Quadcopter CFD Simulation, Acoustic Analysis, Industrial Application

$160.00 $80.00 Student Discount

- In this study, a comprehensive acoustic simulation of a quadcopter was performed using ANSYS Fluent

- Studying Acoustic, Pressure, and Motion analysis.

- We designed the 3-D symmetry model using the SpaceClaim

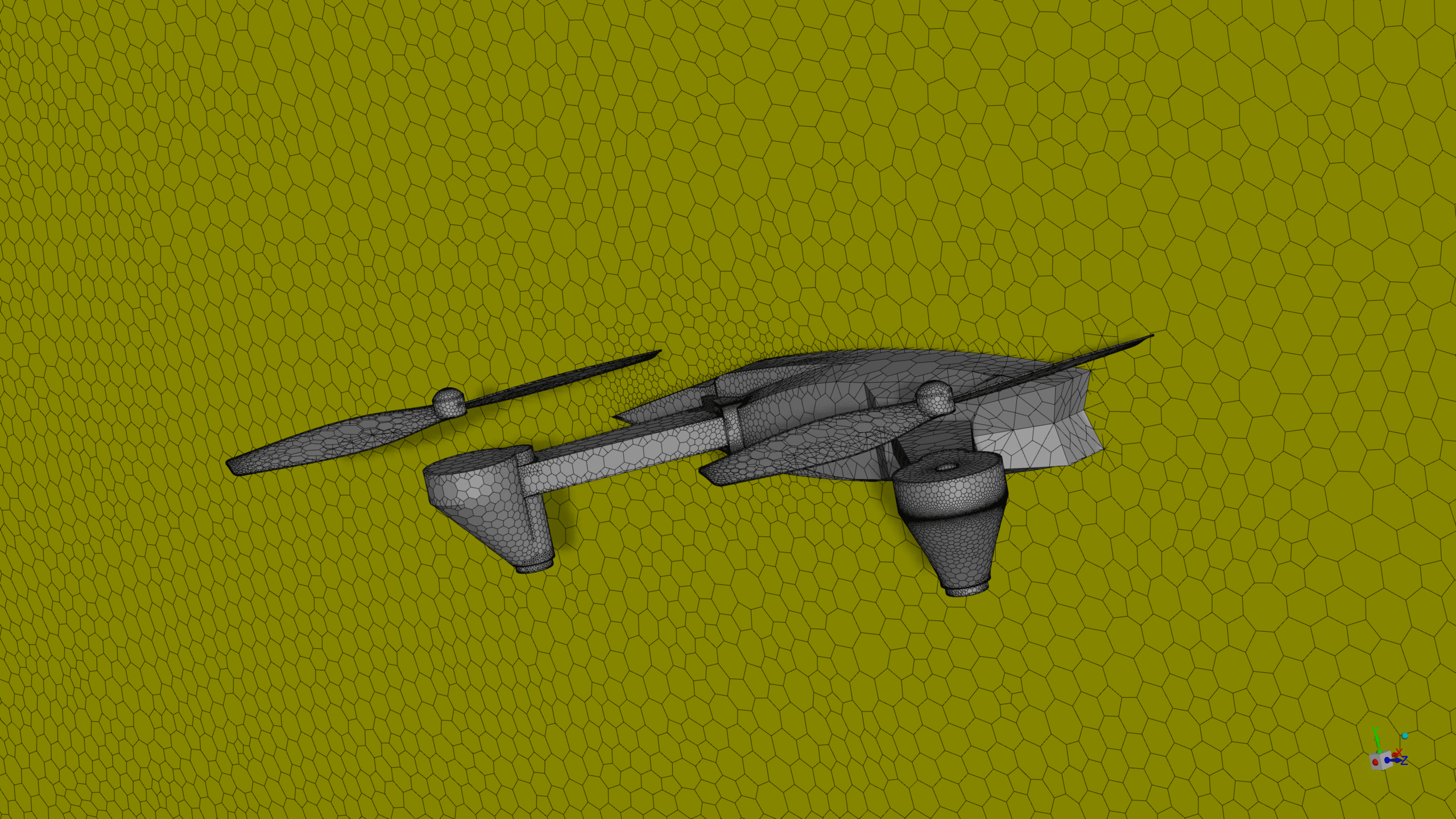

- We mesh the model with ANSYS Meshing software, and the element number equals 1,710,236.

- We perform this simulation as unsteady (Transient).

