Premixed Combustion in a Porous Zone CFD Simulation

$180.00 $90.00 Student Discount

- The problem numerically simulates the Premixed Combustion in Porous Zone using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 8700.

- We use the Premixed Combustion in Species model to define combustion reactions.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Premixed Combustion in a Porous Zone, CFD Simulation Ansys Fluent Training

In this project, Premixed Combustion in Porous Zone has been simulated, and the simulation results have been investigated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The 3-D geometry of the present model is carried out using Design Modeler software. The geometry consists two-section, the lower section is preheating, and the upper section is a stable burn region.

The meshing of this present model has been generated by Ansys Meshing software. The mesh grid is Structured, and the total cell number is 8700.

Premixed Combustion Methodology

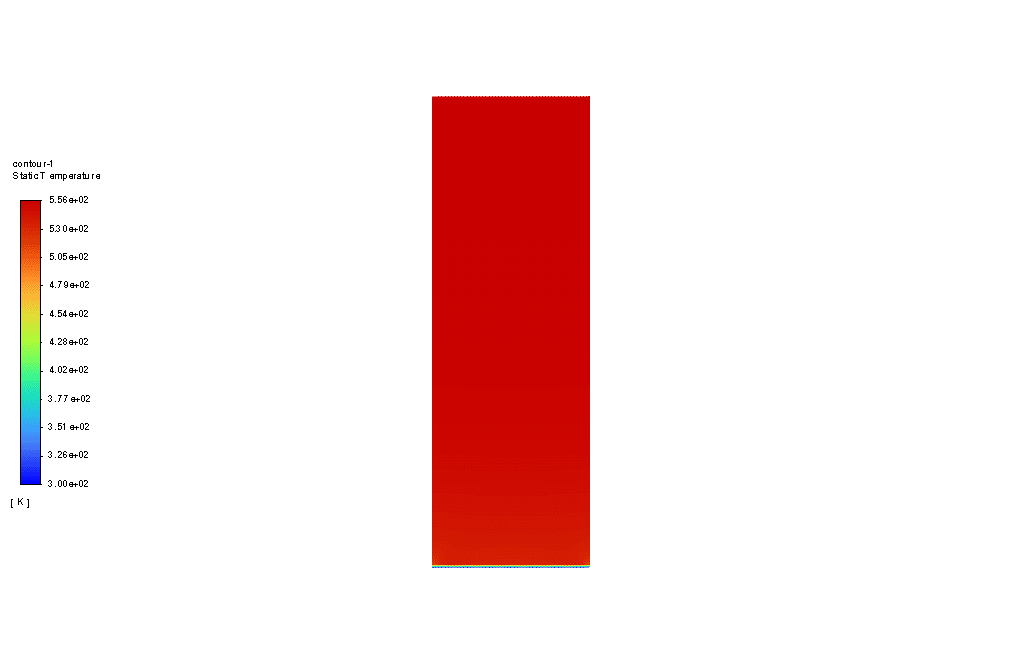

This simulation aims to model Simple Premixed Combustion in a Porous zone by Ansys Fluent Software and see how a porous zone affects combustion temperature and stabilizes it.

This simulation is a matrix-stabilized burner, and the results are compared to the same premixed combustion without porosity. The Species transport model has been used.

