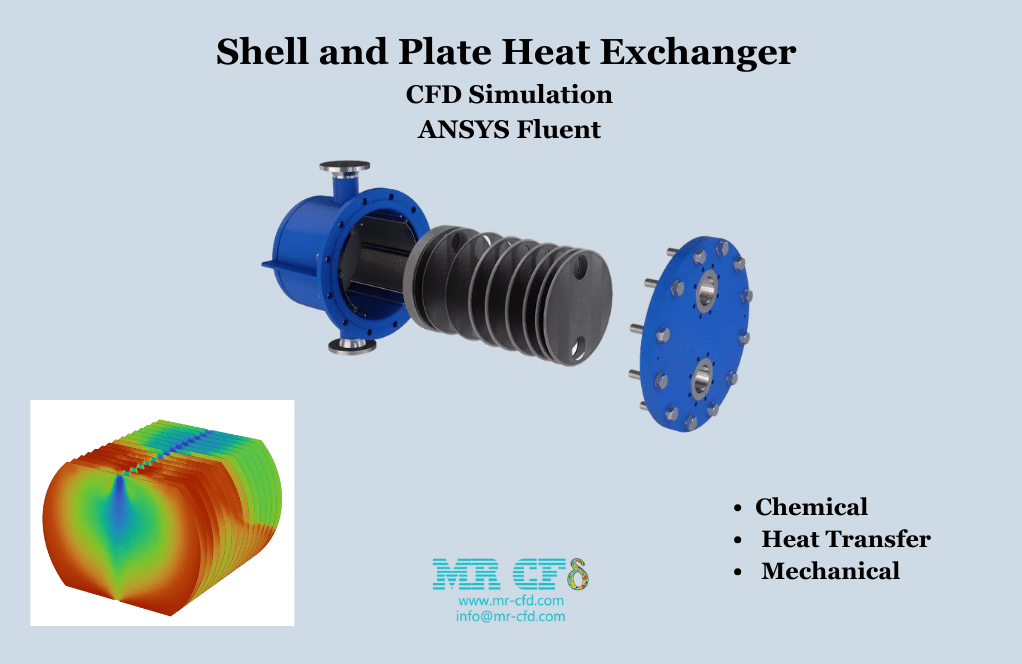

Shell and Plate Heat Exchanger CFD Simulation, ANSYS Fluent

$80.00 $40.00 Student Discount

- This product simulates a shell and plate heat exchanger using ANSYS Fluent software.