- We use the Mesh Motion to define the rotational motion of the Quadcopter blades.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

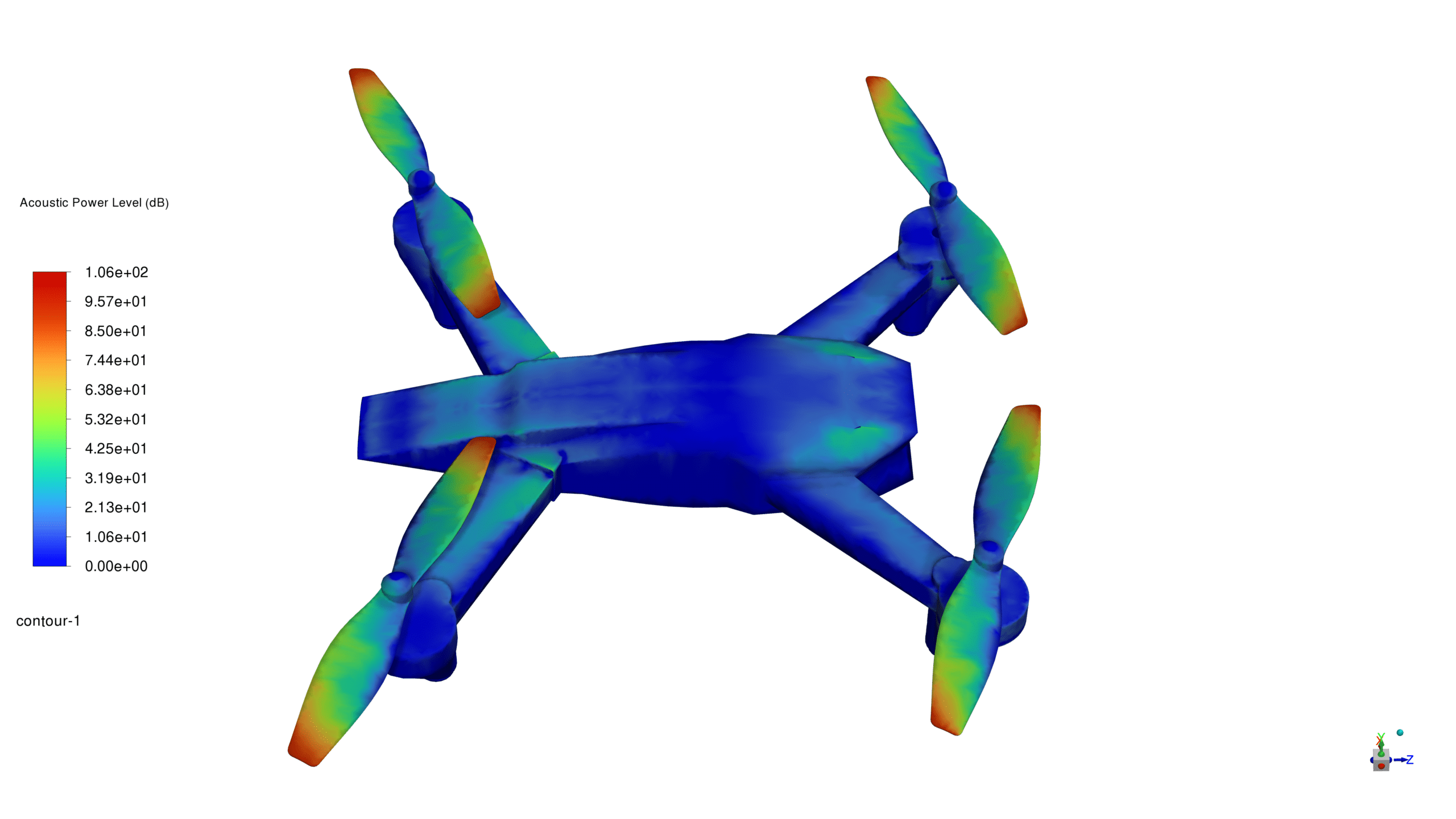

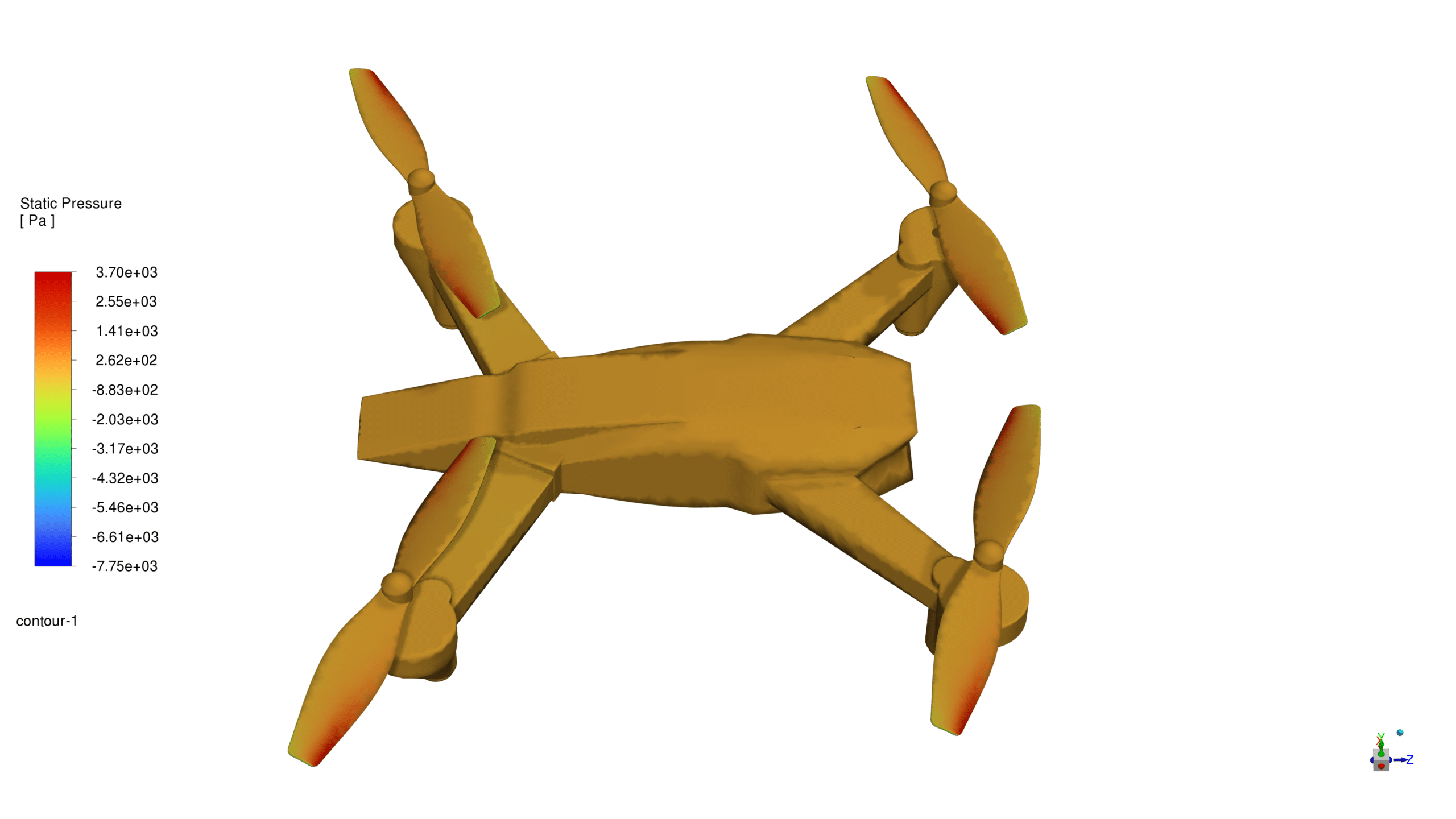

In this study, a comprehensive acoustic simulation of a quadcopter was performed using ANSYS Fluent, a powerful computational fluid dynamics (CFD) software. The primary objective was to investigate the noise generated by the quadcopter during operation and to gain insights into its acoustic characteristics.

