Premixed Combustion Simulation based on the Zimont formulation, ANSYS Fluent

$160.00 $80.00 Student Discount

- In this project, a part of an annular combustion chamber is simulated by Ansys Fluent software.

- Premixed combustion of methane-air is analyzed, and Zimont’s method is also used to model the flame speed.

- Structured grid is used to create a mesh in the computing domain.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

Over the past few decades, there has been a steady increase in interest in detailed numerical modeling of reactive flows. This has to do with the growing significance of developing new combustion equipment and refining already existing technology. Enhancing combustion processes is a particularly challenging undertaking because, because combustion systems are complex, optimizing one aspect of the process frequently results in the worsening of other aspects. For instance, a decrease in flame stability has often resulted from the evolution of combustion technology over the past few decades toward more leaner low- premixed combustion processes in many applications (leading e.g., to flame oscillations, noise, CO-emissions and even flame quenching). Combustion system modifications were required in order to prevent all of these issues, and combustion CFD has grown to be a crucial tool for these investigations. Combustion system modifications were required in order to prevent all of these issues, and combustion CFD has grown to be a crucial tool for these investigations.

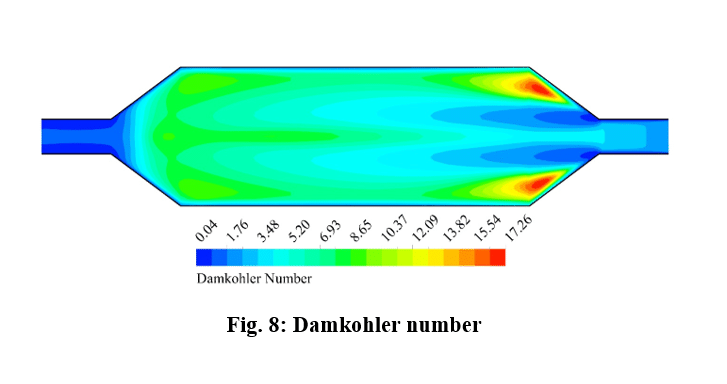

In this project, a part of an annular combustion chamber is simulated by AnsysFluent software. Premixed combustion of methane-air is analyzed, and Zimont’s method is also used to model the flame speed. Figure 1 shows the geometry of this project. The inlet and outlet length of the chamber is 20 mm and its total length is 180 mm. Other geometry dimensions are given in Figure 1.

Fig. 1: Simulation geometry

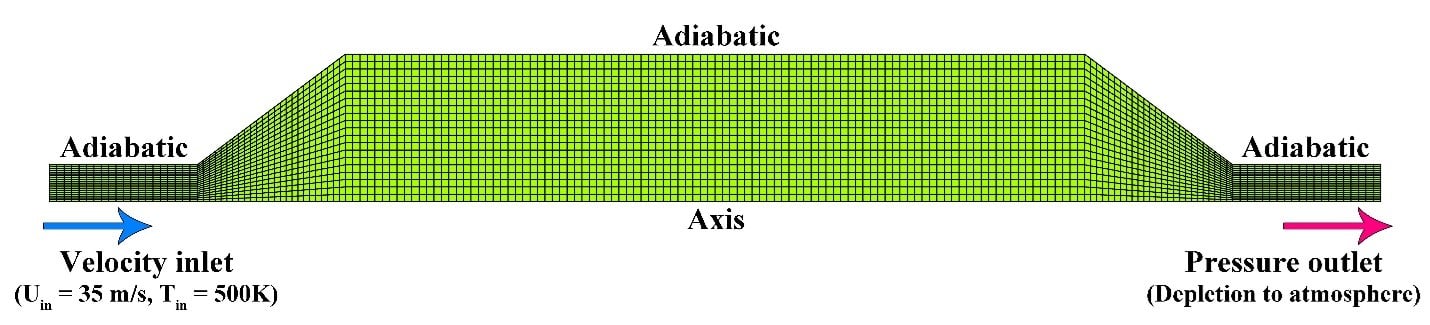

In this project, structured grid is used to create a mesh in the computing domain (Fig. 2). The boundary conditions are such that the velocity inlet is used at the inlet of chamber and the pressure outlet is used at the chamber outlet. At the inlet, the premixed flow enters the combustion chamber with a velocity of 35 m/s and a temperature of 500 K, and on the other hand, the combustion products are depletion into the atmosphere at the outlet. In this project, axisymmetric simulation has been done. As a result, the lower side of the model is axis, and other boundaries are also considered as adiabatic.