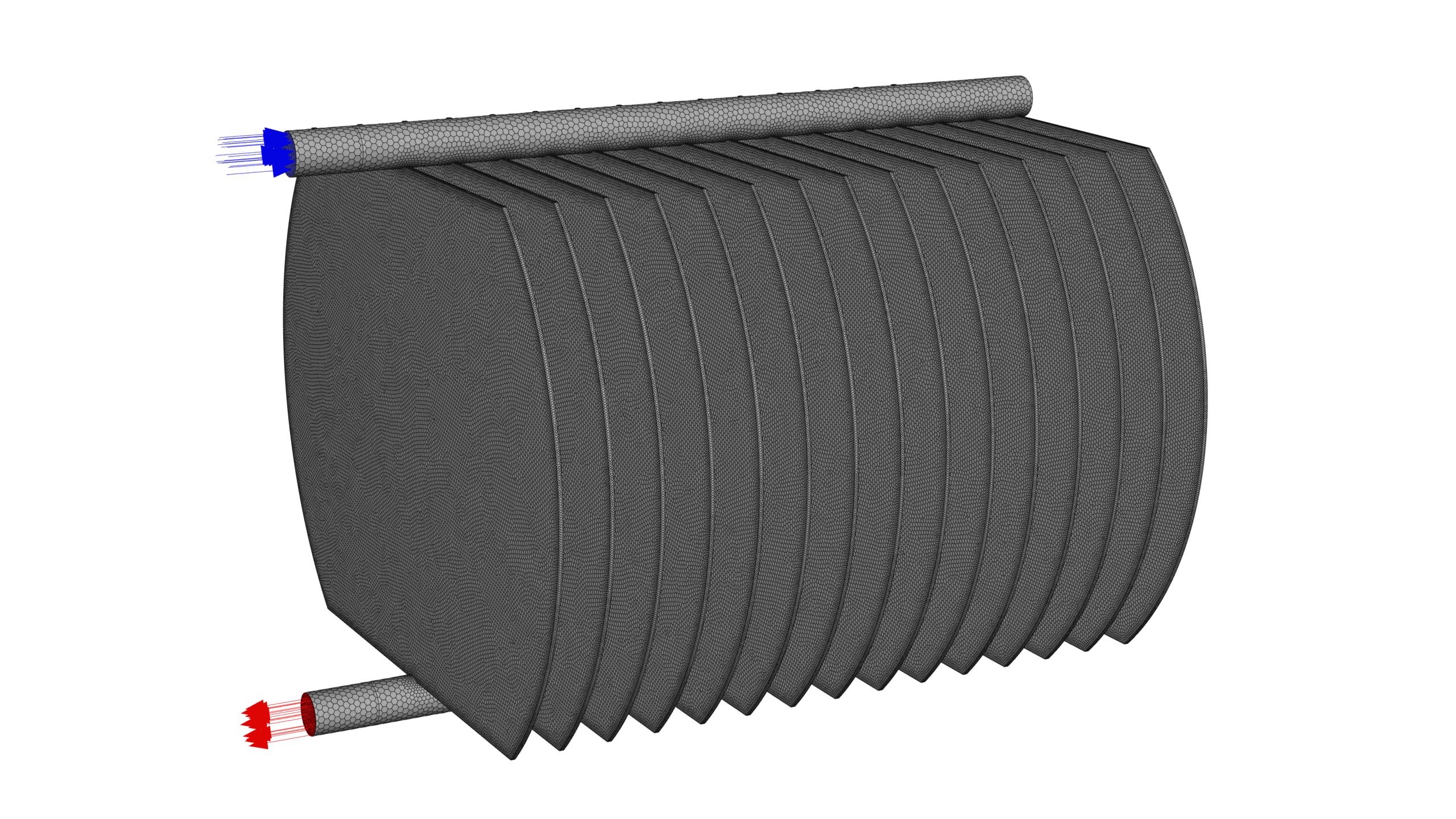

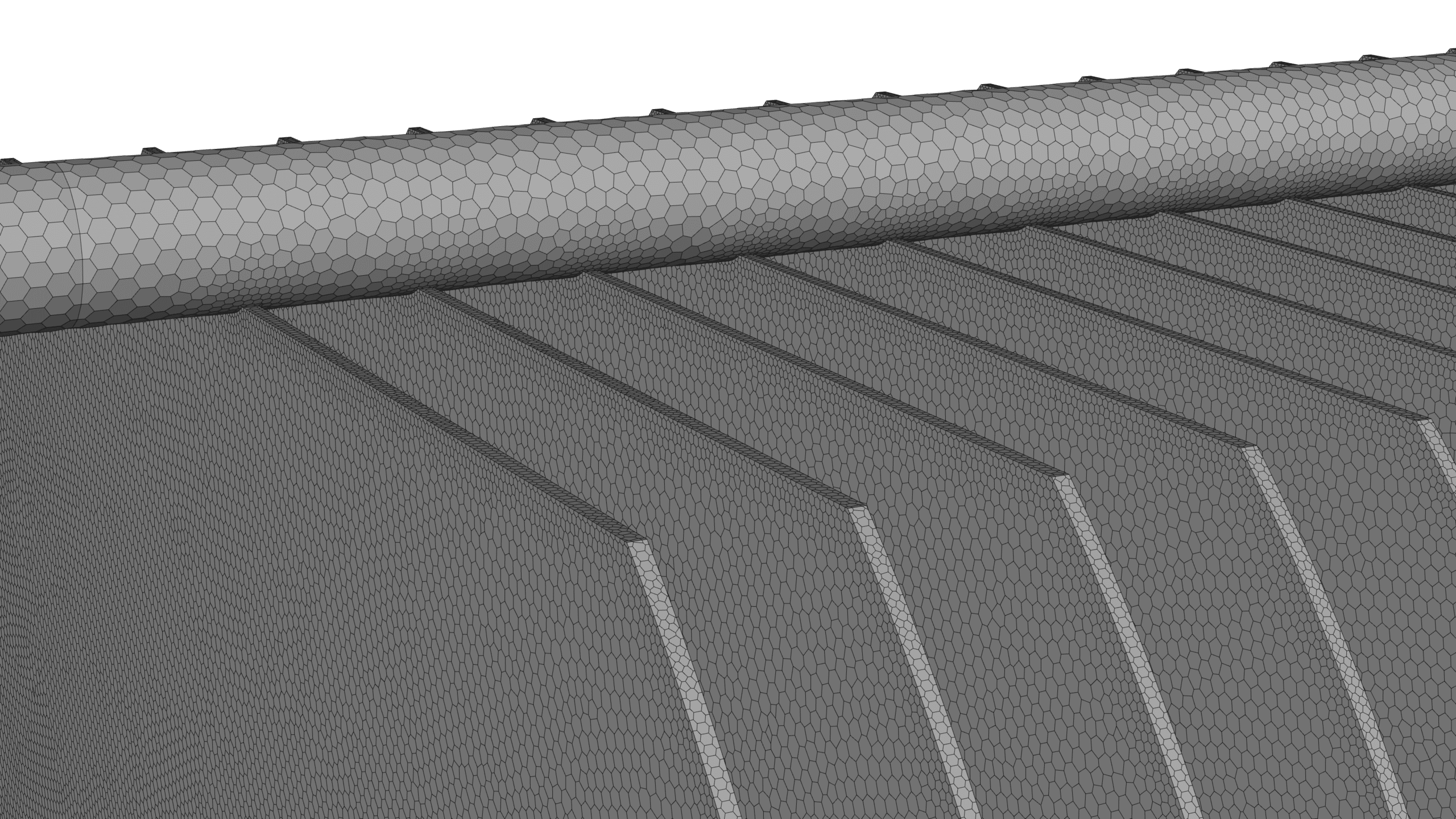

- The geometry of the problem is designed in spaceclaim. Then the Fluent meshing software was used to mesh the geometry producing 3,686,338 polyhedral elements.

