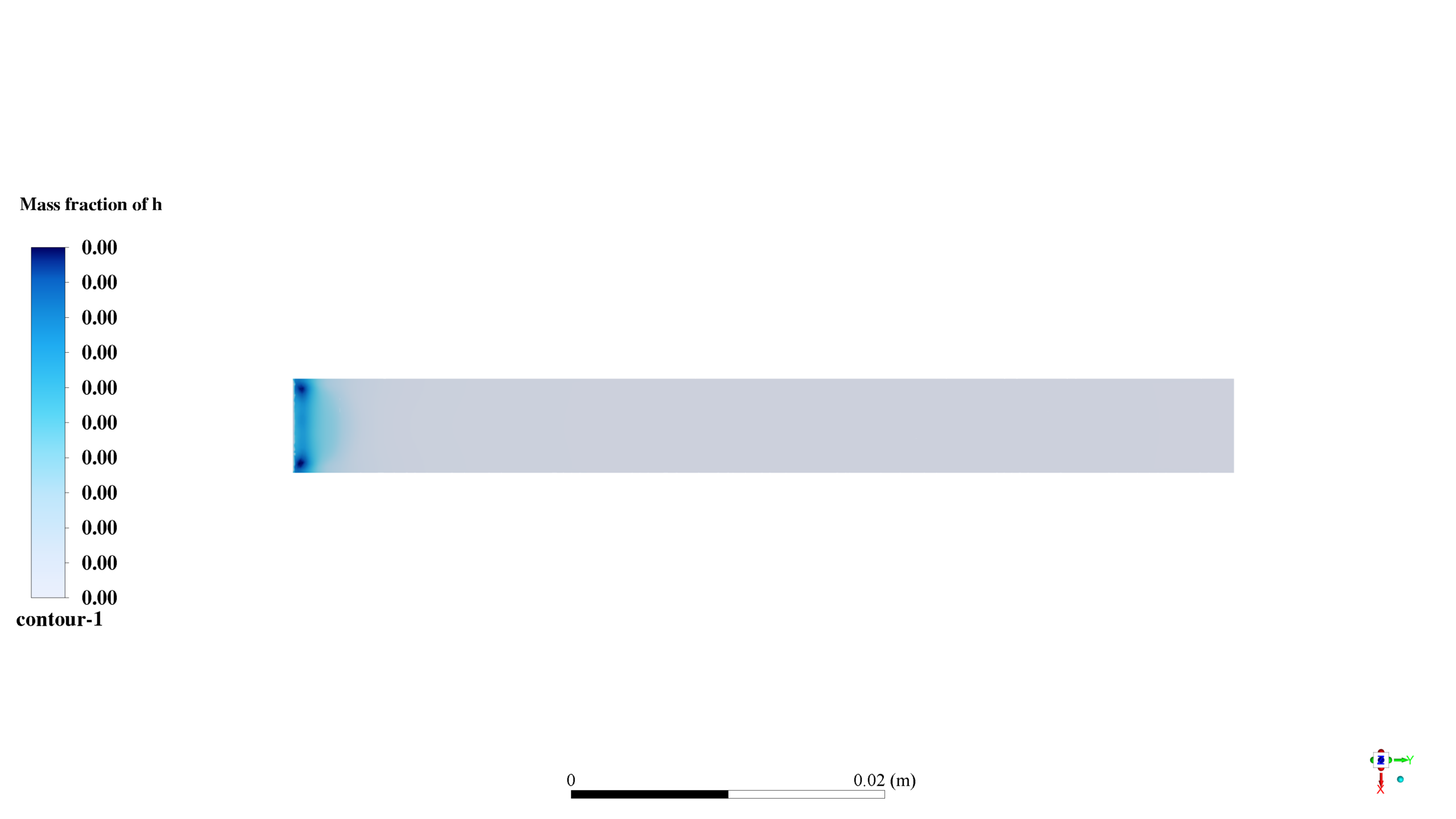

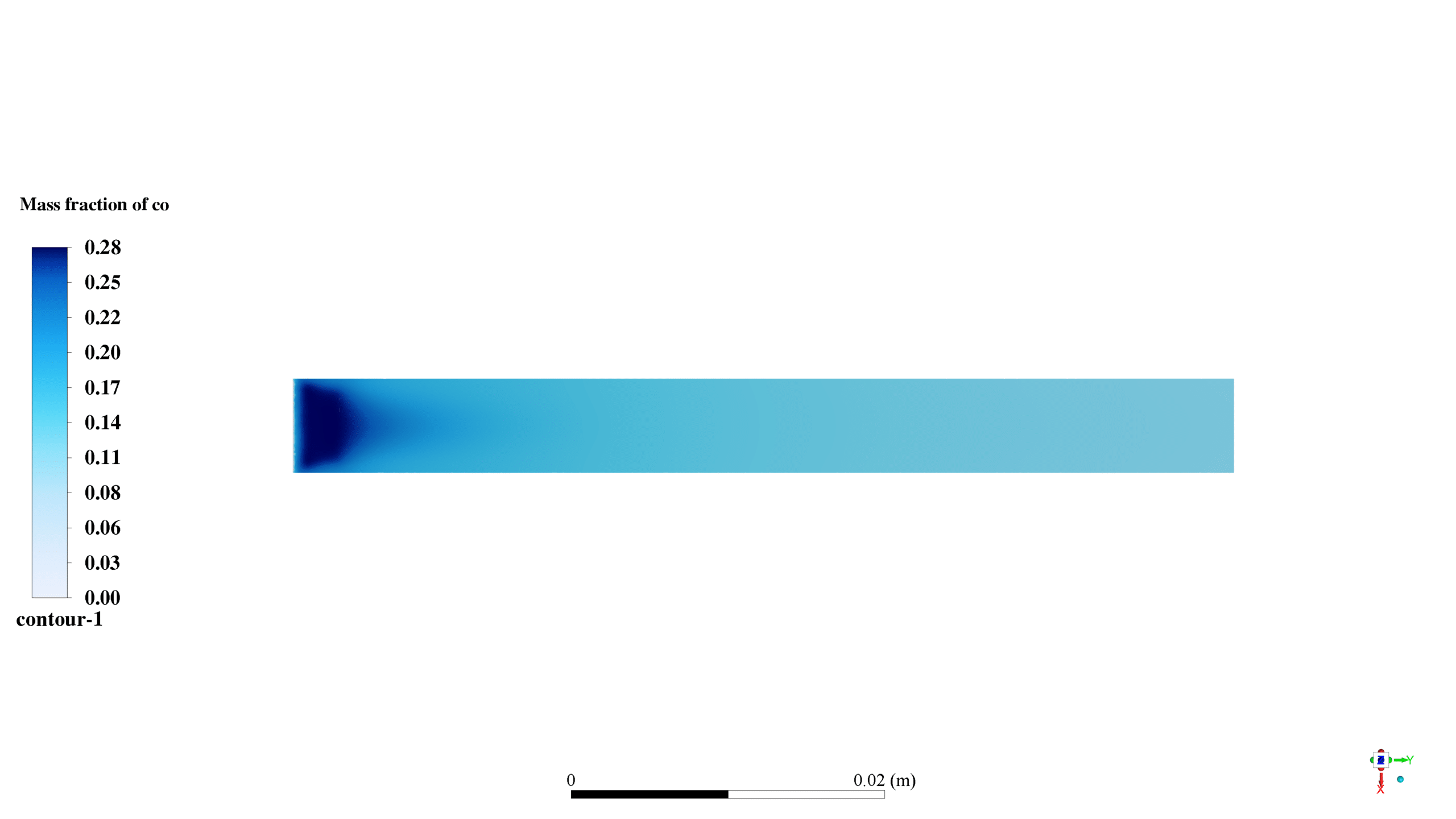

Species Distribution:

Soot: Maximum concentration of 0.000056 near the inlet, rapidly decreasing along the chamber.

NOx: Very low concentrations, with a maximum of 3E-9.

H2O: Maximum mass fraction of 0.43, higher near the inlet and along chamber walls.

CO: Maximum mass fraction of 0.28, higher concentrations in the reaction zone near the inlet.

The simulation results demonstrate the complex interactions between fluid flow, heat transfer, and chemical reactions in the combustion chamber. The porous medium significantly influences the flow patterns, temperature distribution, and species concentrations. The formation and distribution of pollutants such as NOx and soot are captured, providing insights into potential emission reduction strategies.

This analysis can be used to optimize combustion chamber design, improve efficiency, and reduce pollutant emissions. Using the Design of Experiments (DOE), further studies could explore the effects of varying porosity, different porous medium configurations, or alternative fuel compositions on the combustion process.

Reviews

There are no reviews yet.