Porous Zone Inside 3D Channel ANSYS CFX Tutorial

$60.00 $30.00 Student Discount

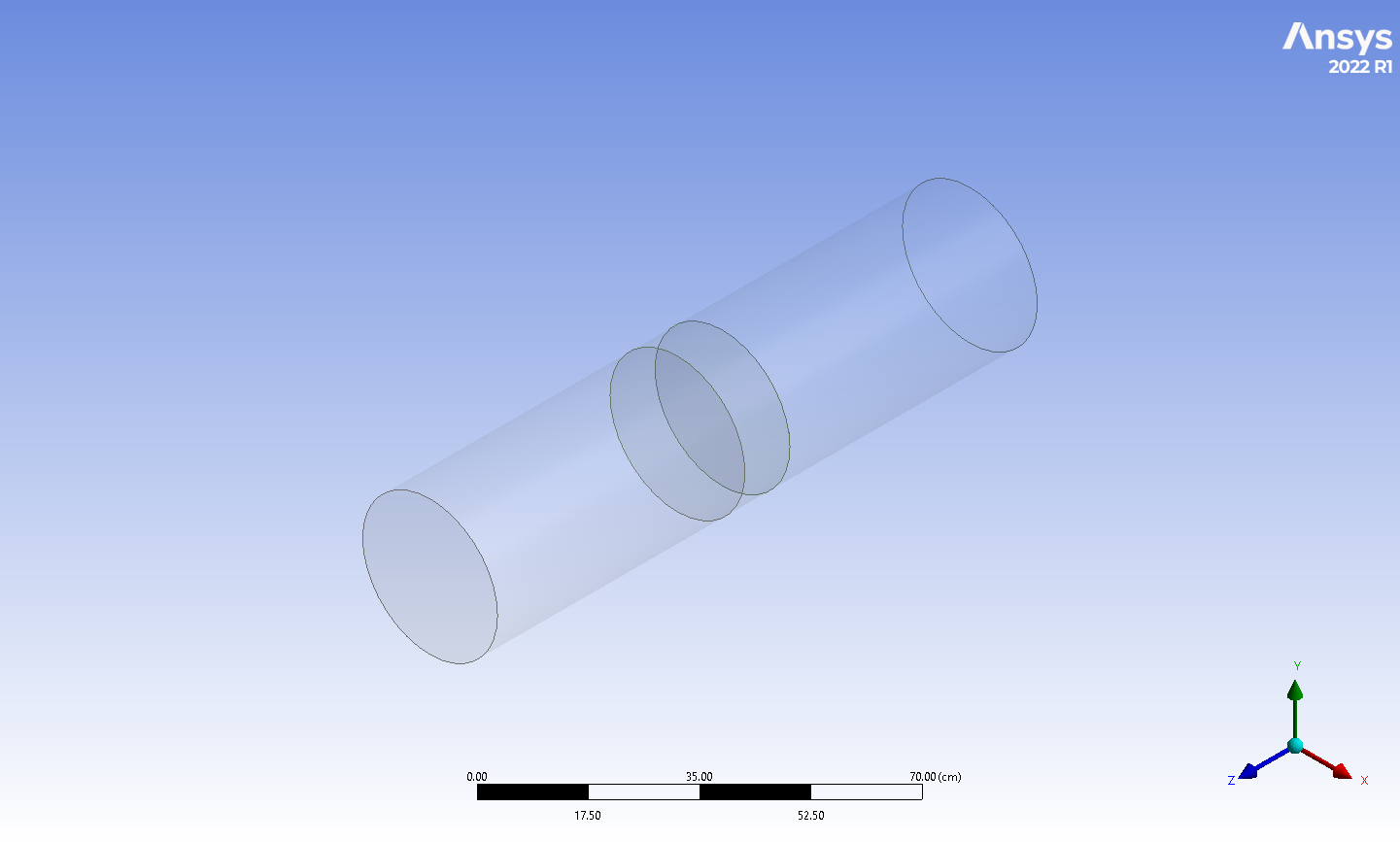

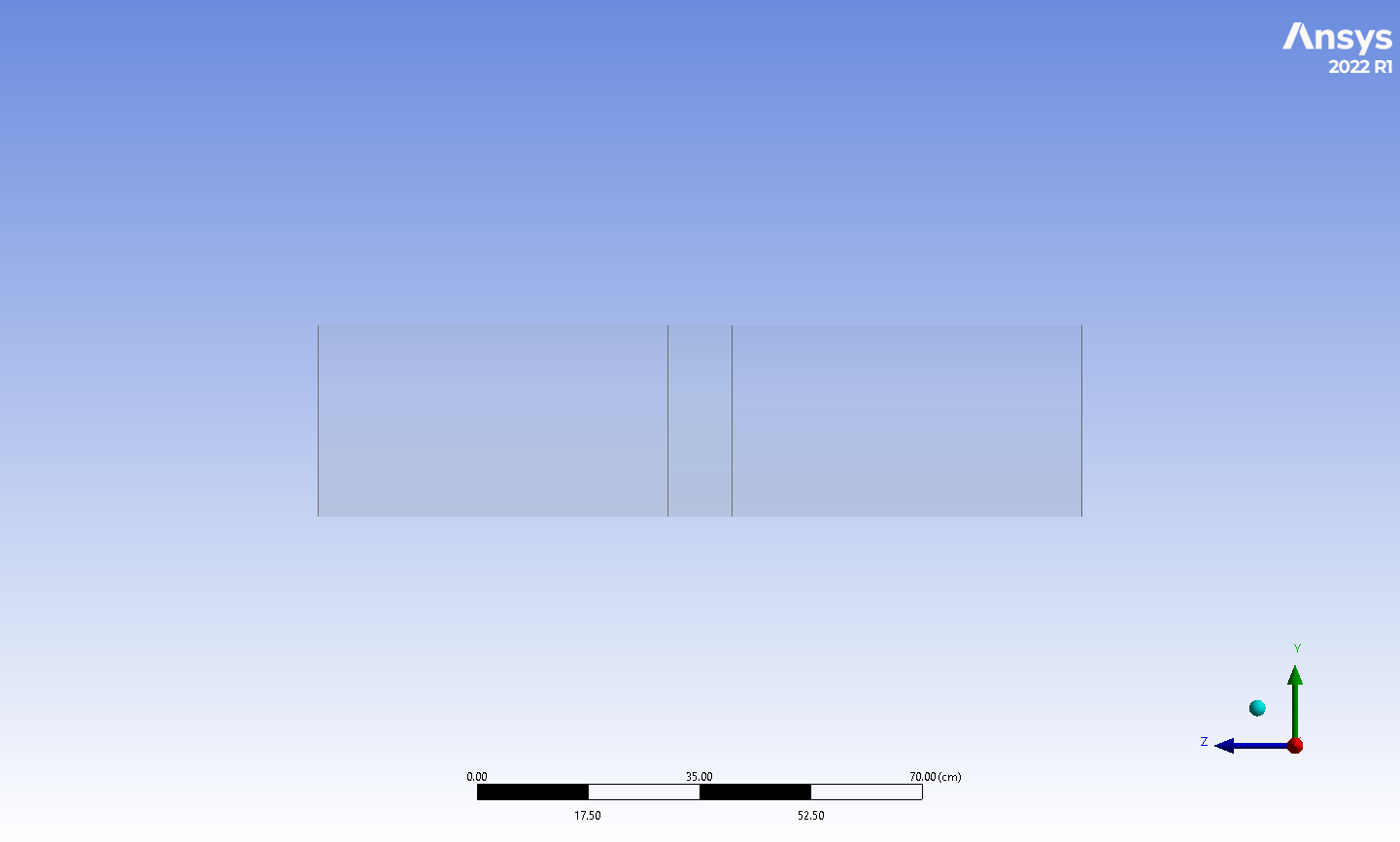

- The problem numerically simulates a Porous Zone inside 3D cylinder using ANSYS CFX software.

