Premixed Turbulent V-shaped flame, Paper Numerical Validation, ANSYS Fluent

$360.00 $180.00 Student Discount

- In this project, a V-Flame is simulated using the Zimont model, then compared with the paper “Numerical simulation of a premixed turbulent V-shaped flame.” by Ansys Fluent software.

- Premixed combustion of methane-air is simulated, comparing the Zimont and Eddy Break-Up models.

- The geometry is designed in Spaceclaim software.

- A structured grid is used to create a mesh in the computing domain using ANSYS Meshing software.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

The Zimont Model versus Eddy Break-Up model (Paper validation of premixed air/methane combustion)

In this project, a V-Flame is simulated using the Zimont model, and the result is compared with the paper that was done using the Eddy Break-Up model (EBU) [1]. The common feature of both models is the solution of C-Equation, and in this case, the chemical reaction and flow equations are solved simultaneously in the computational domain. A significant reduction in the computational cost and high accuracy in simulating the combustion chamber is another aspect of the similarity of both models. However, although these models accurately simulate flame shape, flow turbulence, velocity, and temperature, species’ details are unavailable. In this case, these models are not recommended for complex reactions. Because none of the species and transfer energies were available in all reactions. Of course, in most applications, especially industrial cases, it is the fluid temperature and velocity that is of particular importance, thus the use of these models, which have high accuracy and low computational cost, is highly recommended.

With the general explanations mentioned above, the following points are relevant for both models.

- Although both models are used for premixed combustion, the Zimont model is also used for semi-premixed combustion in addition to premixed combustion.

- Both models show that turbulent mixing may be considered as a cascade process from integration to molecular scales, the cascade process also controlling chemical reactions.

- For both models, the chemical source in the mean turbulent reaction rate is considered based on the mixing time, as well as the mass fraction variances. Meanwhile, for the EBU, the eddy breakup constant, and for the Zimont model, the turbulent flame speed is considered as source terms in the C-Equation.

- The speed of chemical reactions and the composition of products are not considered in both models, only by calculating and entering the thermophysical properties of the material, the desired combustion can be simulated.

- The Zimond model is available in Ansys Fluent 2024, while the EBU is not.

In the following, and of course with the explanations given in this section, the investigation of the geometry, mesh, and results in the simulation of the V-shaped flame is discussed.

Geometry and mesh description

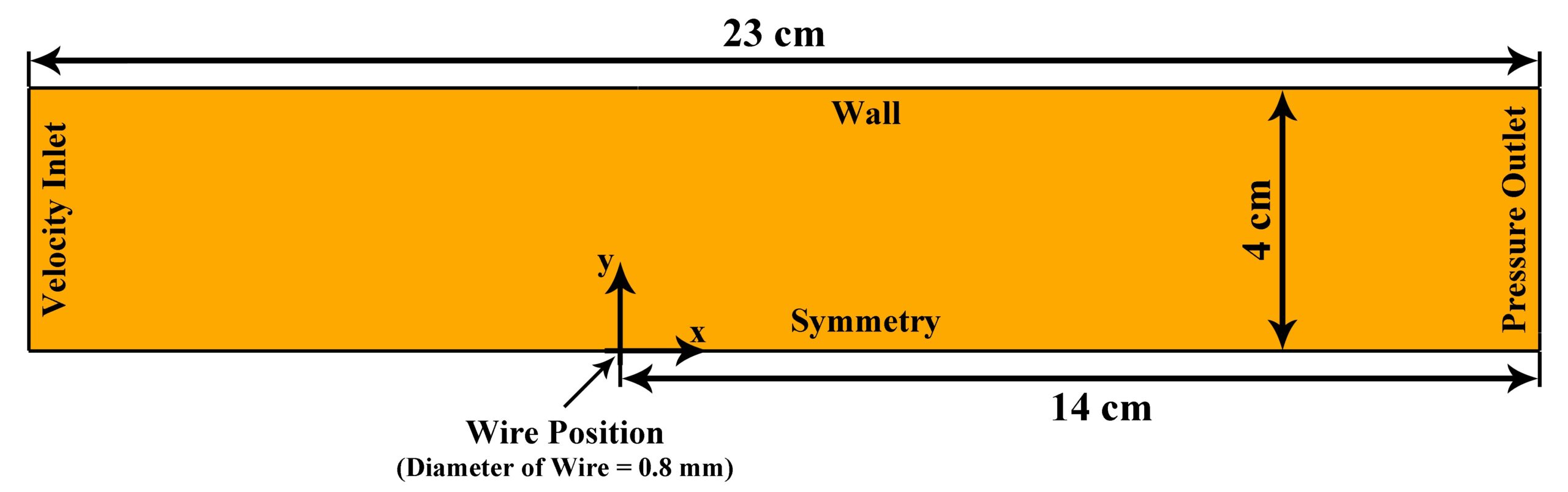

The cross section of the combustion chamber is square with side 8 and length 23 cm. In this project, the simulation is done in two dimensions. Due to the symmetrical shape of the flame, and due to the reduction of computational cost, half of the chamber is modeled. In this way, the area cut from the chamber axis is defined as a symmetric boundary condition. As seen in Figure 1, the wire is placed at a distance of 9 cm from the inlet of the chamber. The boundary conditions are also defined in the paper.

Fig. 1: Two-dimensional combustion chamber geometry with boundary conditions

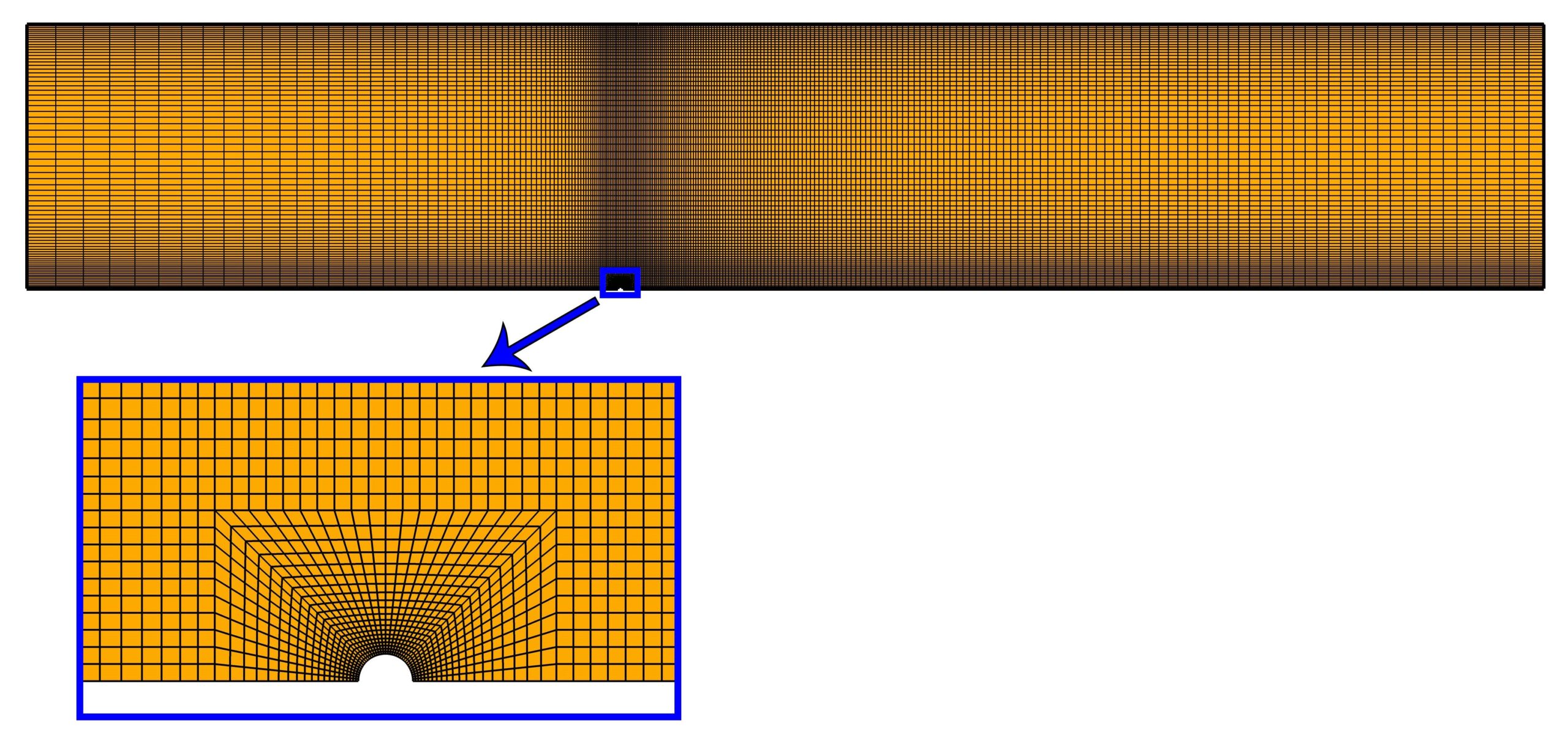

To simulate the flow parameters as well as possible, an organized mesh has been used in the computational domain (Figure 2).

