Silicone Thermal Paste CPU with a Heat Sink CFD Simulation by ANSYS Fluent

$80.00 $40.00 Student Discount

- Simulate forced convective cooling of a heat sink to dissipate 100 W of thermal power from a CPU with silicone thermal paste.

- Copper plate, silicone thermal paste, and aluminum heat sink with seven fins.

- Forced air flow at 7 m/s removes thermal energy through convection.

- CFD simulation using the k-ω SST turbulence model in ANSYS Fluent.

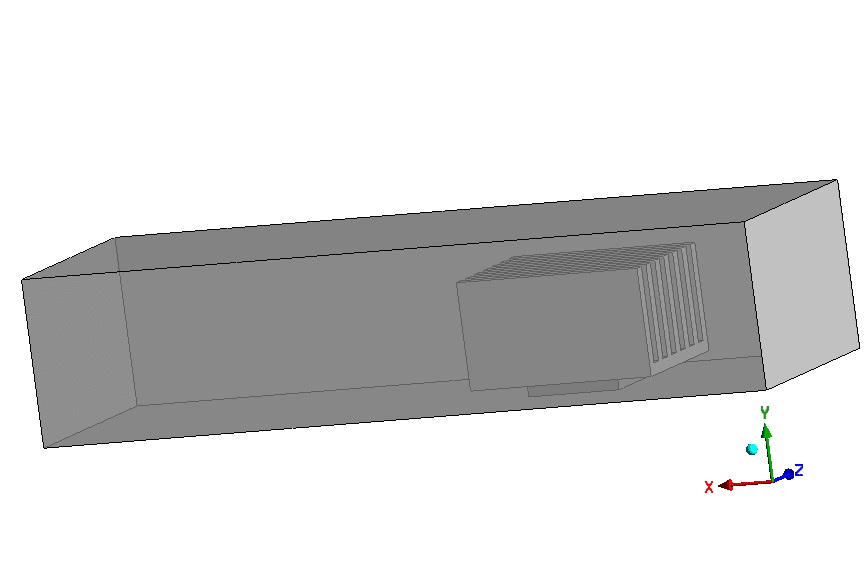

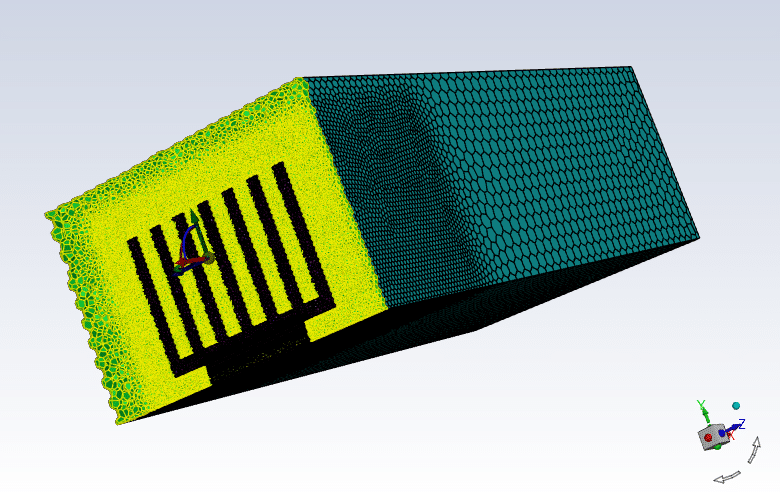

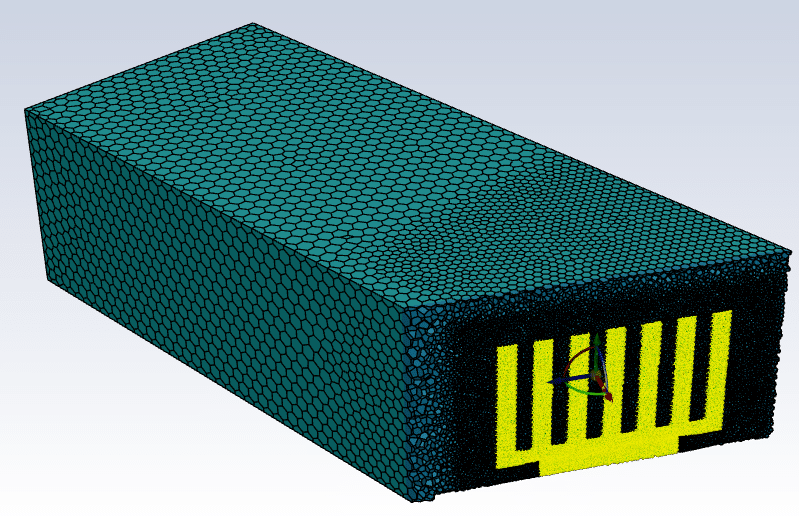

- The model was designed in Design Modeler for simulation.