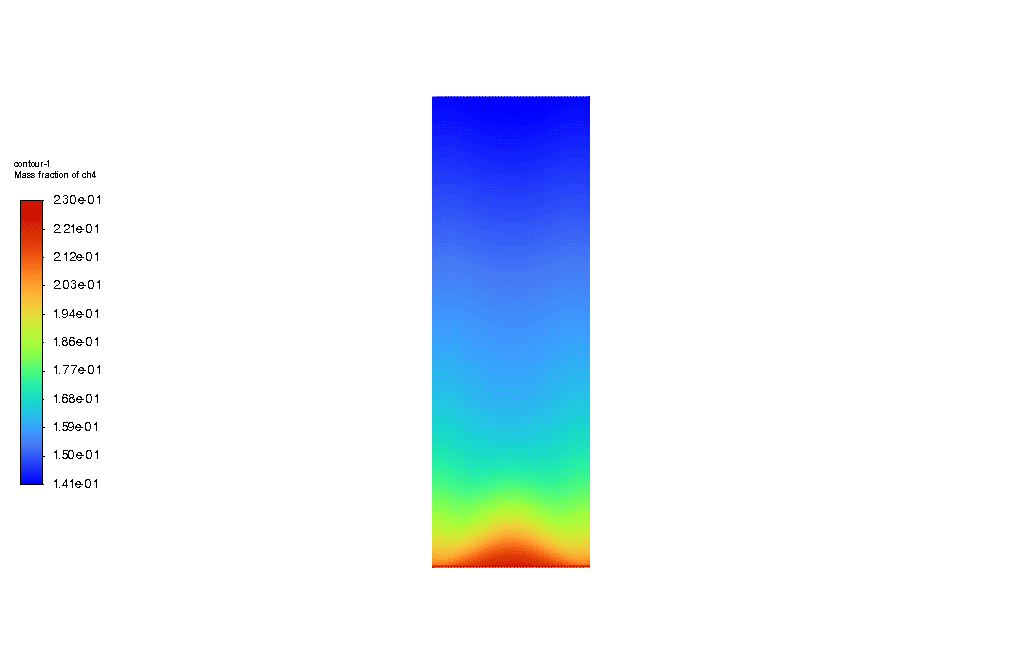

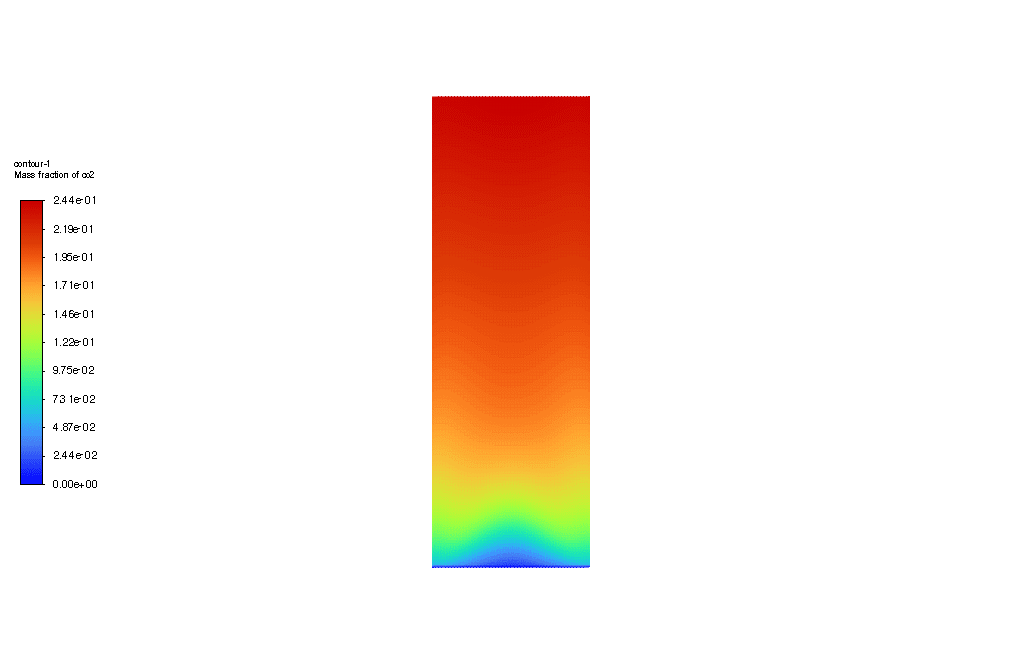

The mixture flow enters the domain with a 0.23 methane mass fraction and 0.77 oxygen mass fraction. Then, using the ignition spark sub-model, the combustion process starts.