Fig. 2: The structural grid

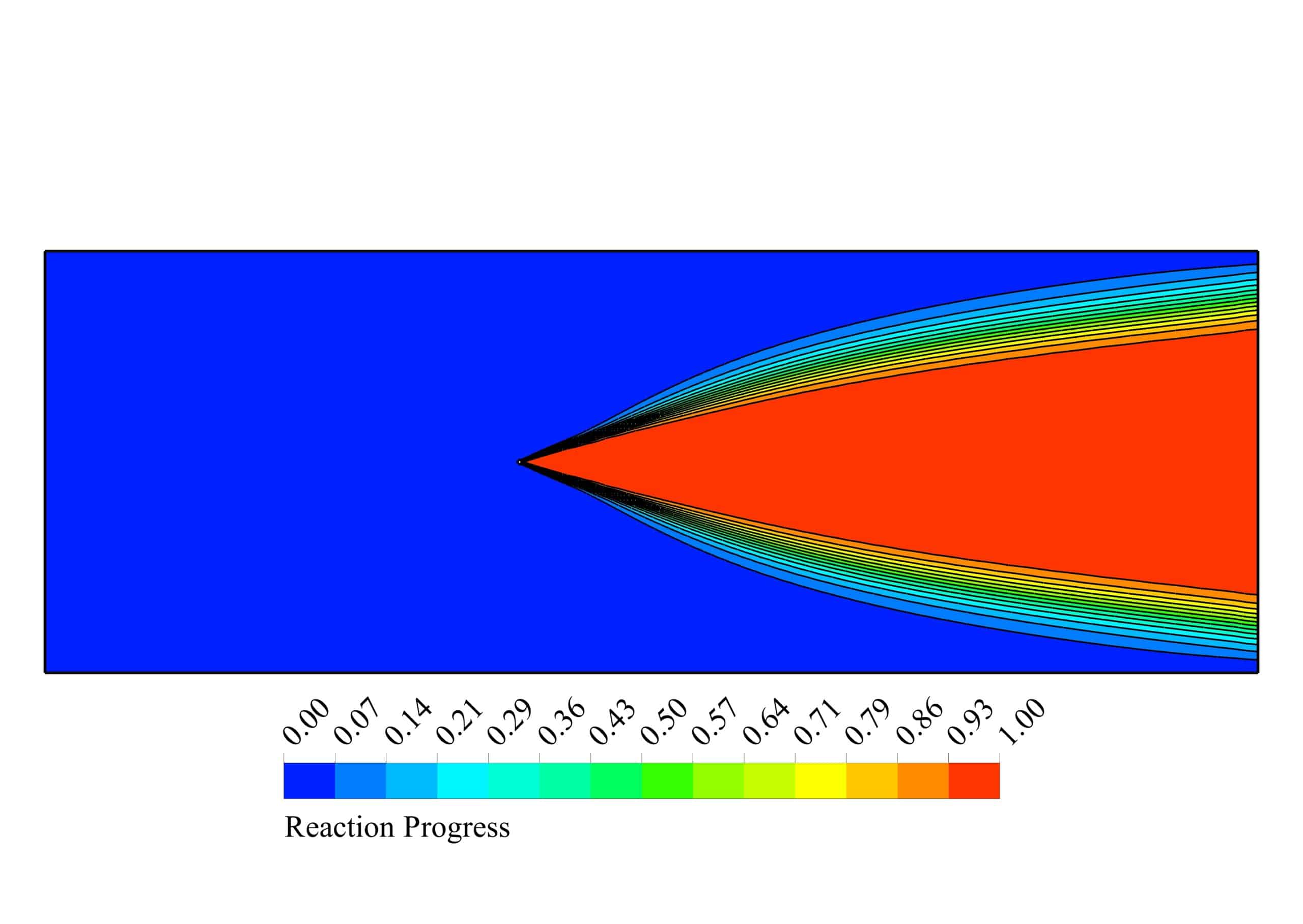

In such problems, the simulation is done in two steps. The first step: is the simulation of fluid flow without C-Equation, and the second step: adding the progress variable and continuing the simulation with all equations. In this project, to add variable progress, a circular region is defined in the cell registrations section with a diameter of 1 mm and reference coordinates. In this way, when the flow equations converged in the first step after 2000 iterations, the progress variable was defined in that circular region, and the solution was continued for another 2000 iterations for the final convergence. By explaining the description of the simulation, the results have been examined and the progress variable compared to the results of the paper.

Results

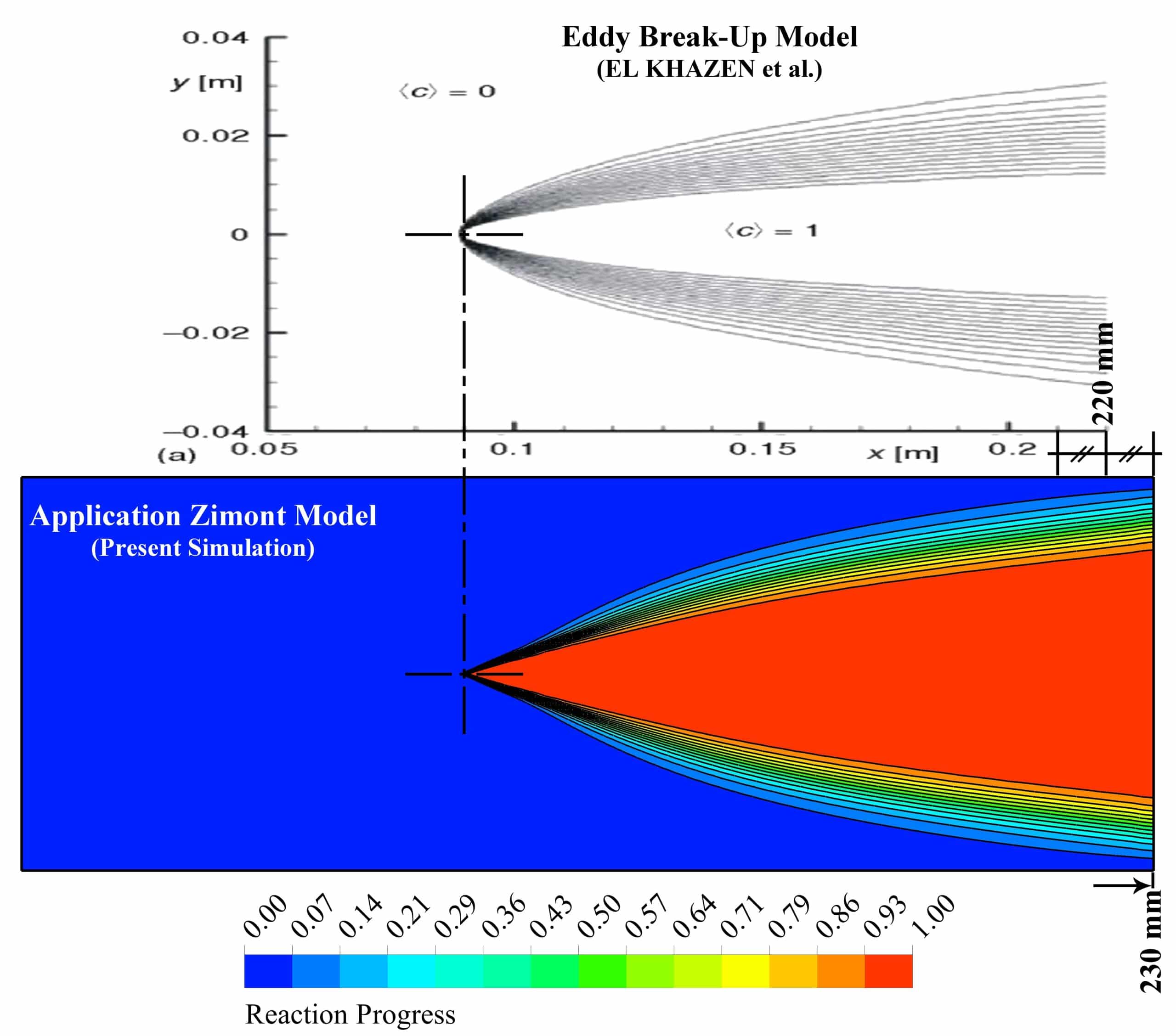

Figure 3 shows the comparison of variable progress with the results of El Khazen et al. The simulation is done at an equivalent ratio of 1, and a turbulence intensity of 9%. Of course, there will be a difference between the present simulation and the existing result. Because each of the contours used different methods to obtain this parameter. However, it can be seen that the simulation by the Zimont method has narrowed the two-phase region. While the EBU has stretched the flame in the computational domain and the y direction. However, the behavior and other flow parameters mentioned in the next contours are very close to the results presented by El Khazen et al.

Fig. 3: Comparison in the progress variable of the present simulation and El Khazen et al. study [1].

