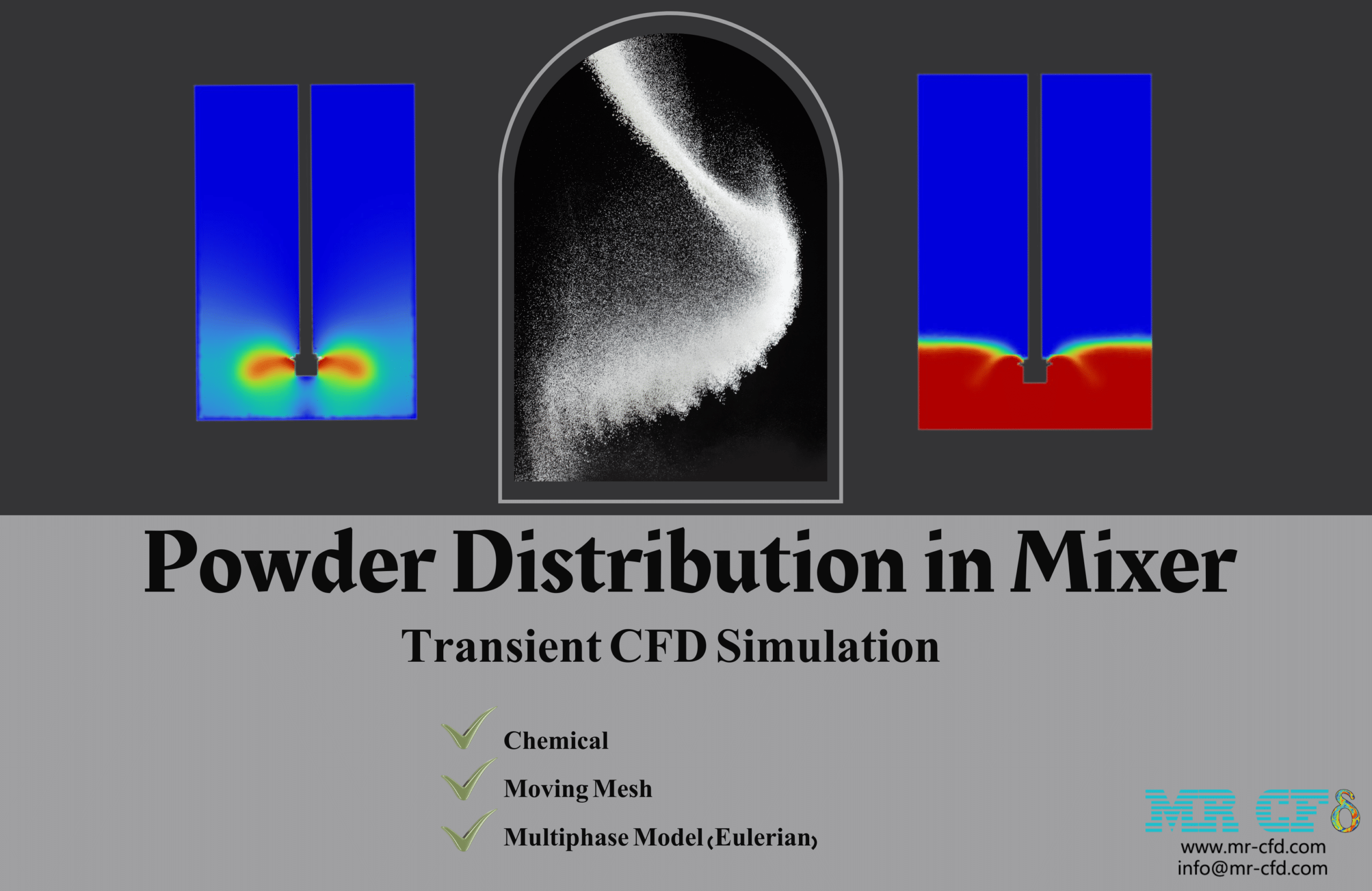

Powder Distribution in Mixer, Transient CFD Simulation

$160.00 $80.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

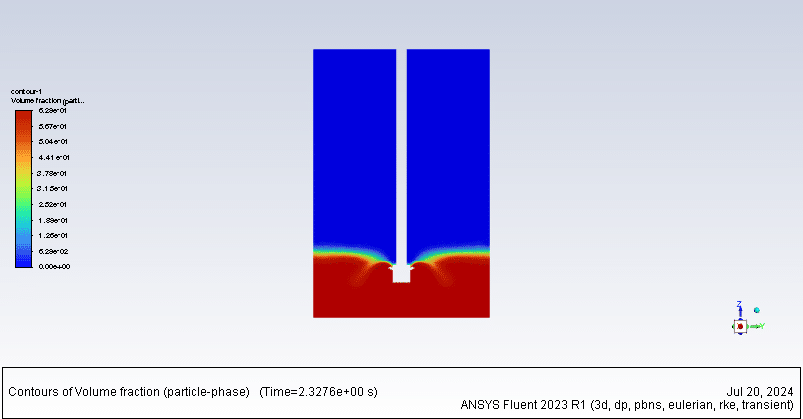

Powder distribution in Mixer CFD Simulation

Project Description

In this project, we are simulating the Powder distribution inside the stationary fluid in a mixer tank. First, the powder is settled at the bottom of the mixer tank. Then, the mixer propeller starts rotating to disperse the powder. This simulation is costly, so only a limited time is performed.

