Pump: ANSYS Fluent Training Package, 7 Advanced CFD Simulations

$449.00 $224.50 Student Discount

- Master advanced pump CFD simulations through specialized configurations

- Learn complex gear-based and positive displacement pump analyses

- Explore cavitation phenomena in various pump designs

- Develop expertise in dynamic mesh and moving boundary techniques

- Perfect your skills in multiphase flow and phase change modeling

- Apply professional-grade simulation approaches to challenging pump scenarios

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Advanced Pump Analysis: Complex Geometries and Dynamic Phenomena

Comprehensive Advanced Pump Simulation Training

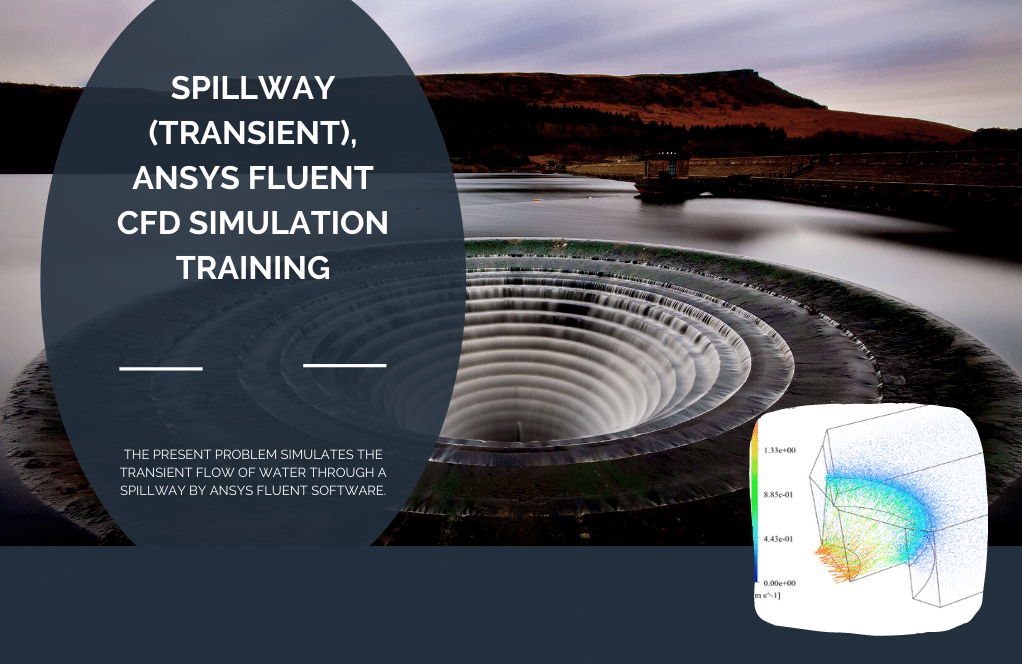

This specialized training package guides experienced users through seven sophisticated pump applications, focusing on complex geometries and challenging flow phenomena. Using ANSYS Fluent, participants master advanced simulation techniques essential for modern pump design and analysis.

Technical Depth and Innovation

The course progresses from fundamental gear pump configurations to intricate cavitation studies, emphasizing practical implementation of advanced CFD techniques. Each module builds upon established knowledge while introducing sophisticated concepts in fluid dynamics.

