Radiator Heat Transfer Simulation by Hot Nanofluid Flow, ANSYS Fluent

$100.00 $50.00 Student Discount

The present problem simulates heat transfer inside a radiator with nanofluid flow using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Project Description

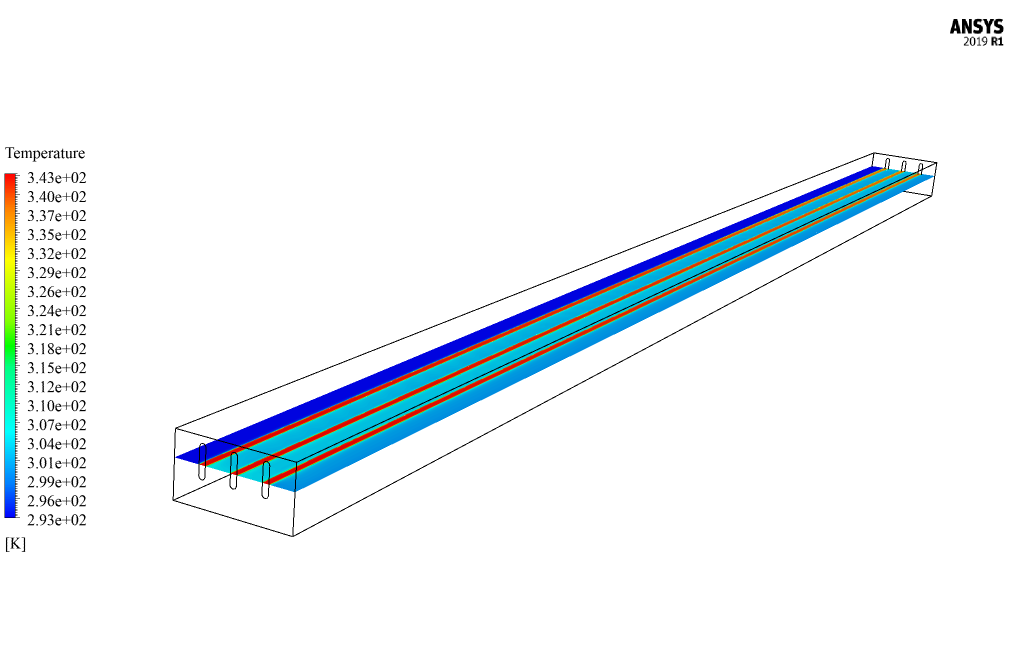

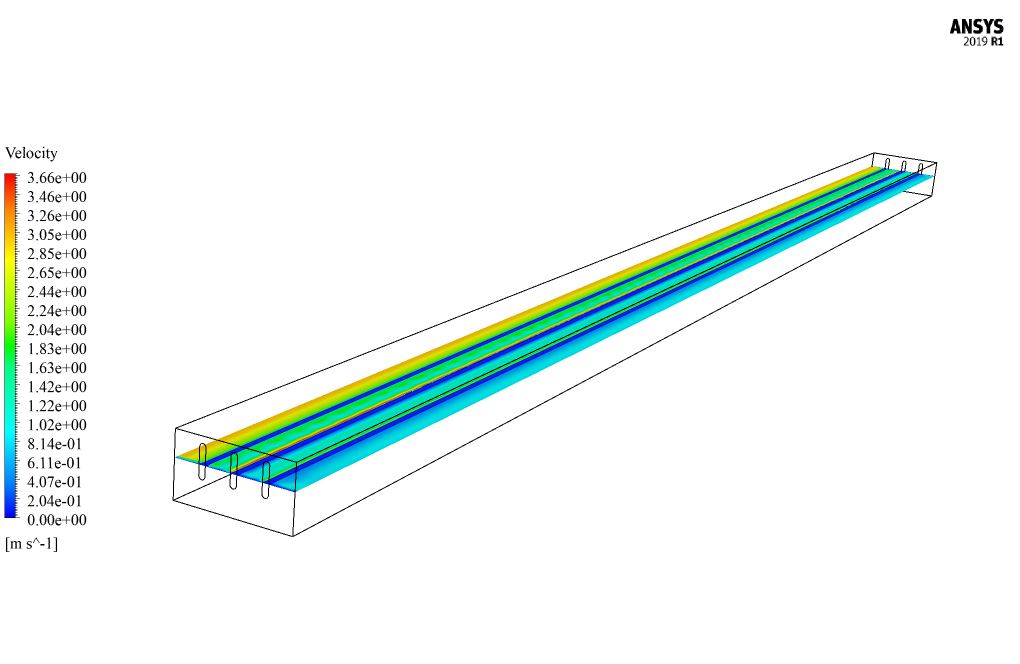

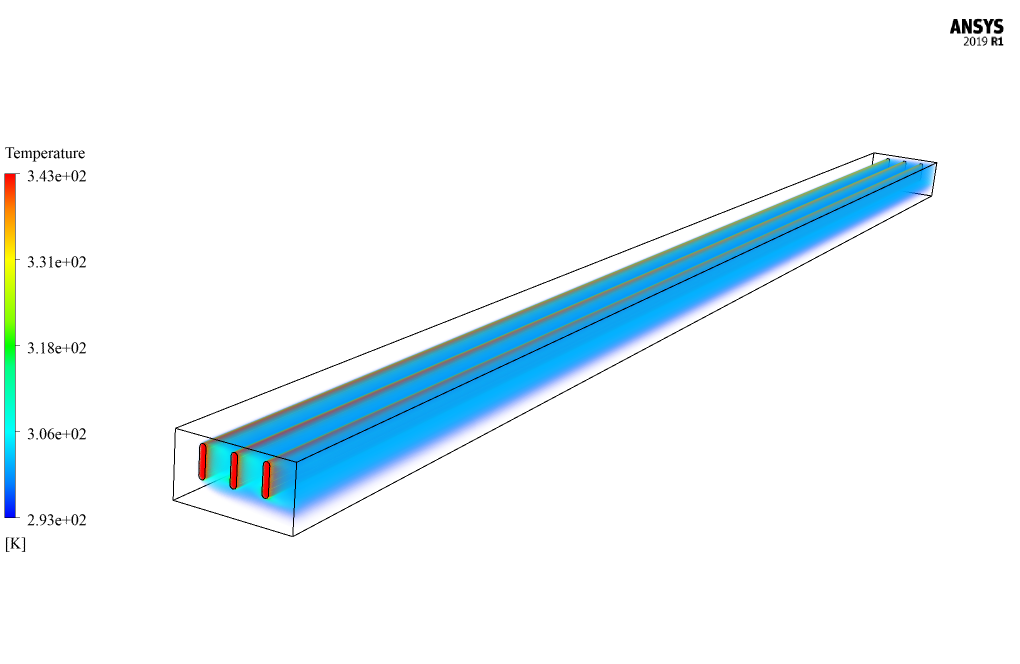