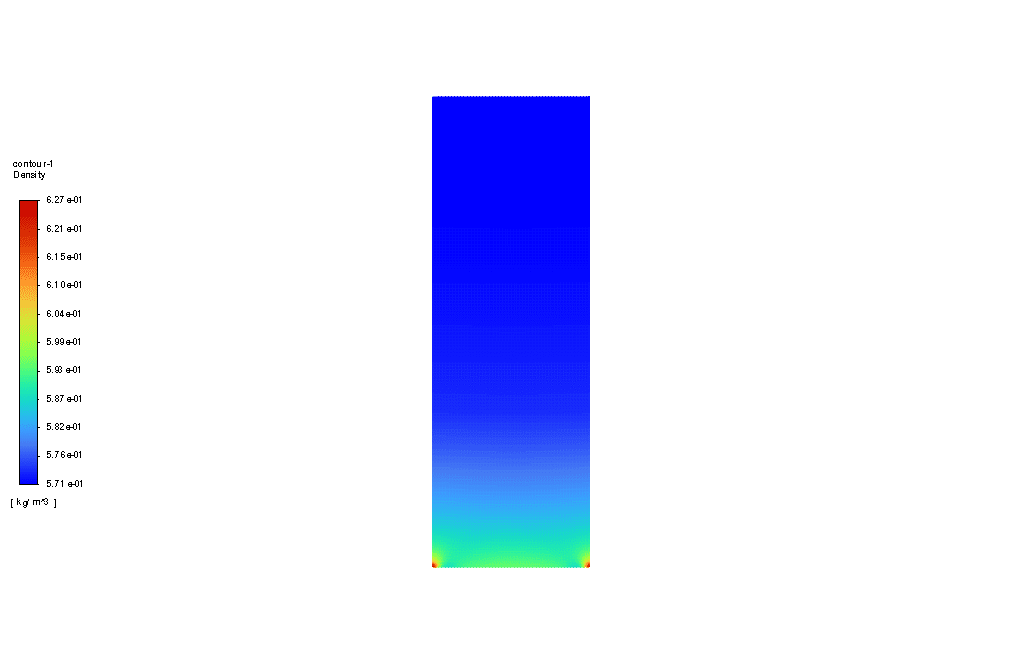

Also, the gravity is considered as -9.81 m/s-2 on the y-axis. Moreover, the SST k-omega model is used to solve turbulent fluid equations.