Fig. 2: Mesh and boundary conditions

Results

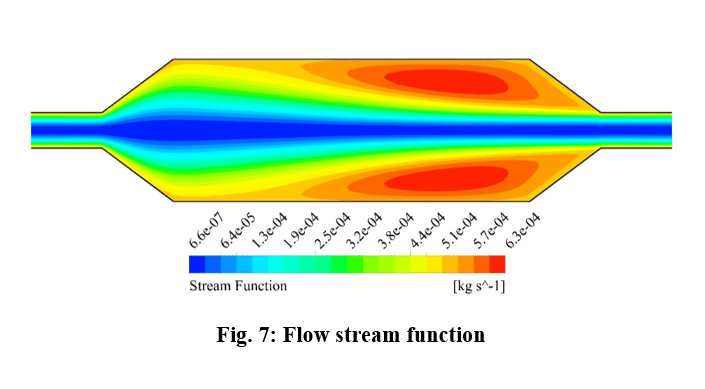

The simulations are conducted in such a way that a lean premixed air-methane mixture, with an equivalence ratio of 0.6, enters the chamber, and after the chemical reactions are completed, the combustion products are depletion to the atmosphere at the outlet. In this case, the properties of the premixed mixture, which is modeled by non-adiabatic, are given in the table 1.

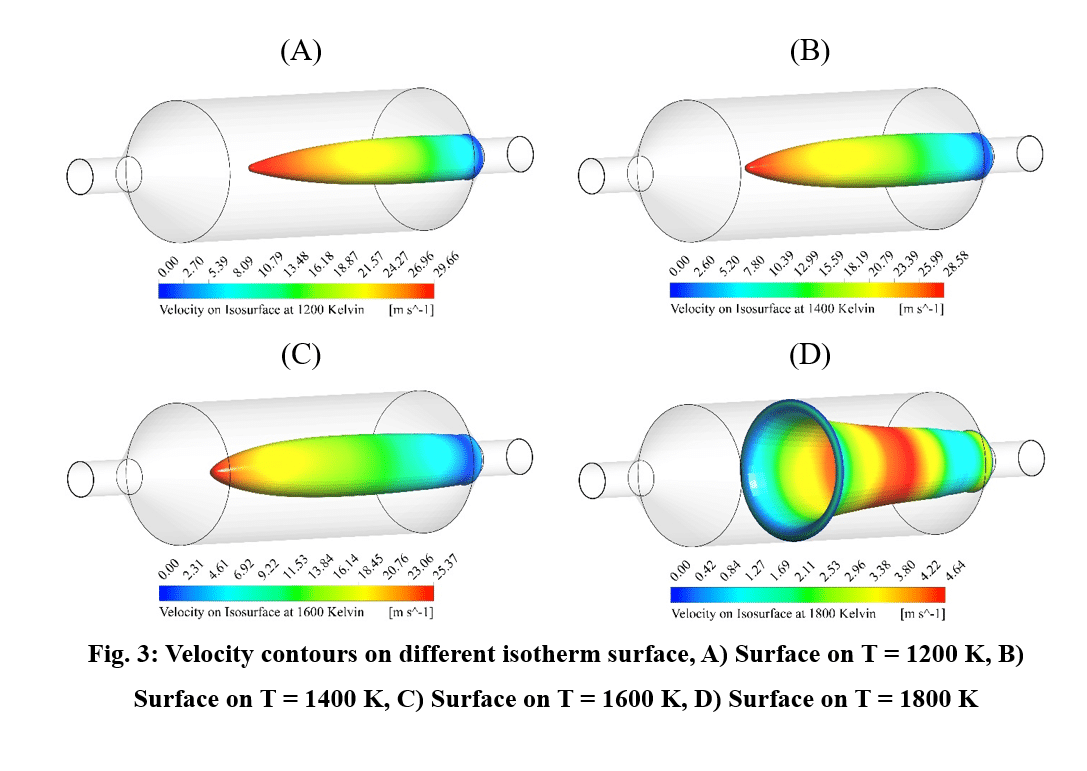

In such problems, simulation should be done in two steps. First, the solution for the two equations of flow and turbulence is done, so that the flow is formed in the computational domain. Then the energy and combustion equations are activated, as well as in the pitch in the iteration section, the value of the progress variable must be set to one. In this case, the convergence of the solution is done in a desirable way, and accurate results are obtained. In Figure 3, the velocity contour is shown on different surfaces of the isotherm.

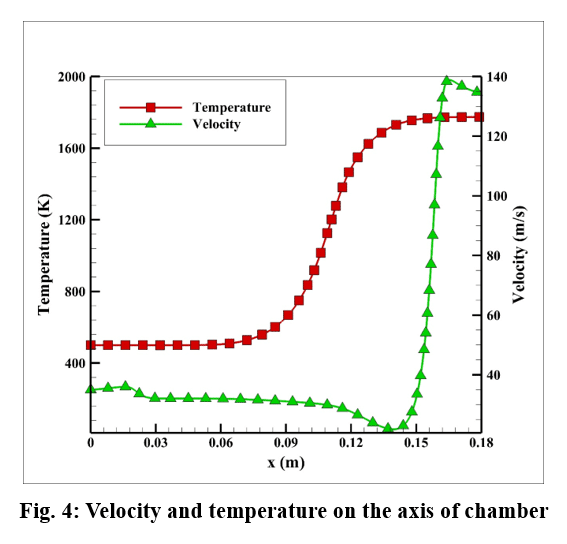

Velocity and temperature curves on the chamber axis are also presented in Figure 4. The maximum velocity was 140 m/s at the outlet of the chamber, and the maximum temperature obtained 1830 K.