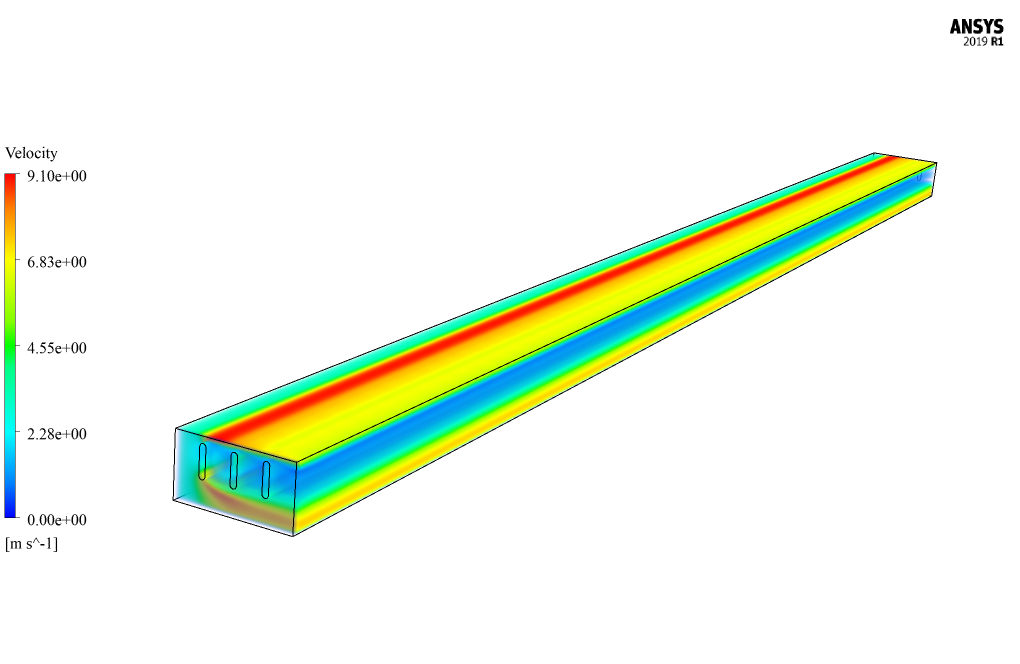

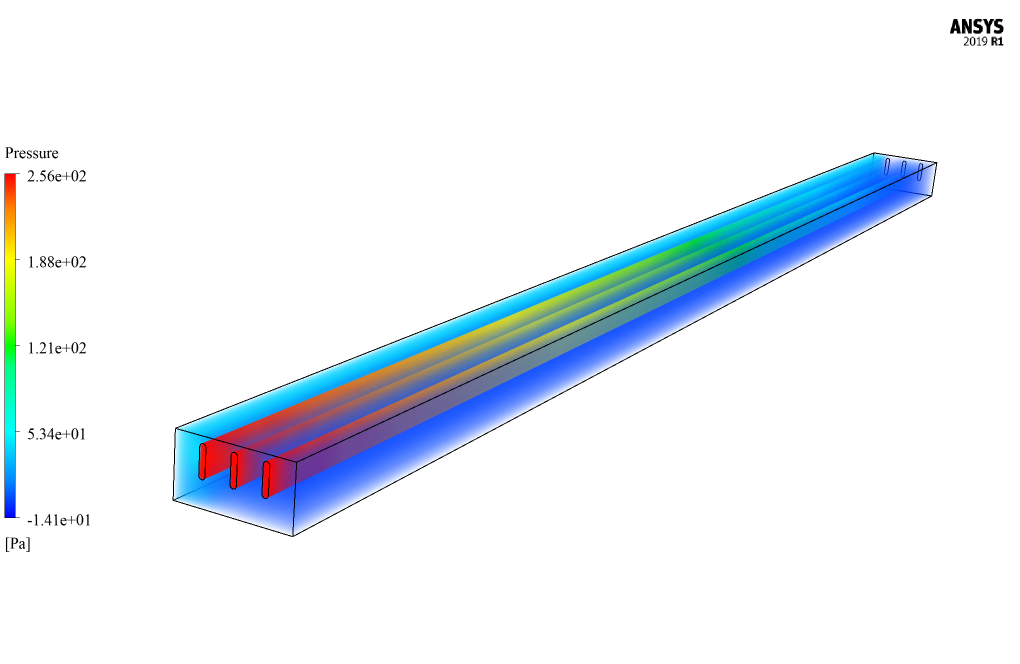

The present problem simulates heat transfer inside a radiator with nanofluid flow using ANSYS Fluent software. The working mechanism of these radiators is such that the flow of hot fluid passes through the pipes inside the radiator and on the other hand, the air flow also passes through the pipes. In this way, the air flow passes through the pipes carrying the hot flow, receiving their heat, and as a result, the resulting hot air flow is transferred to the outside environment. In this simulation, hot nanofluid flows at a velocity of 0.1 ms-1 and a temperature of 343.15 K flows through three pipes inside the radiator, and cold air flows at a velocity of 3 ms-1 and a temperature of 293.15 K passes over this pipe.