The geometry of the mixing tank is designed using SpaceClaim software. Then, it is meshed in ANSYS Meshing. In total, 657330 cells are generated.

Methodology

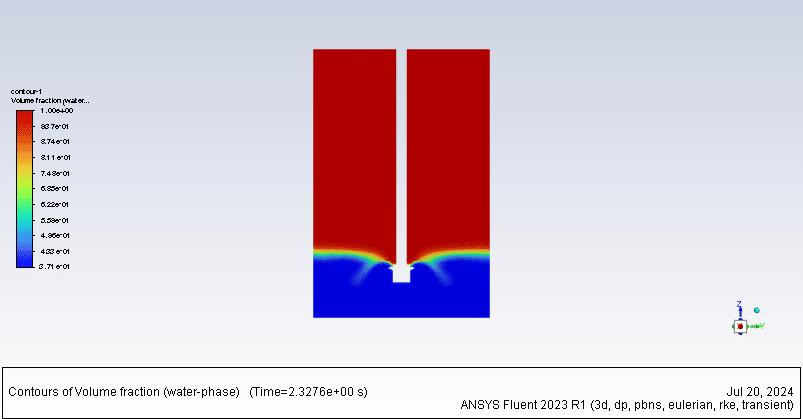

The working fluids are a mixture of powders and water liquid. These phases are modeled using the Eulerian multiphase model.

The powder as the secondary phase has a granular nature, so a granular option is used.

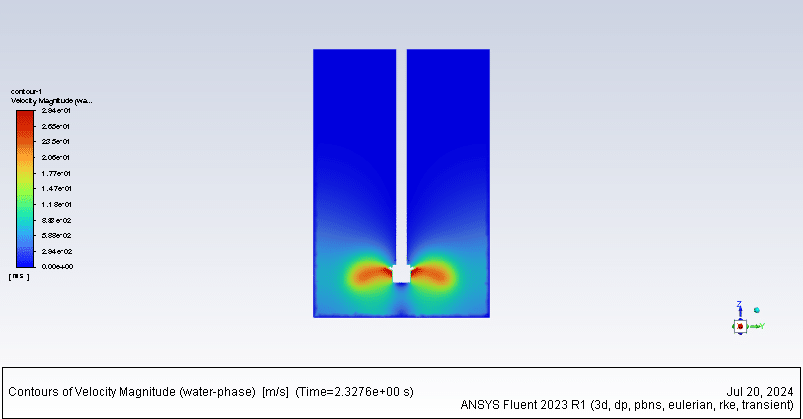

Mesh motion is also used to model the rotation of the mixer propeller. The propeller is rotating at 30 rpm.

Results

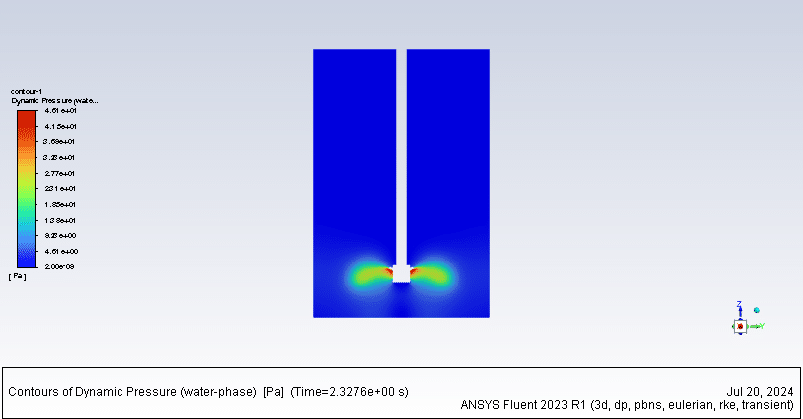

After the solution, contours are given. The simulation results show a clear pattern of powder distribution in the fluid after a certain amount of time of mixing. The contour clearly shows that the powder is layered, with the largest concentration at the bottom of the container. You can see a thin layer of transition just above this area with a lot of powder.

This suggests that the powder is spread out in a gradient. The pattern of the powder’s distribution shows that the mixing process has not yet evenly spread the powder throughout the fluid. This is expected since the mixer has only a short turning time. It is clear that there is a center shaft or impeller, which could change the flow patterns and powder distribution close to it.

Reviews

There are no reviews yet.