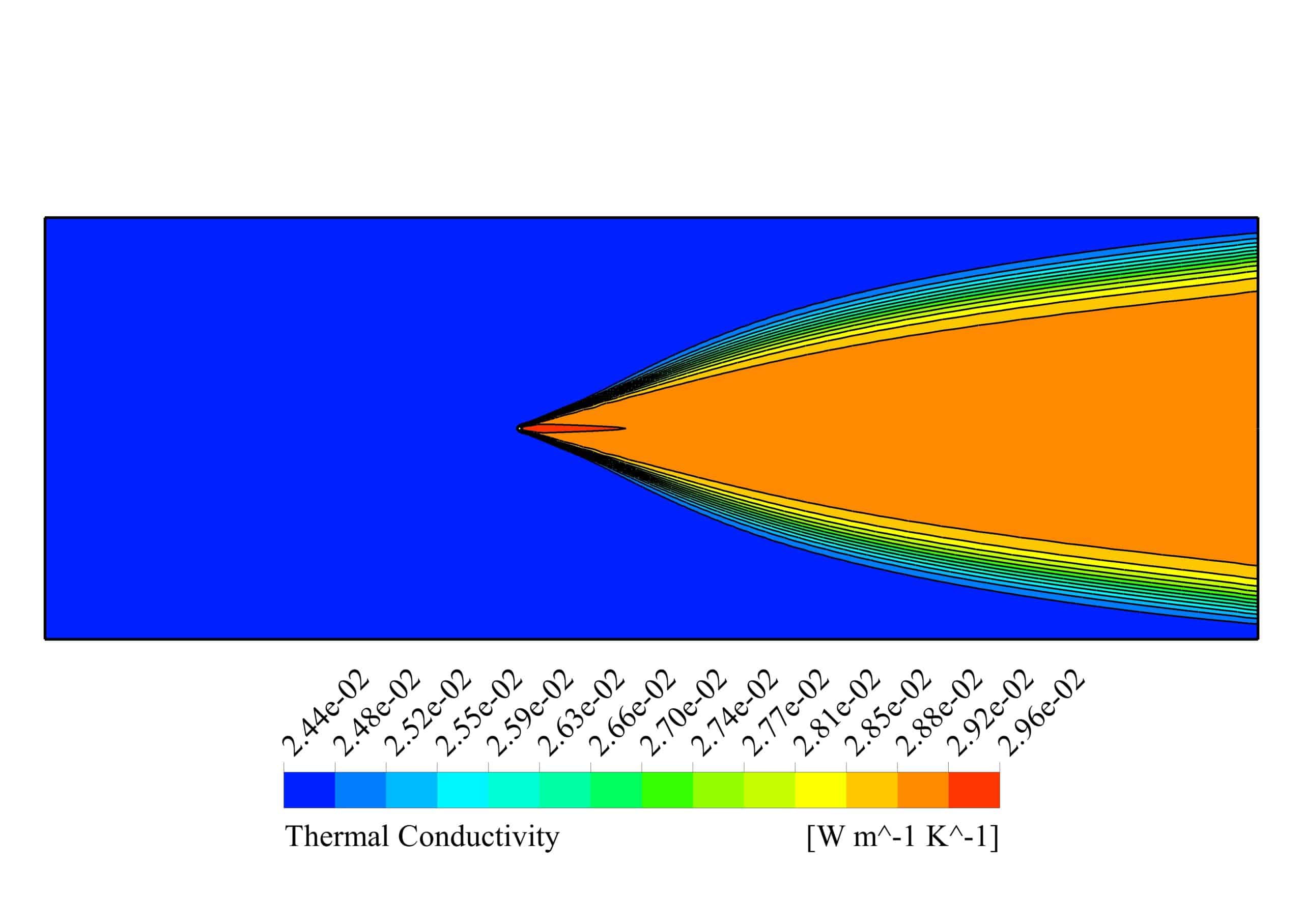

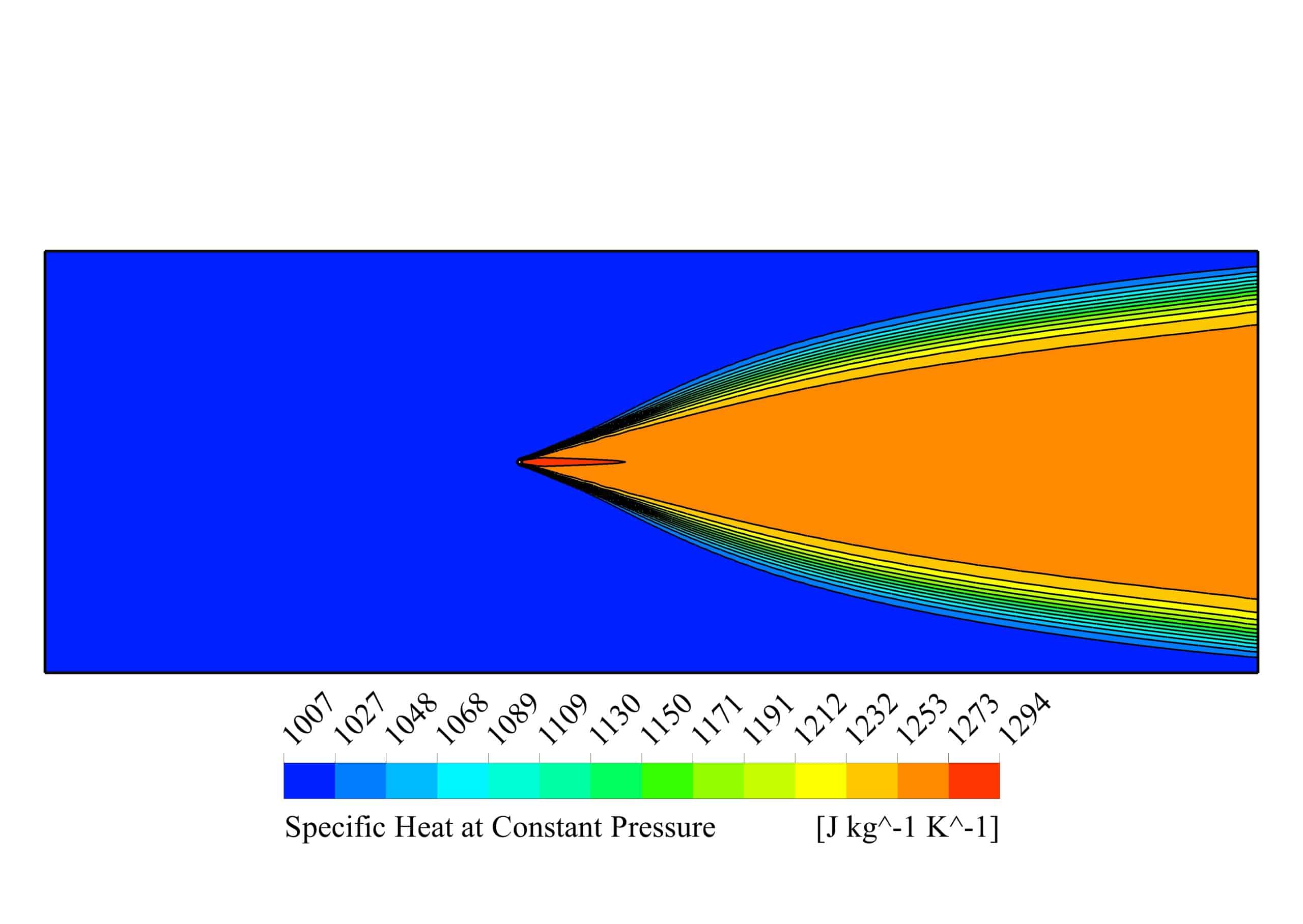

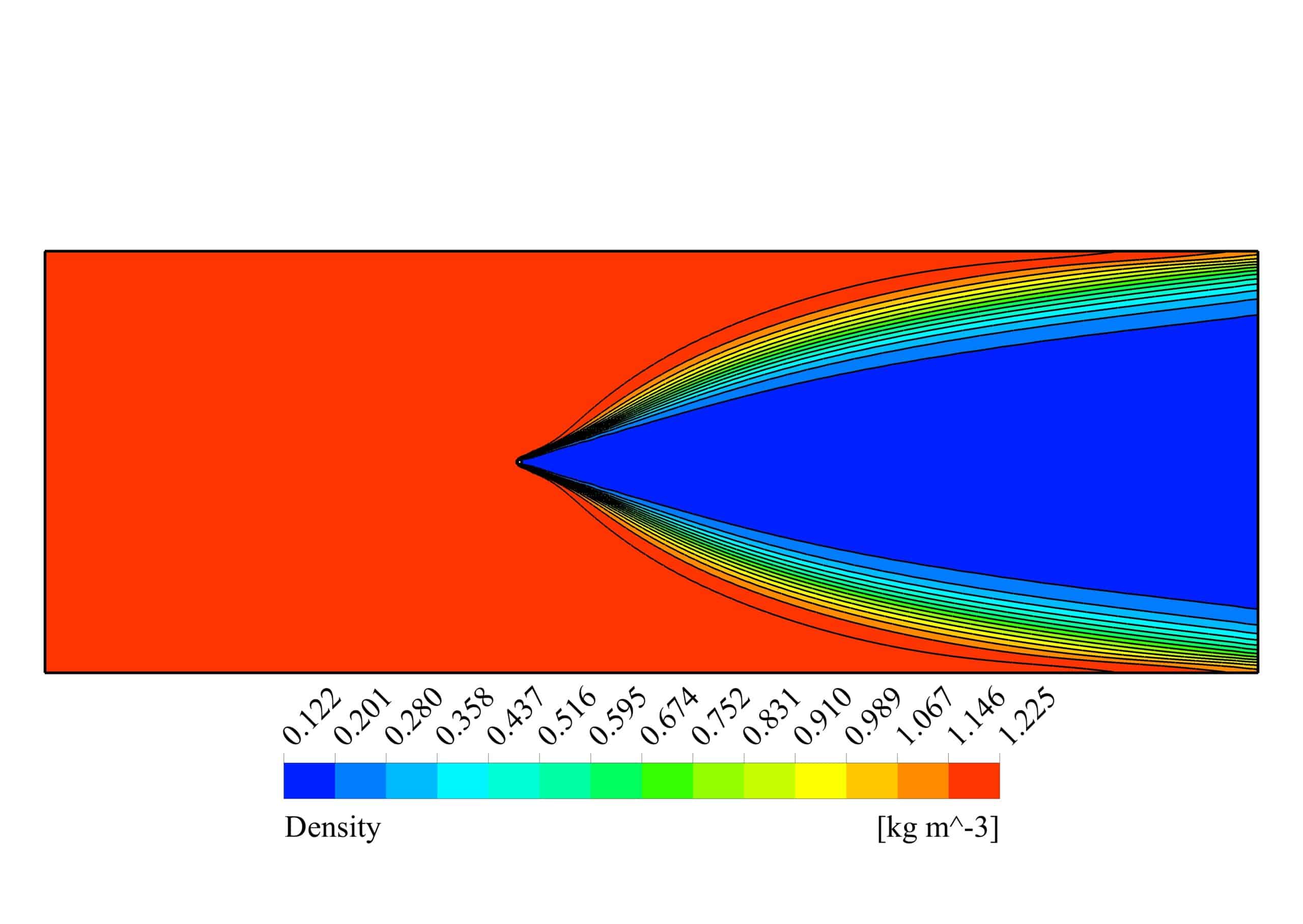

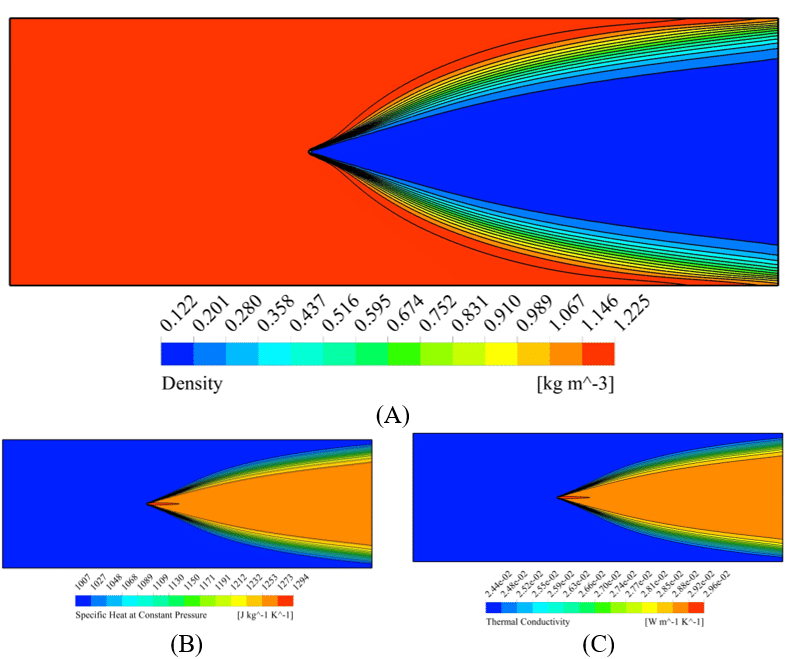

The thermophysical properties of the air/fuel mixture before and after being ignited in the combustion chamber can be seen in Figure 4. As can be seen, the minimum density obtained on the hot wire is 0.122 Kg/m3. The maximum density value is defined in the material properties section of the software to simulate a non-adiabatic flame. However the minimum value was obtained in the simulations, and as can be seen, this value is close to the density given in the article (the burnt density value in the paper for equivalence ratio 1 is given as 0.149 Kg/m3). The amount of thermal conductivity and heat capacity are also estimated for the software from the methods of Kinetic Theory and piecewise polynomial, respectively.

Fig. 4: thermophysical properties of air/methane, A) Density, B) Specific heat, C) Thermal conductivity