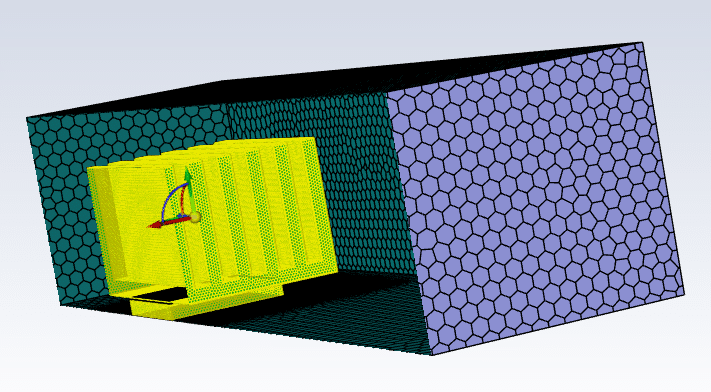

- The simulation uses 1,477,676 mesh elements in Fluent Meshing for accuracy.

- Heat sink assembly ensures efficient cooling and maintains safe operating temperatures for the CPU.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Overview

Electronic components such as CPU, chips and microprocessors generate heat, making thermal management essential for their longevity and performance. As these components become smaller, the design of heat sinks plays a crucial role in dissipating heat.

Heat sinks typically have fins that increase surface area and improve heat transfer. Heat is conducted to the fins and then transferred to the surrounding air through convection (either natural or forced). In laptops and desktop computers, fans direct cool air onto the heat sink, dissipating the heat.

This project simulates the forced convective cooling of a thermal heat sink to cool silicone thermal paste CPU. The heat sink assembly consists of a copper plate, silicone thermal paste and an aluminum heat sink. In this model, 100 W of thermal power is applied to the copper plate surface. Cold air is forced over this heat sink, thereby removing thermal energy. The primary objective of this simulation is to predict the steady-state average temperature of this copper plate.

Methodology

- An silicone thermal paste CPU component is generating 100 W of a thermal power. This CFD model simulates the dissipation of this thermal energy into a stream of cold air blowing over a heat sink

- The heat sink assembly comprises of a copper plate, silicone thermal paste and an aluminum heat sink. The thermal energy, which is conducted by this heat sink from the copper plate, is dissipated into the flowing stream of cold air through convection.

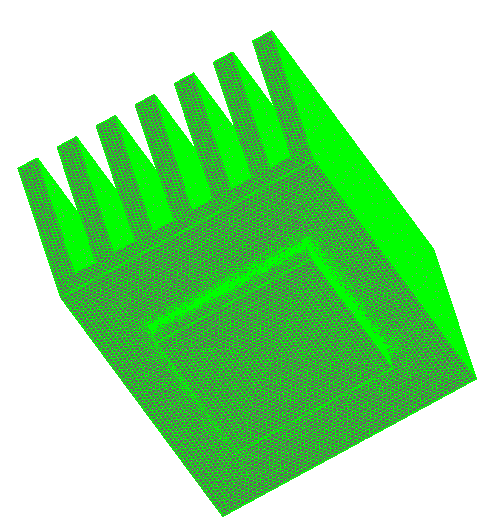

- copper plate dimensions (40 mm * 5 mm * 40 mm)

- silicone thermal paste dimensions (40 mm * 1 mm * 40 mm)

- heat sink dimensions (40 mm * 1 mm * 40 mm)

- fin dimensions (80 mm * 40 mm * 5 mm)

- Number of fins – 7

- Fluid dimensions (320mm * 70 mm * 105 mm)

