Screw pump CFD Simulation, ANSYS Fluent Training

$140.00 $70.00 Student Discount

- The problem numerically simulates the Screw Pump using ANSYS Fluent software.

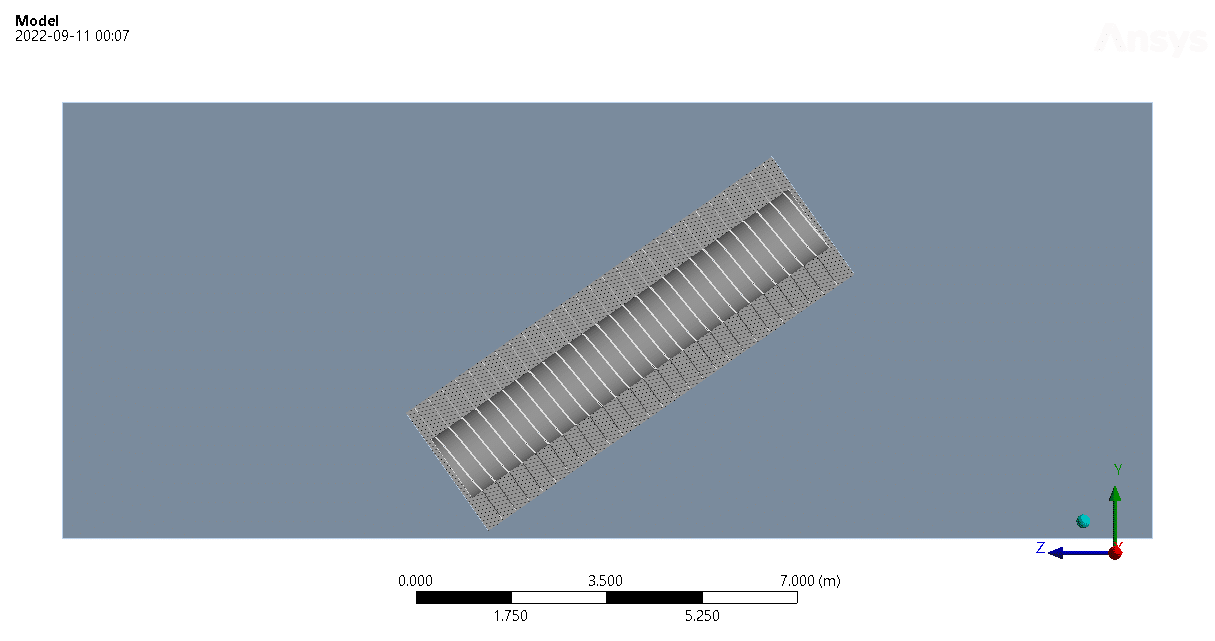

- We design the 3-D model by the Design Modeler software.