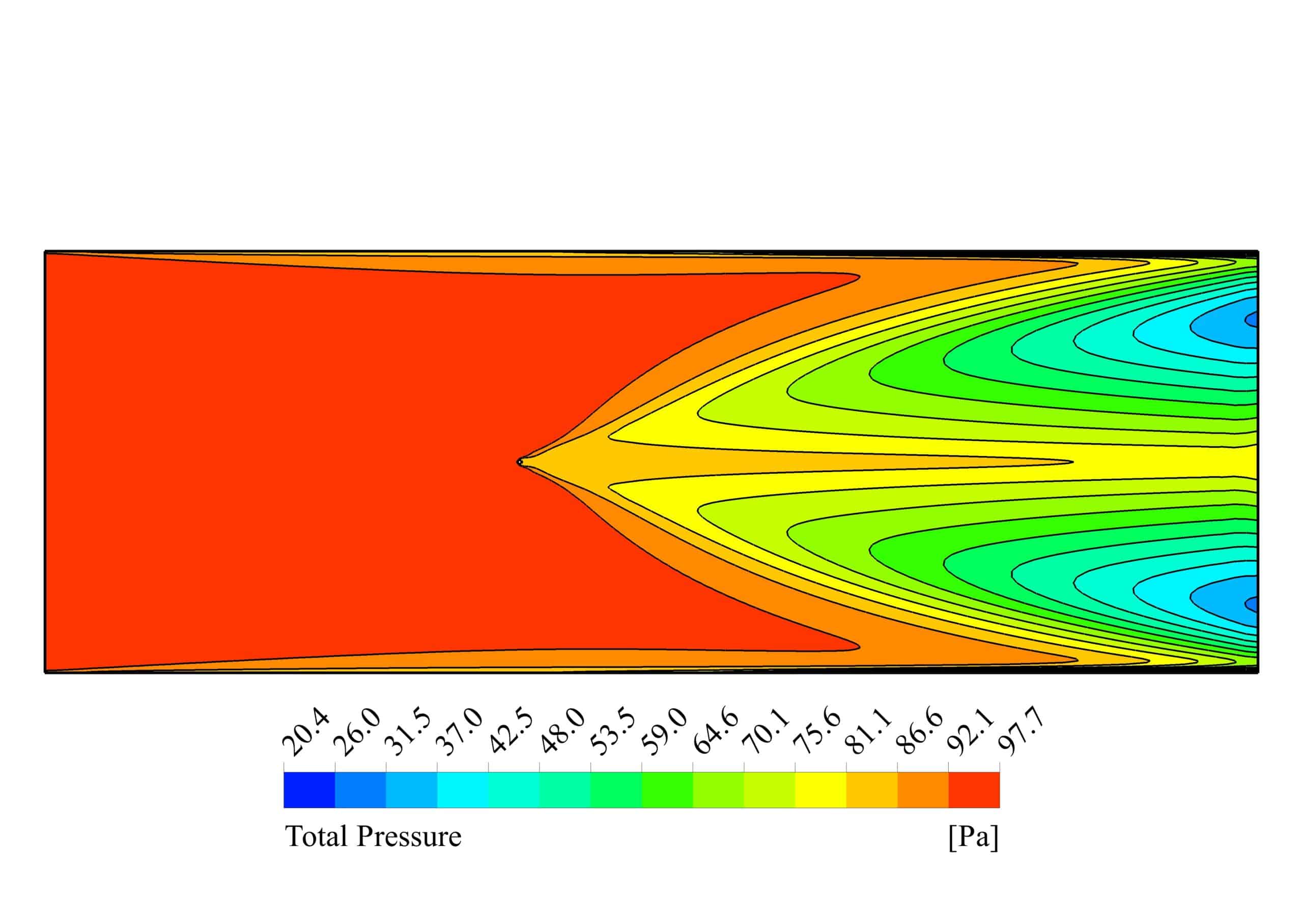

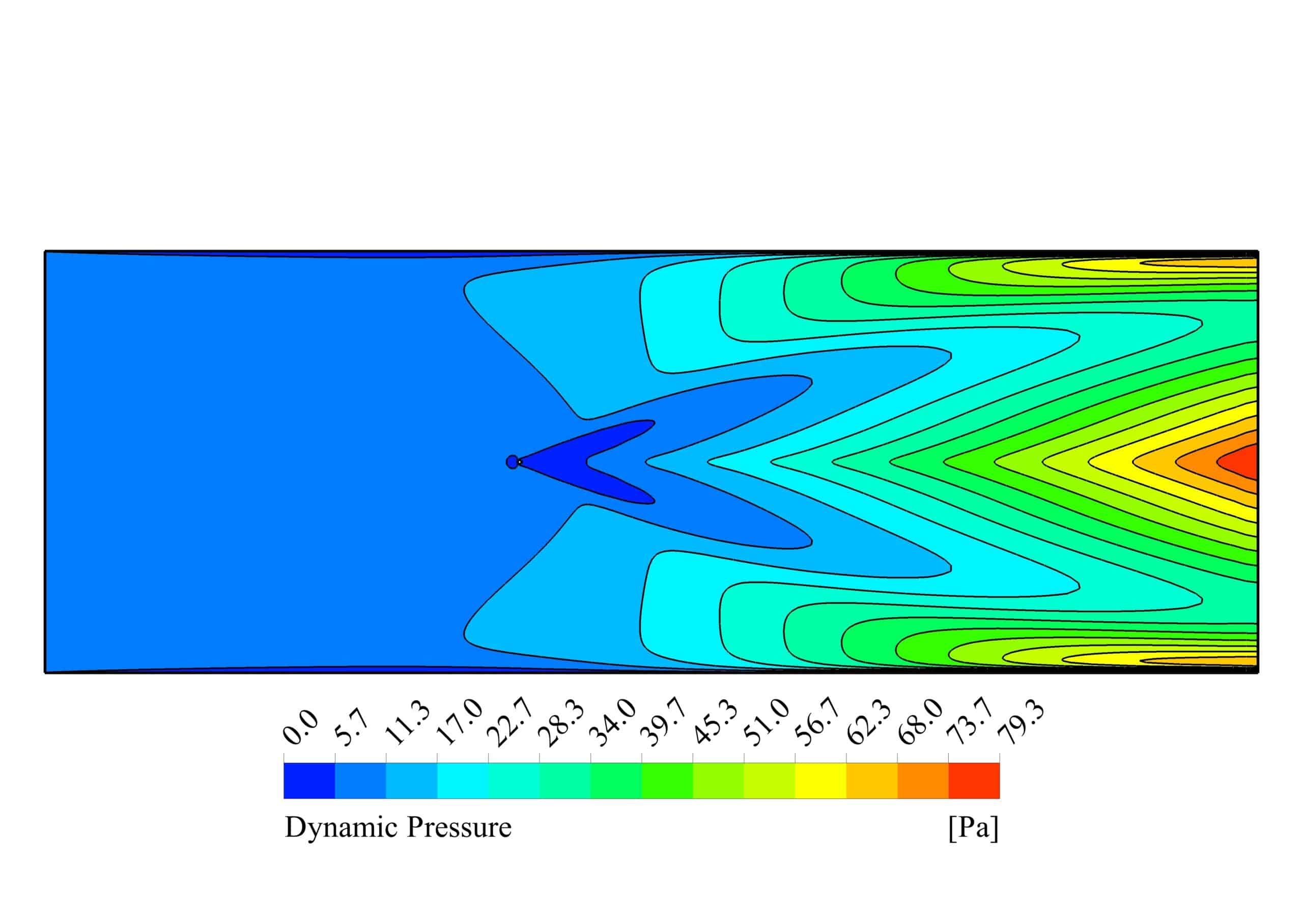

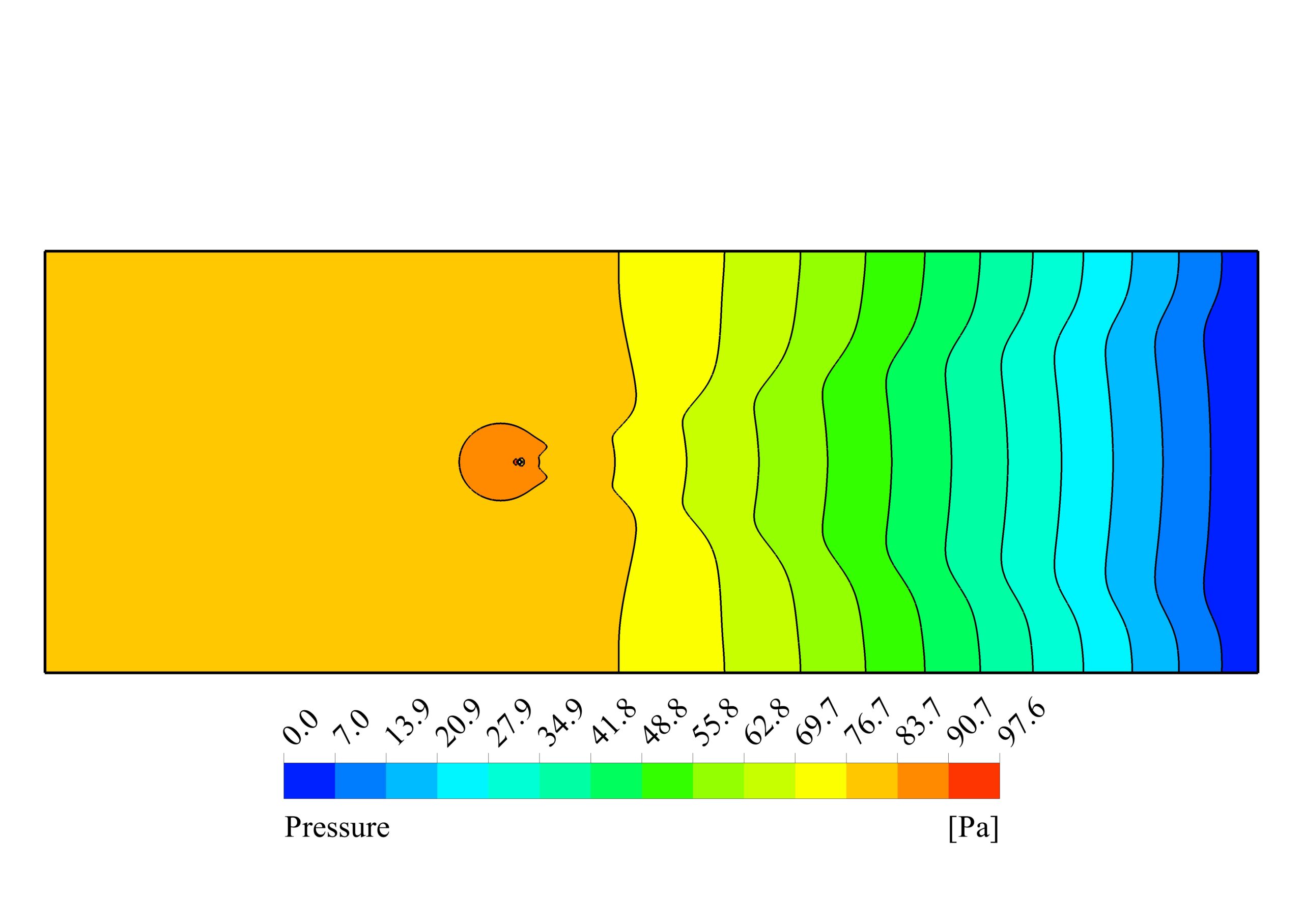

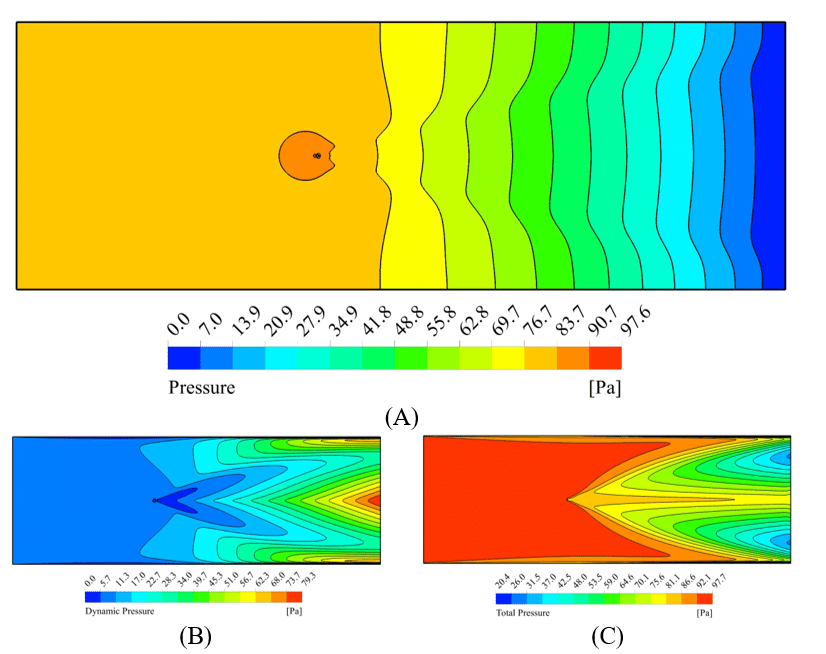

Static, dynamic, and total pressures are also presented in Figure 5.