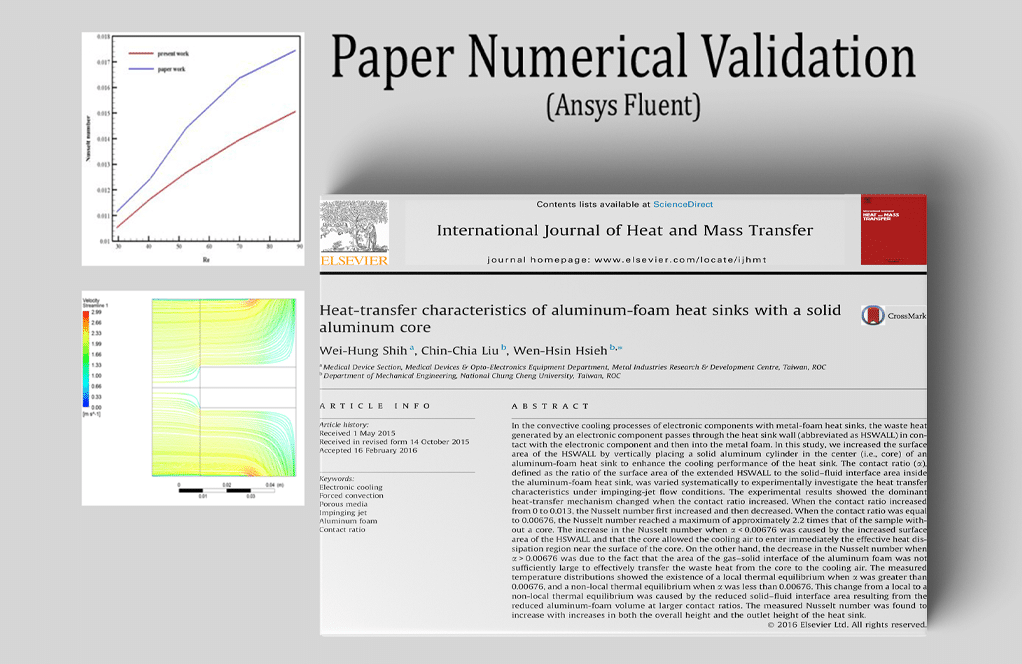

Flow Reynolds number at the inlet boundary is 40,250. A Turbulent viscous model (K-W SST) is employed in this project.

- Boundary condition

- Air inlet: u = 7 m/s, T = 303 K.

- Outlet: open to atmosphere

- Heat source: 62500 W / (m . m)

- Fluid walls: adiabatic

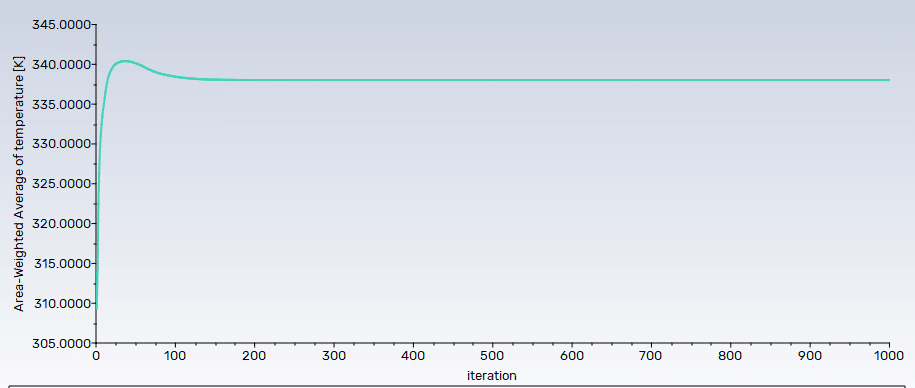

- A steady – state solution is obtained using the pressure – based coupled solver in ANSYS Fluent.

Results and Discussion

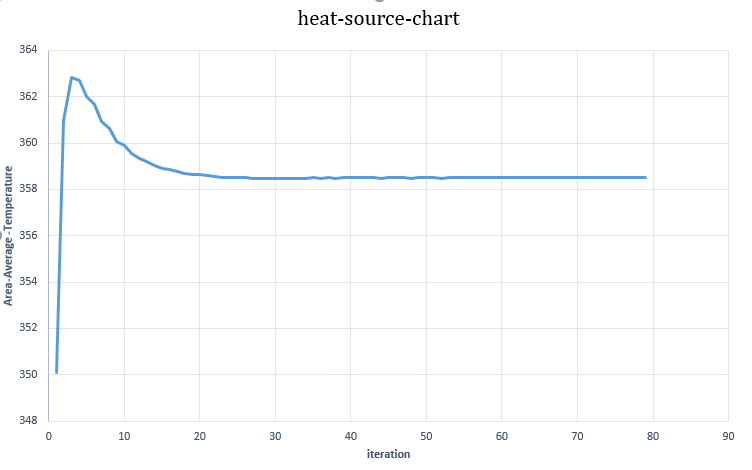

The simulation successfully models the forced convective cooling of a heat sink designed to dissipate 100 W of thermal power from a CPU component with silicone thermal paste. The steady-state analysis provides insights into the thermal behavior of the system and its cooling efficiency.