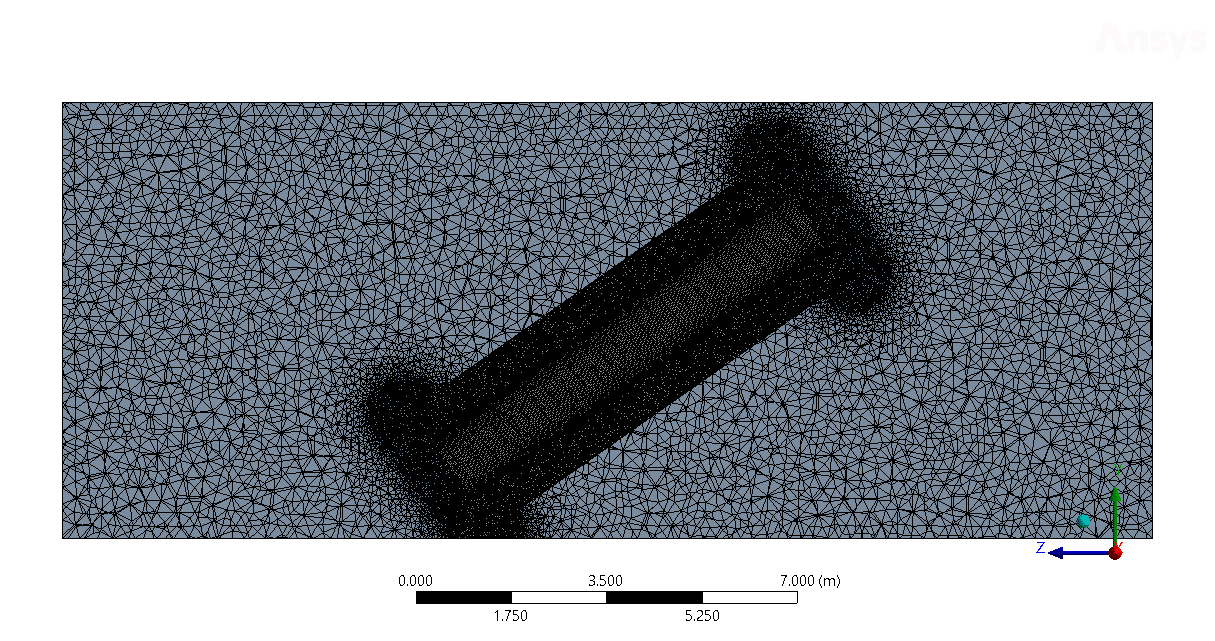

- We Mesh the model by ANSYS Meshing software, and the element number equals 3,886,425.

- The simulation is performed as unsteady (Transient).

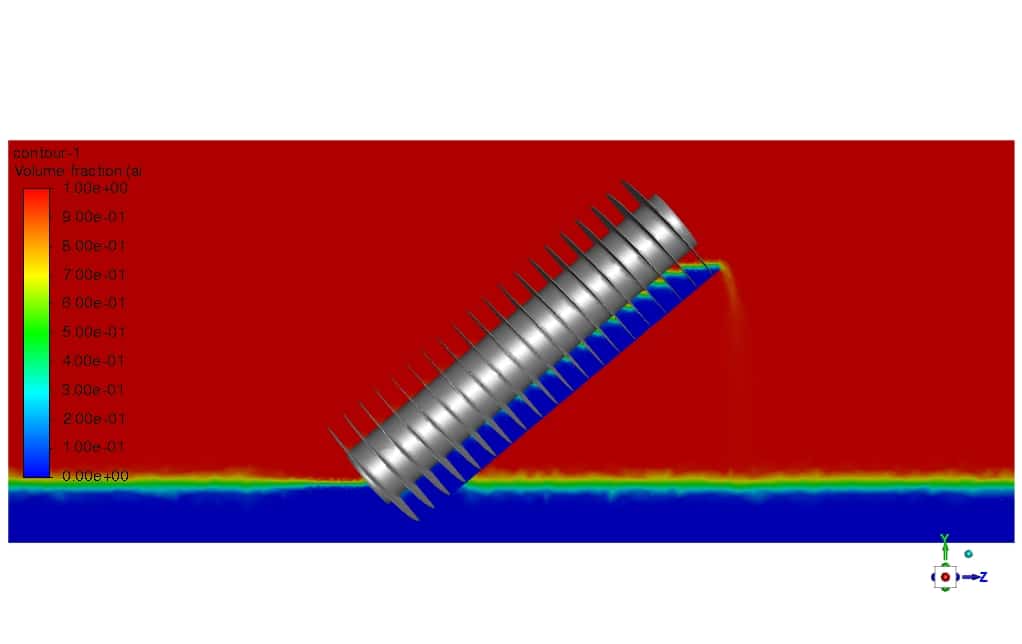

- We use the Volume of Fluid (VOF) model to define the different phases of the solution.

