Ram Pump, CFD Simulation Ansys Fluent Training

$100.00 $50.00 Student Discount

In this project, a ram pump has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Ram Pump Project Description

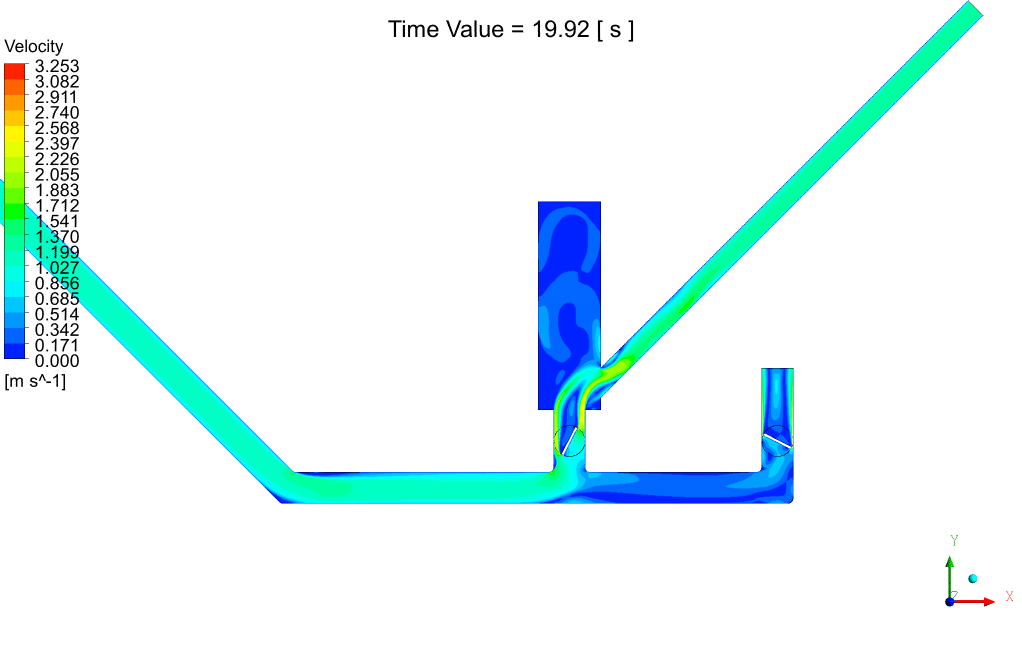

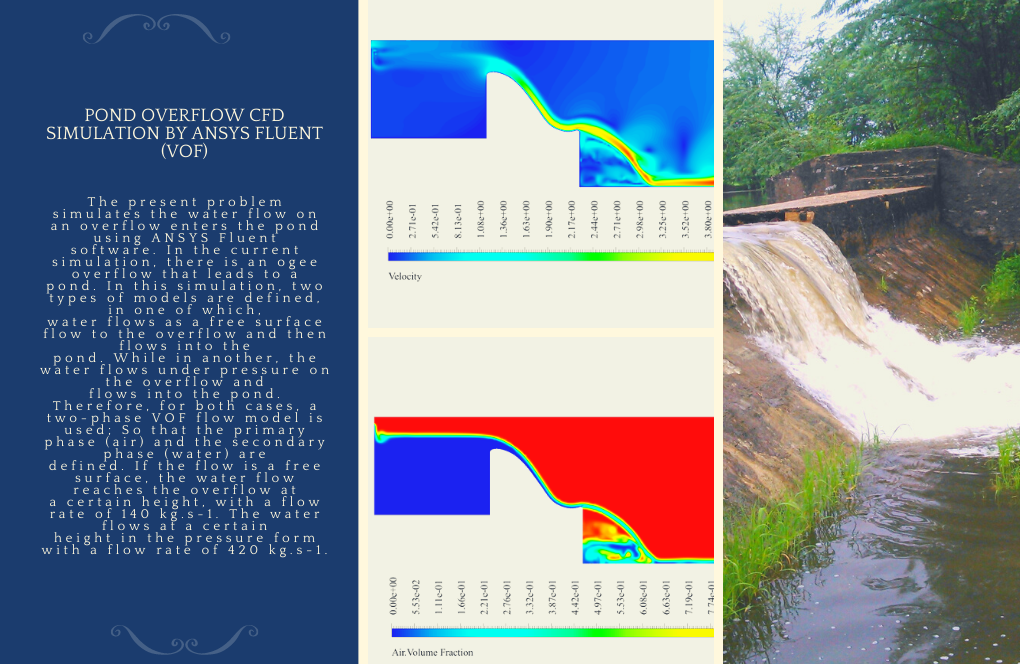

In this project, a ram pump has been simulated by Ansys Fluent software. In this simulation, a mesh motion model with an angular velocity of 1 radian per second has been used, and the input speed has Water is one m/s, and at the outlet, water is discharged at atmospheric pressure.

Geometry & Mesh

The two-dimensional geometry of this project has been produced with Spaceclim software. The length of the calculation domain is 220 cm, and its height is 153 cm.

The meshing of this project has been done with Ansys Meshing software, and the type of elements is unstructured. Also, the total number of elements is 325579.

Ram Pump CFD Simulation

- Due to the incompressibility of the flow, the pressure-based solver method has been selected.

- The simulation is transient.

- The gravity effect is considered equal to -9.81 m.s-1on Y-axis

The following tables represent a summary of the defining steps of the problem in this project and its solution:

| Models | ||

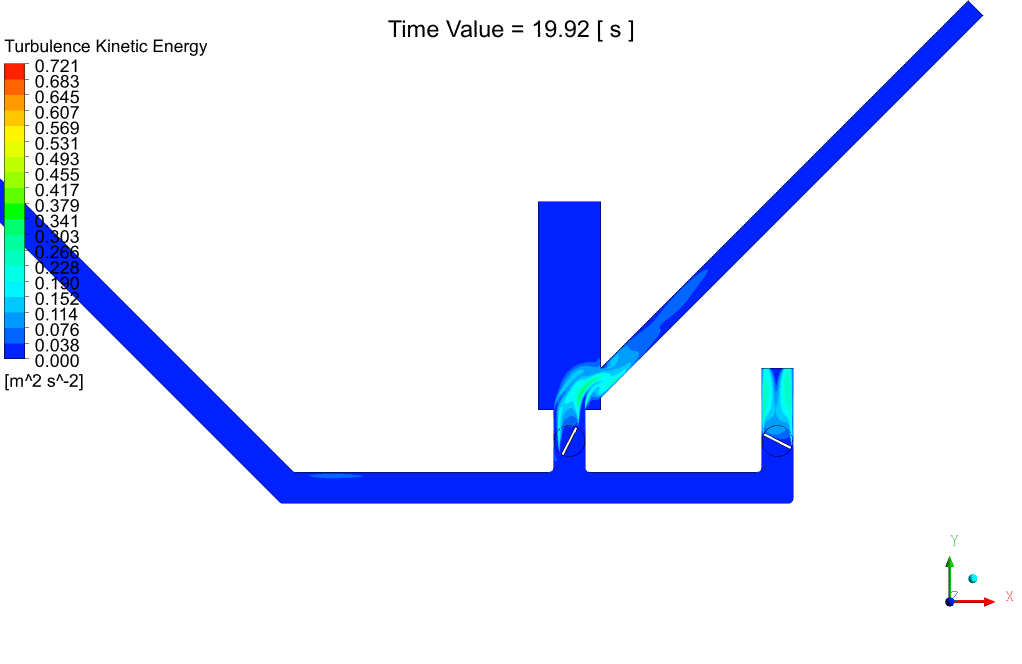

| Viscous model | k-omega | |

| Model | SST | |

| Cell zone condition | ||

| Valve left &right | Mesh motion | |

| Rotational velocity | 1 rad/s | |

| Boundary conditions | ||

| Inlet | velocity inlet | |

| Velocity magnitude | 1m/s | |

| Outlet | Pressure outlet | |

| Gauge pressure | 0 pa | |

| Walls | Stationary wall | |

| Solution Methods | ||

| Pressure-velocity coupling | Coupled | |

| Spatial discretization | Pressure | Second-order |

| Momentum | second-order upwind | |

| Turbulent kinetic energy | first-order upwind | |

| Turbulent dissipation rate | first-order upwind | |

| Initialization | ||

| Initialization method | Hybrid |

Ram Pump Results

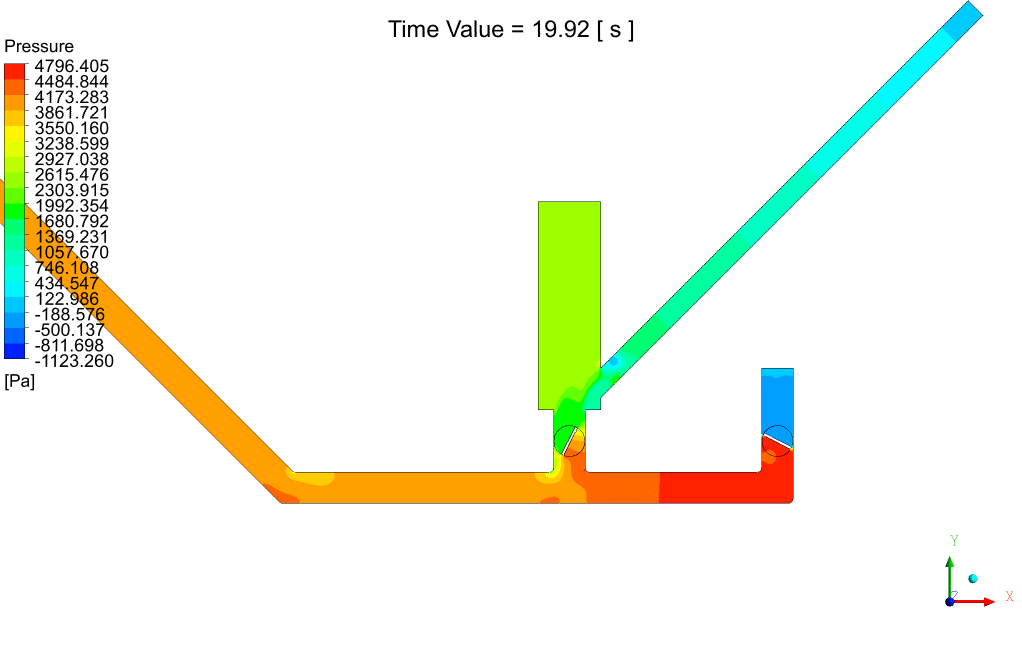

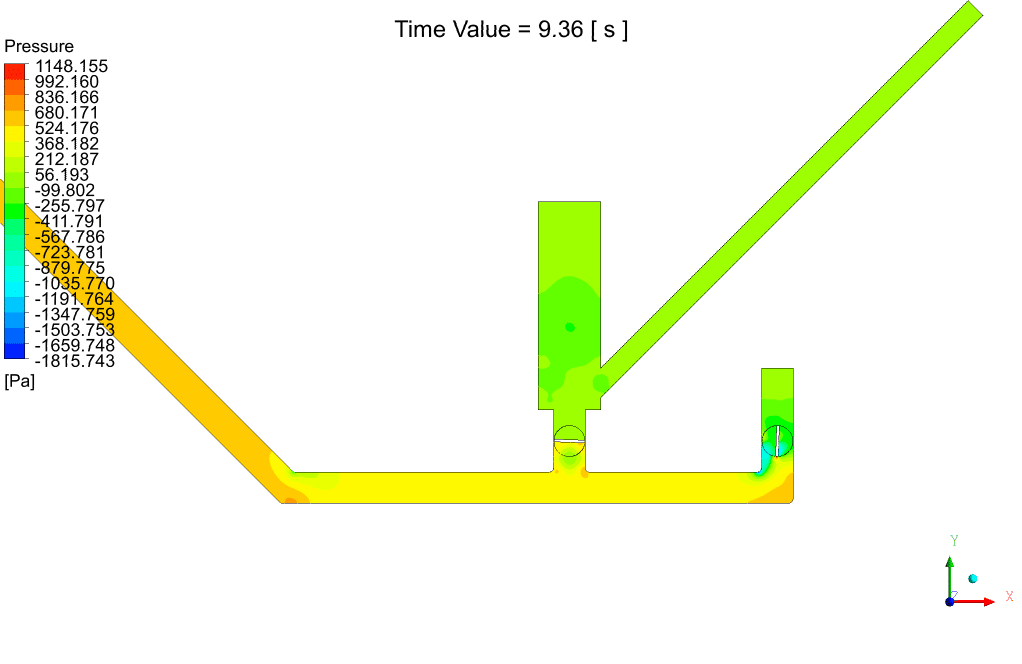

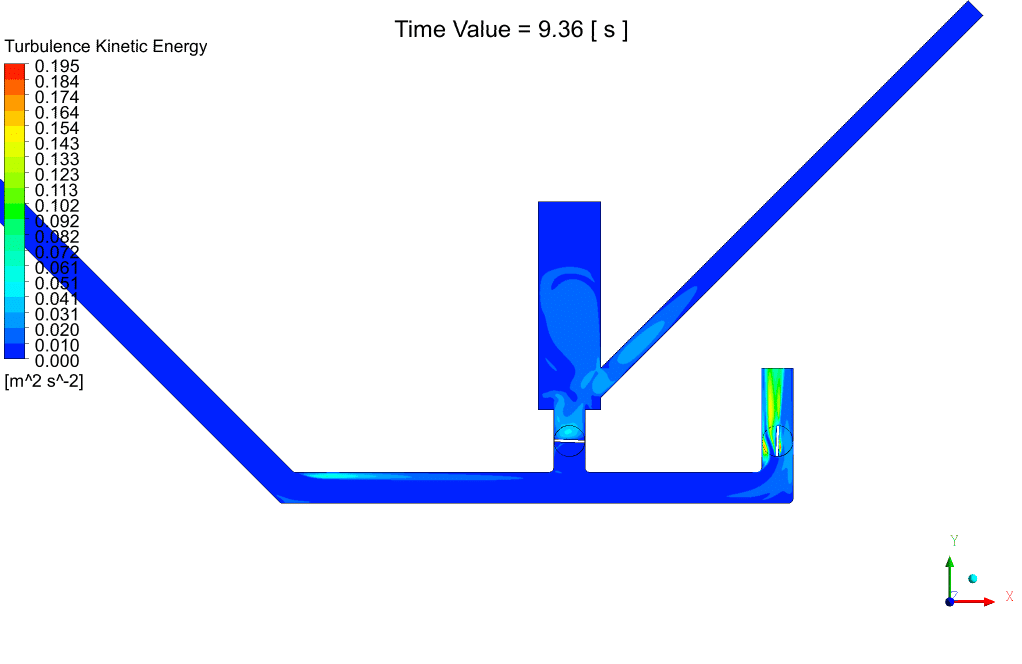

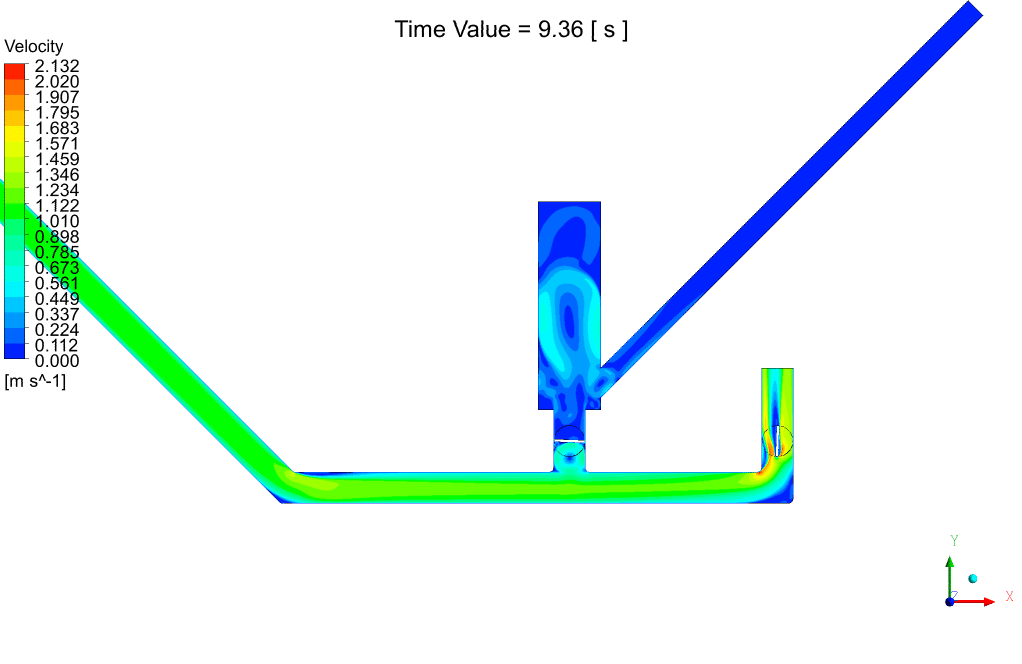

At the end of the simulation, we can see the velocity and pressure meters. It is clear that when both valves are half-closed, this suffocation increases the pressure in the pipe and when one of the valves, The face is entirely open. The other valve is completely closed. All the inlet fluid comes out with the high pressure created by the open side