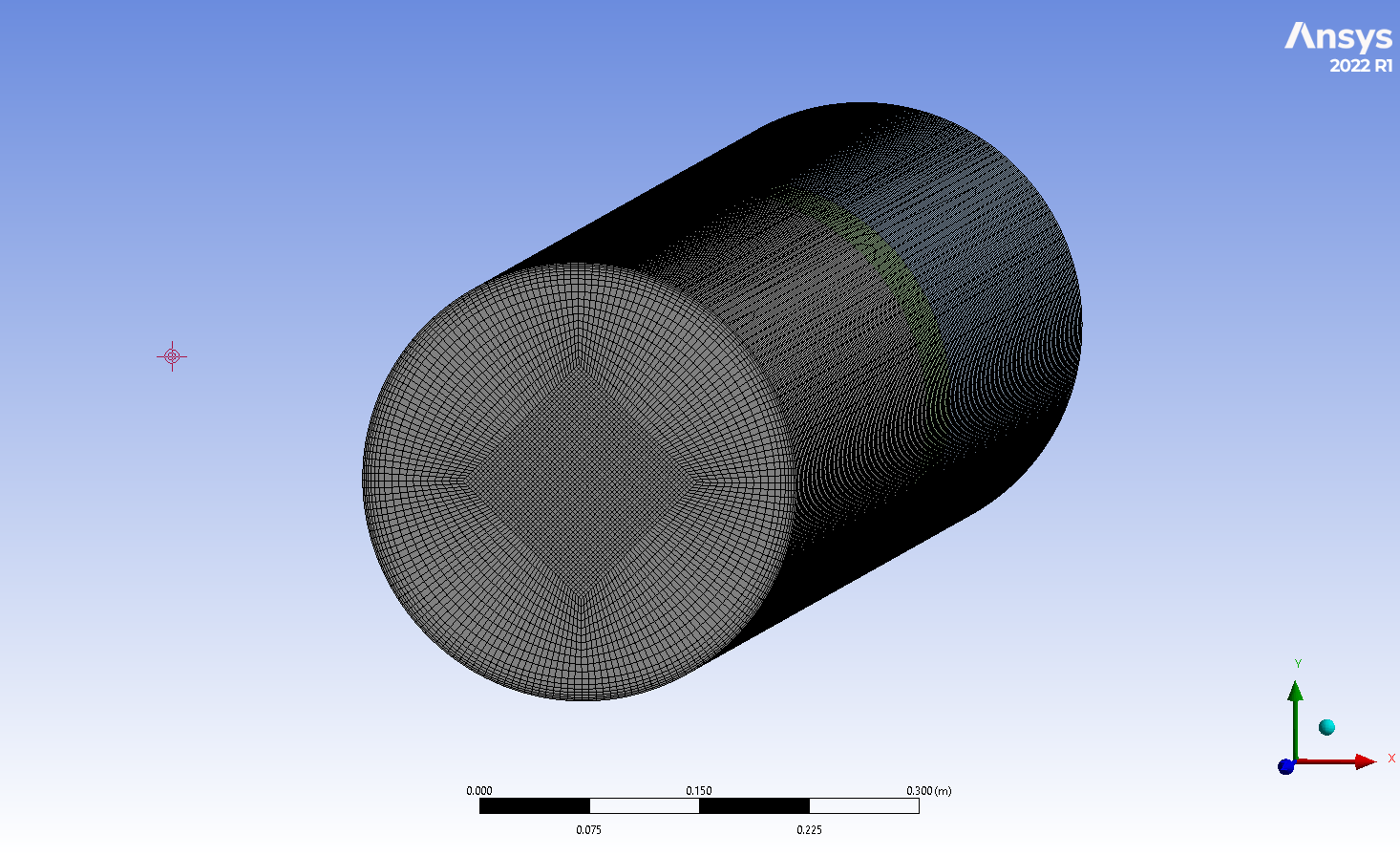

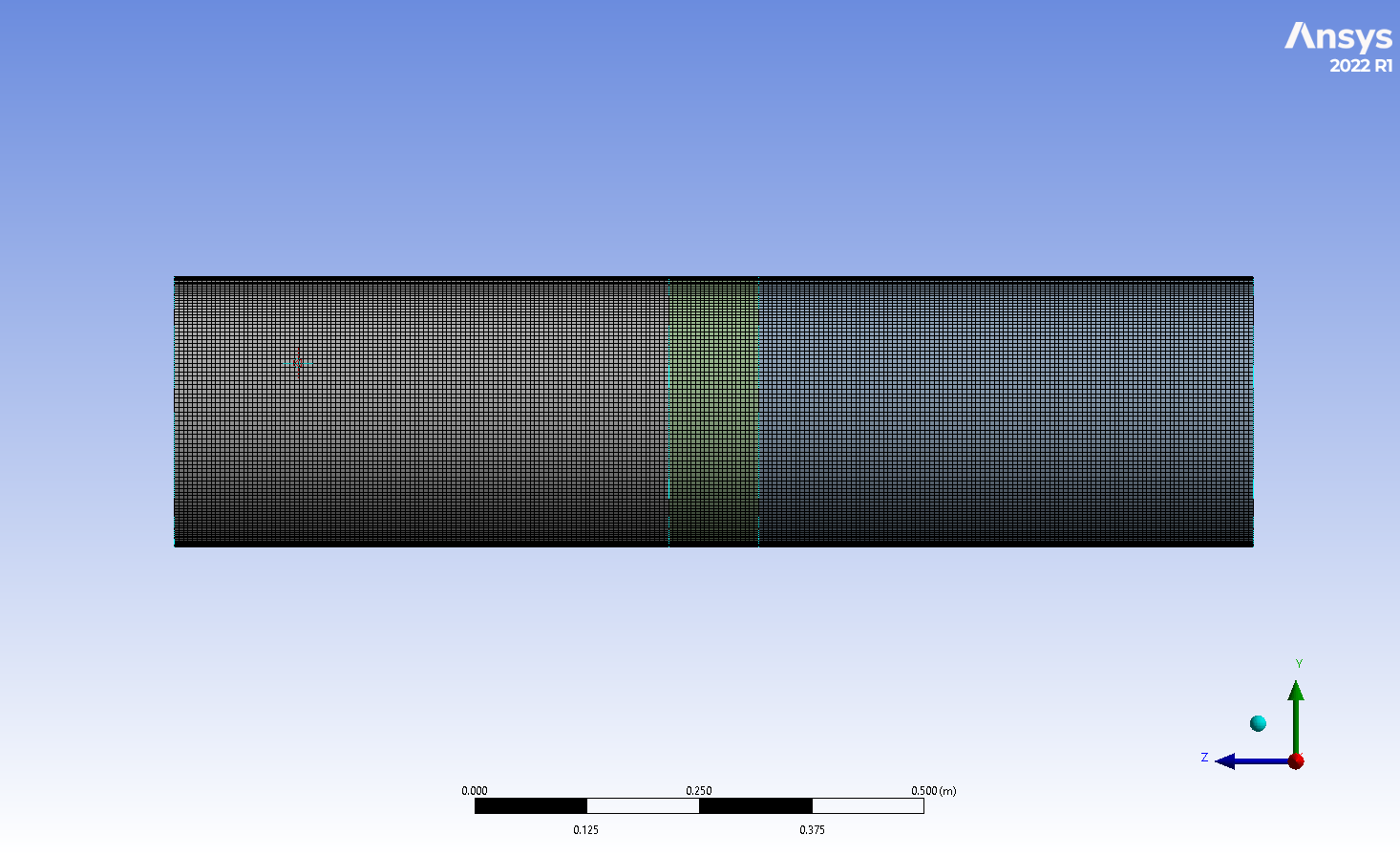

- We modeled the geometry using ANSYS Design Modeler and created the mesh using ANSYS Meshing software.

- The mesh type is Structured and the number of them is 1,308,762.

- Porosity has been used in the simulation.

