Series Fans CFD Simulation using MRF Method

$120.00 $60.00 Student Discount

- The problem numerically simulates the airflow between two 3-bladed Series Fans using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 1914000.

- We use the Frame Motion to define rotational motion for fan blades.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Series Fans CFD Simulation using MRF Method, ANSYS Fluent Tutorial

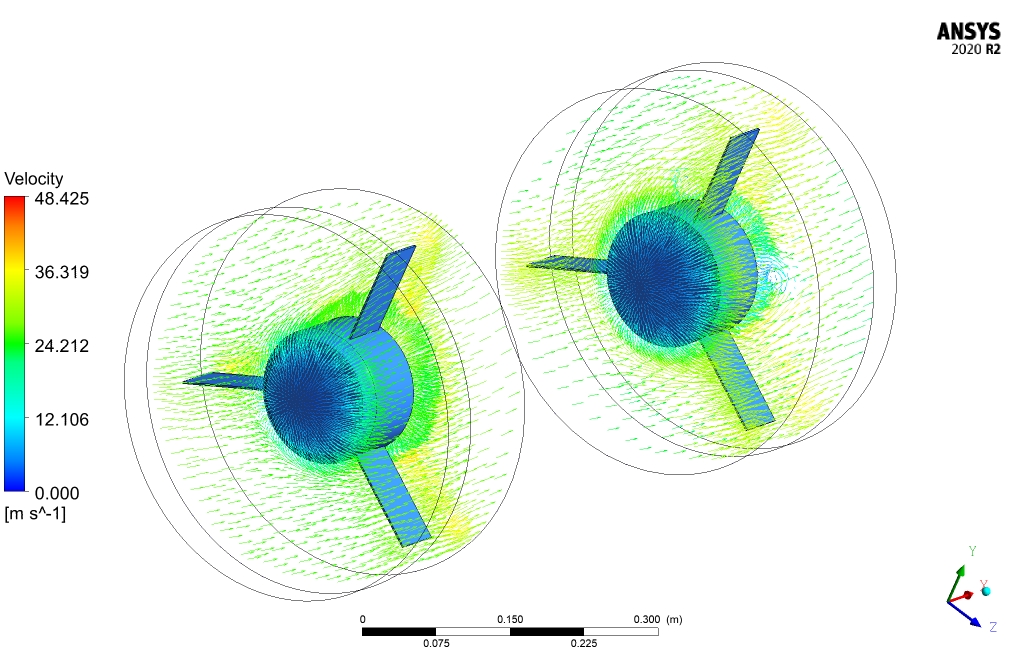