Premixed Combustion Conclusion

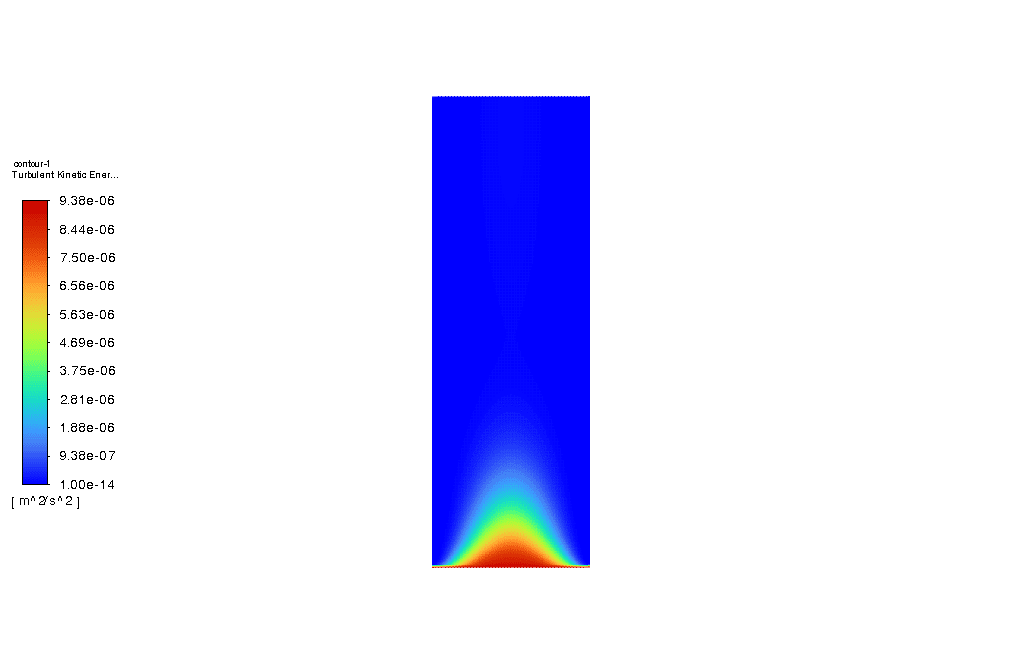

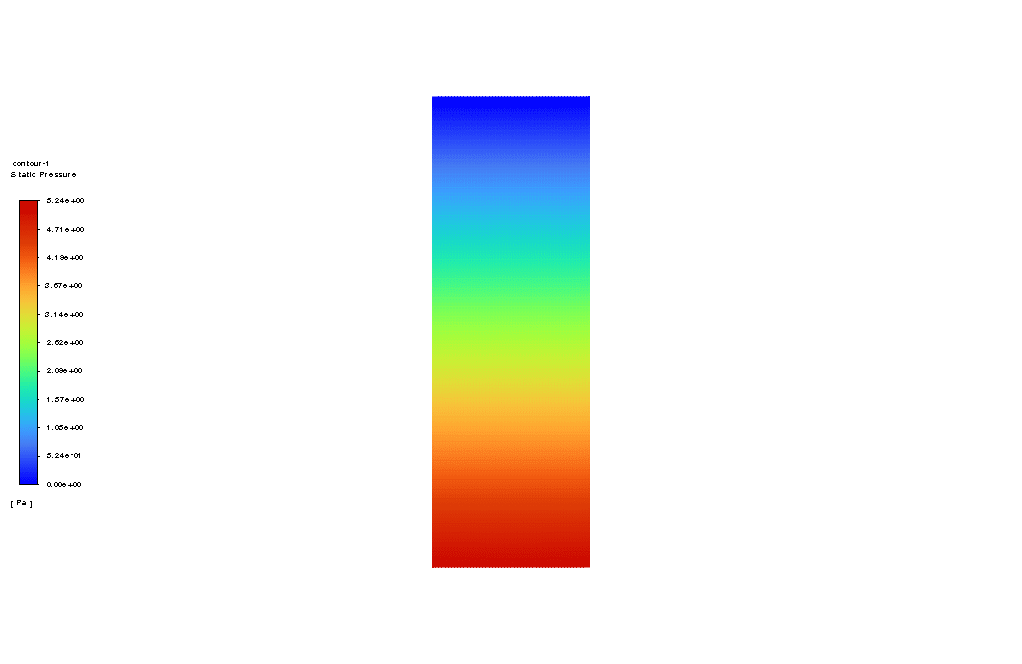

At the end of the solution process, three-dimensional velocity, air and water volume fraction, and animation are obtained. The result shows that the porous zone affects static temperature by reducing it and making combustion more monotonous and stable than a zone without porosity.

Miss Katrina Kuvalis –

I just completed the Premixed Combustion in a Porous Zone CFD Simulation course, and I’m incredibly impressed by the learning experience! The attention to detail in the setup of the model and meshing process provided me with a deep understanding of how to simulate nuanced scenarios such as combustion in porous media. The use of the species transport model and the inclusion of the ignition spark sub-model was fascinating to observe and added a layer of complexity that I appreciated mastering. Discovering the impact of the porous matrix on flame stabilization was the highlight for me. Excellent course material and expert-level guidance throughout!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found the course material and the level of detail in the Premixed Combustion in a Porous Zone simulation valuable and educational. It’s wonderful that the course helped enhance your understanding of combustion simulation in porous media and that you appreciated the complexity of the models being taught. We’re particularly happy that you enjoyed discovering the role of a porous matrix in flame stabilization. Your kind words are greatly appreciated, and we look forward to continuing to provide you with high-quality CFD training and simulations!