- Pressure Drop inside the channel due to porosity is investigated.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

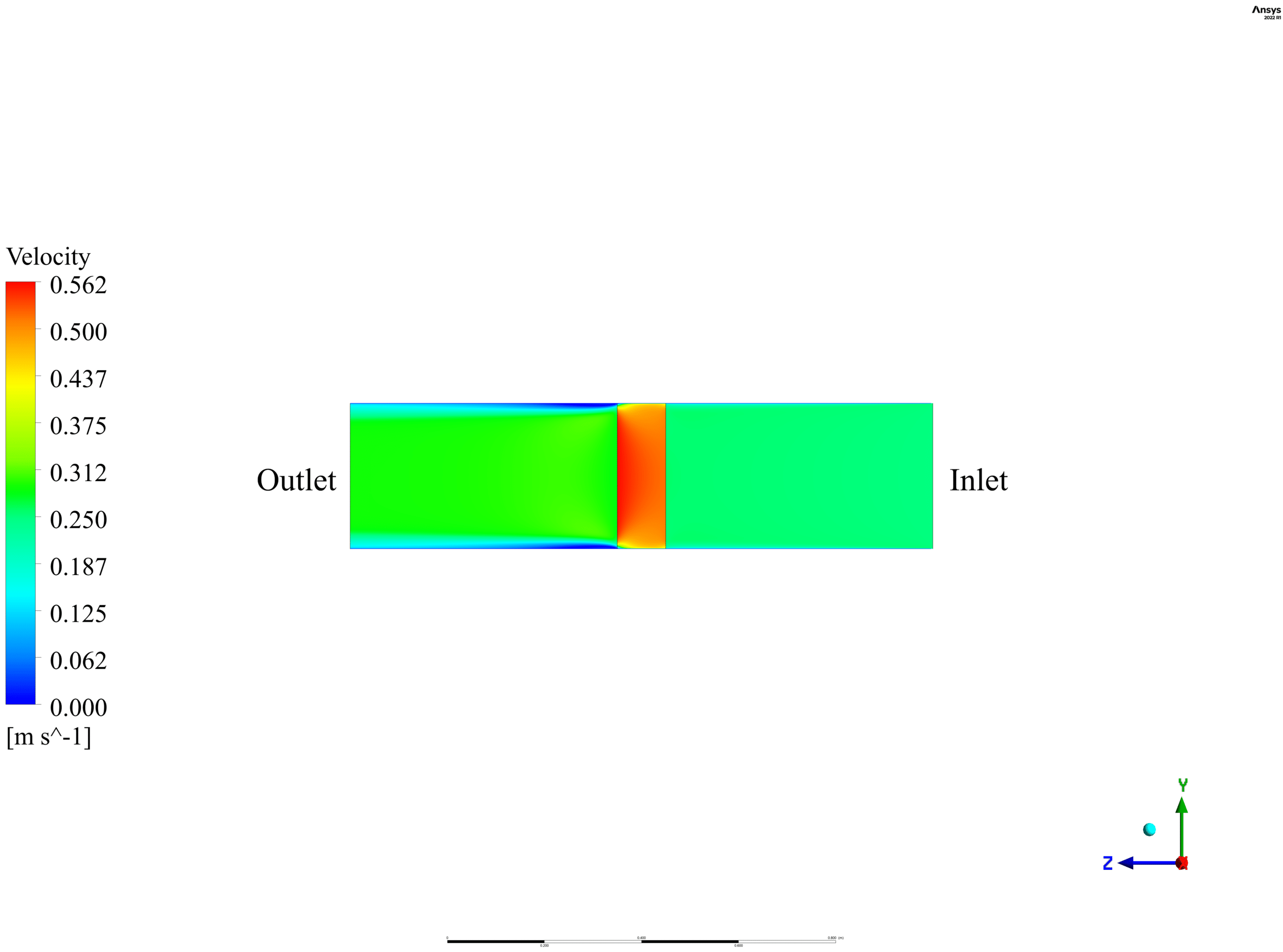

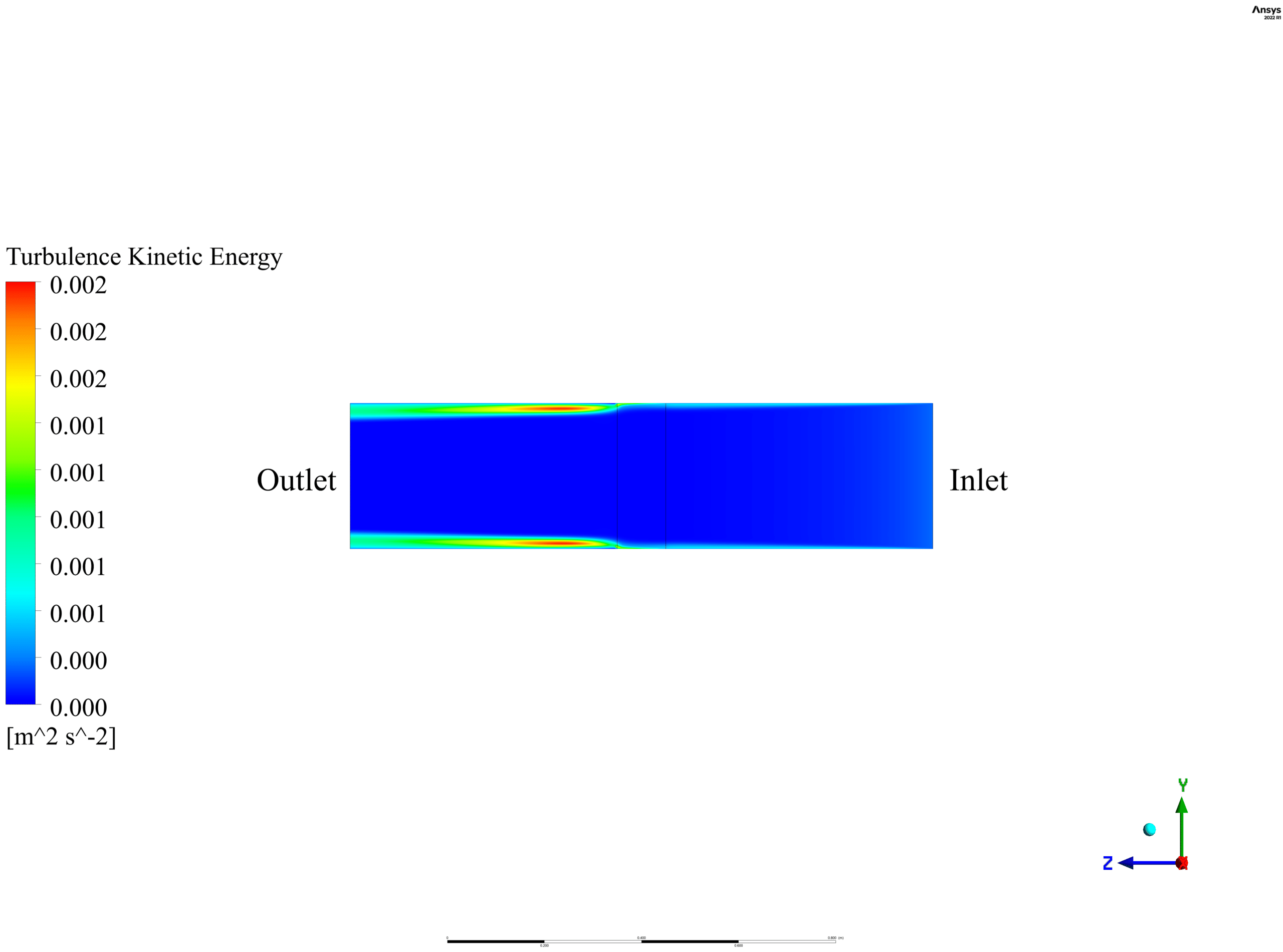

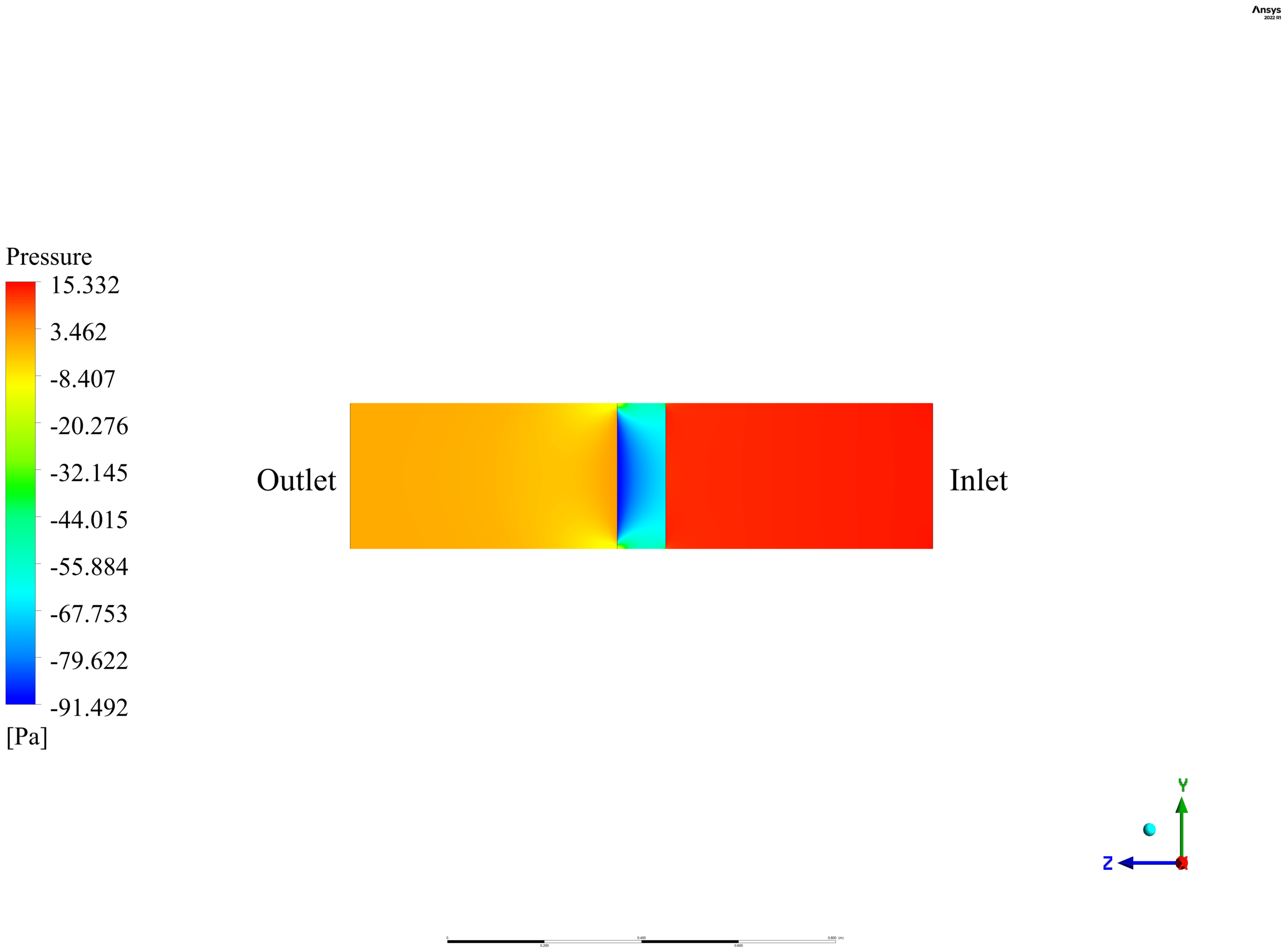

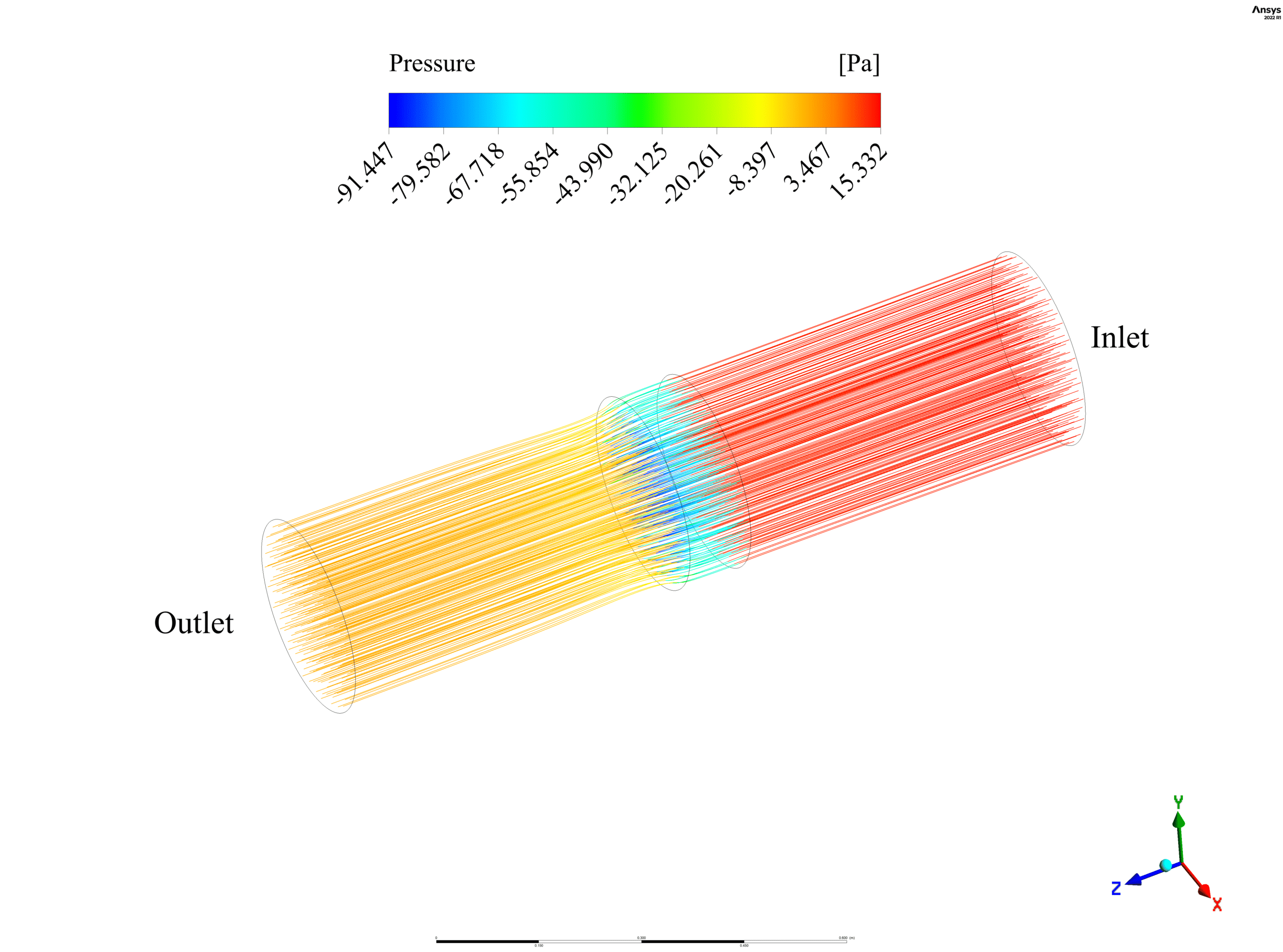