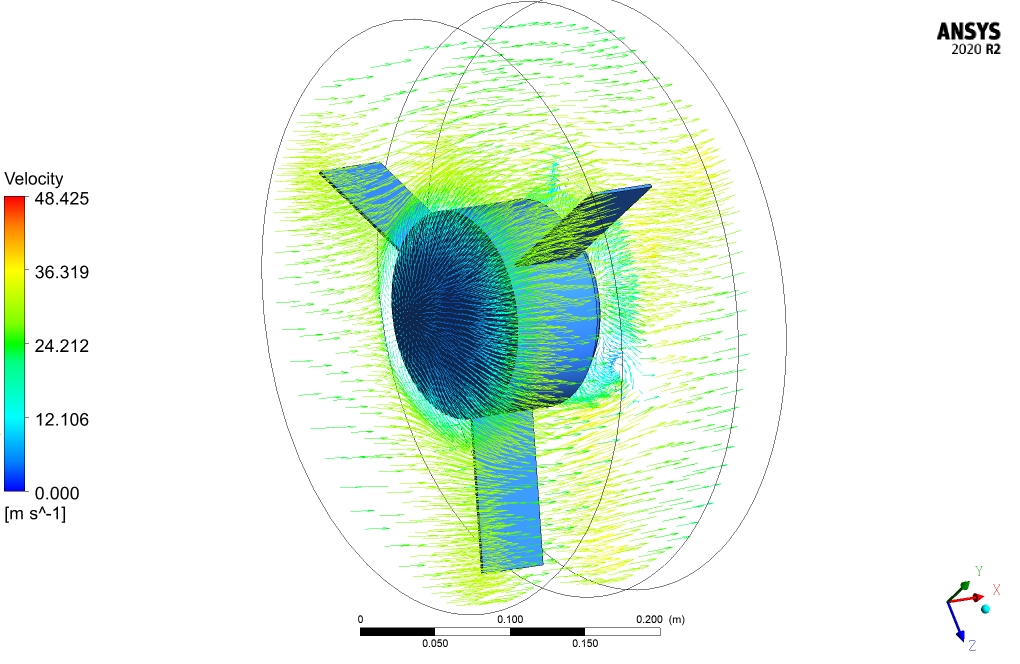

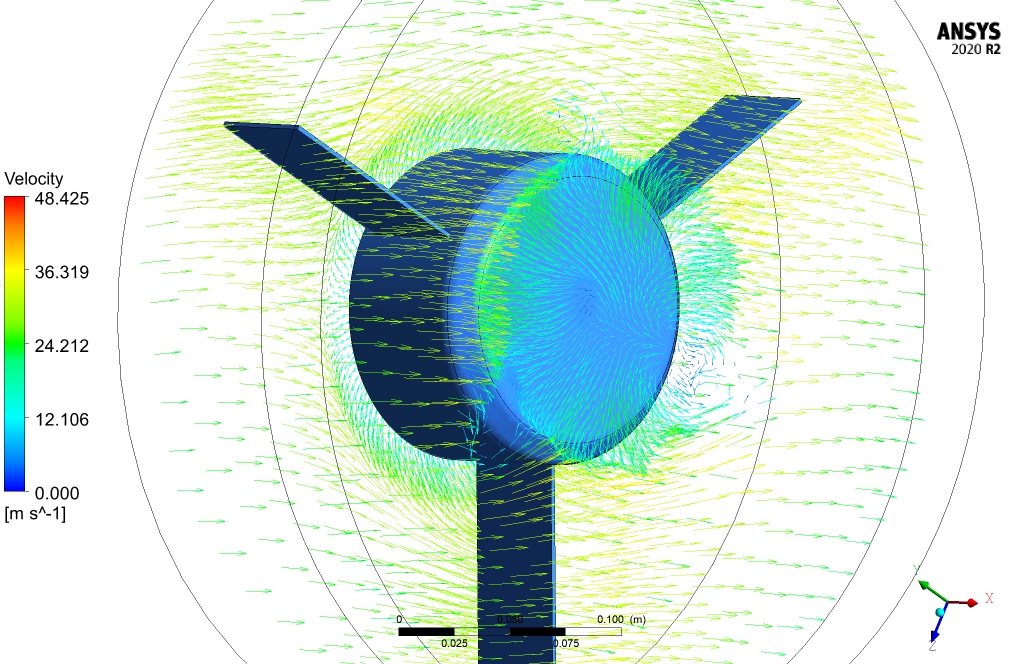

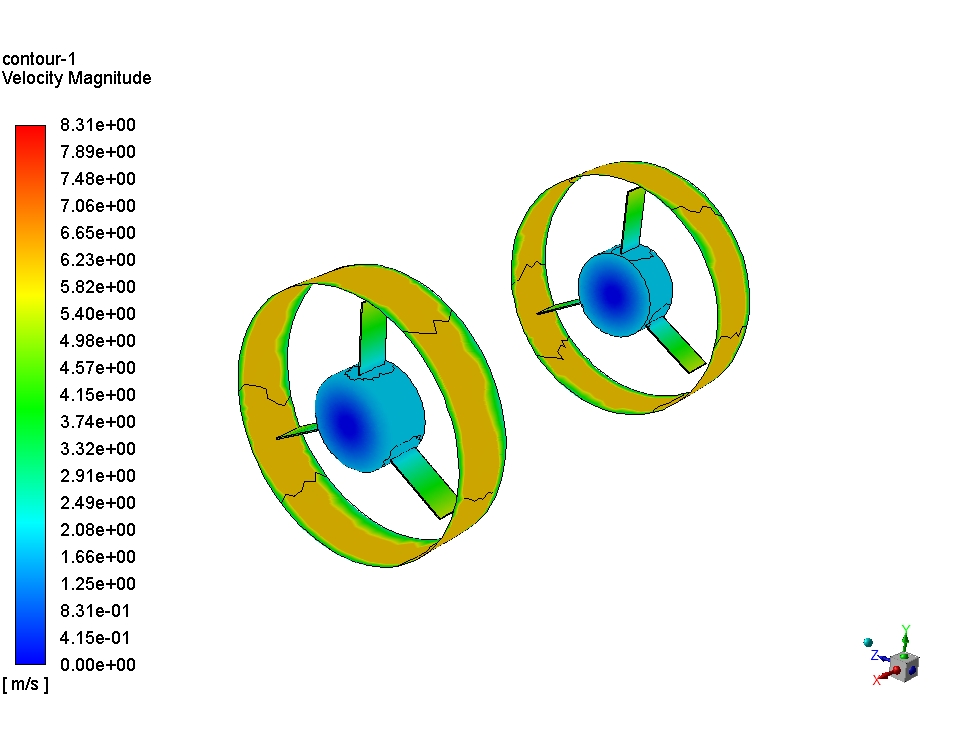

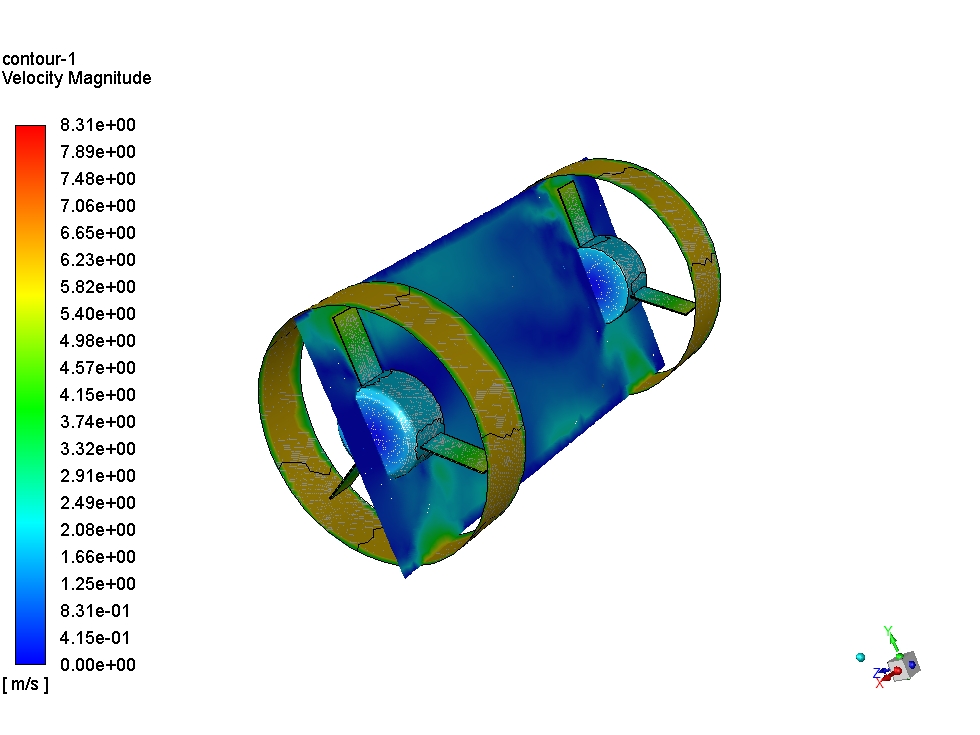

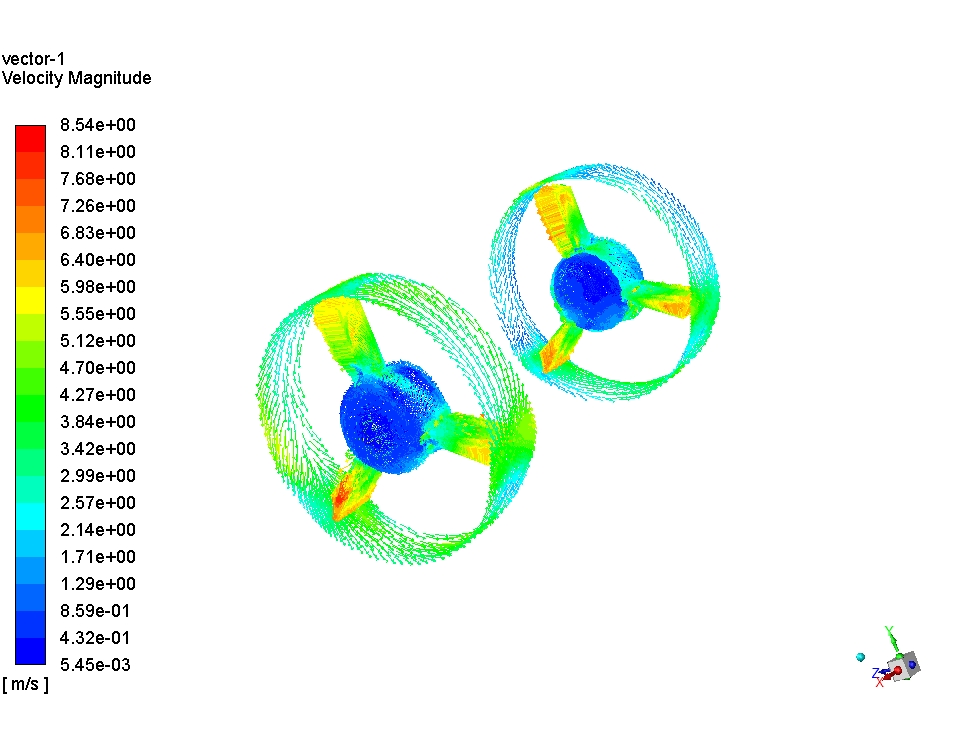

In this project, steady air flow is investigated between two 3-bladed Series Fans CFD Simulation rotating at an angular velocity of 300 rpm using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The three-dimensional geometry of this project has been designed with spaceclaim software. The meshing of this project has been done with ANSYS Meshing software. The element number is 1914000.

Series Fans Methodology

In this project, steady air flow is investigated between two 3-bladed series fans rotating at an angular velocity of 300 rpm by ANSYS Fluent software. The rotation of fans generates air suction at the inlet boundary with a flow rate of 2.95755 m3/s.