- The Mesh Motion option is used to model the rotational movement of the pump.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

The present problem simulates a screw pump at work using ANSYS Fluent software. A screw pump is a positive-displacement pump that uses one or several screws to move fluid solids or liquids along the screw(s) axis.

A single screw rotates in a cylindrical cavity, thereby gravitationally trapping some material on top of a section of the screw as if it was a scoop and progressively moving the material along the screw’s axle until it is discharged at the top.

The present model is designed in three dimensions using Design Modeler software. The model includes two zones the fluid zone is modeled for an open channel and one rotating zone for a screw pump.

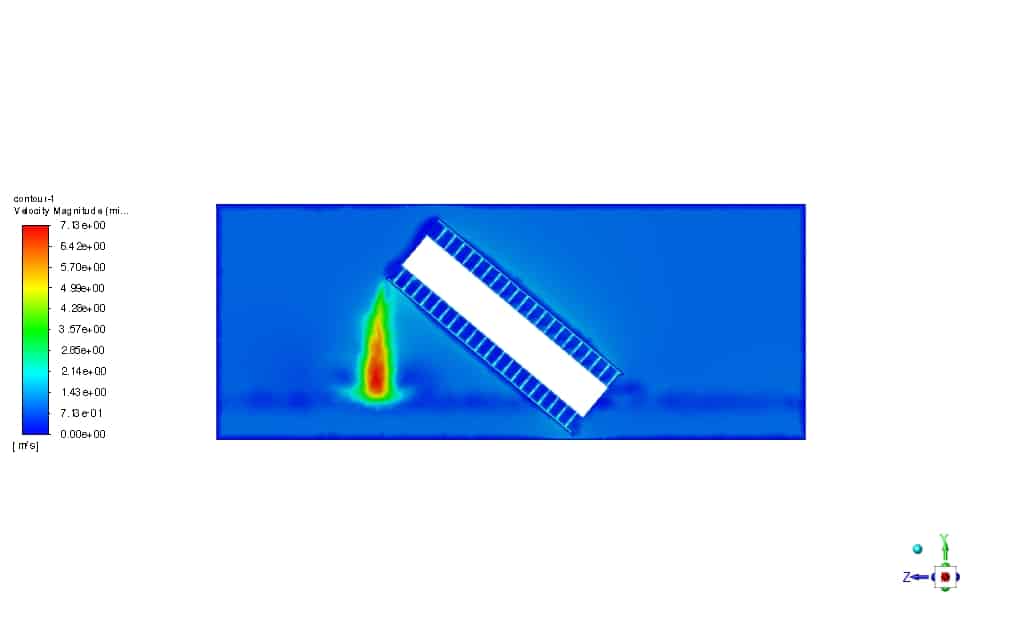

The screw pump itself inclines 40 deg and has a length of 7 m. screw pump pitch is 0.5 m. We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is unstructured. The element number is 3,886,425.