- The turbulence of the flow is simulated via Realizable k-e model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This product simulates a shell and plate heat exchanger using ANSYS Fluent software. Shell and plate heat exchangers are a type of heat transfer device that combines features of both shell-and-tube and plate heat exchangers. These innovative heat transfer solutions are designed to handle high-pressure and high-temperature applications while offering the compactness and thermal efficiency typically associated with plate heat exchangers.

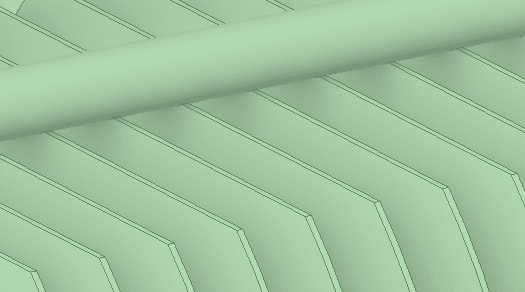

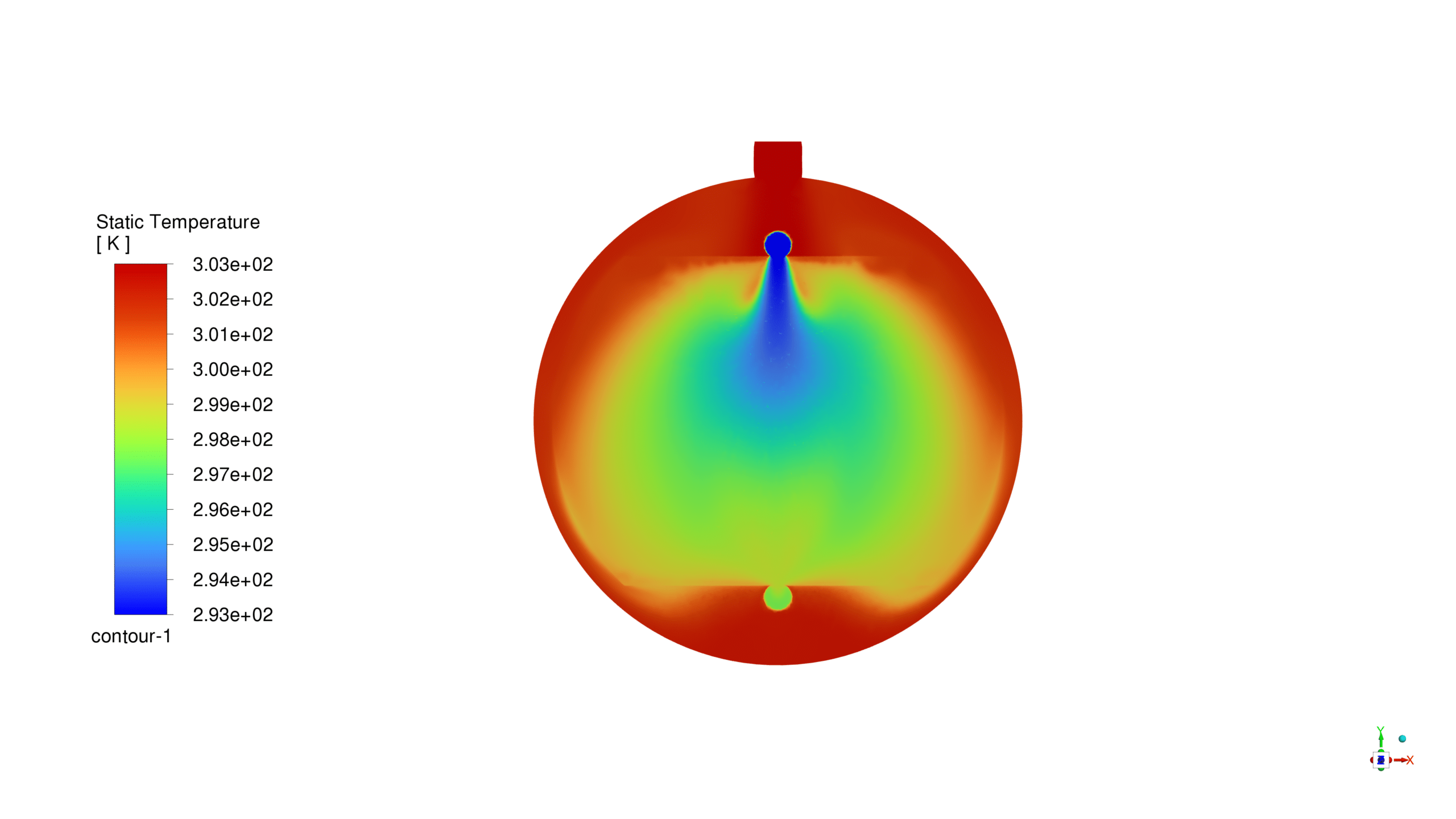

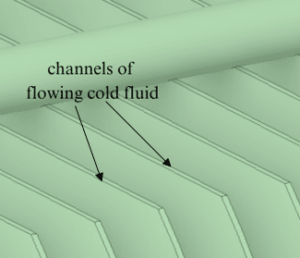

The plates in a shell and plate heat exchanger act as efficient thermal conductors, facilitating rapid heat transfer from the hot fluid in the shell to the cooler fluid flowing through the plate channels. As the hot fluid flows through the shell, it comes into contact with the large surface area provided by the plates, allowing for extensive heat conduction.