Advanced Applications and Analysis

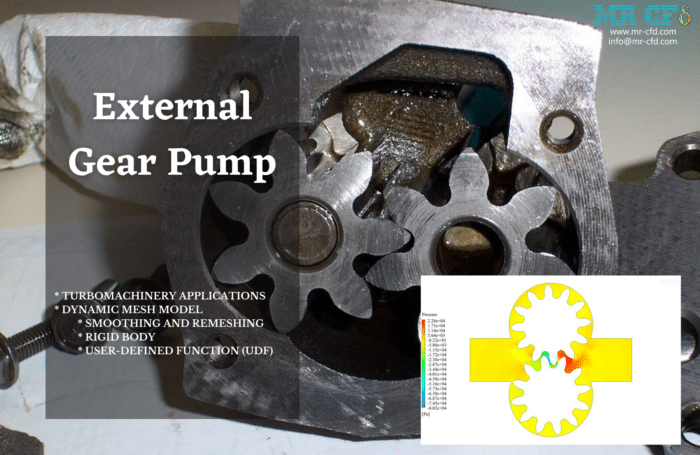

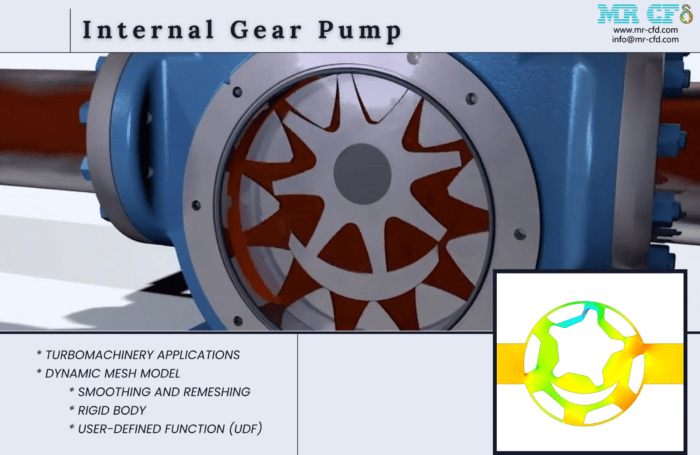

Gear-Based Pump Systems

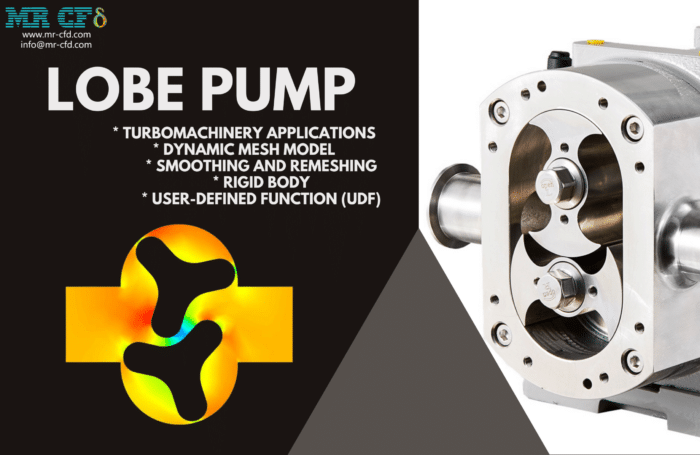

Beginning with external and internal gear pump simulations, the course establishes advanced principles of moving mesh techniques and complex geometry handling. This foundation extends into specialized applications like gerotor and lobe pump analyses, demonstrating various approaches to simulating intricate rotating geometries.

Positive Displacement Technologies

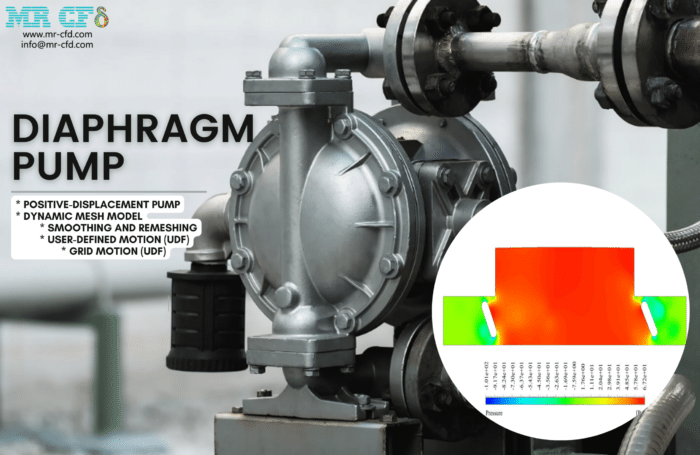

The course advances into specialized positive displacement applications, exploring diaphragm pump dynamics and complex flow patterns. These modules demonstrate advanced simulation strategies for non-continuous flow systems and moving boundaries.

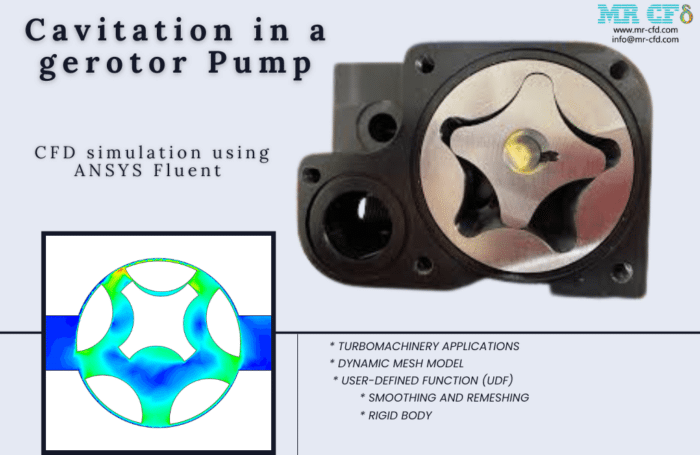

Cavitation Analysis

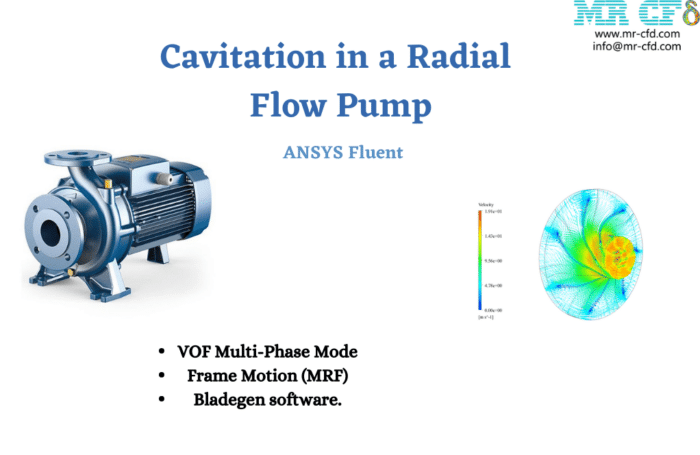

The final segments focus on critical cavitation phenomena, particularly in radial flow and gerotor pumps. These modules integrate multiphase flow modeling with complex geometry handling, providing comprehensive understanding of phase change dynamics in rotating machinery.

Professional Implementation

The course structure ensures deep understanding of advanced pump phenomena while maintaining focus on practical applications. From complex gear systems to cavitation studies, each module contributes to mastery of sophisticated simulation techniques. This approach equips engineers with advanced skills for:

Multi-Physics Integration

Understanding the intricate relationships between moving geometries, phase change phenomena, and system performance, particularly in specialized pump applications.

Advanced System Design

Applying complex simulation techniques to enhance pump performance and reliability, meeting modern requirements for innovative engineering solutions.

This comprehensive coverage bridges theoretical understanding and practical implementation, preparing engineers for advanced challenges in pump design and analysis. The course synthesizes sophisticated modeling approaches with practical applications, enabling engineers to tackle complex pump-related challenges in various industrial contexts.

Reviews

There are no reviews yet.