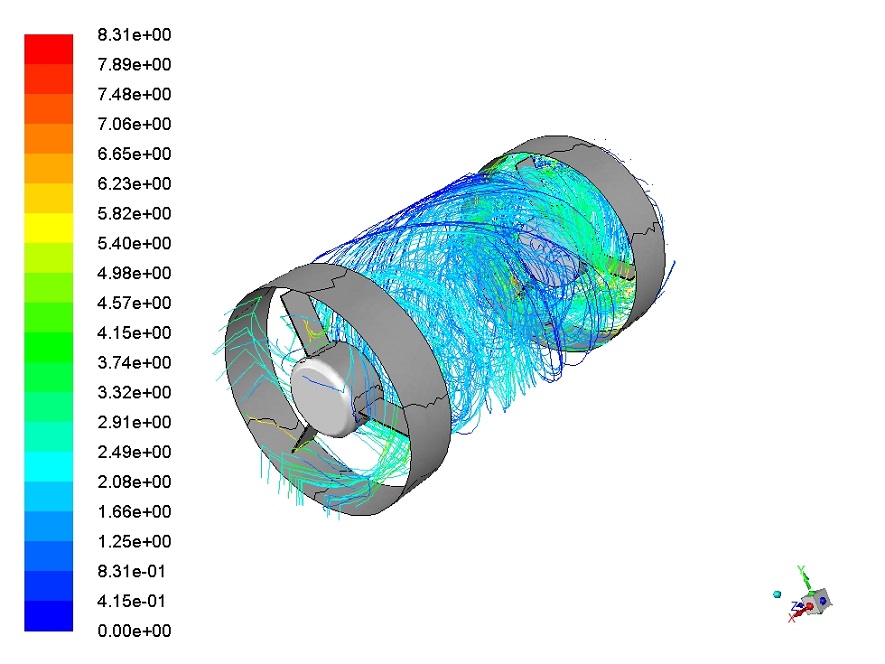

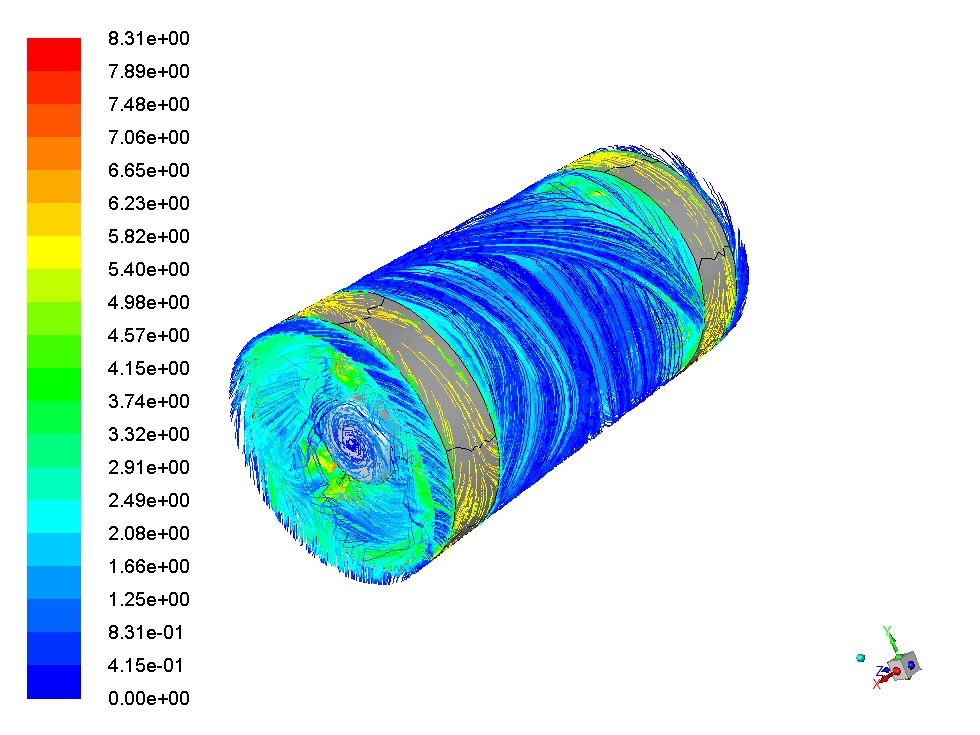

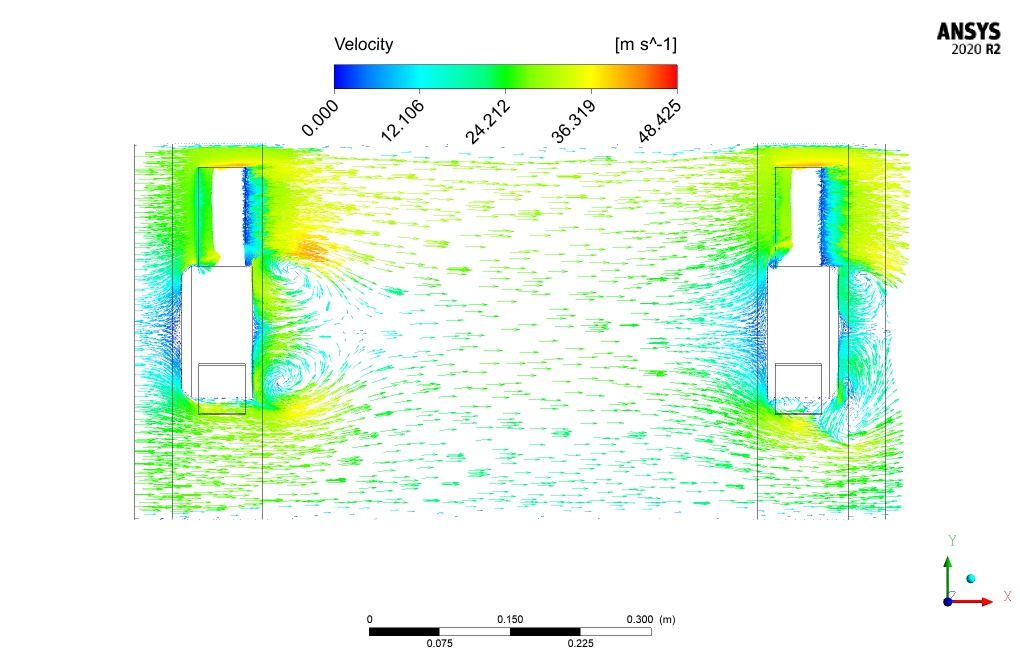

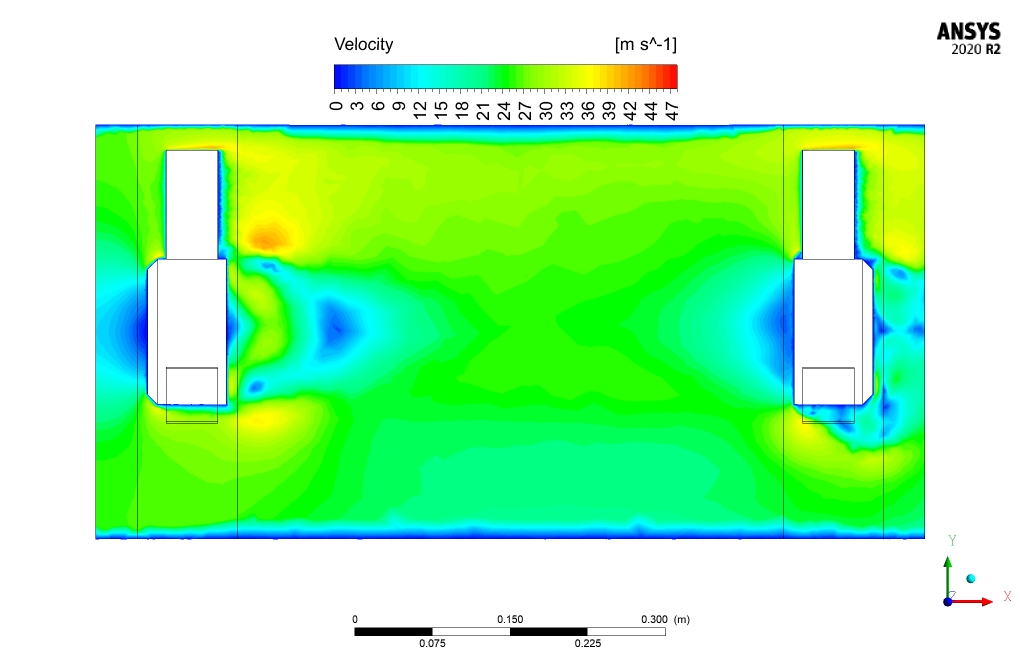

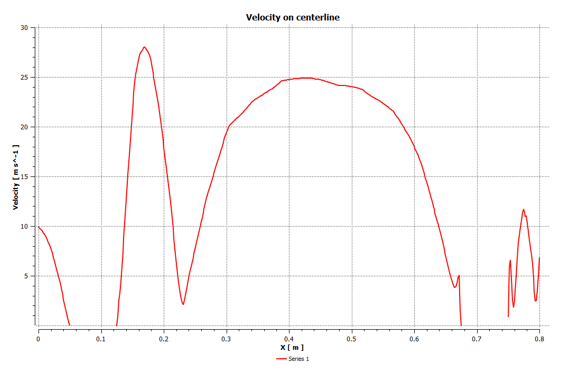

The air velocity reaches values up to 25 m/s on the domain centerline; however, the maximum air velocity in the domain is equal to 47.05 m/s, which is captured downstream of the first fan. Moreover, the RNG k-epsilon model is enabled to solve turbulent fluid equations.