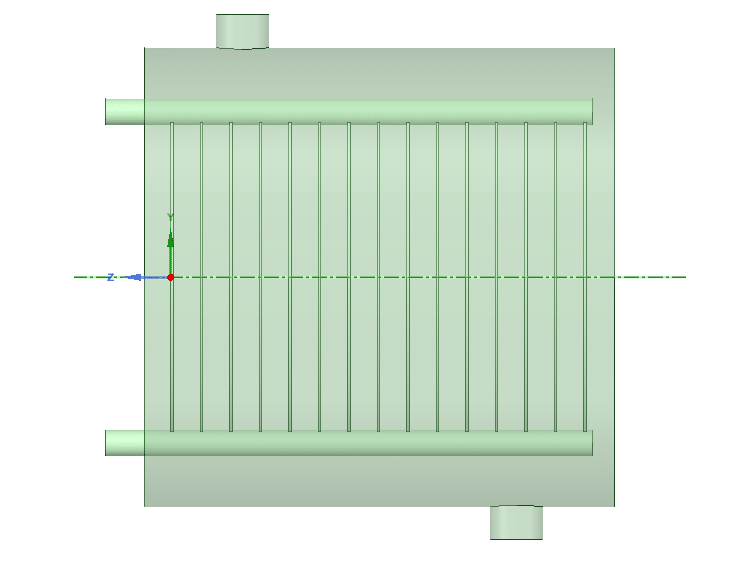

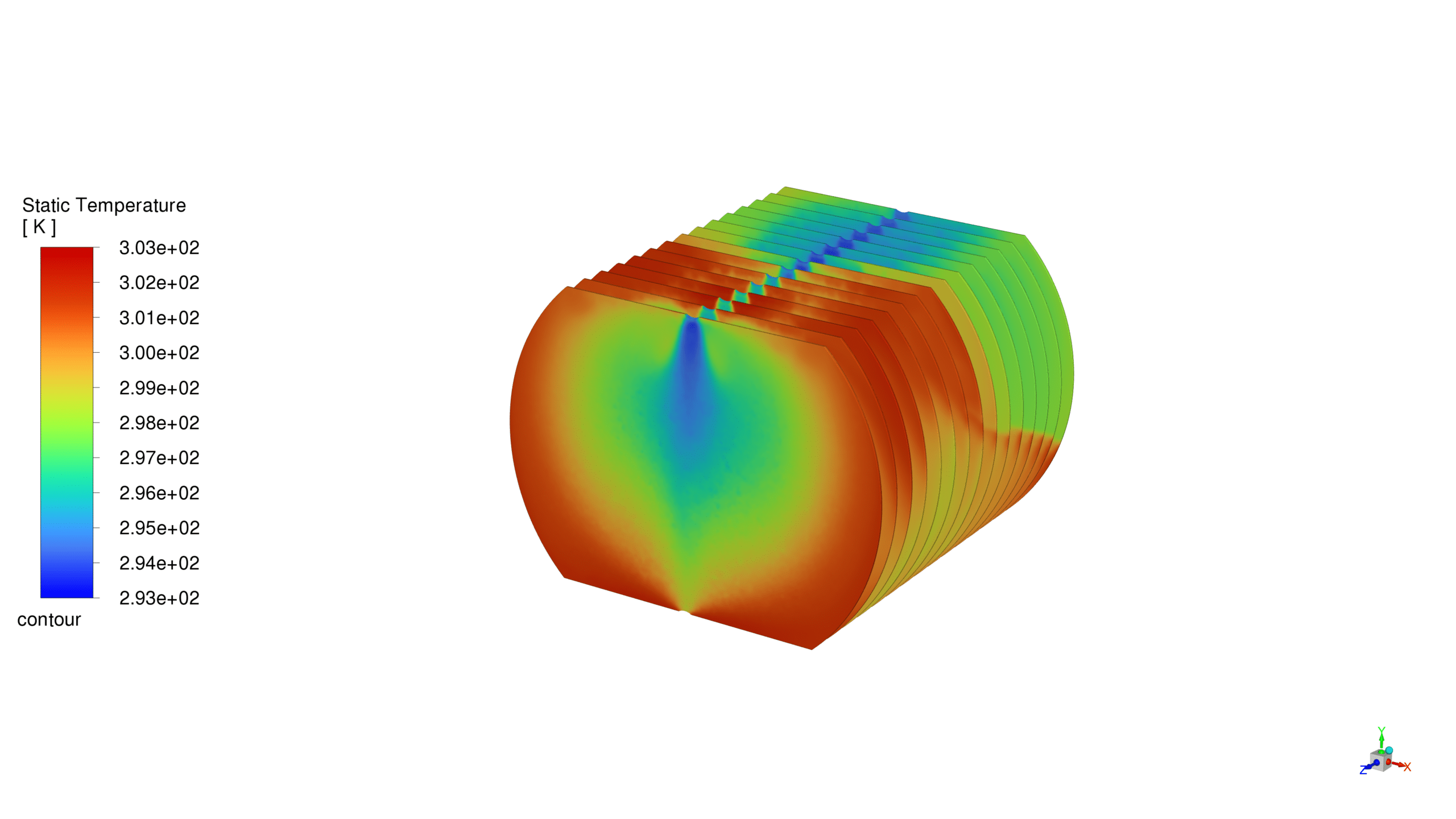

The simulation consists of flowing two fluid; liquid Ammonia as the hot fluid entering the shell with the temperature of 303.15 [K] and mass flow rate of 0.32 [kg/s] and the water as the cold fluid flowing through the channels has the temperature and mass flow rate of 293 [K] and 0.16 [kg/s] respectively.

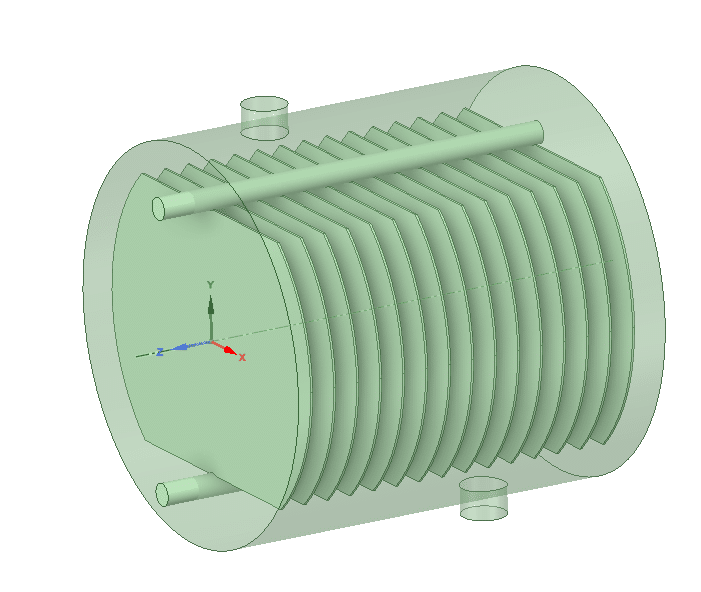

The geometry of the problem is designed in spaceclaim (following figure).Then the Fluent meshing software was used to mesh the geometry producing 3,686,338 polyhedral elements.

Methodology

Generally, the thin design of the plates maximizes the contact area between the fluid and the plate material, enhancing the conductive heat transfer process. In this simulation we considered virtual thickness of 0.8 [mm] for the plates in fluent set up. It should be mentioned that the space between the plates which the cold fluid flows, is called channels. The turbulence of the flow is simulated via Realizable k-e model. We used coupled algorithm for pressure-velocity coupling and Warped-Face Gradient Correction was uses to improve the accuracy of calculations on meshes with non-planar (warped) cell faces.