Fig. 5: A) Static pressure, B) Dynamic pressure, and C) Total pressure

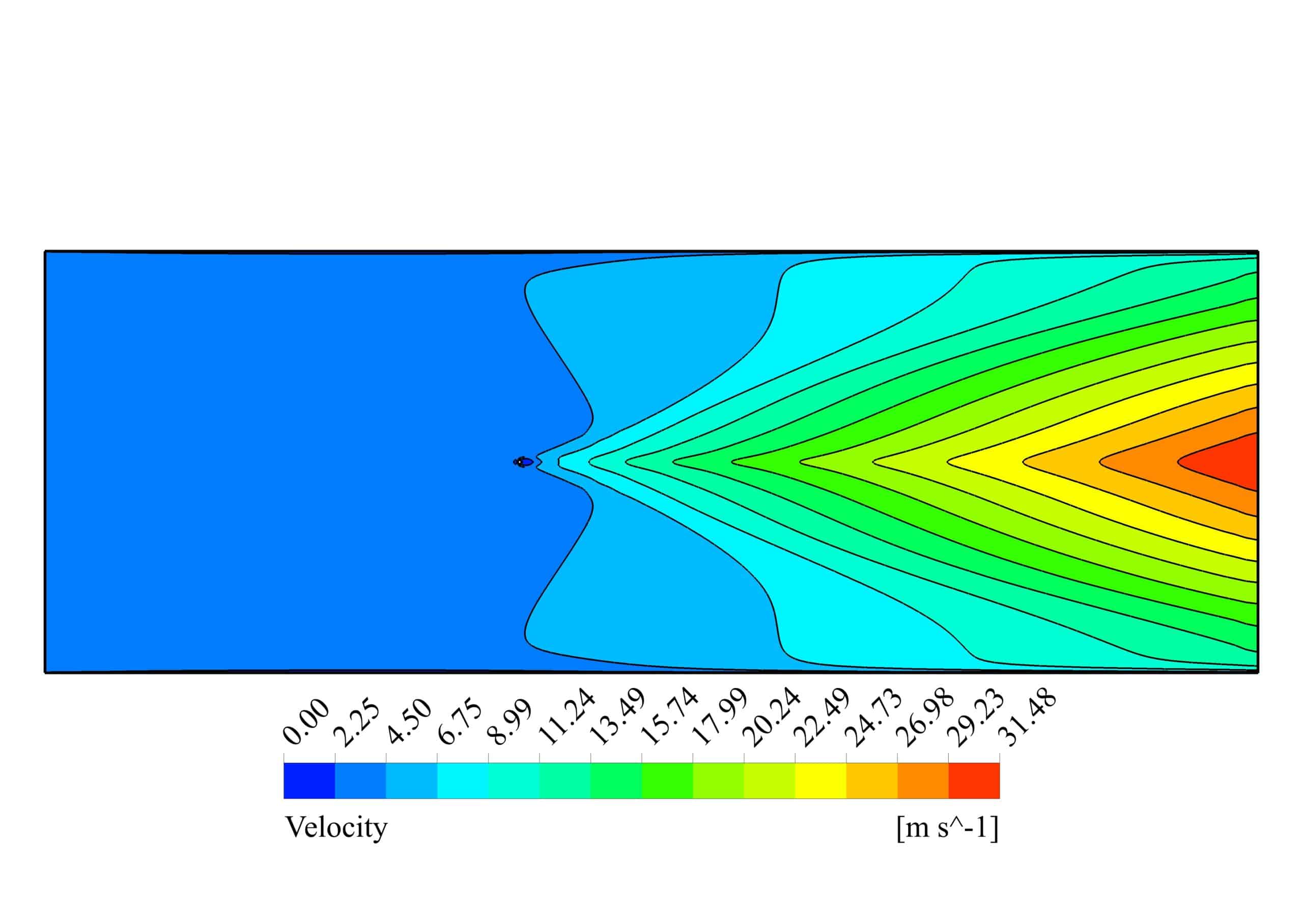

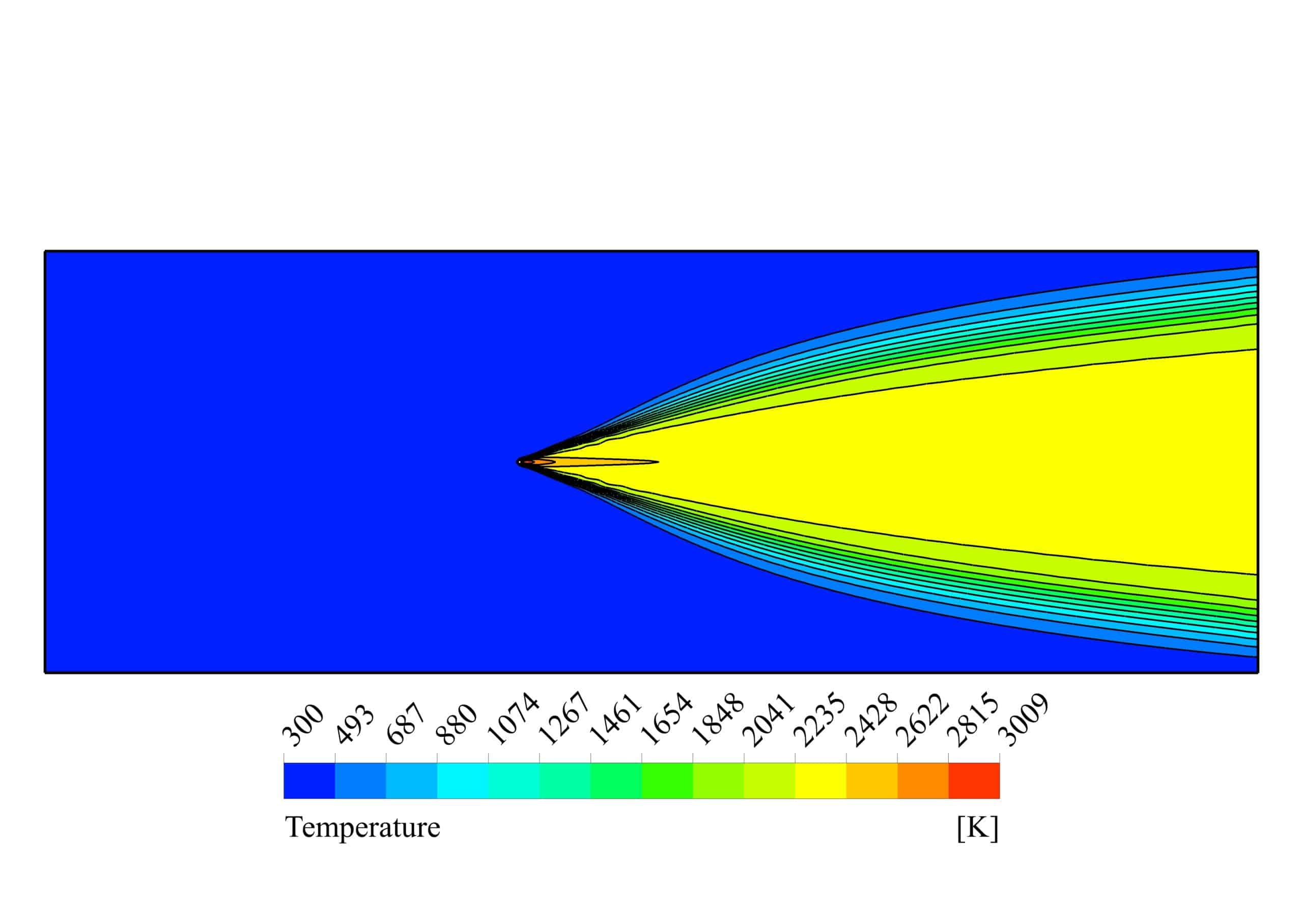

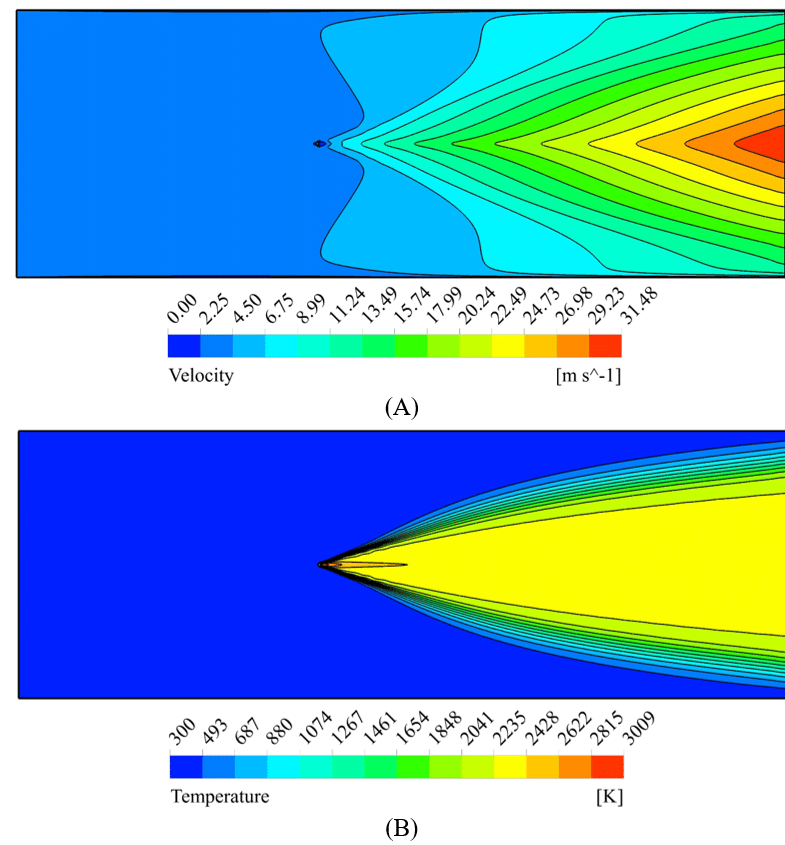

Figure 6 also shows the velocity and temperature contours in the computing domain. The maximum velocity is 31.48 m/s and the maximum temperature is about 3009 K (2736oC).