Series Fans Conclusion

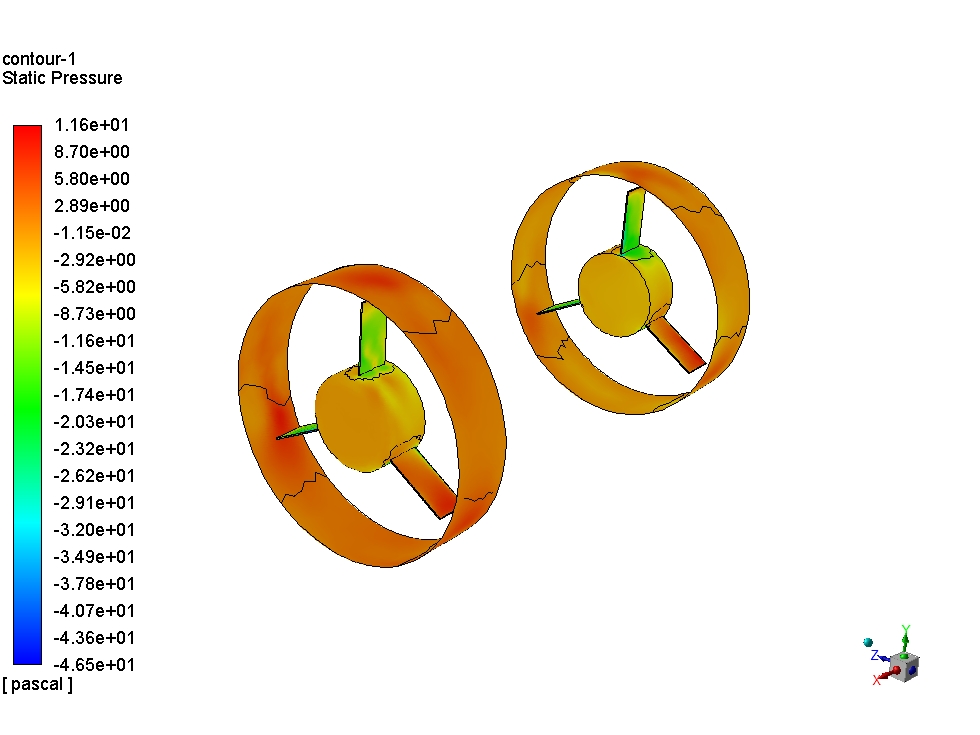

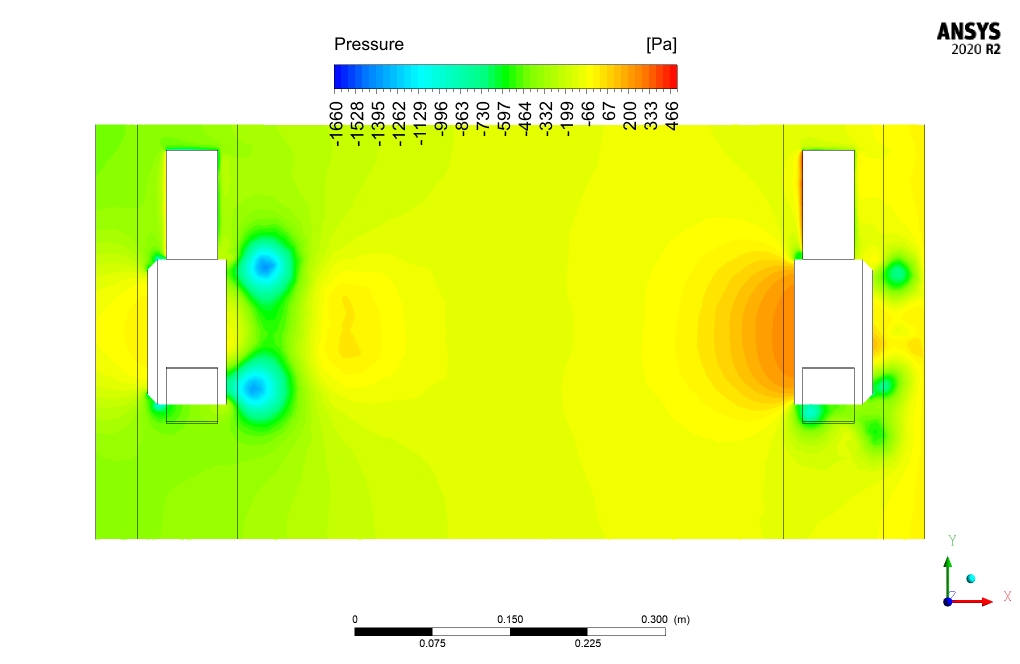

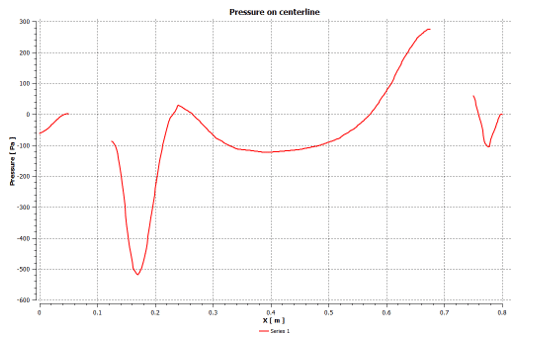

At the end of the simulation, two- and three-dimensional contours related to pressure, velocity, velocity vectors, and streamlines are obtained. Also, based on Fluent’s calculated data, the air mass flow rate at the inlet equals 3.62019 kg/s.

A comparison between the pressure drops of the first and second fan shows that the pressure drops in the first fan have a higher value of 2 times more than the second fan. The pressure drop in the first and second fans equals 500 and 230 Pa, respectively.

Negative gauge pressure is observed downstream of both fans, where the pressure downstream of the first fan is five times less than the dual fan. Gauge pressure downstream of the first and second fan equals -500 and -100 Pa.

Based on the results obtained from the pressure drop values in both fans, the pressure drop in the first fan is higher, and the velocity magnitude downstream of the first fan has a higher value (28m/s) than the second fan (12m/s).

Dortha Crona –

I noticed that the simulations use the MRF method. Can you explain why this method was chosen over others?