Results

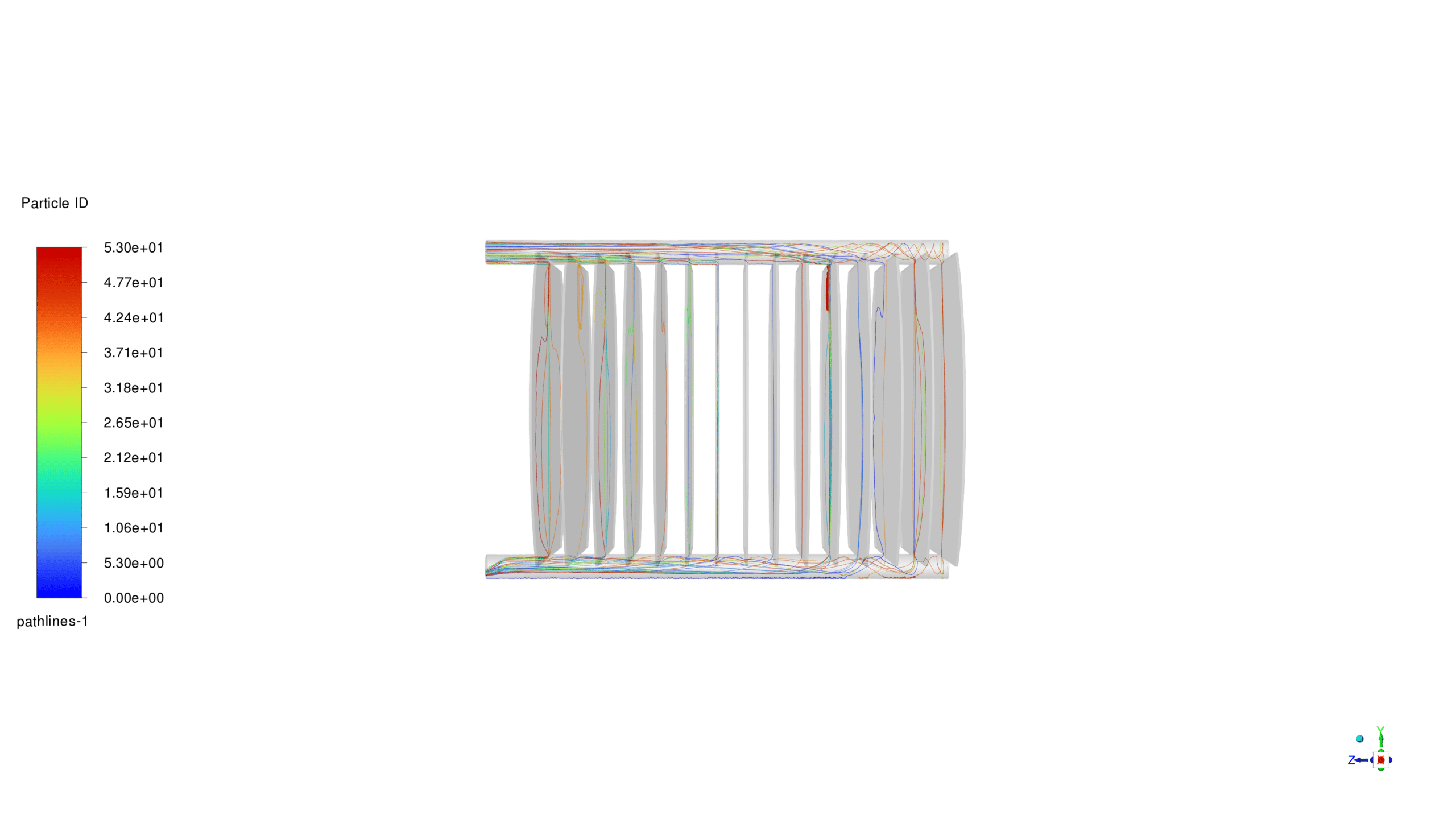

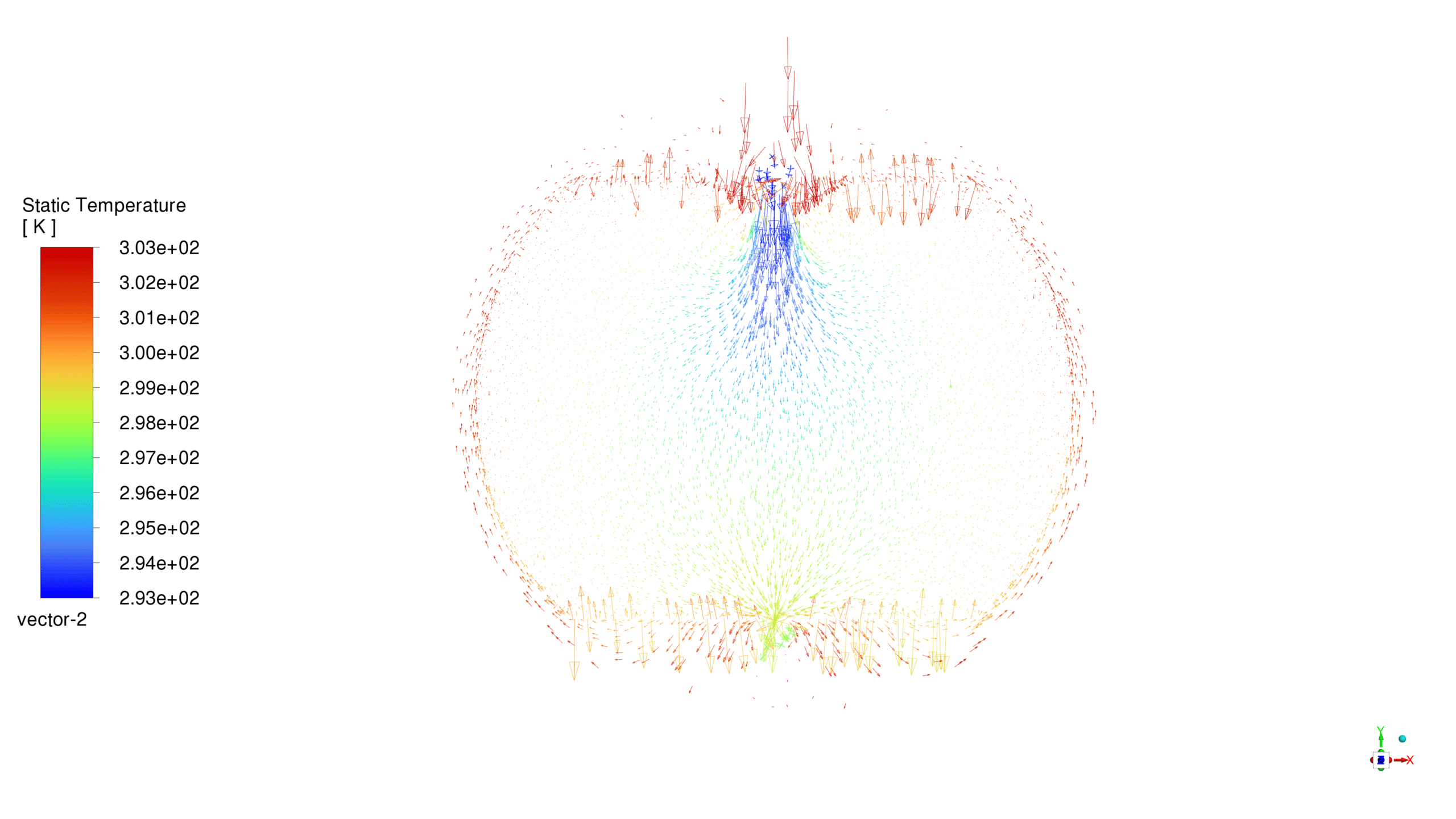

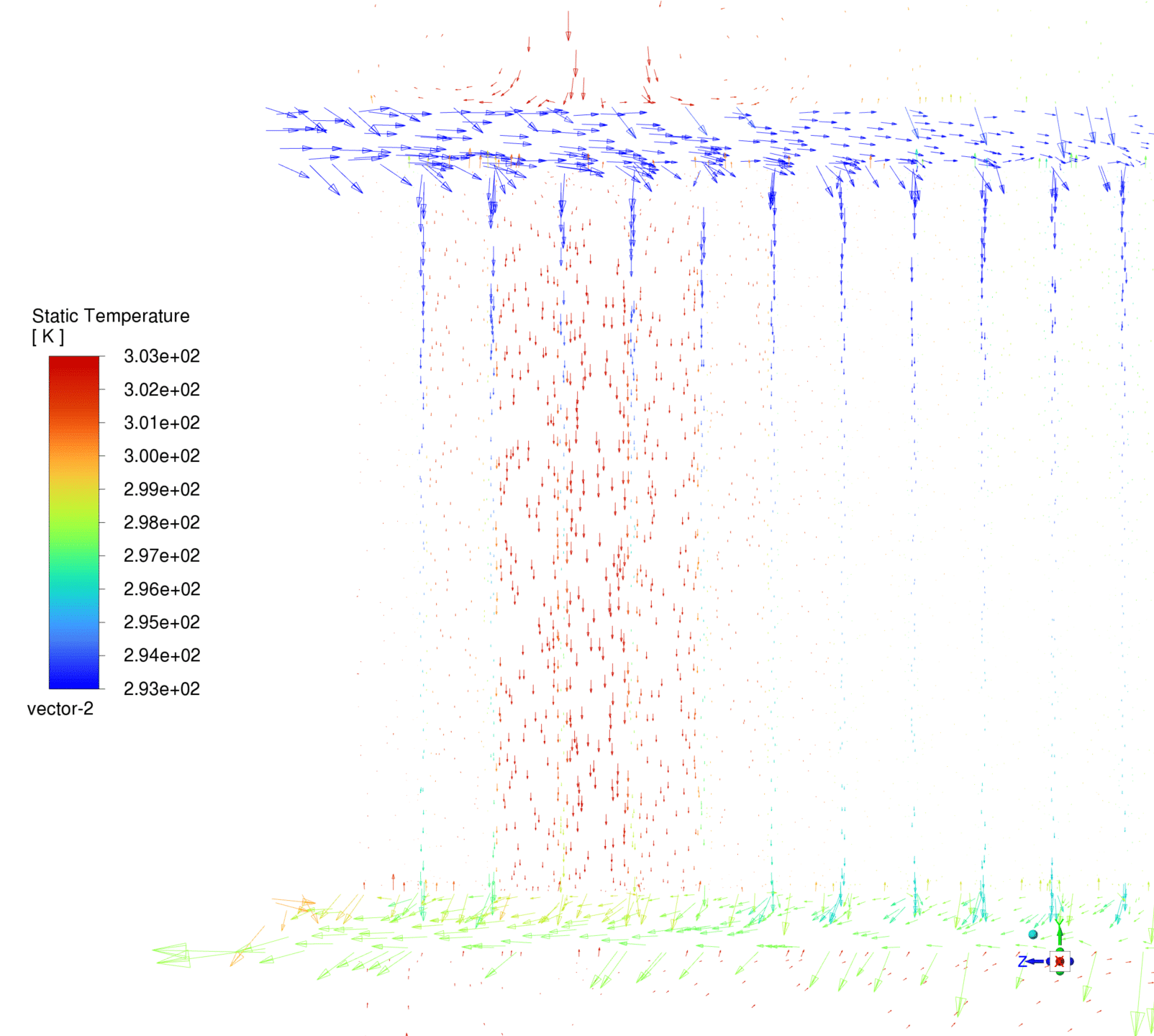

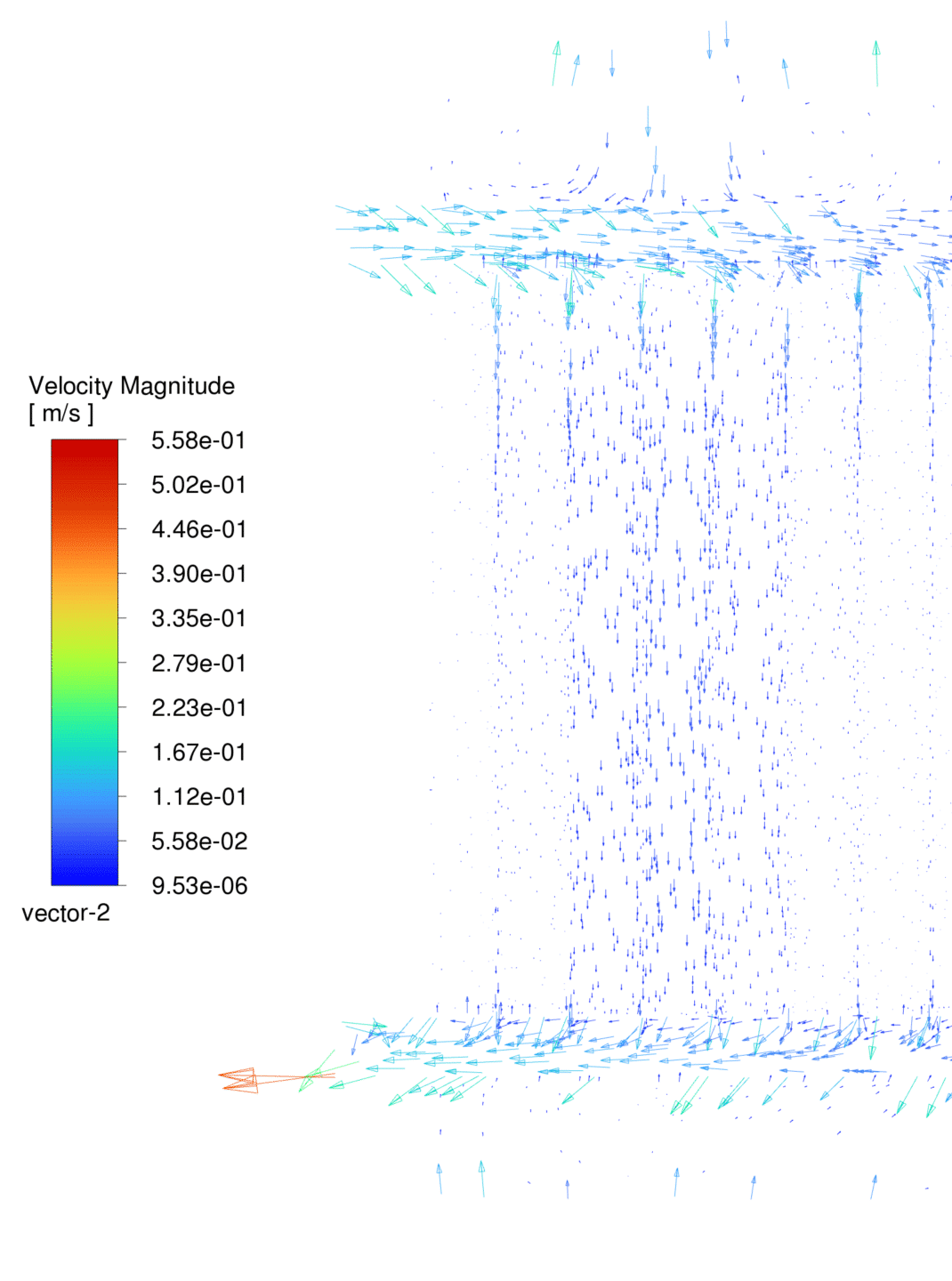

The CFD simulation results for the shell and plate heat exchanger provide comprehensive insights into its thermal and fluid dynamic performance. Temperature distributions, shown in both cross-sectional and longitudinal views, illustrate the effective heat transfer between the hot ammonia in the shell and the cold water in the channels. The contours demonstrates the cooling of the hot fluid and the warming of the cold fluid along the exchanger length. Pathlines visualize the complex flow patterns within the exchanger, highlighting areas of turbulence that enhance heat transfer. The velocity magnitude contours show higher velocities near the inlets and outlets, with more uniform flow in the central regions of the exchanger. This flow distribution contributes to the overall heat transfer efficiency. The vector field representation of temperature further emphasizes the directional nature of heat transfer, with vectors pointing from hot to cold regions. Collectively, these visualizations confirm the exchanger’s effectiveness in facilitating heat transfer between the two fluids while providing valuable information on flow distribution and potential areas for design optimization.

Reviews

There are no reviews yet.