Fig. 6: A) Velocity, and B) Temperature

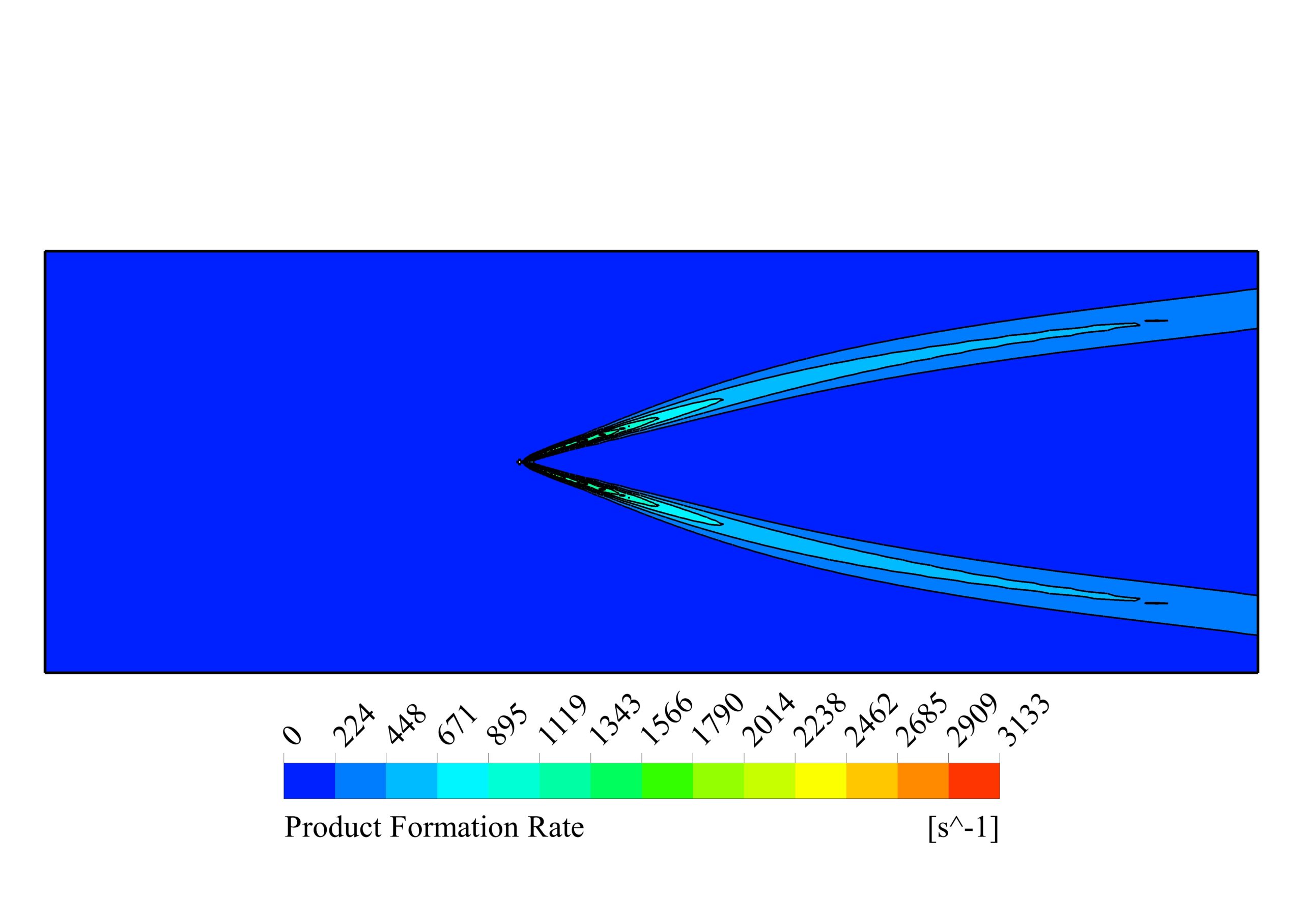

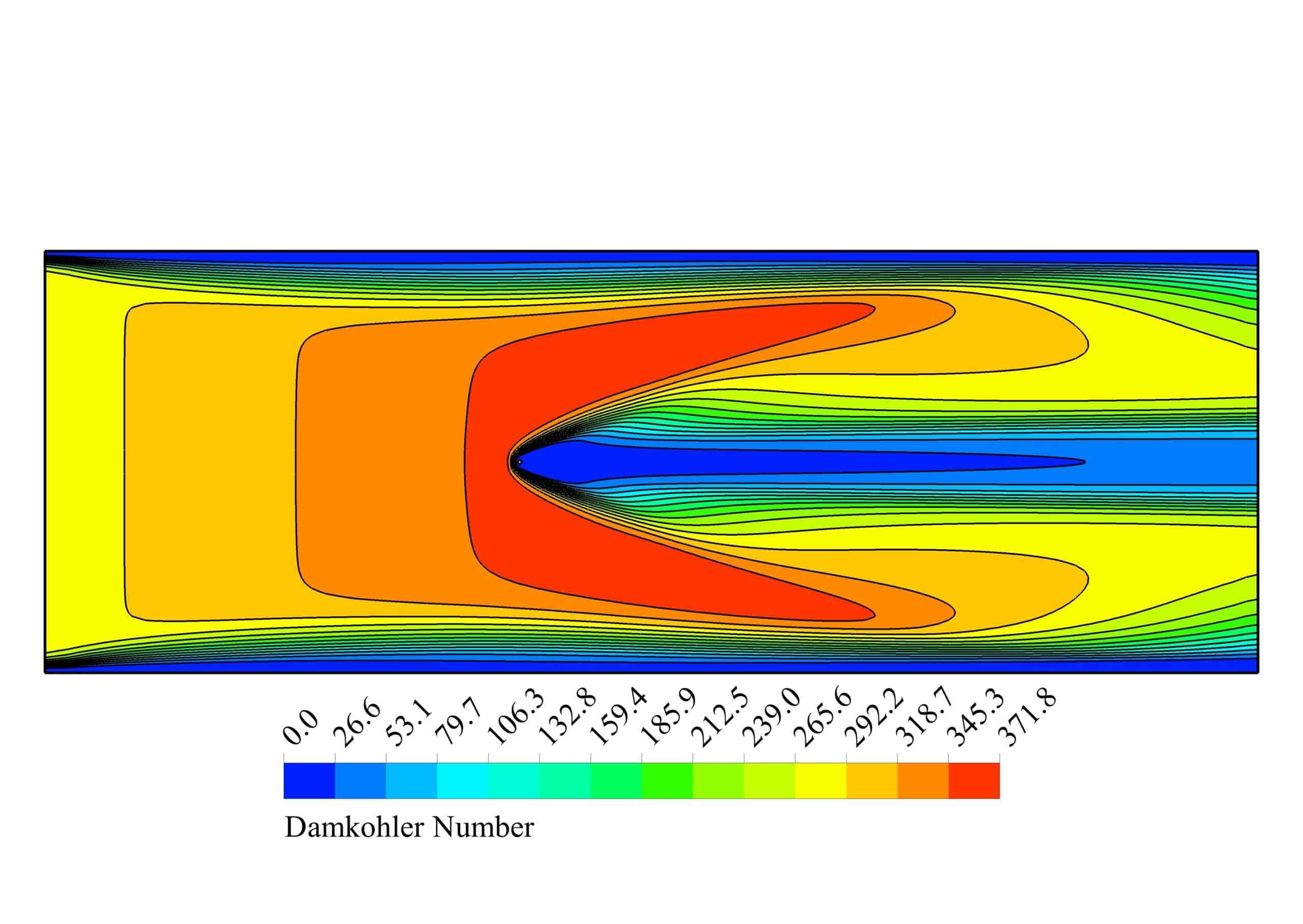

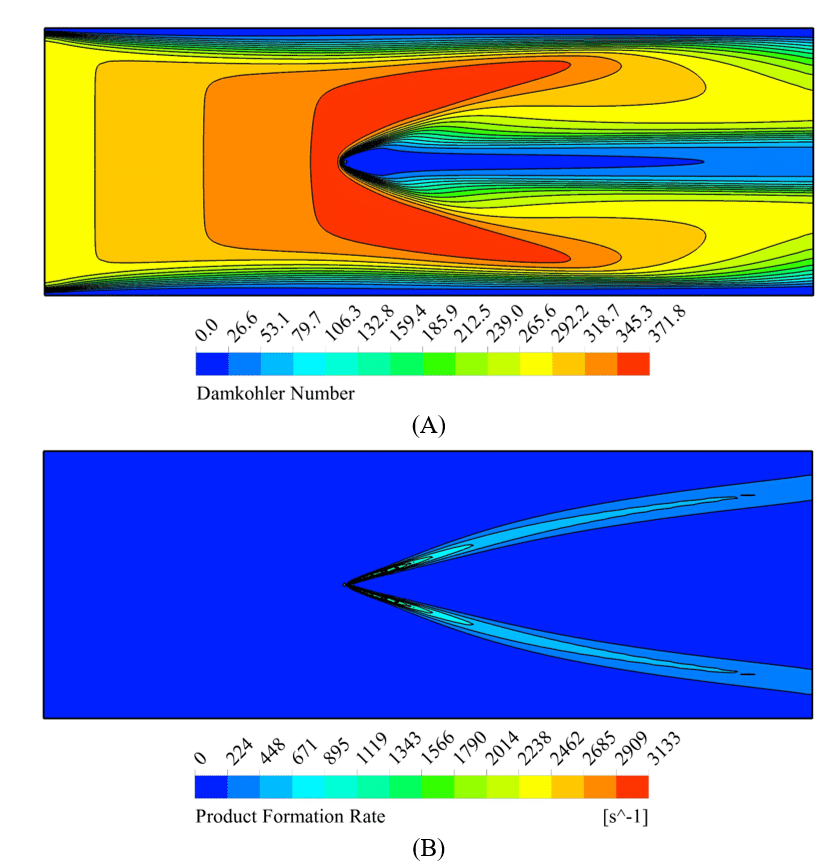

The Damkohler number and formation rate of combustion products can also be seen in Figure 7.