MR CFD Support –

The MRF (Multiple Reference Frame) method is a popular choice for simulating rotating machinery like fans. It simplifies the simulation by creating a stationary and a rotating zone, which makes it computationally efficient while still providing accurate results.

Roderick Romaguera –

How accurate are these simulations in predicting the actual performance of the fans?

MR CFD Support –

Our simulations are based on well-validated models and methods, such as the MRF method. While no simulation can perfectly replicate reality, they can provide a very close approximation and valuable insights into the performance of the fans.

Dr. Deborah Dicki IV –

Are there any limitations to these simulations?

MR CFD Support –

Like all simulations, ours have some limitations. For example, they assume steady-state conditions and use certain simplifications. However, they are still a powerful tool for predicting fan performance.

Abagail Ernser –

Everything in the tutorial seems really clear, but I just had one thing I’m wondering about: how is the rotating motion of the fans represented in the simulation? Is there a special method for that?

MR CFD Support –

In the simulation, the rotating motion of the fans is represented using the Multiple Reference Frame (MRF) method. This method involves treating the rotating fan blades as moving within their own rotating reference frame, which is then interfaced with the stationary reference frame of the surrounding air. This approach effectively captures the impact of the rotational movement without the need to physically animate the rotation of the fans.

Dr. Jeff Doyle Sr. –

The ANSYS Fluent tutorial on Series Fans CFD Simulation was incredibly detailed and helped me understand the dynamics of fan operation. The visualization of airflow and the explanation of pressure drops between the two fans were particularly enlightening.

MR CFD Support –

We’re thrilled to hear that our Series Fans CFD Simulation tutorial was informative and valuable to your understanding. Your feedback on the detailed explanations and visual presentation of the airflow is much appreciated. Thank you for taking the time to review our product!

Ms. Gabriella Halvorson Jr. –

I’ve completed the Series Fans simulation tutorial, and the details are fantastic! Watching the air flow captured so precisely also clarified a lot about the influence of fan arrangements in systems design. Impressive!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our Series Fans simulation tutorial was helpful and provided clear insight into fan arrangements and airflow dynamics. If you have any more questions or require further assistance, feel free to reach out!

Prof. Nadia Kozey –

Fantastic tutorial! The step-by-step instructions and detailed explanation for setting up the MRF method for the simulation of series fans in ANSYS Fluent made it a breeze to understand complex concepts. This has greatly enhanced my understanding of fan simulations in CFD.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our tutorial on using the MRF method for simulating series fans in ANSYS Fluent has been helpful to you. We strive to present complex concepts in an accessible manner, and your success with the tutorial validates our efforts. If you have any more questions or need further assistance, please don’t hesitate to reach out to us.

Leopold Kunde –

I’m absolutely amazed at the level of detail and insight in the simulation of series fans using the MRF method! The conclusions provided a clear view of the performance distinguishing between the two fans, which was exactly the type of analysis I needed for my research. Genuinely impressed with the precision of the airflow patterns captured in the domain.

MR CFD Support –

Thank you so much for your kind words and feedback. We’re thrilled to hear that our simulation provided you with the detailed insights you were looking for! It’s always our goal to deliver accurate and valuable analysis for our users’ research and projects. If you ever need more information or assistance with our products, don’t hesitate to reach out.

Prof. Hillary Shanahan DDS –

The tutorial sounds comprehensive, and it seems I can replicate this CFD analysis in my own simulations. Was the tutorial easy to follow along with in-depth explanations for each step, especially for someone new to using the ANSYS Fluent software?

MR CFD Support –

Thank you for your feedback! We aim to design our tutorials to be user-friendly and informative. We include step-by-step instructions and comprehensive explanations to ensure that even users new to ANSYS Fluent can follow along and understand the simulation process. Your satisfaction with our tutorial format is appreciated!

Juana Beahan –

I’ve noticed from the series fans simulation conclusions, yet I’m curious about why the pressure drop in the first fan is higher than that in the second fan. Could it be due to the orientation or design of the fans?

MR CFD Support –

The greater pressure drop observed in the first fan compared to the second may result from the initial fan handling the majority of the pressure head gained from the airflow. As the air moves through the system, the first fan accelerates the flow, creating a high-pressure zone as the air is compressed and then a low-pressure zone as it is expelled and moves toward the second fan. By the time the air reaches the second fan, it has already been given kinetic energy, leading to a lower required pressure change to maintain the velocity developed by the first fan. Additionally, any system losses between fans could be a factor, as well as any slight differences in fan design or mounting that could impact performance.

Joanny Dach –

The detailed simulation results for the Series Fans product are impressive, particularly the pressure drop observed being higher for the first fan. Great application of CFD analysis using ANSYS Fluent!

MR CFD Support –

Thank you for your positive feedback on the Series Fans CFD Simulation. We’re delighted to hear you found the results and our use of ANSYS Fluent impressive. Your satisfaction with the detail and application is very important to us.

Mr. Sim Buckridge –

The tutorial result was fantastic! It clearly showed how series fan systems behave and the impact of each fan on pressure and velocity profiles.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the tutorial was helpful for your understanding of series fan systems. Your satisfaction is our top priority!