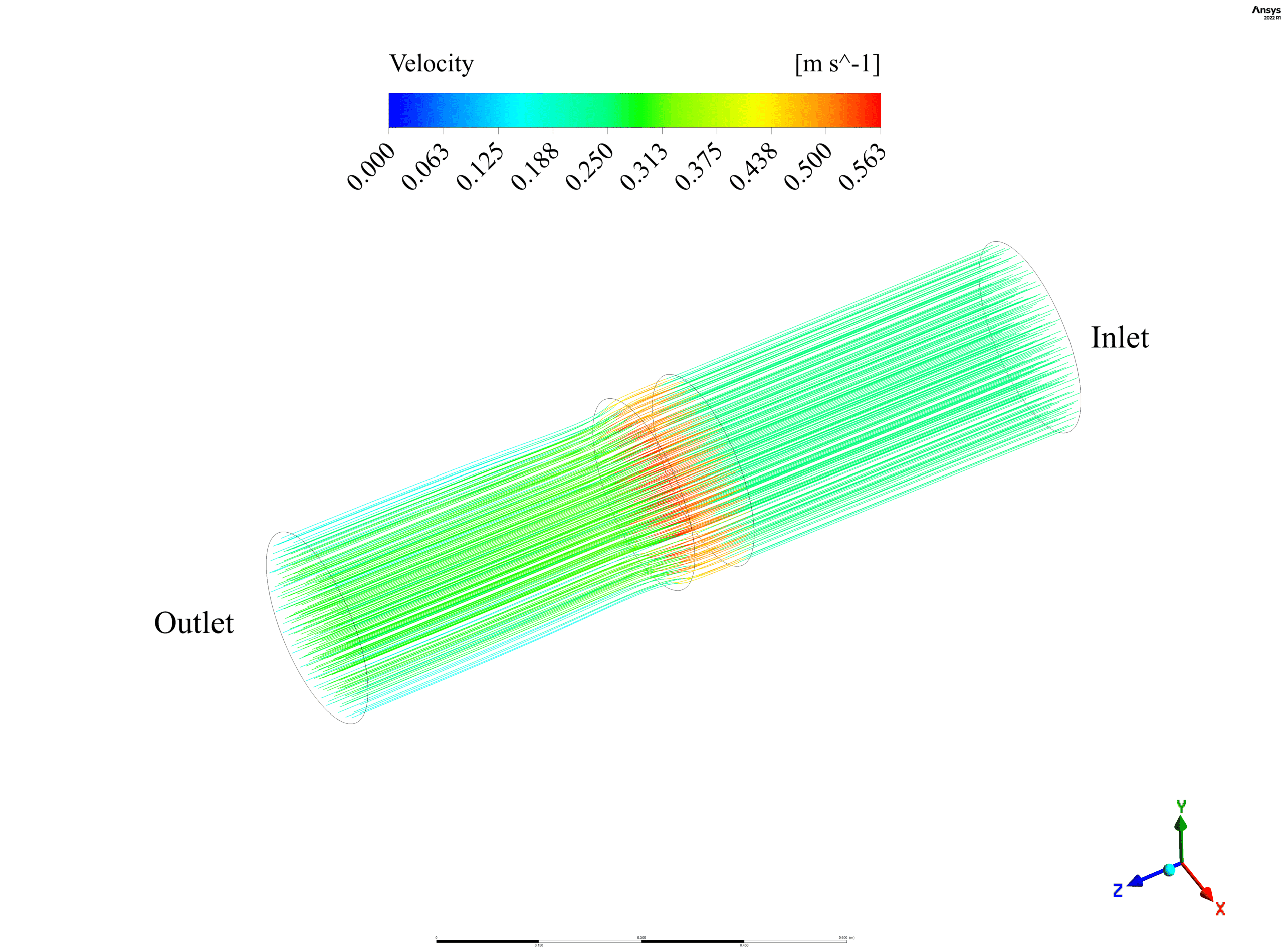

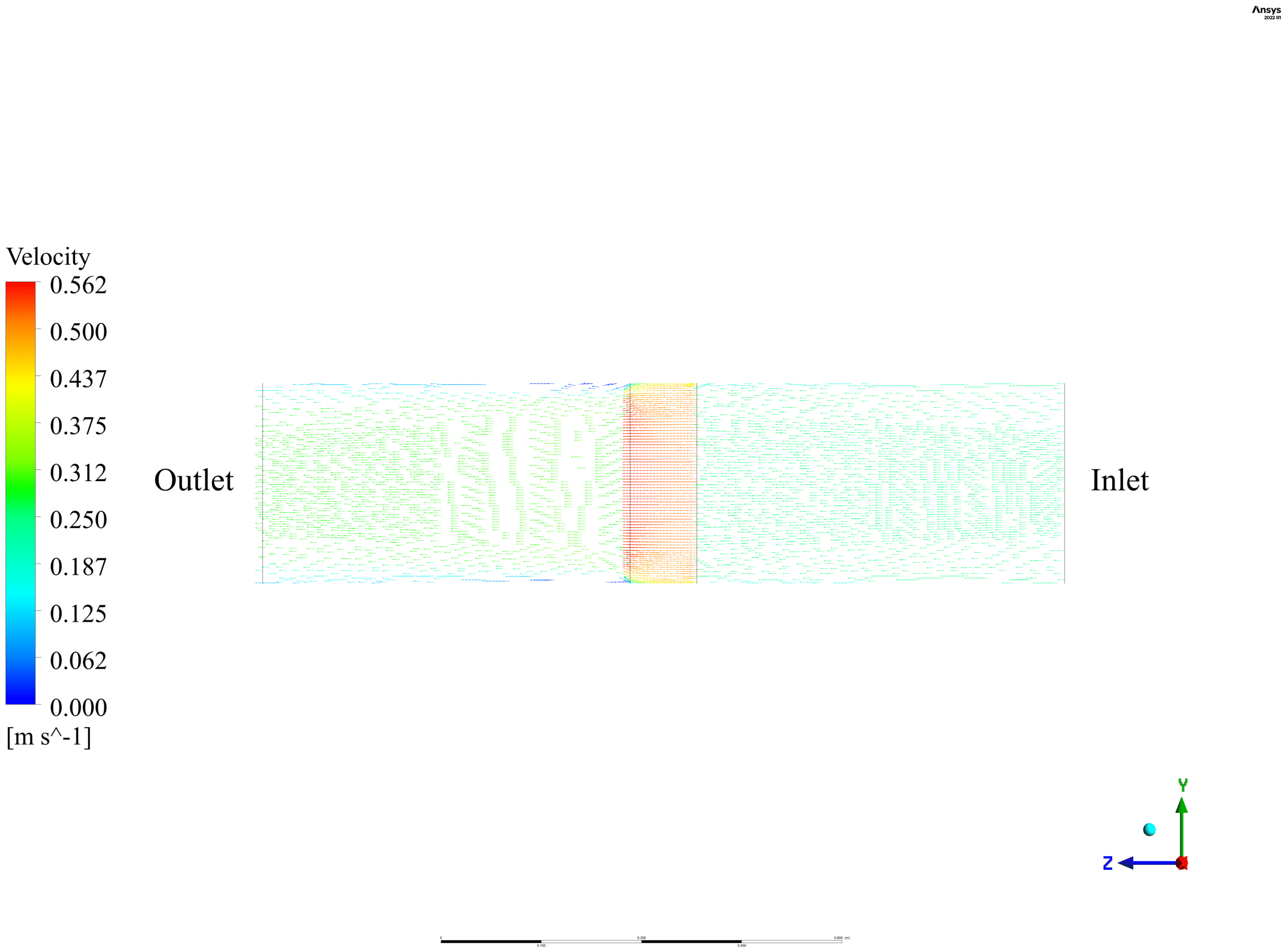

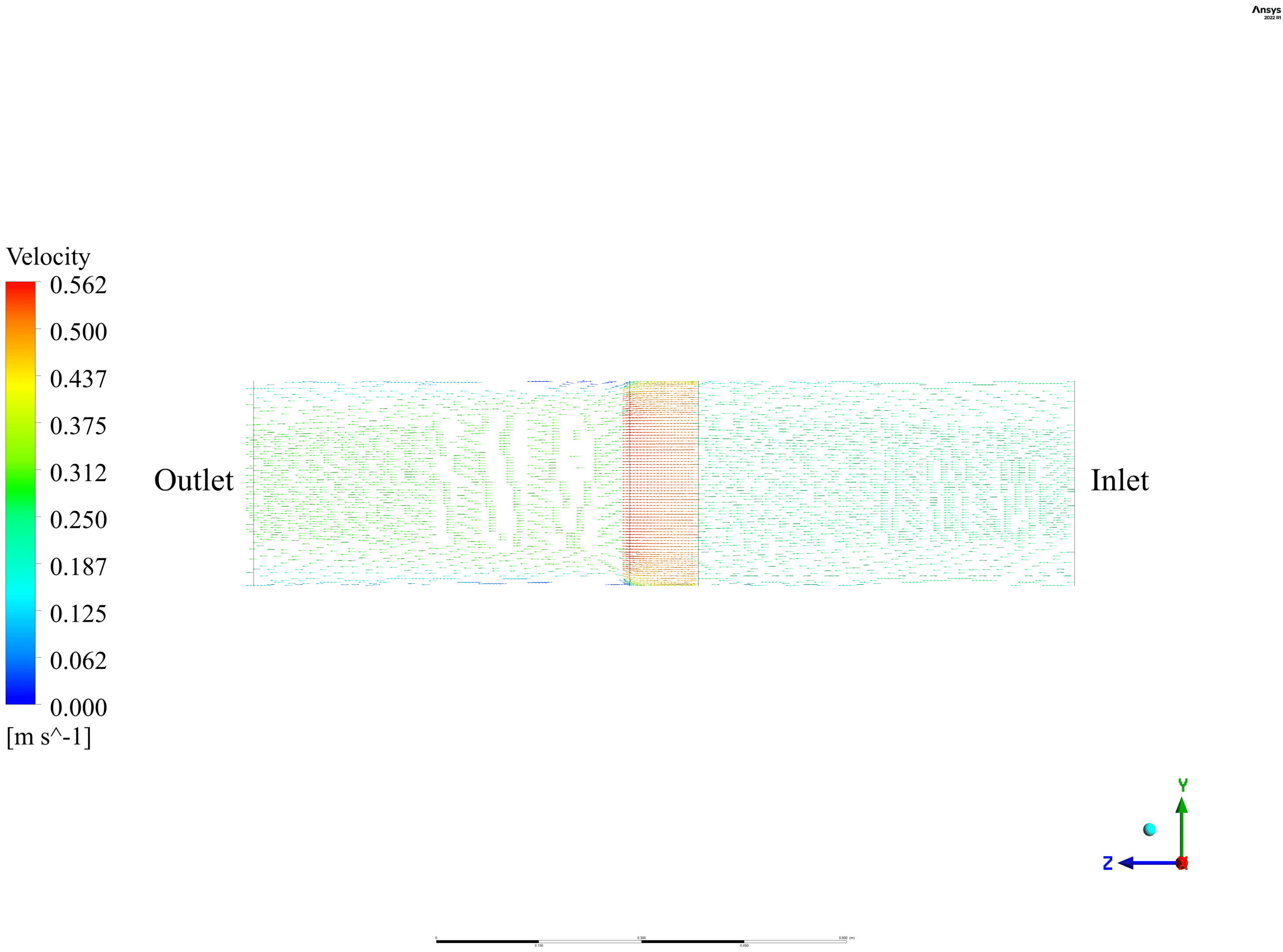

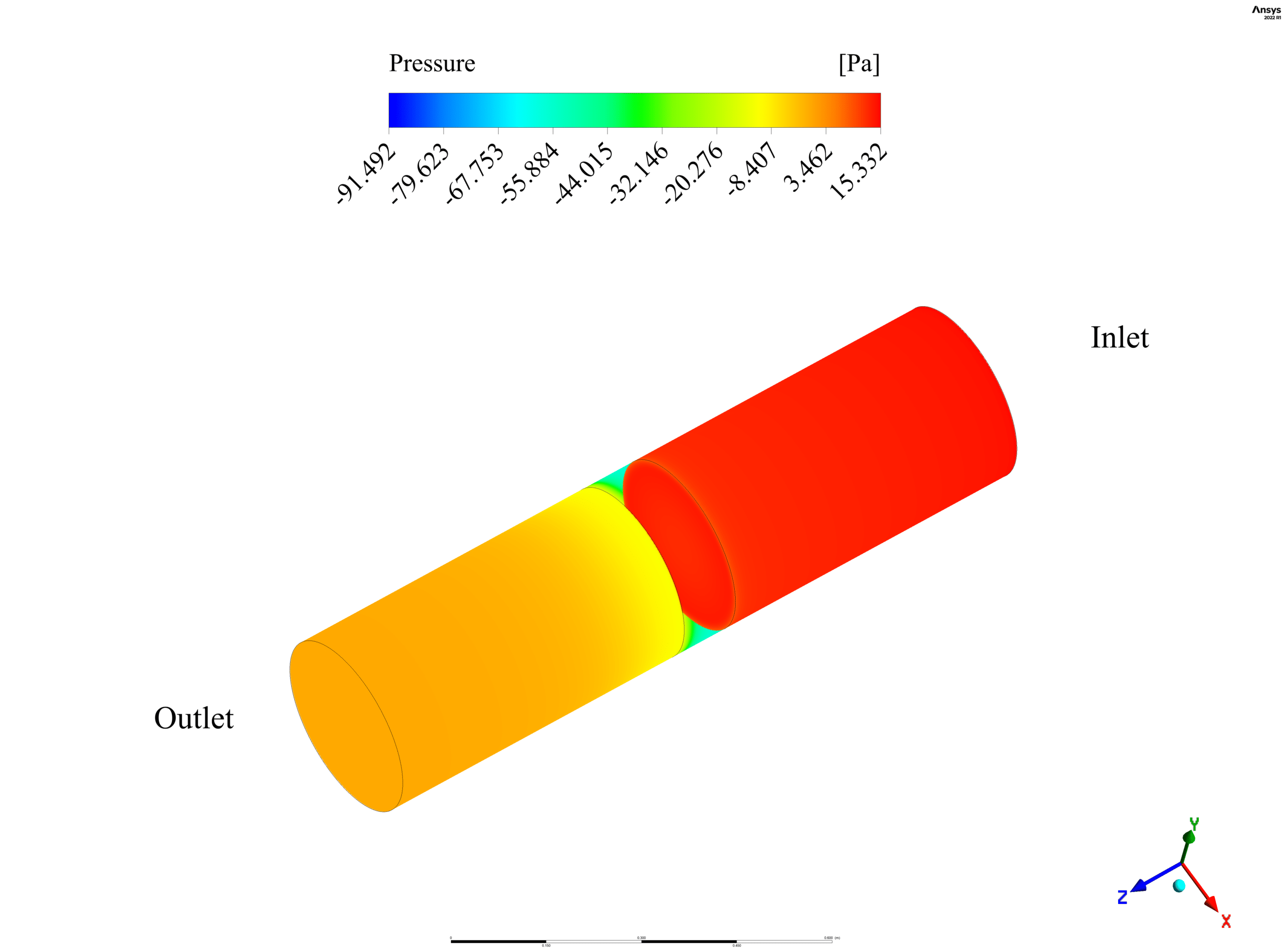

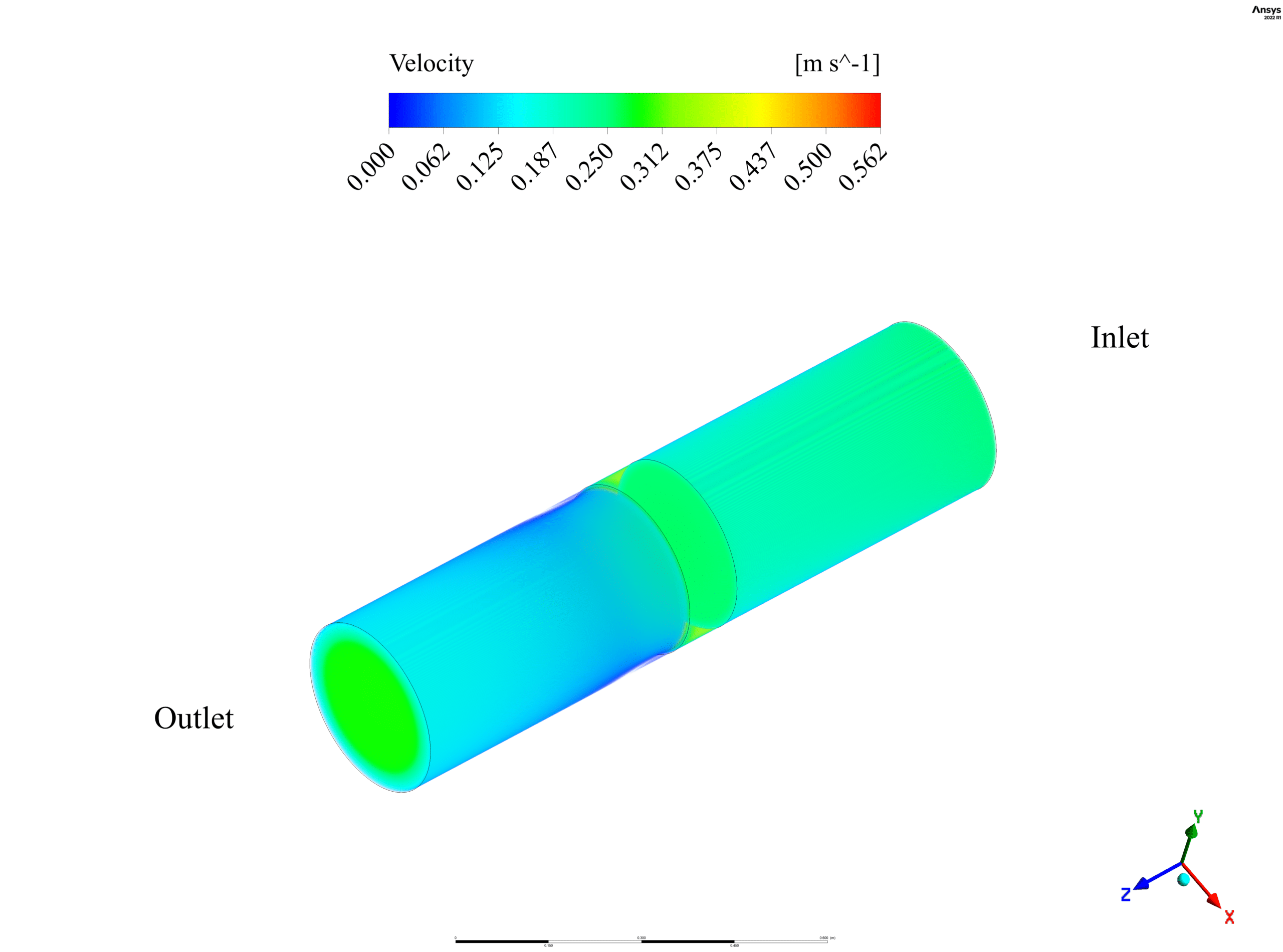

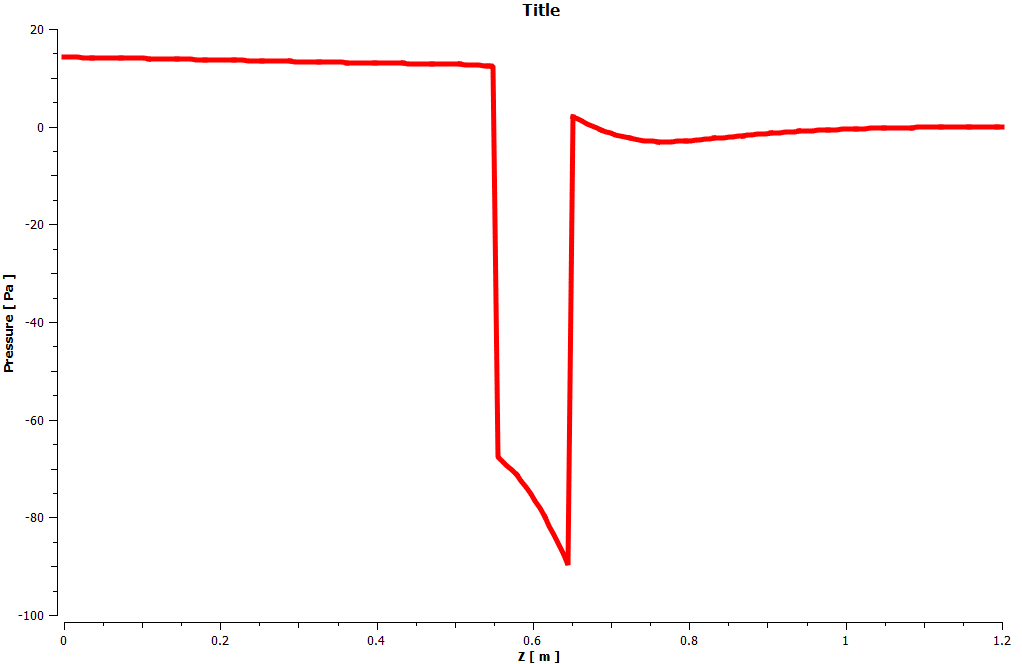

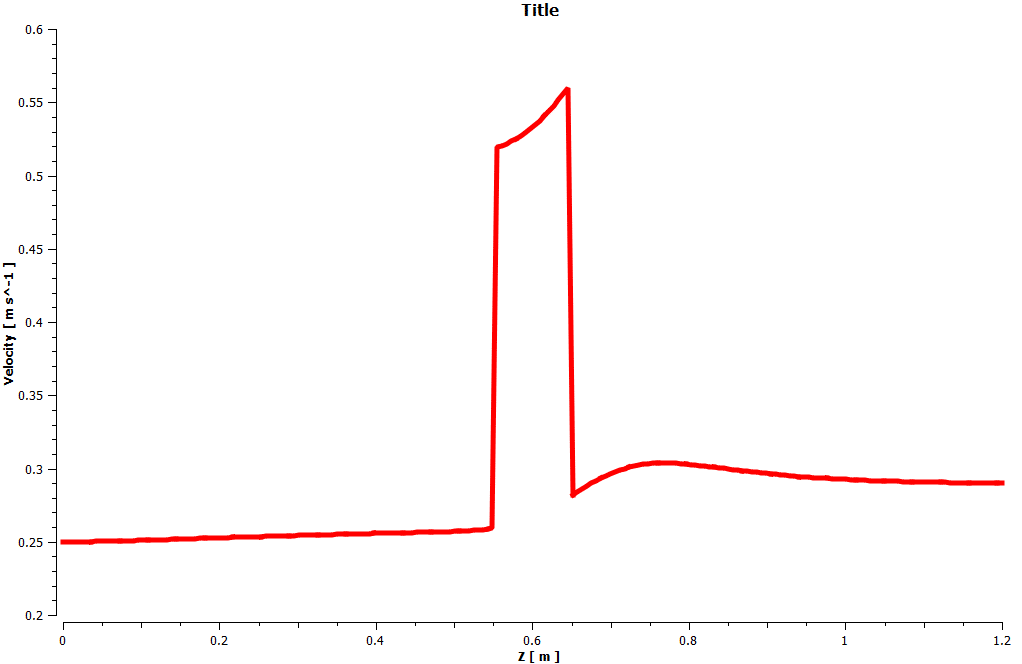