To define the hot fluid inside the pipes inside the radiator, a kind of nanofluid has been used. The nanofluid used in this model is Al2_O3-Water which has a density equal to 1086.287 kg.m-3 and a specific heat capacity equal to 3804.691 j.kg-1.K-1 and a thermal conductivity equal to 0.6672643 Wm-1.K- 1 and the viscosity is equal to 0.00108236 kg.m-1.s-1. The purpose of this work is to investigate the quality of heat transfer inside the radiator in the presence of hot nanofluid.

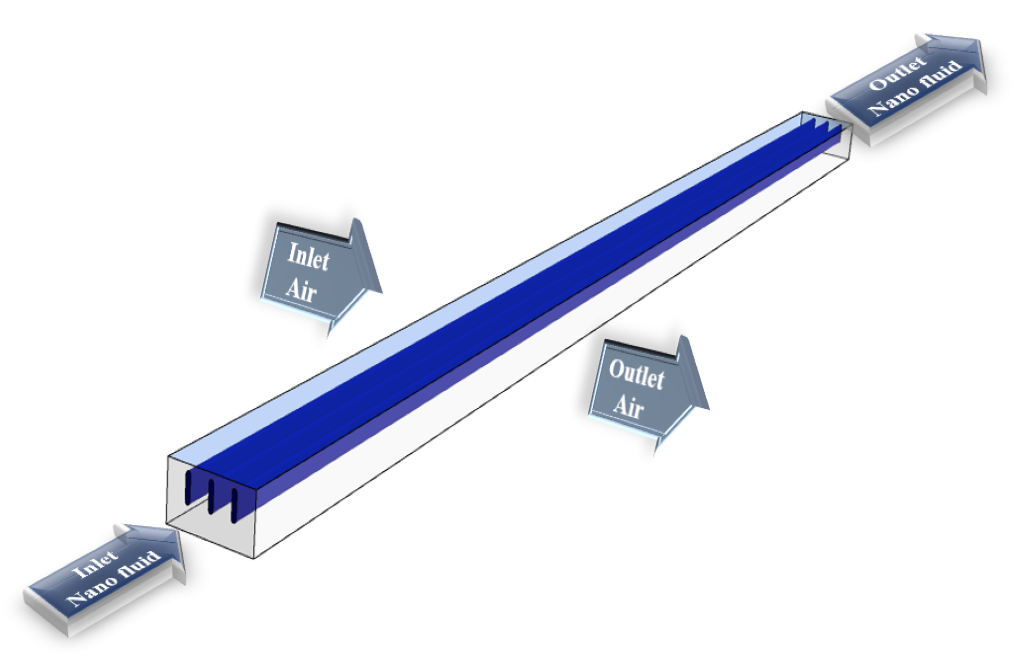

Radiator Geometry & Mesh

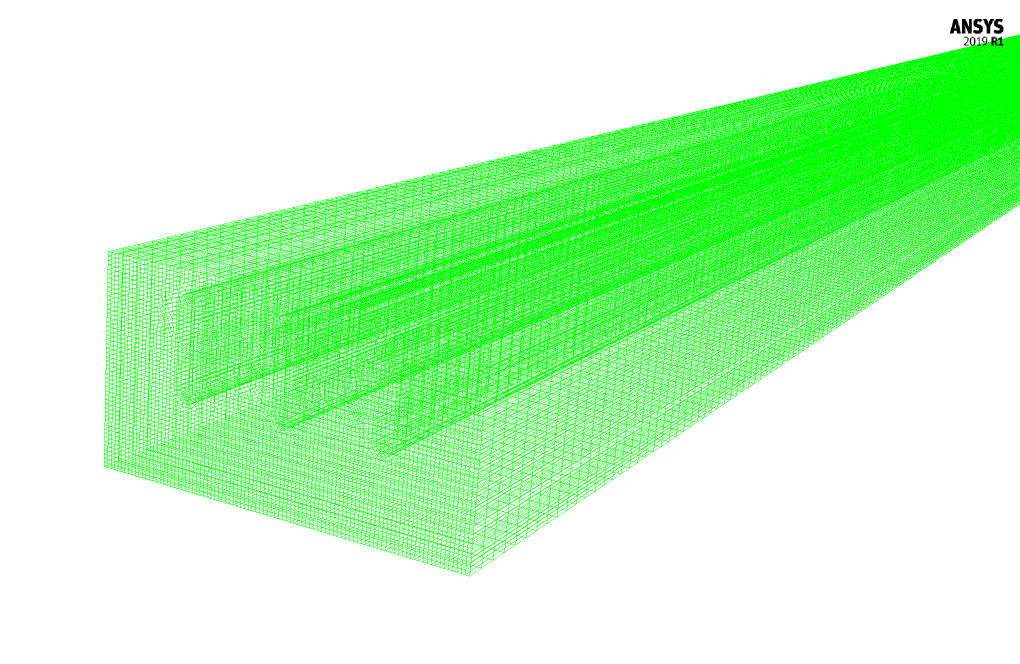

The present model is designed in three dimensions using Spaceclaim software. The model includes a symmetrical radiator, which is semi-drawn due to its symmetrical geometric structure and in order to avoid heavy calculations. This radiator has air inlet and outlet sections on both sides. Also inside this radiator, three pipes have been designed for the passage of nanofluid flow.

The meshing of the model has been done using ANSYS Meshing software and the mesh type is unstructured. The element number is 1,033,305. The following figure shows the mesh.

Radiator CFD Simulation

To simulate the present model, several assumptions are considered:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

| Models (radiator) |

||

| Viscous | k-epsilon | |

| k-epsilon model | standard | |

| near wall treatment | standard wall functions | |

| Energy | On | |

| Boundary conditions (radiator) |

||

| Inlet – Air | Velocity Inlet | |

| velocity magnitude | 3 m.s-1 | |

| temperature | 293.15 K | |

| Inlet – Nanofluid | Velocity Inlet | |

| velocity magnitude | 0.1 m.s-1 | |

| (heat transfer) | temperature | 343.15 K |

| Outlet – Air | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Outlet – Nanofluid | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Internal Walls | Wall | |

| wall motion | stationary wall | |

| thermal condition | coupled | |

| Bottom Wall | Wall | |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| Methods (heat transfer) |