Kaylee Schneider –

I’m impressed with how the setup catered for accurate pressure drop measurements across both series fans. The specific speeds and mass flow rates are also insightful for understanding fan performance.

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that our detailed simulation methodology and the accurate results we present are helpful to understand the performance of the series fans. Our goal is always to provide valuable insights and realistic simulations that can be instrumental for design and analysis purposes. If you have any further questions or need clarification on other parts of the simulation, feel free to ask. We appreciate your interest in our CFD products.

Dr. Reva Watsica III –

I am truly impressed by how well the interaction between the fans and the airflow is portrayed. The details on the velocity magnitude discrepancy between the two fans were particularly enlightening. Congratulations on a job well done!

MR CFD Support –

Your feedback is greatly appreciated! We’re thrilled to hear that our attention to detail in the simulation between the two series fans offered insights into their interaction with the airflow. Thank you for taking the time to review our product. Please do not hesitate to reach out if you have any more insights or comments.

America Bergstrom –

I was fascinated by the simultaneous coordination of two fans in the simulation. How does the MRF method enable the study of this dual fan system without involving actual fan rotation?

MR CFD Support –

The MRF (Multiple Reference Frame) method allows for the simulation of rotating machinery by defining stationary and rotating zones within the computational domain. The rotating zones in this case contain the fan blades, and they are set to rotate at the given angular velocity (300 rpm), while the bulk of the fluid domain remains stationary. MRF provides the effect of rotation and captures the flow features generated by the fan blades without the computational expense of physically rotating the mesh.

Ms. Gladyce Predovic V –

I just installed the simulation tutorial on Series Fans using the MRF Method, and I must say it’s a great learning tool! The step-by-step guidance made setting up the simulation quite easy, and it’s fascinating to see the pressure and velocity changes from one fan to the other. The clear demonstration of the pressure drop and how it’s greater in the first fan was particularly insightful.

MR CFD Support –

Thank you for your positive review of the Series Fans CFD Simulation using the MRF Method tutorial! We’re thrilled to hear that you found the step-by-step instructions helpful and that you gained insights from observing the pressure and velocity outputs. It’s always our goal to provide detailed and instructive simulations that aid in understanding complex concepts. Your feedback keeps us motivated to continue offering high-quality learning products. If there is more you wish to learn or explore, don’t hesitate to reach out to us for additional materials or support!

Danika Lindgren –

The tutorial for the Series Fans CFD simulation was incredibly helpful and intuitive. The step-by-step guidance through the MRF method in ANSYS Fluent made the complex turbine interactions easier to understand. I was impressed by the detailed visualization of pressure drops and velocity patterns between the two fans, which clarified the performance impact in a series configuration.

MR CFD Support –

Thank you very much for your positive feedback! We’re glad to hear that our tutorial was effective in simplifying the complexities of CFD simulation, particularly for analysing series fans using the MRF method in ANSYS Fluent. If you have any more questions or need further assistance with your simulations, feel free to reach out to us!

Doug Kautzer –

I’m truly impressed with the level of detail in this simulation! The understanding of different pressure drops across the series fans was crucial, and the visualization of airflow with velocity vectors helped cement the concepts. The results of the pressure and velocity contours after the fans were especially interesting. Keep up the good work!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the detailed presentation and visual aids in our Series Fans CFD Simulation tutorial were helpful and that you found value in the clear representation of pressure drops and velocity. Stay tuned for more high-quality CFD learning materials!

Prof. Morgan Kris –

I’m impressed by the level of detail provided in the velocity and pressure drop results. Could you provide insights on why the first fan experiences a higher pressure drop compared to the second?

MR CFD Support –

Thank you for the positive feedback! The higher pressure drop in the first fan can be attributed to its position in the airflow sequence. Being the first point of contact, it has to overcome the static pressure and initial resistance of the air mass, increasing the energy required to move the air. Consequently, it experiences a higher drop in pressure. As the second fan operates on air already in motion from the first fan, it encounters less resistance, leading to a lower pressure drop.

Dr. Jadyn Schroeder –

This tutorial helped me understand the MRF method clearly. The airflow patterns depicted in the various contours were really insightful. Fantastic work on visualizing the process and the detailed explanation of the pressure drops between the two fans.

MR CFD Support –

Thank you for your positive feedback on the Series Fans CFD Simulation tutorial. We’re delighted to hear that you found the contents helpful and the visualizations insightful. Your understanding and appreciating the detailed explanations encourages us to continue delivering high-quality learning materials. If you need any further assistance or have more questions in the future, feel free to reach out!

Mr. Larry Erdman –

This product’s tutorial was superb! I now better understand how series fans work, especially the part explaining differential pressure and flow rates between the fans. The inclusion of RNG k-epsilon for turbulence was particularly enlightening. Well done on presenting complex data in an accessible format!

MR CFD Support –

Thank you for your kind words and positive feedback! We’re thrilled to hear that our tutorial has enhanced your understanding of series fans. Your ability to grasp concepts such as pressure drops and flow rates is exactly what we strive to achieve with our learning products. If you have any more questions or need further clarification on any topic in the future, please do not hesitate to reach out.