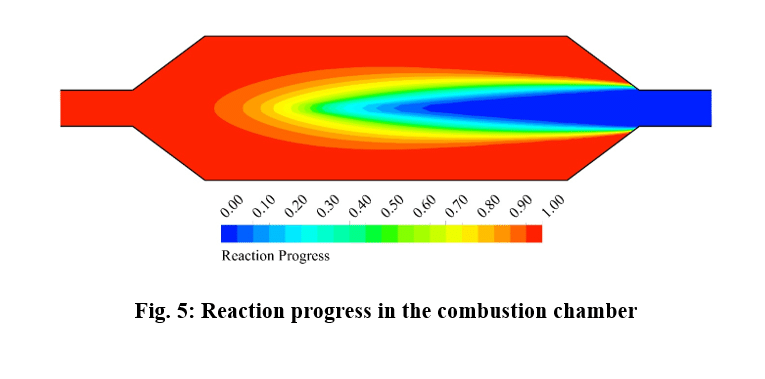

The progress of the reaction in the combustion chamber, which represents the completion of the process, is shown in Figure 5.

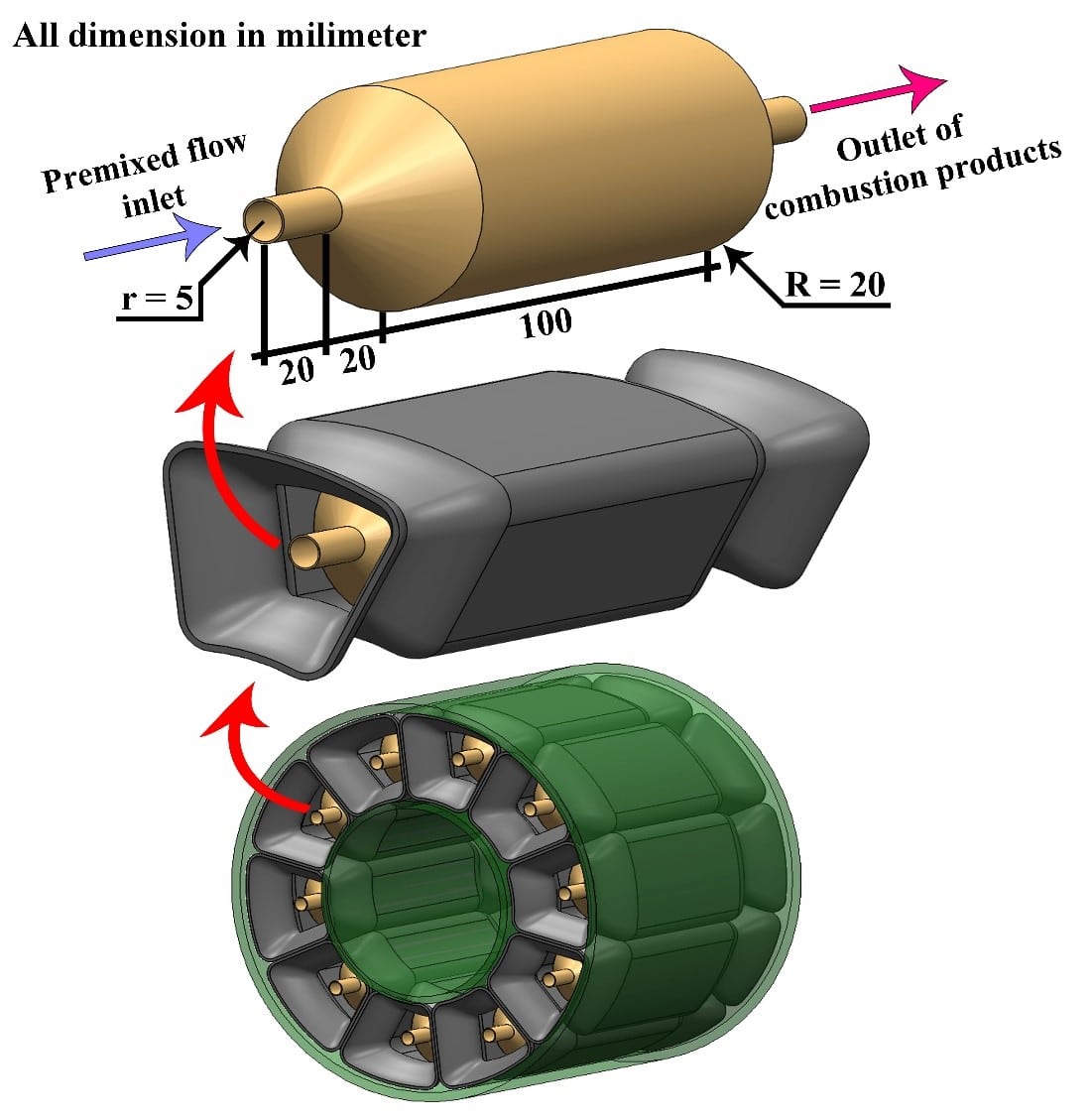

The stream function that shows the behavior of the flow is also observed in Figure 7.

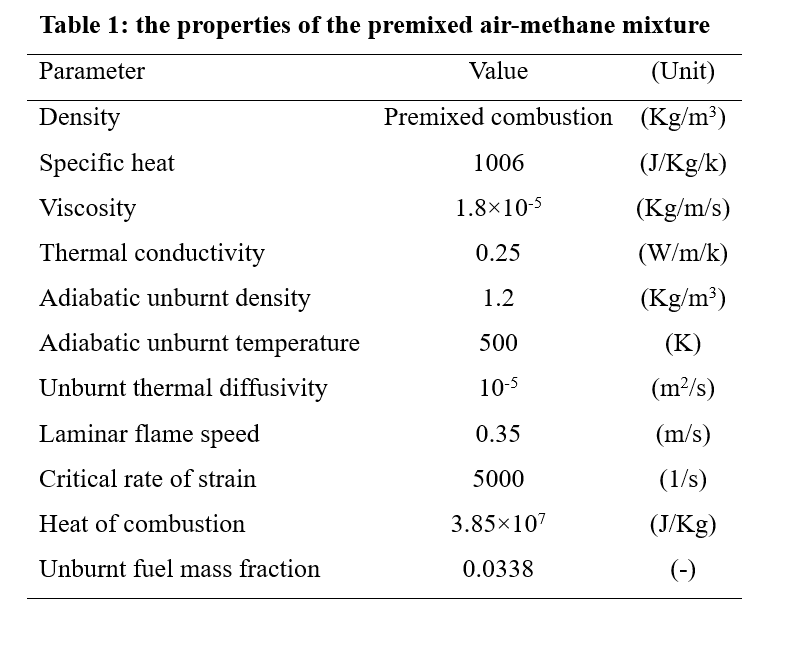

The Domkohler number, which indicates the dimensionless time of gas residence during the chemical reaction process, is also shown in Figure 8.

Conclusion

In this project, premixed combustion, in a chamber, is simulated by Zimont model. Zimont model has increased the simplicity and speed of simulations by adding only one equation in calculations, and on the other hand, it has relatively high accuracy in flame modeling. This issue can reduce computational costs in complex problems, and for all that, it has a good simulation accuracy. This is the main goal of computational fluid dynamics. Independently of this, the formulation presented by Zimont in terms of a variable that shows the progress of the flame is used for the numerical simulation of the intermediate steady propagation (ISP) of flame.