In this project, a 3-dimensional simulation of a channel with a Perforated Plate is performed using ANSYS CFX software. Ethanol enters the domain with a velocity of 0.25m/s from the inlet and collides with the porous zone located in the middle of the domain. This interaction causes a dramatic drop in pressure.

Design modeler software was used to create the 3D geometry. A 1.2-meter-long in z-direction cylinder with a perforated plate is 55 cm apart from the inlet and outlet. In addition, a Structured mesh grid was produced using ANSYS Meshing software, generating a total of 1,308,762 elements.

Methodology: Porous Zone Inside 3D Channel

The simulation is independent of Time, so it has performed in steady state form. Moreover, the gravitational effects are ignored.

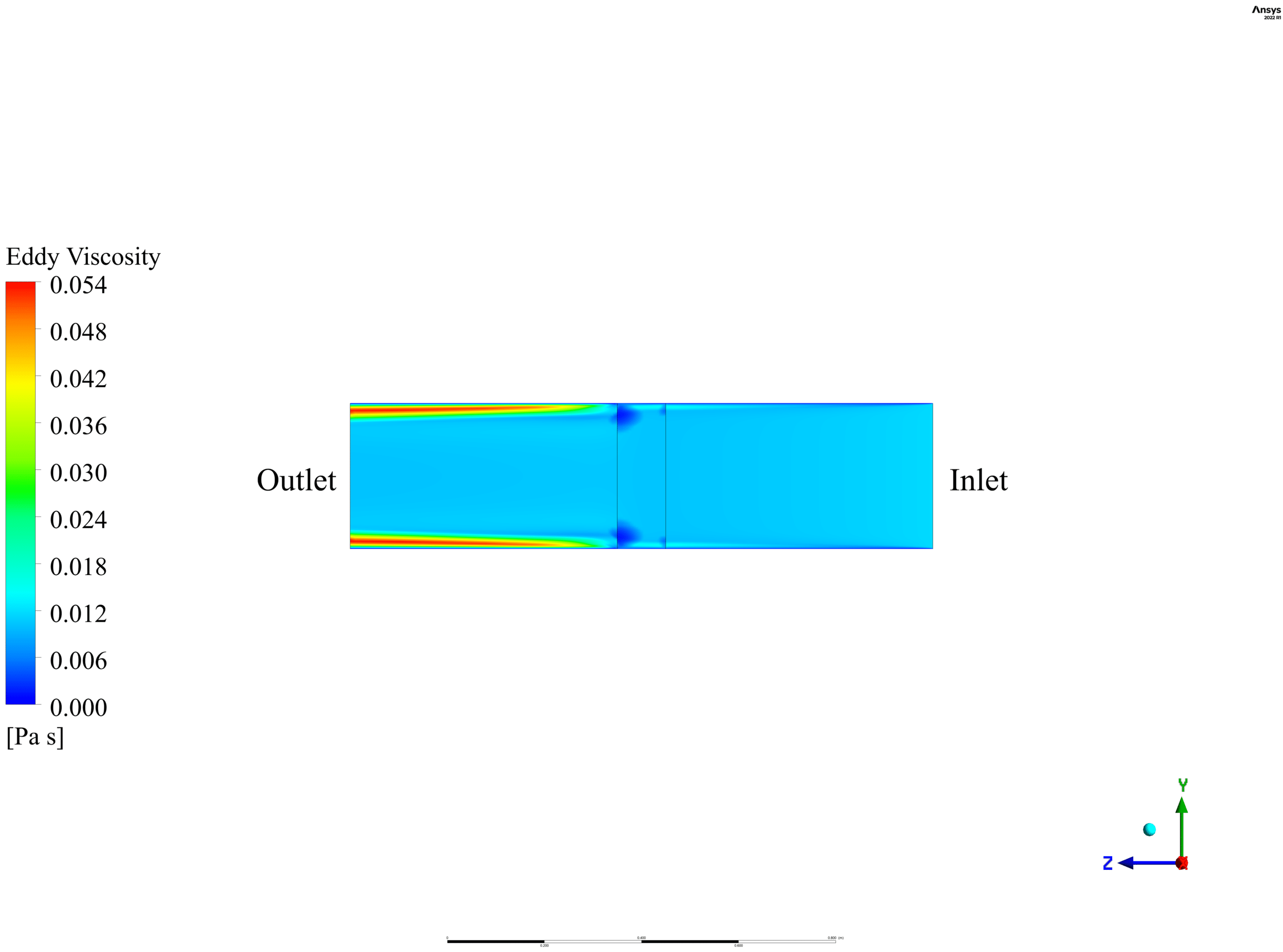

Turbulence model is Shear Stress Transport (SST).