Fig. 7: A) The Domkohler number, and B) Formation rate of the product

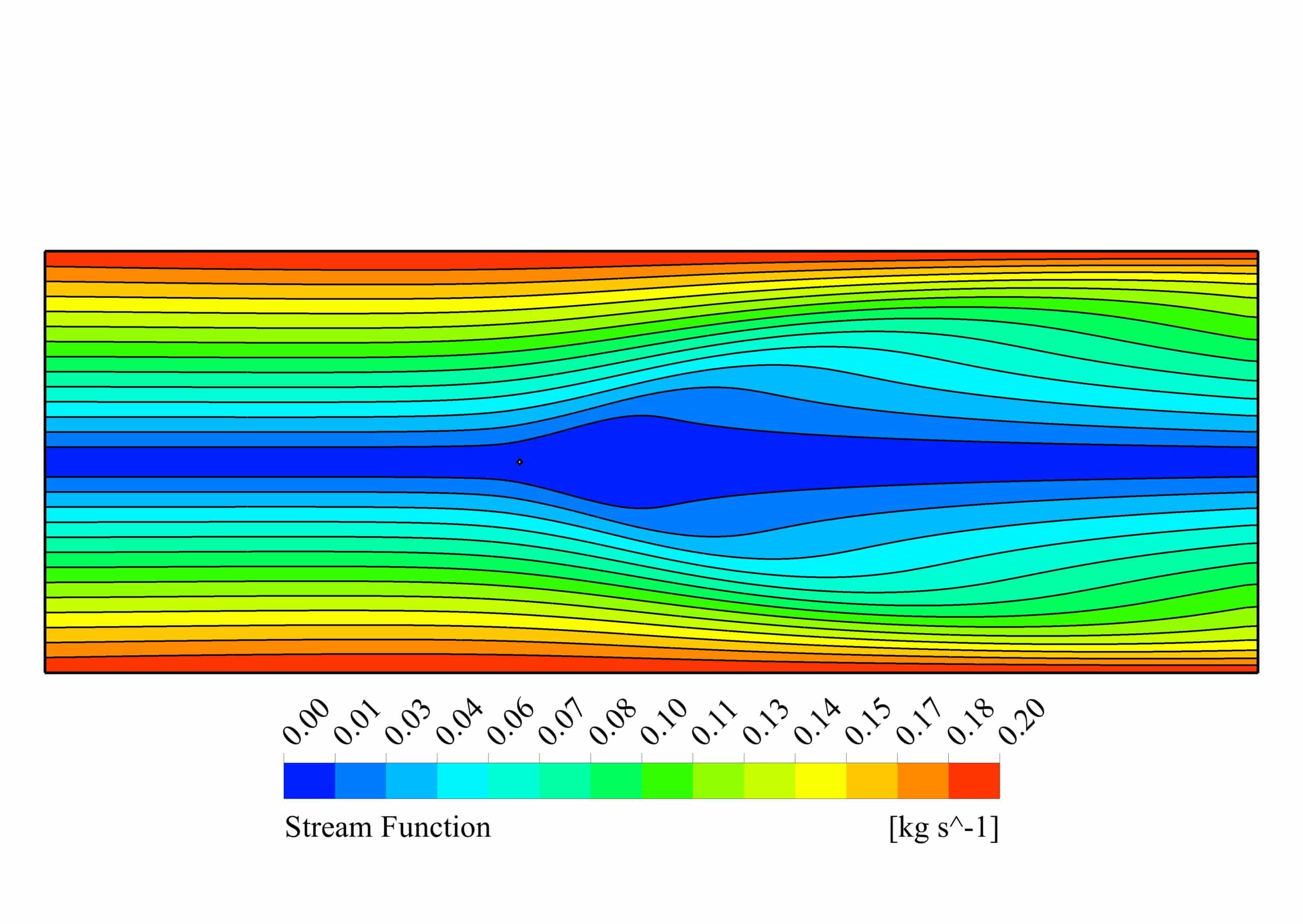

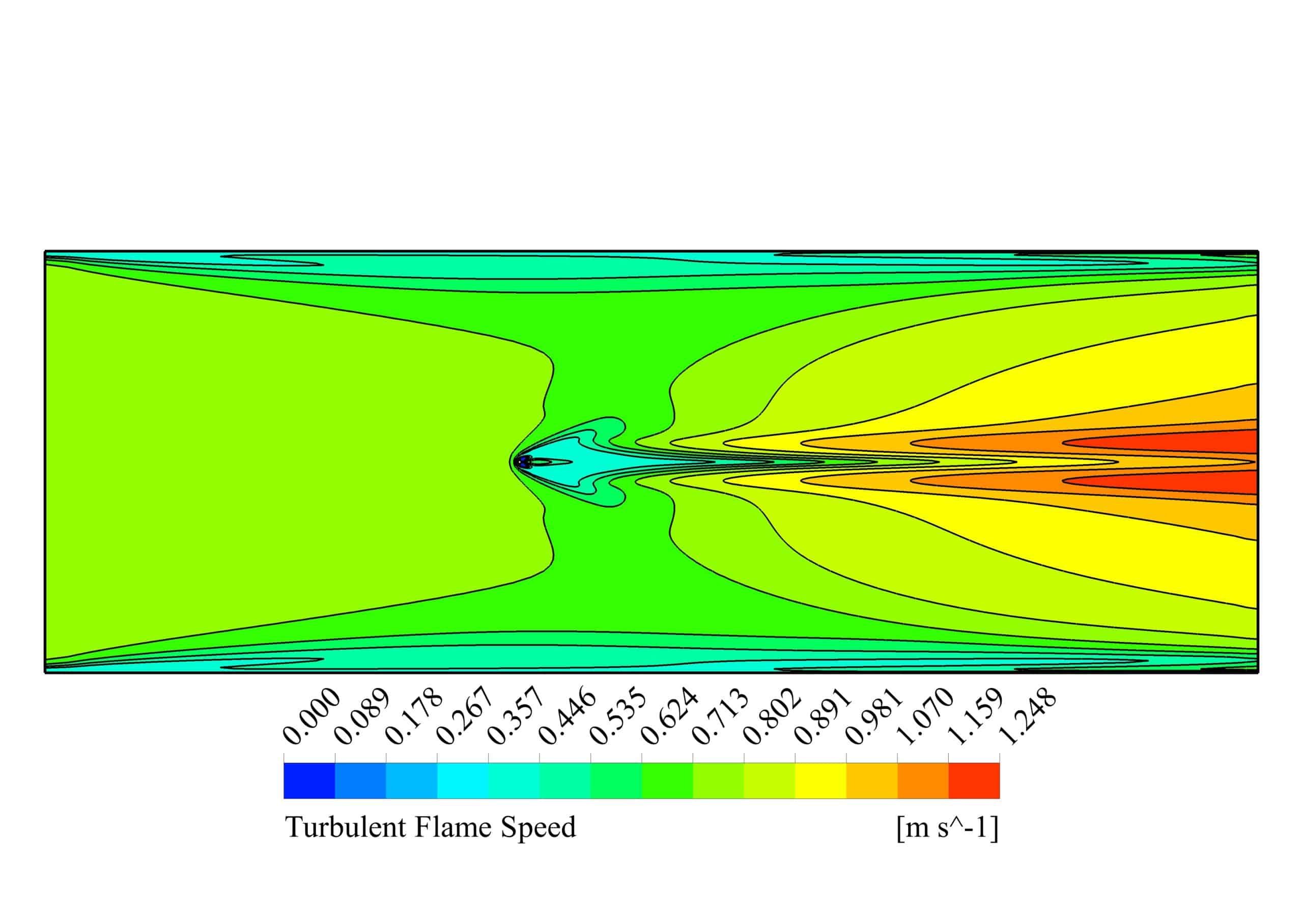

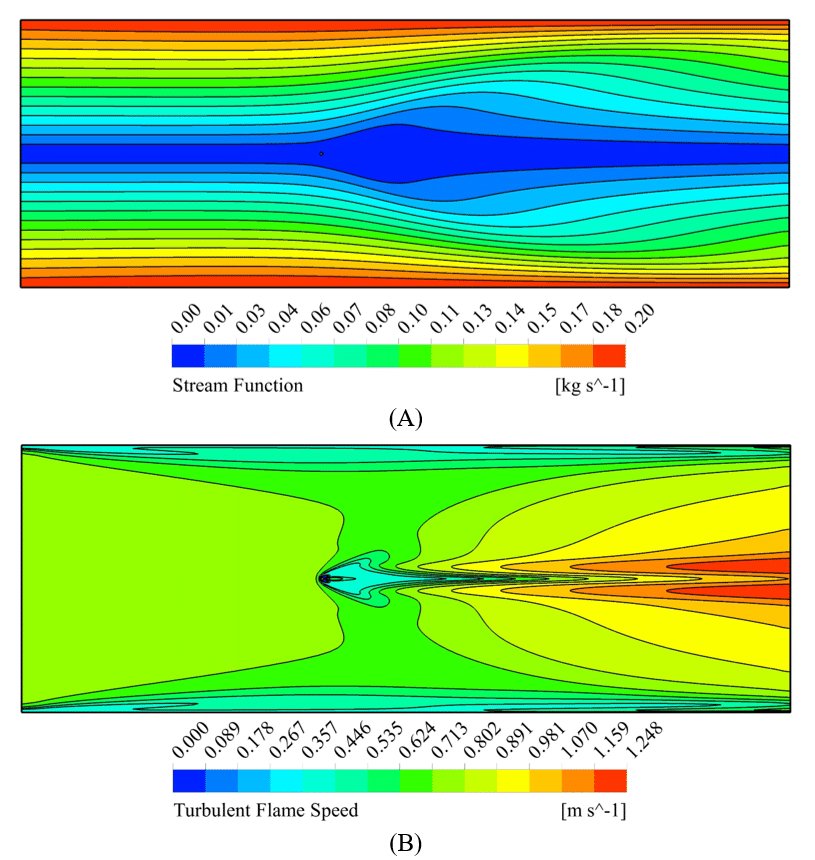

The stream function and turbulent flame speed complete the contours presented in this project. The highest value of turbulent flame speed is 1.248 m/s.

Fig. 8: A) Stream function, and B) Turbulent flame speed

Conclusion

The details of the simulation of the V-shaped flame by the Zimont method provide the ability for scientific development from the point of view of energy, flow characteristics, and dimensions of the flame in the premixed combustion process. With its good accuracy and relatively low computational cost, this method helps a lot in the design of industrial combustion chambers. However, understanding the combustion phenomenon and how to correctly simulate it with high accuracy is very important in the design of various systems. In this project, it is tried to provide complete details of the simulation of air-methane premixed in a combustion chamber. To validate the simulation, the obtained result has been compared with an existing scientific study [1]. The results of the flame shape as well as the comparison of the obtained density with the data of the paper show the good accuracy of the present simulation. However, the difference in the results also arises from the change in the selected model compared to that research. In the selected paper, the authors used the EBU for flame simulation, while in the present project, the Zimont method was used for flame modeling. The Zimont method has good accuracy in simulations, and more importantly, it can be simulated with the help of Ansys Fluent 2024. While the EBU method existed in older versions of the software, it is not available in the 2024 version of this software.

Reference

[1] El, Khazen MI, Hmaied Benticha, and Francois-Xavier Demoulin. “Numerical simulation of a premixed turbulent V-shaped flame.” Thermal Science 15, no. 2 (2011): 311-320.

Reviews

There are no reviews yet.