Methodology: Screw pump CFD Simulation

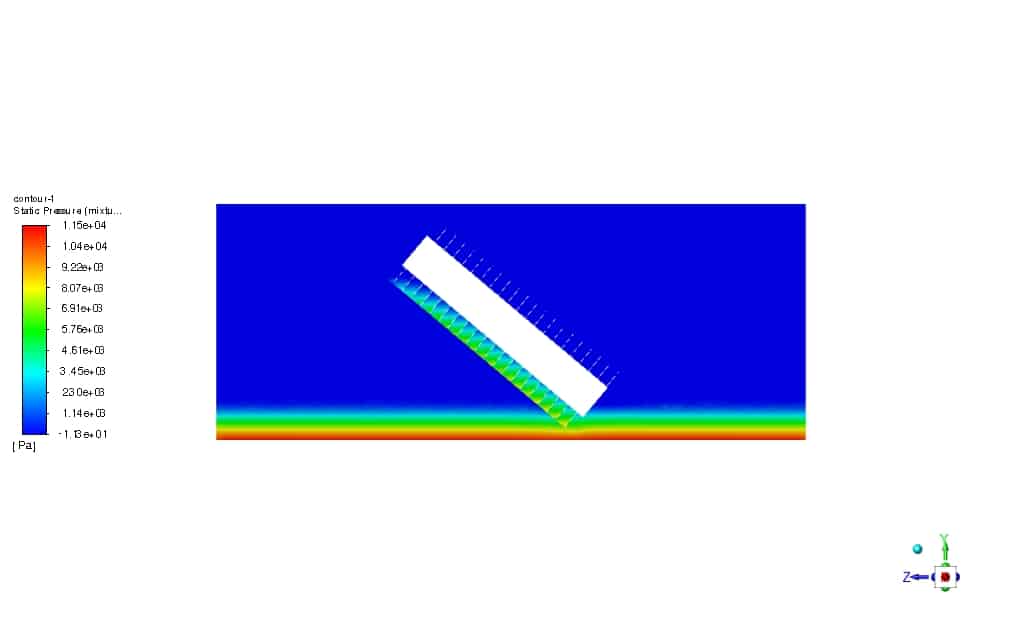

The Mesh Motion method is enabled to simulate the rotational motion of the pump. To model different phases of the solution, the Volume of Fluid (VOF) model is selected. The Open Channel model is also used to define the open channel boundary condition. Definitive density is equivalent to air density, i.e., 1.225 kg.m-3. The simulation is Transient.

Conclusion

According to the simulation animation, you can see how a screw pump works, and how it transfers water from the downstream channel to the upstream. The pressure contour shows the increase in pressure at the bottom of the pump wall, which has increased due to the presence of water.

On the other hand, the time taken to transfer water from downstream to upstream is equal to 141 seconds. The calculated pump head is equal to 2.5 meters at a circulation speed of 2 radians per second.

Dr. Emmie Satterfield –

I enjoyed learning from the Screw pump simulation training. The explanation of the process and the visual animation helped me understand how a screw pump efficiently moves water. It’s fascinating to see the practical application of the Volume of Fluid model in showing the fluid motion!

MR CFD Support –

We’re thrilled to hear that our Screw pump simulation training gave you a clearer understanding of its operation and that the visual animations added to your learning experience. Thank you for your positive feedback! It’s our pleasure to provide materials that demonstrate CFD concepts in a practical and interesting way.

Prof. Theodora Pfannerstill I –

Fantastic product! Seeing the screw pump in action and understanding the pressure changes were eye-opening. Brilliant CFD simulation that crystallizes complex concepts.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you found the screw pump simulation effective in understanding the mechanics and pressure dynamics of the system. If you have any more questions or need further clarifications, feel free to reach out!

Bettie Lehner –

I’m highly impressed by the realistic simulation of the screw pump’s operation. Learning how the rotation of the screw effectively moves water along its path, conceptualized through your software, has offered a practical experience in fluid dynamics education. The successful pressure and screw incline to replicate a functional pump condition, particularly caught my attention. Keep up the good work!

MR CFD Support –

Thank you very much for your kind words! We are delighted to know that our simulation was able to provide you with a comprehensive and realistic understanding of screw pump operations. Your positive feedback encourages us to continue delivering quality CFD education and simulations. If you have any further questions or need assistance with other simulations, please feel free to reach out.

Prof. Evie Sauer PhD –

The project’s approach to visualizing the screw pump’s function through CFD is impressive. The detailed pressure contours and animations really help to understand the operation’s dynamic nature. Great work on capturing the pump head and efficiency of water transfer within the simulation!

MR CFD Support –

Thank you for your positive feedback! We are glad that the simulation results and visual aids were clear and helpful in enhancing your understanding of the screw pump mechanics. We appreciate your acknowledgment of the level of detail provided in our CFD results.