The Advection Scheme and Turbulence Numerics is set to High Resolution.

Also, the Isotropic Porous Model is used inside the cylinder, while the Loss Velocity Type is set to True Velocity.

Conclusion

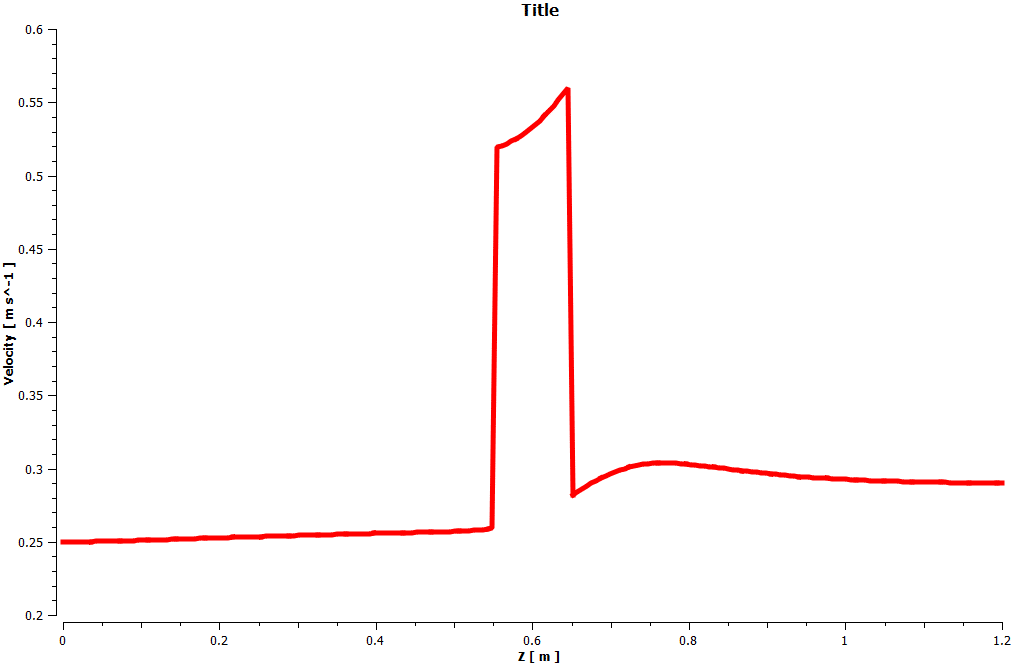

The Ethanol flow enters the channel with a 0.25m/s velocity magnitude. After a while, a collision with a perforated plate with 0.5 porosity causes an extreme pressure drop. As can be seen in the following plot, the amount of pressure decreases suddenly from 16 to zero. Also, this pressure drop is clearly visible in the 2D and 3D contours above.

Autumn Shanahan –

The given review is highly informative and seems complete. Nice work!

MR CFD Support –

Thank you for your kind review. We’re pleased to hear that you found our tutorial on the Porous Zone Inside a 3D Channel using ANSYS CFX informative and to your satisfaction. If you have any further questions or need assistance with your future simulations, feel free to reach out! We appreciate your feedback.

Mr. Kody Stracke PhD –

I’m very impressed with the porous zone channel simulation on MR CFD’s ANSYS CFX tutorial. The results showing the ethanol flow and pressure drop were clear and detailed. It effectively demonstrated the impact of the perforated plate on flow dynamics!

MR CFD Support –

Thank you for your positive feedback! We are delighted to know our tutorial provided clear and detailed results, and that the demonstration of flow dynamics impact due to the perforated plate met your expectations. It’s great to hear that our users are having such positive experiences with our learning products.

Pearl Schultz –

I’m thrilled with how the porous zone interaction was detailed. Felt like I was getting insights into what happens in industrial settings!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that the project provided you with a deeper understanding of industrial application scenarios. Your enthusiasm fuels our commitment to delivering detailed and practical simulations. If you have further inquiries or need assistance with future projects, please don’t hesitate to reach out.

Dr. Dallin Wuckert III –

I’m particularly impressed with the way ethanol velocity changes around the porous region. The visualization diagrams help greatly in understanding the physics!

MR CFD Support –

Thank you! We’re thrilled to hear that the visual aids within the tutorial effectively demonstrated the behavior of ethanol flow through the porous zone, and helped enhance your grasp of the simulation’s dynamics.

Vinnie Predovic –

The project looks extremely comprehensive and it seems to explain the pressure changes effectively. The methodology for handling porosity and the pressure drop across the perforated plate is particularly interesting. Nicely done!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the methodology and pressure drop analysis in the ‘Porous Zone Inside 3D Channel’ tutorial detailed and insightful. Should you have any more questions or need further clarification on any aspect, feel free to ask. We’re here to help!

Orlando Ryan –

Your detailed insights have really helped me understand where the velocity changes occur. Thank you for including plots showing this transition!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation and accompanying visuals have enhanced your understanding of the flow dynamics involved. If you have any further questions or need additional information, feel free to reach out. Your enthusiasm for learning makes our work even more rewarding. Have a great day!

Summer Hermann –

The structured mesh grid in this simulation consists of over 1.3 million elements. Is it always necessary to have such a dense mesh for simulations involving porous media, and how does this affect computation time?

MR CFD Support –

The necessity for a dense mesh depends on the complexity and accuracy required for the simulation. In the case of porous media, having a fine mesh ensures that the flow details through the perforations are captured accurately. However, this can lead to longer computation times and requires higher computational resources. It’s important to balance the need for accuracy with the available computational power and the goals of the simulation.

Erika Morissette –

This tutorial was a game changer for my understanding of porous media in CFD! The clear step-by-step approach made all the difference. Kudos to the team for creating such a well-organized and informative guide!

MR CFD Support –

Thank you so much for your positive feedback! It’s great to hear that our tutorial on the Porous Zone Inside a 3D Channel in ANSYS CFX was helpful to you. If you ever have more questions or need further assistance, don’t hesitate to reach out. We’re here to help you succeed with your CFD projects!

Colten Labadie –

Absolutely fantastic tutorial explaining the porous zone effects! The visuals really bolstered my understanding!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that the tutorial was helpful and the visuals enhanced your learning experience. If there’s anything else you’re curious about or more products you’d like to explore, don’t hesitate to reach out. Happy learning!

Jaycee Champlin –

I found the simulation details very informative. The explanation regarding the pressure drop caused by the collision with the perforated plate was insightful, and it provided a clear understanding of the flow dynamics within the porous zone.

MR CFD Support –

We’re thrilled to hear that you found the simulation informative and clear in detail. Understanding the flow dynamics is crucial, and we’re glad we could provide a comprehensive understanding of the pressure drop phenomena! Thank you for your positive feedback.

Mr. Ransom Schultz I –

I’m thrilled with how detailed the pressure drops and velocity changes are depicted in the simulation. The visuals make it so easy to understand complex fluid dynamics!

MR CFD Support –

We are delighted to hear that our simulation visuals on the pressure drop and velocity changes within the porous zone have greatly enhanced your understanding. Thank you for choosing our tutorial, and we are here to continue providing clear and comprehensive learning tools.

Ashton Rogahn –

I’m impressed by how the porous zone interaction is simulated. Great tutorial for understanding pressure drops in simulations!

MR CFD Support –

Thank you for your kind words! We are glad that you find our tutorial on simulating a porous zone inside a 3D channel with ANSYS CFX helpful for understanding pressure drop phenomena. If you have any further questions or need more insight, feel free to reach out!