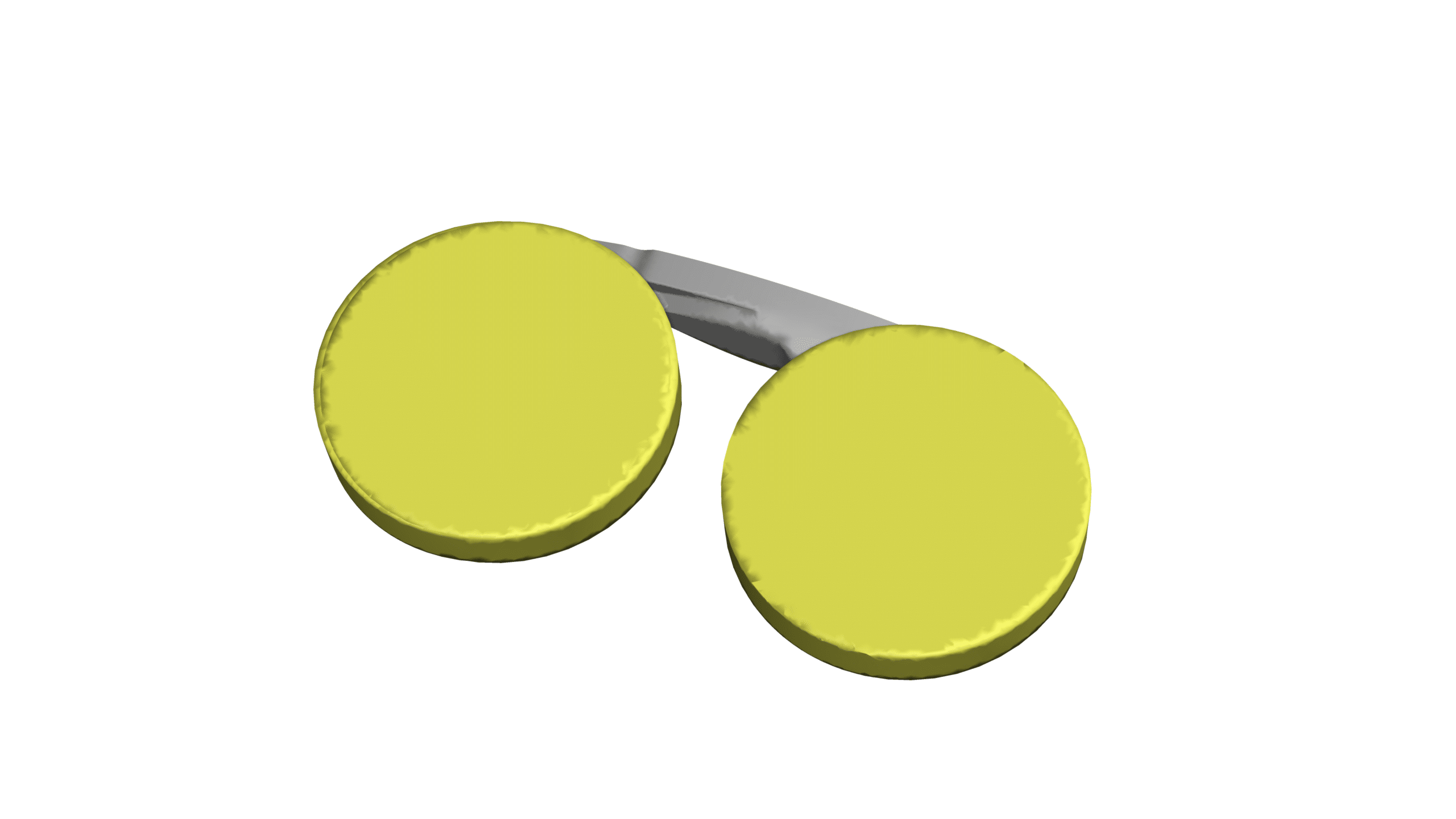

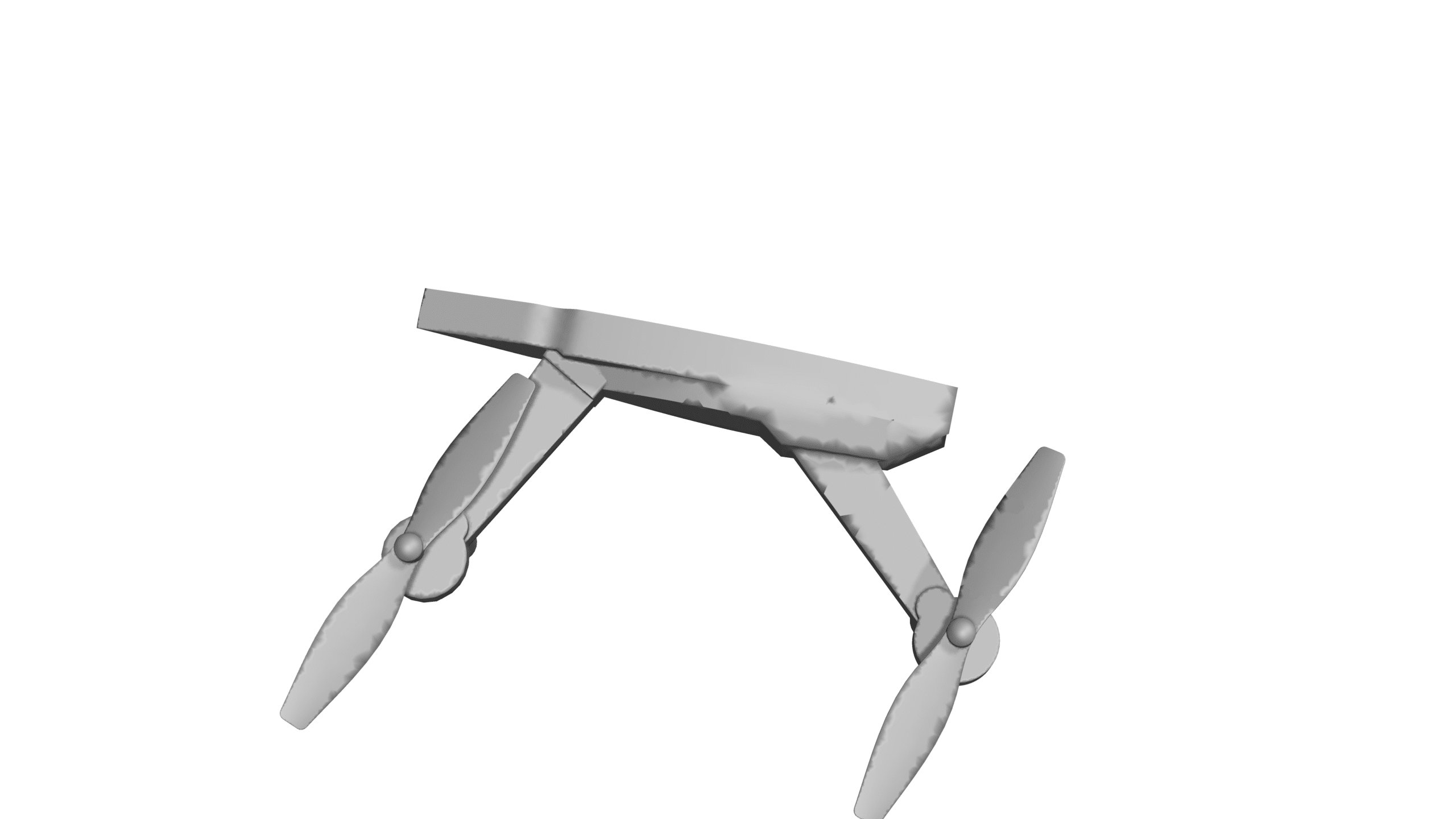

The quadcopter geometry was designed using SpaceClaim, a 3D modeling software integrated with ANSYS. Leveraging the symmetry of the quadcopter, a 3D symmetric model was created, which significantly reduced the computational cost while maintaining the accuracy of the simulation. The designed geometry captured the essential features of the quadcopter, including the main body, rotors, and other relevant components.

Once the geometry was finalized, it was imported into ANSYS Meshing for discretization. The meshing process involved dividing the computational domain into smaller elements, creating a mesh that accurately represented the quadcopter’s geometry. Care was taken to ensure that the mesh quality was high, with appropriate refinement in regions of interest, such as near the rotors and the quadcopter body.

The acoustic simulation of the quadcopter using ANSYS Fluent demonstrated the effectiveness of CFD in studying the noise characteristics of complex systems. The 3D symmetric model and the high-quality mesh ensured accurate and efficient simulations. The results obtained from this study can be used to optimize the quadcopter design, minimize noise emissions, and enhance the overall acoustic performance of the system.

you can Also visit Quadcopter FSI and Dynamic Stability Derivatives Analyses.