Dr. Doug Ernser –

I was impressed by the detail on simulating the ram pump’s mesh motion model. I wonder how effective the system is in creating higher pressure compared to a valve that is already open?

MR CFD Support –

The simulation you refer to involved an angular rotation to create a mesh motion pattern, which reflects on the mechanism how a ram pump can increase water pressure. During the operation of the ram pump in the simulation, when both valves were set to half-closure, it resulted in an increase in water pressure within the system. The efficiency of this system, as compared to a fully open valve, depends on the specific design and opeartional parameters. Thus, in the simulated environment, closing one valve entirely while the other remains open enables the ram pump to elevate the pressure effectively. The degree of efficiency improvement is typically evaluated by observing the difference in fluid pressure at the outlet when valves are positioned differently.

Malika Breitenberg –

The project description is very comprehensive! I can see how the ram pump’s operation was simulated and the meticulous attention to detail in setting up the model. Great job on using the mesh motion model and considering the effect of gravity – it shows a real understanding of the dynamics at play within the system.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you appreciate the depth of our simulation and the detailed setup process. Our aim is to ensure that our models are as close to real-world physics as possible, so we’re glad this was evident to you. If you need further information or support about our simulations, feel free to reach out.

Craig Ankunding –

The explanation of the outlet boundary condition is somewhat confusing to me. Could you clarify if we utilize a specific pressure value at the outlet or if it is actually the standard atmospheric pressure?

MR CFD Support –

In the CFD simulation of the ram pump, the outlet boundary condition is set to a pressure outlet with a gauge pressure of 0 Pa, meaning it is atmospheric pressure. This typically represents ambient air pressure at the simulation’s outlet, letting the water flow out without additional pressure applied.

Prof. Salvatore Carroll MD –

I am excited to see how the ram pump simulation is visualized. Does the product provide detailed visual results for better understanding?

MR CFD Support –

Thank you for your enthusiasm! Yes, the product offers detailed visual results, including velocity and pressure fields. These results demonstrate the impact of valve positions on fluid flow dynamics and pressures within the ram pump.

Mr. Bernie Goyette –

This course seems very comprehensive—was the setup and any troubleshooting during the simulation process also covered?

MR CFD Support –

Yes, the course includes detailed instructions on setting up the simulation as well as guidance for troubleshooting common issues that may arise during the simulation process.

Lonzo Walker –

Can you tell me more about how the simulation accounts for the gravity effect on the ram pump?

MR CFD Support –

The simulation accounts for the gravity effect by setting the gravitational acceleration to -9.81 m/s^2 in the Y-axis direction. This ensures that the force due to gravity is properly applied in the physical model, affecting fluid behavior in a way that closely matches the real-world behavior of water in the pump under the influence of gravity. The gravity setting plays a crucial role in determining the pressure variations and flow dynamics within the ram pump system during the simulation.