Joshuah Bogan PhD –

The project was an absolute gem to learn from! Setting up cyclone separators in simulations always challenged me, but this CFD methodology laid everything out so clearly. Seeing the distinct impact the porous zone has on stabilizing the temperature during combustion was illuminating. Huge thanks to the team behind this. Keep up the fantastic work!

MR CFD Support –

We’re delighted to hear that the Premixed Combustion in a Porous Zone CFD simulation project served as a valuable learning resource for you! Understanding the complexities of cyclone separators can indeed be challenging, and it’s great to know that our methodology was able to clarify those details. We appreciate your kind words and encouragement; your enthusiasm fuels our commitment to delivering top-notch educational content. Thank you for taking the time to leave such a positive review!

Sven Crona –

I’m really impressed with the stability in combustion provided by the porous zone as detailed in the training. It seems to effectively control temperatures and stabilize combustion. Can I see these stabilizing effects across different combustion applications or is this specific to the setup used here?

MR CFD Support –

We’re thrilled to hear that you’re pleased with the training! The effects of a porous zone on combustion stability can vary between applications. However, the core principle of how porosity influences temperature distribution and stabilization should generally be observable across similar premixed combustion processes. Different setups might need adjustments in terms of materials and porous zone specifics, but the underlying theory remains valuable across various combustion scenarios.

Prof. Francisco Rogahn MD –

I’m thrilled with how direct and informative the content is about premixed combustion in a porous zone!

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the training on Premixed Combustion in a Porous Zone informative and helpful. Your enthusiasm for learning more about CFD applications with ANSYS Fluent is greatly appreciated!

Lizzie Kunde –

What are the benefits of including a porous zone in the premixed combustion simulation?

MR CFD Support –

Including a porous zone in the premixed combustion simulation can lead to a more stable combustion process by evenly distributing the fuel-air mixture and enhancing heat recirculation, which stabilizes the flame front. This can also result in reduced peak temperatures, thus minimizing the formation of thermal NOx emissions.

Marques Purdy –

I was impressed with the detailed preheating and stable burn sections in the simulation. Has the training provided any information on the actual materials used for the porous matrix, or is that outside the scope of this project?

MR CFD Support –

Thank you for the kind words and your curiosity! The project primarily focuses on the CFD simulation aspects of premixed combustion in a porous zone and how porosity affects the combustion process. While it emphasizes simulation parameters and outcomes, specific material details for the porous matrix may not be a central part of the training itself, but such details are typically determined based on the specific applications and real-life scenarios being emulated. If needed, the training materials can guide on how to include those effects assumed for the simulation purposes.

Matt Spinka DDS –

I’m really impressed with the Premixed Combustion simulation in a Porous Zone. The concept is fascinating, and the idea of comparing a matrix-stabilized burner with and without porosity provides valuable insights!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you’re impressed with the Premixed Combustion in a Porous Zone simulation. It’s great to know that our training and simulations are able to provide valuable insights and that the comparisons made helped in understanding the impact of porosity. We appreciate your feedback and are glad that our product met your expectations.

Prof. Cole Kohler –

The project divided the model into a lower preheating section and an upper stable burn region. How does the presence of porosity in the upper section stabilize the combustion process?

MR CFD Support –

The porosity in the upper section of the model helps in stabilizing the combustion by evenly distributing the fuel mixture and improving the heat exchange. A porous medium can improve flame stability by ensuring that proper temperatures are maintained across the region, allowing the combustion process to continue smoothly without generating hot spots or temperature spikes that could lead to detonation.

Kaleb Johns –

I’d like to know, how did you manage to initialize the combustion process in the porous zone? Was a special method used for ignition?

MR CFD Support –

In the simulation of Premixed Combustion in a Porous Zone, the ignition process is initiated using the ignition spark sub-model in ANSYS Fluent. This approach helps in starting the combustion process within the porous zone by providing localized energy enough to ignite the mixture of methane and oxygen.

Carter Rau Sr. –

I’m truly impressed with the details of this Premixed Combustion CFD Simulation. Great to see how porosity influences combustion stability.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the project provided valuable insights into the effects of porosity on combustion stability. It’s our aim to deliver comprehensive analyses which can be eye-opening and educational for those interested in CFD applications.