Methodology

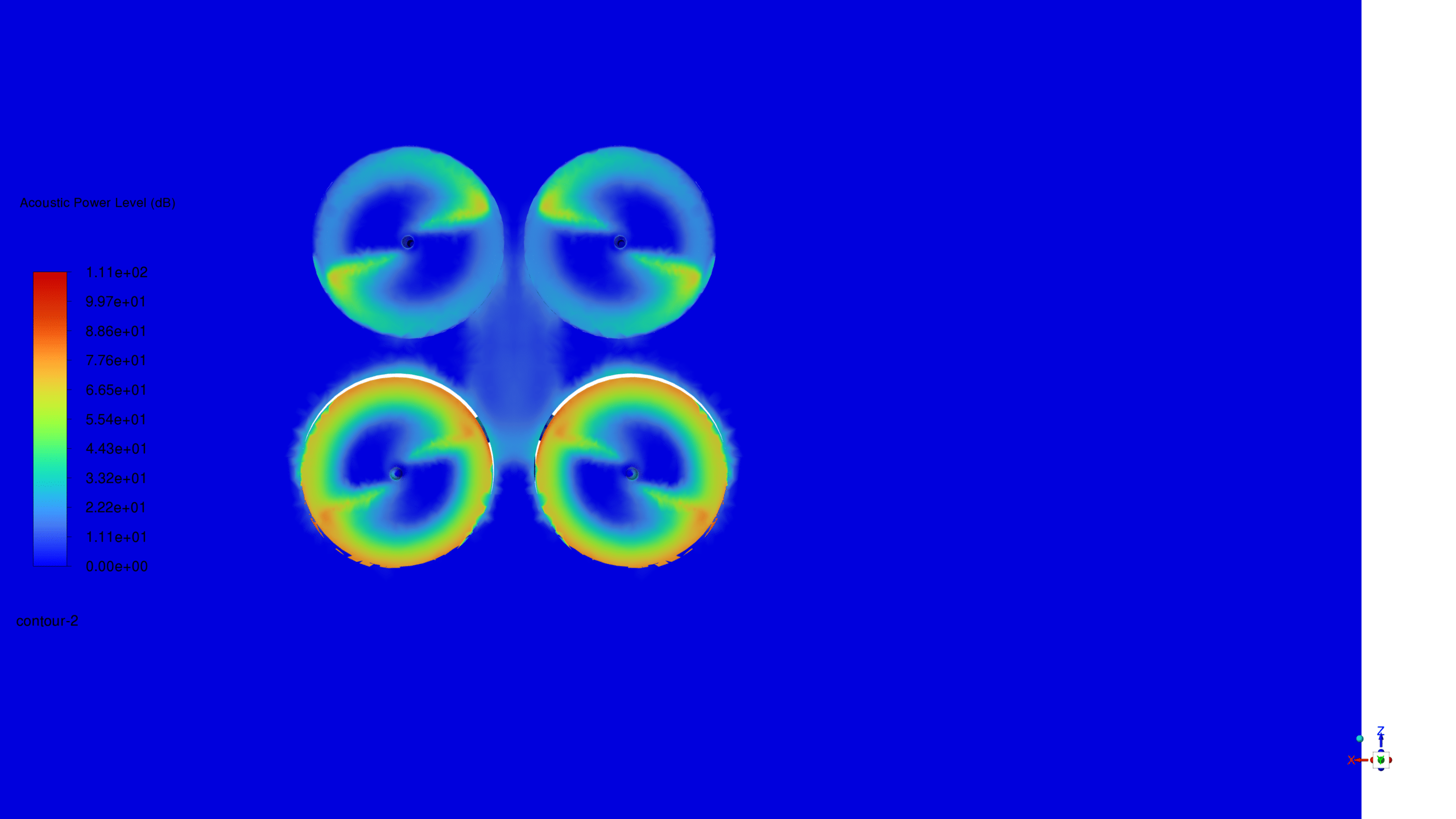

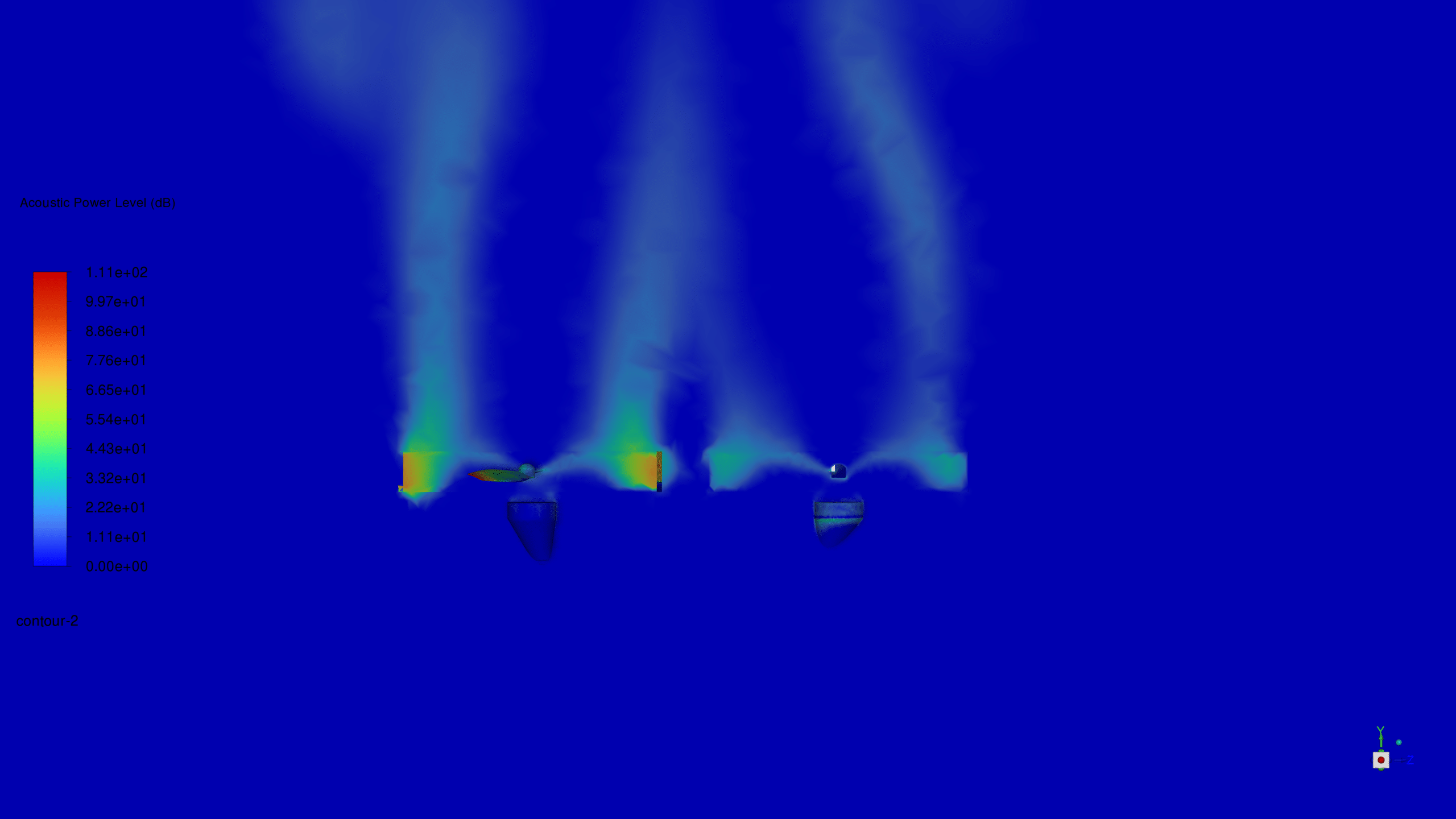

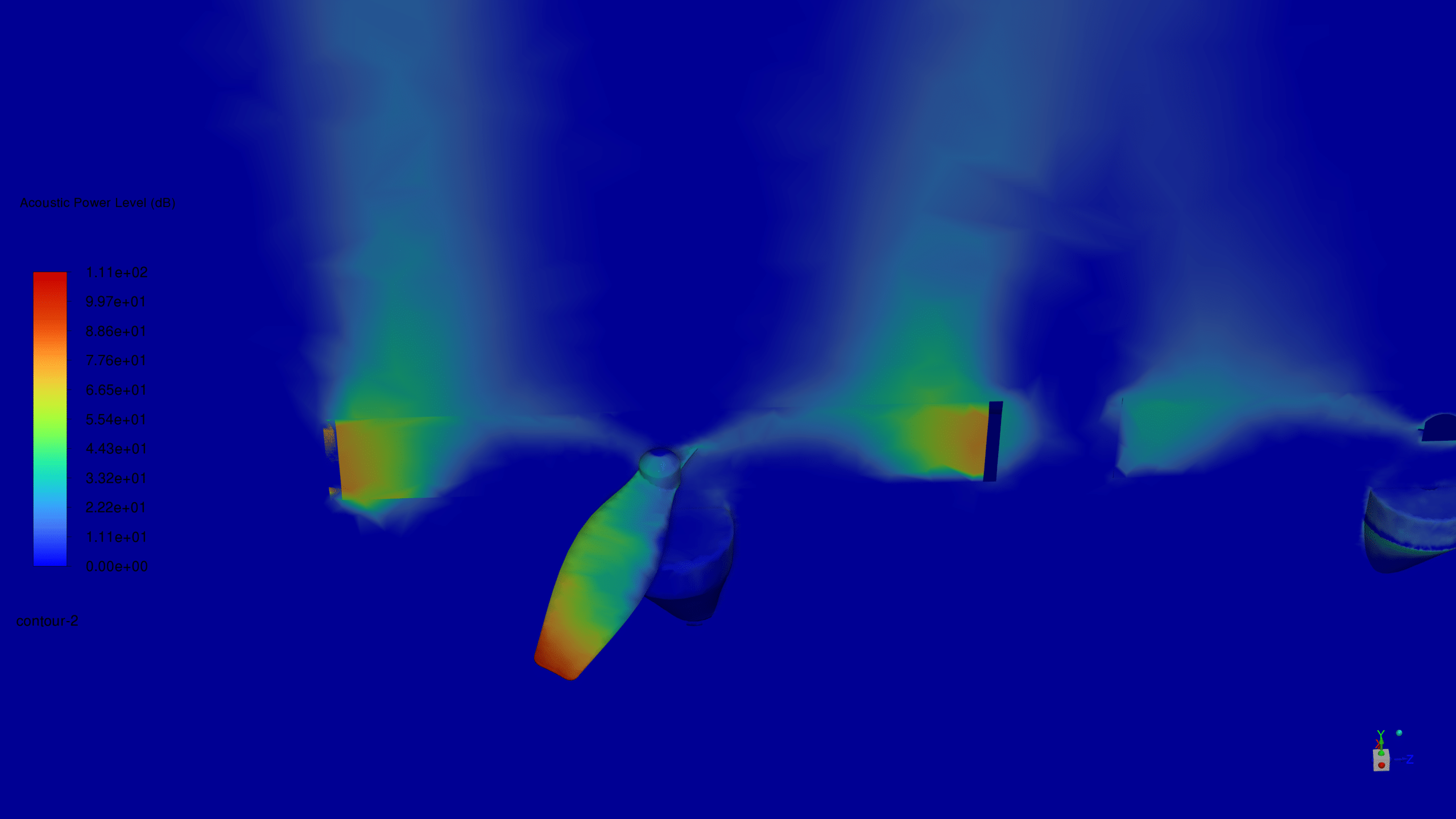

we employ ANSYS Fluent software and leverage the applications of Computational Fluid Dynamics (CFD) to absorb the sound level around the domain and generate sound by the propeller. In this simulation, To capture the rotational motion of the quadcopter blades with an angular velocity of 1200 RPM, we employed two mesh motion zones. These zones allowed for accurate simulation of the blade dynamics and airflow characteristics around the quadcopter.