||

| Pressure-Velocity Coupling | Coupled | |

| Pressure | second order | |

| momentum | second order upwind | |

| energy | second order upwind | |

| turbulent kinetic energy | second order upwind | |

| turbulent dissipation rate | second order upwind | |

| Initialization (heat transfer) |

||

| Initialization methods | Standard | |

| gauge pressure | 0 pascal | |

| x-velocity | 3 m.s-1 | |

| y-velocity , z-velocity | 0 m.s-1 | |

| temperature | 293.15 K | |

Results

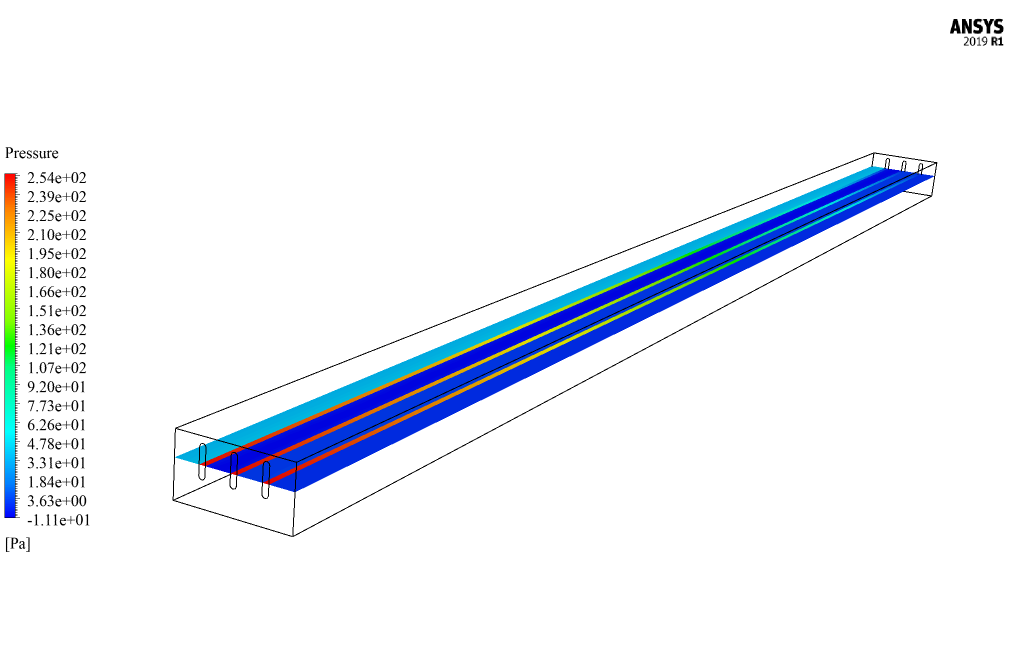

At the end of the solving process, two-dimensional and three-dimensional contours related to pressure, velocity, and temperature are obtained.

Miss Dessie Brakus II –

This simulation of a radiator with hot nanofluid flow was fascinating, especially how it mimicked the heat exchange process with remarkable detail. Fantastic work distinguishing each phase with clear boundary conditions and meshing strategy procedures!

MR CFD Support –

Thank you for your kind words! We’re thrilled to know you appreciate the effort put into replicating the heat exchange process and the detailed approach to defining boundary conditions and meshing strategies for the radiator heat transfer simulation. If you need any further information or assistance, feel free to reach out. Thanks for choosing MR CFD Company’s learning products!

Gardner Windler –

I’m curious about why you selected a velocity of 0.1 m/s for the nanofluid in the pipes and 3 m/s for the air flow. Was this difference in velocities based on specific design criteria or standards?

MR CFD Support –

The velocity selection of 0.1 m/s for the nanofluid and 3 m/s for the air flow is based on common thermal management requirements in radiator designs. The lower velocity of the nanofluid helps to maintain effective heat transfer, as the increase in exposure time enhances energy transfer. Conversely, the higher velocity for air flow optimizes the convective heat transfer benefits, facilitating rapid heat dispersion into the environment.

Simone Jacobs –

Does this simulation take into account any changes in properties of the nanofluid with temperature change?

MR CFD Support –

In the given description, there is no explicit mention of temperature-dependent properties for the nanofluid. Typically, for accurate results, a simulation might consider variable properties that change with temperature. However, for this simulation, it might have used fixed properties based on average values. If the simulation did account for variable properties, this usually would be highlighted as part of the simulation setup due to its impact on the accuracy of the model.

Abigale Koepp –

What is the reason for using Al2O3-Water nanofluid specifically in this radiator simulation, and how does it affect heat transfer efficiency compared to using just water?

MR CFD Support –

Aluminum oxide (Al2O3)-Water nanofluid is chosen for the simulation because of its superior thermophysical properties compared to pure water. This includes higher thermal conductivity, which enhances the heat transfer rate. As a result, it can transfer heat more efficiently, improving the performance of the radiator.