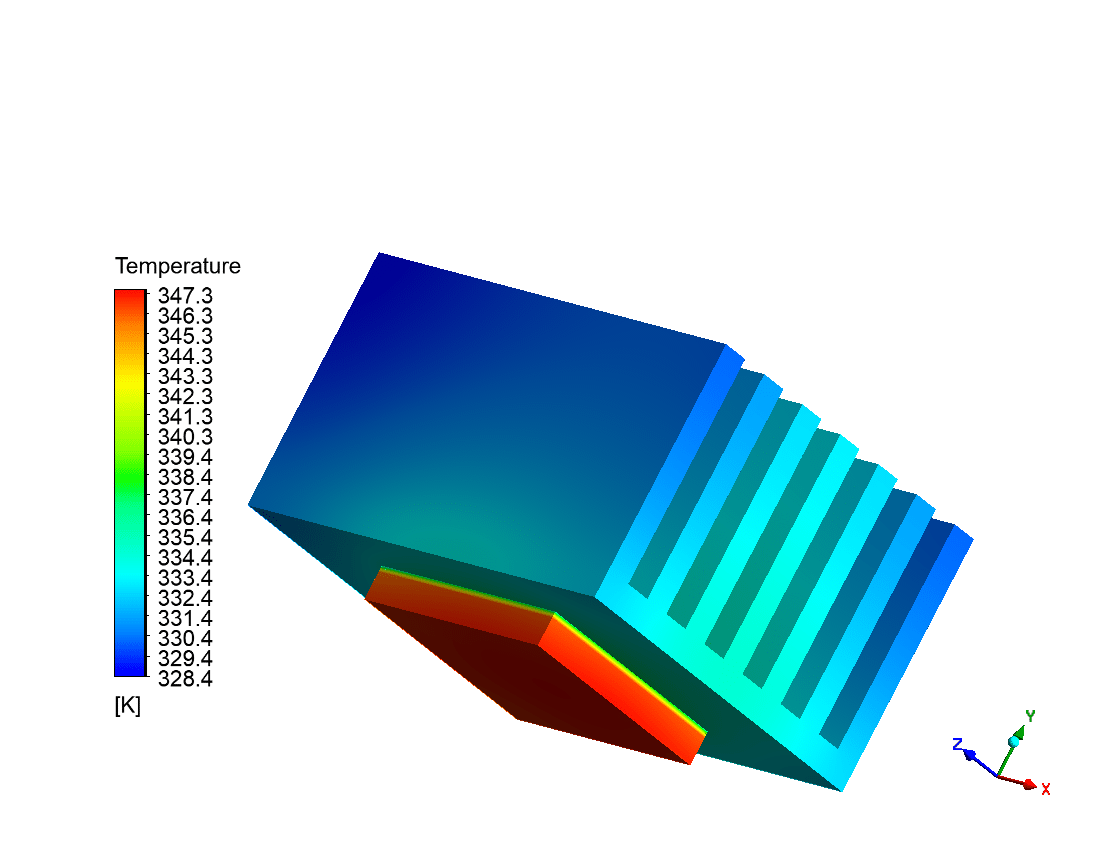

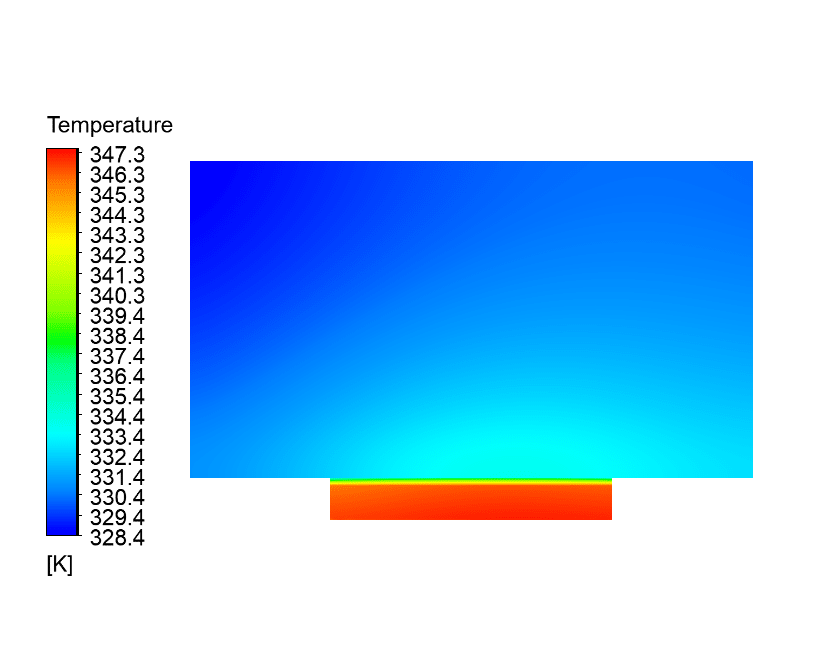

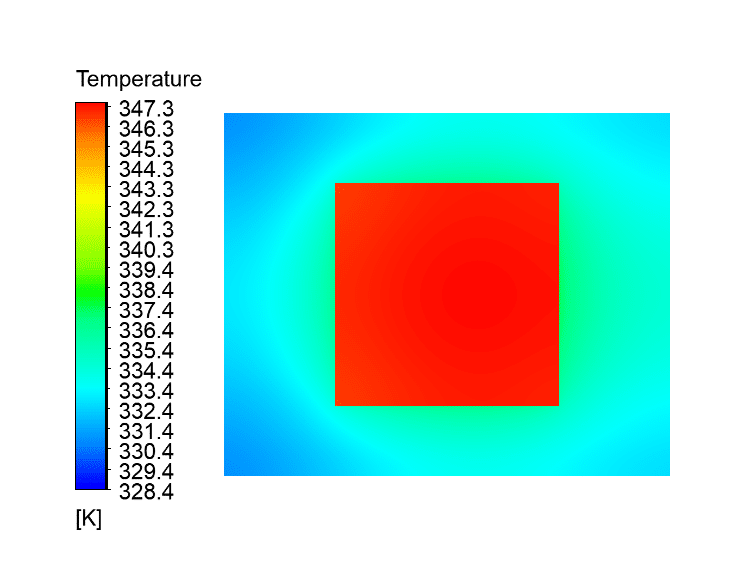

Temperature Distribution

The results indicate that the steady-state average temperature of the copper plate stabilizes at a value that ensures efficient heat dissipation. The presence of seven fins significantly enhances heat transfer by increasing the surface area available for convection. The aluminum heat sink effectively conducts heat away from the copper plate, while the forced airflow at 7 m/s further promotes cooling.

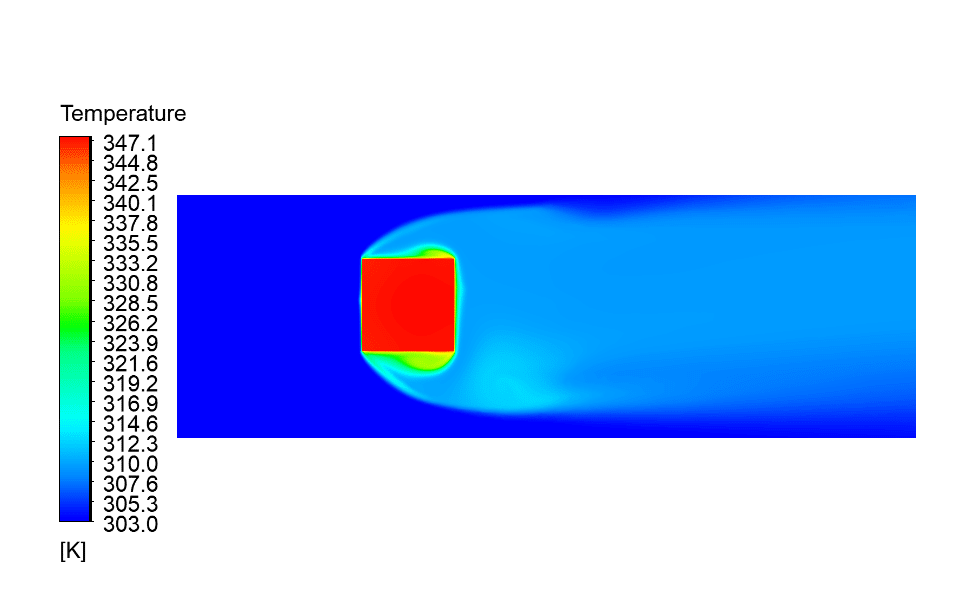

Flow Characteristics

With an inlet Reynolds number of ~ 40,250, the flow remains in the turbulent regime, which improves convective heat transfer. The k-ω SST turbulence model accurately captures flow separation and reattachment around the fins, contributing to a precise prediction of thermal performance.

Key Observations

- The heat sink efficiently transfers heat to the surrounding airflow, preventing excessive temperature rise.

- The temperature gradient across the copper plate, silicone thermal paste, and aluminum heat sink aligns with expected conduction and convection behavior.

Conclusion

The simulation confirms that the heat sink assembly effectively cools the CPU component under the given conditions. The forced convection mechanism, supported by turbulent airflow, enables efficient thermal management, ensuring that the component operates within safe temperature limits. These insights can aid in optimizing heat sink designs for improved cooling performance in electronic systems.

Reviews

There are no reviews yet.