Mrs. Blanca Davis II –

Top-notch CFD course! Seeing the screw pump simulation in action gave me immense clarity on the functionality and pressure dynamics. After going through the course contents, the increase in pressure at the bottom of the pump was visually evident and I could clearly trace the water transfer timeframe. Incredible attention to detail and excellent presentation of complex concepts in an understandable format. Great job on crafting such an insightful and practical guide for mastering screw pumps in ANSYS Fluent.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our screw pump CFD simulation training has provided you with clarity on the processes and mechanisms involved. It’s fantastic that you were able to gain comprehensive insight into the functionality and witness firsthand the dynamics at play. Your appreciation of the detail and presentation confirms that we’re fulfilling our goal to deliver high-quality educational content. If you ever have any further questions or need further assistance, we’re here to help.

Dr. Tremaine Graham –

The visual displays provided in the training truly highlighted the functionality of the screw pump and helped solidify my understanding of the pressures involved. The step-by-step simulation approach made the concepts clear and easy to understand for somebody without a deep technical background like myself.

MR CFD Support –

Thank you for your feedback! We’re pleased to hear that our focus on visual learning and step-by-step simulation contributed to your increased understanding of the screw pump dynamics. We strive to make our training materials comprehensive and accessible for learners at all levels. If you have further interest in our simulations or need any more guidance, please do not hesitate to reach out.

Mattie Hudson –

Thanks to the MR CFD Company’s detailed simulation on screw pump using ANSYS Fluent, I gained deep insights into the operational mechanics. The provided animation of water transfer was particularly enlightening!

MR CFD Support –

We truly appreciate your positive feedback! It’s great to hear that our simulation of the screw pump provided valuable understanding. Thank you for highlighting the animation – we strive to create resources that not only inform but also engage.

Fritz Raynor –

I’m particularly interested in the meshing strategy for the rotating zone of the screw pump. Does the simulation account for the possible mesh deformation due to the screw’s rotation?

MR CFD Support –

Yes, the simulation does account for possible mesh deformation due to the rotation of the screw. The Mesh Motion method, which is enabled in the simulation, allows the mesh in the rotating zone of the screw pump to adapt as the screw rotates to accurately capture the dynamics of the fluid as it moves through the pump.

Dr. Wilfredo McKenzie II –

This tutorial was fantastic! Watching the simulation animation made the operating principle of the screw pump incredibly clear. Great work!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that the tutorial with its animation was instrumental in enhancing your understanding of the screw pump’s functioning. If you have any more questions or need further assistance, please don’t hesitate to reach out to us.

Alexie Kirlin III –

I’m impressed with the level of detail provided about the screw pump simulation using ANSYS Fluent. Your work really showcases the capabilities of the software in representing complex fluid dynamics scenarios.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our description of the screw pump simulation was informative and helped to highlight the strengths of ANSYS Fluent. We appreciate your feedback and are here if you have any more questions or need further information on our training materials.

Sophia D’Amore –

I’m so impressed with the Screw pump CFD Simulation from MR CFD’s ANSYS Fluent training. Seeing the pump in action and understanding the water transfer were very enlightening. The quality of the training material made learning complex concepts like screw pump mechanics and CFD simulation accessible. Brilliant job on this educational material!

MR CFD Support –

Thank you for taking the time to write such a wonderful review of our Screw Pump CFD Simulation! We are thrilled to hear that the simulation was able to provide you with clear insight and make the learning process easier. At MR CFD, we strive to produce educational content that is both informative and accessible, and we’re glad to know we’ve succeeded. Keep on learning and should you have any further questions or require assistance, don’t hesitate to reach out. Thanks again for your positive feedback!

Harmony Williamson –

This training clarified the mechanics behind screw pumps tremendously! Seeing the visualizations helped solidify my understanding. Fantastic material!

MR CFD Support –

We are thrilled to hear that our training material on screw pump CFD simulation effectively enhanced your understanding and that you found the visualizations particularly helpful. Your positive feedback is greatly appreciated!