Alexane Steuber –

The simulation outcome is truly intriguing. The use of nanofluid for cooling offers a modern take on heat transfer processes. I’m curious to know if the incorporation of Al2O3 nanoparticles significantly enhanced the thermal conductivity compared to the base fluid without the nanoparticles.

MR CFD Support –

Thank you for your compliment on the simulation outcome. Indeed, the incorporation of Al2O3 nanoparticles into the base fluid enhances the thermal conductivity of the nanofluid, which improves heat transfer efficiency in the cooling process within the radiator. This enhancement occurs due to the higher thermal conductivity of Al2O3 particles compared to the base fluid, allowing for a more effective transfer of heat.

Winnifred Gorczany –

Are the nanofluid properties standard or were they adjusted for simulation accuracy?

MR CFD Support –

In this simulation, the properties of the Al2O3-Water nanofluid were specifically adjusted to reflect its realistic behavior under operating conditions including its density, specific heat capacity, thermal conductivity, and viscosity.

Dayna Block IV –

I want to know how the thermal conductivity and viscosity values are set for the nanofluid. Are they constant, or are they temperature-dependent in the simulation model?

MR CFD Support –

In the simulation model, the thermal conductivity and viscosity values for the Al2O3-Water nanofluid are typically input as constant properties. However, in more advanced simulations, temperature-dependent properties can be input or defined through user-defined functions based on experimental data or theoretical models for the nanofluid’s behavior. Whether these properties are constant or temperature-dependent in this specific case would depend on the details of the simulation setup and data provided for the properties of the nanofluid.

Florine Ferry –

The detailed description of the simulation setup and results is very informative. The choice of Al2O3-Water nanofluid and your methodology seems meticulous. Do you have any resources that can help beginners understand the basics of nanofluid properties and their impact on heat transfer?

MR CFD Support –

Thank you for your interest in the radiator simulation with hot nanofluid flow. We have several educational materials that provide an introduction to nanofluids, their unique thermal properties, and their application in enhancing heat transfer in various systems. I would be happy to point you to some tutorials and articles that can give you a solid foundation in nanofluid dynamics.

Quinton Flatley –

I wasn’t able to find any pictures of the mesh or the contours in the description. Can you provide visual results pertaining to the mesh quality and the temperature, pressure, and velocity contours obtained from the simulation?

MR CFD Support –

As your message suggests, the description does not include specific visual results or images; unfortunately, I cannot provide any as they are not within my capabilities. For visual outcomes such as mesh quality and contour plots, I encourage you to contact MR CFD Company directly through their customer support or visit their website where they might have these resources available for clients.

Julian Blick –

The simulation process detailed in the description is quite comprehensive. However, can you clarify what specific advantages nanofluid brings to the heat transfer process in this radiator design?

MR CFD Support –

Nanofluids have nanoparticles that enhance the thermal properties of a base fluid. In the context of this radiator design, using an Al2O3-Water nanofluid with improved thermal conductivity, it allows for higher heat transfer rates, making the exchange between the hot nanofluid and the air more efficient compared to using the base fluid alone. This results in better cooling performance for the radiator.

Flo Hyatt –

The level of detail in the simulation results shows a thorough analysis. Does the inclusion of nanofluids significantly improve heat transfer efficiency in the radiator compared to conventional fluids?

MR CFD Support –

Thank you for your review! The use of nanofluids like Al2O3-Water increases the thermal conductivity compared to conventional fluids, resulting in enhanced heat transfer efficiency. This improvement is due to the unique properties of the nanoparticles dispersed in the fluid.

Rosie Hauck –

Was the radiator model in this simulation based on an actual radiator design, or was it a simplified version to facilitate analysis?

MR CFD Support –

Dear customer, thank you for your curiosity. Indeed, the radiator model in this simulation is a simplified version designed in a way to capture the essential details for the heat transfer analysis. Simplifying the geometry allows for efficient computation while still yielding valuable insights into the performance of the radiator with hot nanofluid flow.