Results

Acoustic performance is essential in quadrotors, as it can impact the system’s safety and efficiency. Excessive noise can be a safety hazard, as it can interfere with communication between the pilot and ground crew and disturb wildlife in the surrounding area.

In addition, noise can indicate inefficiencies in the system, such as unbalanced rotors or aerodynamic issues. By optimizing the acoustic performance of quadrotors, designers can improve their safety, efficiency, and overall performance. This can lead to more reliable and effective use of quadrotors in various applications, from aerial photography to search and rescue operations.

Turbulence can have a significant effect on the sound generation of a propeller. As the airflow around the propeller becomes more turbulent, it can cause pressure and velocity fluctuations, leading to increased noise levels.

This can be especially pronounced in the near-field region of the propeller, where the turbulent flow can interact with the blades and ring structure. Designers of propellers must take turbulence into account when optimizing their acoustic performance.

Adrian Emmerich –

The simulation comparison between the toroidal and standard propellers is remarkable. The reduction of sound levels in the toroidal propeller seems quite significant. Excellent project execution and great potential for practical applications in noise-sensitive areas. Could you possibly detail whether these results have been validated with experimental data?

MR CFD Support –

Thank you for your compliments on our project work. The simulation studies provide valuable insights, and we agree that the acoustic reduction achieved with the toroidal propeller is promising. We ensure that our CFD simulations aim for high accuracy, but due to the nature of this exchange, we don’t have direct access to the specific experimental validation data. However, it is standard practice to validate simulation results with experimental data or analytical solutions when possible. This would be the next step to ensuring our findings are as reliable as possible and can confidently inform future designs and applications.

Rubie O’Reilly –

What a thorough explanation and clear results! Very impressive how much quieter the toroidal propeller is. A reduction to 85 dB from 213 dB is remarkable.

MR CFD Support –

Thank you so much for your positive review! We are thrilled to hear that you found the simulation and its results impressive and easy to understand. It is our goal to provide comprehensive insights into product performance, and we are glad to hear we succeeded. Your feedback is greatly appreciated!

Abby Wintheiser –

Wonderful, thorough analysis and presentation in the Quadcopter CFD Simulation project! It’s great to see how acoustic considerations are integral to the design and the significant noise reduction achieved with the toroidal propeller.

MR CFD Support –

Thank you for your kind feedback! We’re thrilled to know that the project met your expectations and provided insightful analysis. The acoustic performance of drones is indeed critical, and we’re glad our simulation could highlight the benefits of using a toroidal propeller. Should you have any more questions or need further assistance, feel free to reach out!

Dr. Kale Von –

The customization, innovation, and rich detailed analysis provided in comparing the toroidal and simple propellers for acoustic performance in quadcopters really catered to our project’s needs. The reduction of noise levels from 213 dB to 85 dB by switching to the toroidal propeller has significant environmental and commercial implications. Excellent presentation of technical information and practical application!

MR CFD Support –

Thank you for your positive feedback and appreciation of the technical depth and real-world applications provided in the comparison of the toroidal and simple propellers’ acoustic performance. It’s wonderful to hear that the information presented has been valuable to your project. Your recognition of the significant reduction in noise levels illustrates the potential impact our simulation results could have in various sectors. Thanks again for taking the time to review our work!

Dennis Ratke –

The improvements in the sound level from using a toroidal propeller are extraordinary! I’m very impressed by how this design significantly reduces noise pollution while enhancing comfort, as evident in the CFD simulation results. Kudos to the MR CFD team for insightful and high-quality simulations that contribute positively to drone acoustic analysis and design.

MR CFD Support –

Thank you for your kind words! We are always thrilled to receive positive feedback on our products. Your recognition of the effort we put into our CFD simulations motivates us to continue providing high-quality and insightful simulation work. We’re glad to hear about your satisfaction with the acoustic analysis and the remarkable noise level reduction achieved with the toroidal propeller simulation. Feel free to reach out for more information or support with any of our simulation products!

Prof. Blaze Ryan –

The simulation results mentioned a significant noise reduction using a toroidal propeller. Was this reduction achieved through design modification of the propeller or by inherent qualities of the toroidal shape?

MR CFD Support –

The noise reduction achieved with the toroidal propeller is primarily due to the inherent qualities of its shape. The ring-shaped structure of the toroidal propeller helps absorb and dissipate sound waves, which contributes significantly to lower noise levels. However, specific design modifications and optimizations during the CFD simulation process may have enhanced these inherent acoustic benefits.