Dr. Jarrell Fritsch –

This training course appears extremely interesting. Can you highlight what specific skills or concepts someone could expect to learn from the ‘Premixed Combustion in a Porous Zone, CFD Simulation Ansys Fluent Training’ course?

MR CFD Support –

Participants of this training course would gain a solid understanding of modelling premixed combustion phenomena within porous media using ANSYS Fluent. Specific skills and learning outcomes would include setting up complex boundary conditions, applying species transport and SST k-omega models for combustion and turbulence respectively, interpreting the effects of porosity on combustion stability, and analysis of computational results to better understand the temperature distribution and flow patterns resulting from premixed combustion. Additionally, attendees would learn how to perform mesh generation and use ignition spark sub-models for initiating combustion.

Mrs. Marcelina Ullrich DDS –

I had some great findings using the Premixed Combustion in a Porous Zone simulation. The clear visualization and stability difference between combustion with and without the porous zone were impressive. Thanks for such a detailed simulation model!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation provided you with clear insights and impressive results. It’s great to know that our detailed models have been effective in demonstrating the impact of the porous zone on combustion stability. Your satisfaction is our top priority, and we look forward to continuing to support your future CFD endeavors! If you have any more questions or need further assistance with your simulations, please do not hesitate to reach out.

Miss Lyla Jakubowski –

I’m impressed by how the porous zone impacts the stability of the premixed combustion according to the results. Great use of CFD analysis tools!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you appreciated the detailed analysis of the premixed combustion in a porous zone and the role it plays in stabilizing the combustion process. It’s great to know that our efforts in CFD simulations are valued by our customers. If you have any more feedback or need further assistance with our products, please feel free to reach out.

Winfield Luettgen –

I was really impressed with the clarity of the results. The temperature stabilization within the porous zone was particularly remarkable. Great visuals for understanding the combustion dynamics!

MR CFD Support –

Thank you for your feedback! We’re thrilled to hear that you found the simulation results clear and informative, particularly regarding the impact of the porous zone on stabilizing combustion temperatures. It’s wonderful to know our visuals effectively aided in understanding combustion dynamics. We appreciate your positive review!

Fredy Jaskolski –

Wow! The impact of porosity on combustion stability is incredibly fascinating. I’m impressed with the depth of analysis that this simulation allows. It’s clear how accurate simulations contribute to the advancement in combustion engineering. Well done, MR CFD and the team!

MR CFD Support –

Thank you for your kind words and recognizing the effort that goes into our computational fluid dynamics simulations. We are pleased to hear our Premixed Combustion in a Porous Zone simulation was able to deliver the depth of analysis you appreciate. Your feedback encourages us to keep providing detailed and accurate training materials. If you have any further questions or need assistance, please do not hesitate to reach out!

Prof. Roberto Friesen II –

I’m amazed at the level of detail in the simulation results for the Premixed Combustion in a Porous Zone provided by MR CFD. The visualizations of temperature and mixture fraction are top-notch, making this training material incredibly useful for understanding the combustion process. Well done!

MR CFD Support –

Thank you for recognizing the detail and quality of our Premixed Combustion in a Porous Zone simulation. We’re thrilled to hear that you found the training materials and visualizations helpful for your understanding of combustion processes. Your positive feedback is much appreciated!

Angeline Schuppe –

I’m thrilled with the detail presented in the Premixed Combustion in a Porous Zone simulation. The results indicating how the porosity stabilizes combustion temperature is especially interesting. Excellent learning material!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the simulation has served as an excellent learning tool and that the insights on porous zones and combustion stability were particularly useful to you. Your feedback motivates us to continue providing quality educational content.

Olga Adams –

Is the ignition spark sub-model important for the simulation, and if so, why?

MR CFD Support –

The ignition spark sub-model in this simulation is crucial for initiating the combustion process. It simulates the actual ignition source in reality which starts the combustion. It’s especially important in premixed combustion contexts to accurately predict how the combustion will establish itself from an initial source of ignition.