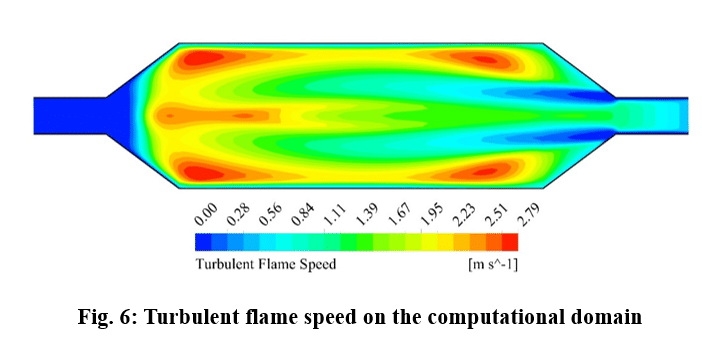

In this project, the lean air-methane mixture is entered into the computational domain, after the completion of chemical reactions, the combustion products are depletion from the chamber into the atmosphere. The velocity and temperature of the mixture at the inlet are considered to be 35 m/s and 500 K, respectively. Also, the equivalence ratio of the mixture at the entrance of the computational domain is 0.6. Axisymmetric simulation is done in two steps for better convergence. In the first step, only the flow and turbulence equations are modeled to simulate the flow behavior. Then, in the second step, the energy and premixed combustion equations are activated, the progress variable Initialized, and the solution is continued. After completing the solution, things such as velocity, temperature, reaction progress, turbulence flame speed, stream function and dimensionless Damkohler number are the results that are presented in this project for a better understanding of the problem.

Reviews

There are no reviews yet.