Single Tubular Porous Reactor, Numerical Investigation of Flow and Heat Transfer

$200.00 $100.00 Student Discount

- In this project, we have simulated the performance of a Porous Media Reactor Tube with the presence of catalyst using ANSYS Fluent software.

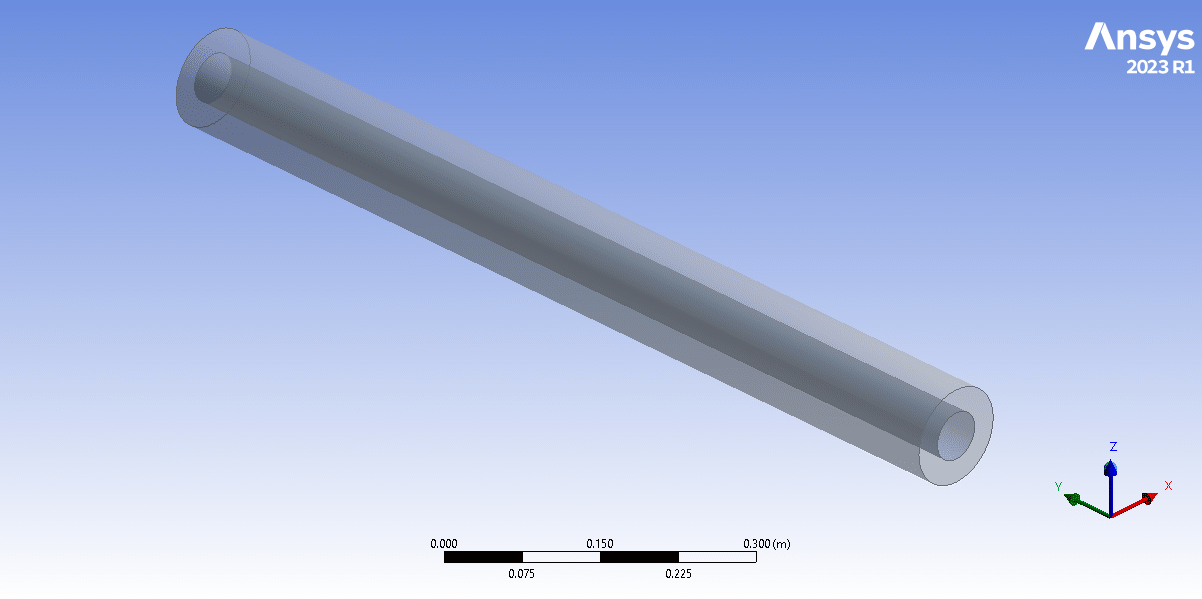

- Three-dimensional modeling was done using Design Modeler software.

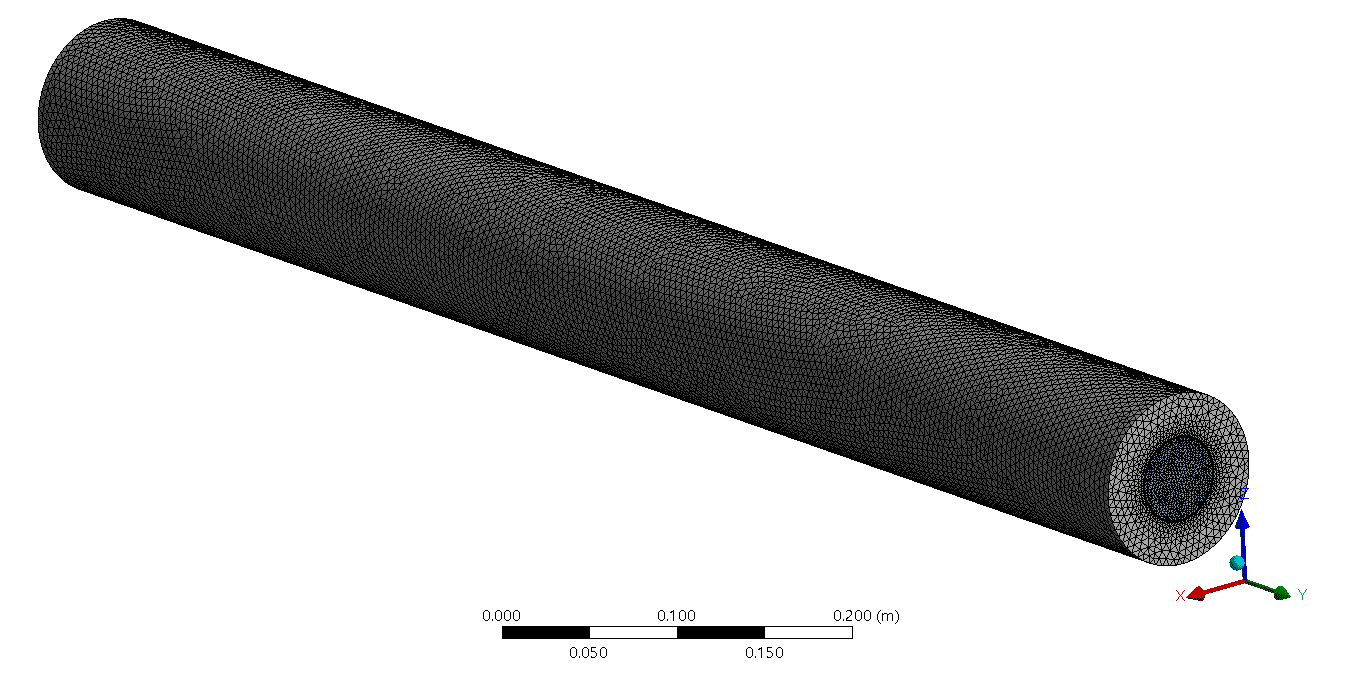

- The meshing of the model has been done using ANSYS Meshing software and the element number equals 4,255,042 .

- To simulate the behavior of molten salt and reactor inlet flow, the multiphase VOF Eulerian model is utilized.

- The porous media model is employed to impact the flow inside the reactor.

- For the reactions, the species transport model with two reactions is used.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

The Single Tubular Porous Reactor with Molten Salt Catalyst is a significant innovation in the field of chemical engineering. It is a reactor system that uses a porous medium, typically a solid structure with interconnected voids, to enhance the efficiency of chemical reactions. The molten salt catalyst, a mixture of salts in a liquid state, is utilized within this porous structure.

The molten salt catalyst provides an excellent medium for chemical reactions due to its high thermal stability, ability to dissolve a wide range of reactants, and excellent heat transfer properties. The porous media reactor tube allows for the efficient distribution of the molten salt catalyst, enhancing the surface area available for the chemical reaction.

This leads to increased reaction rates and improved yield of the desired products. Moreover, the combination of porous media and molten salt catalyst can be tuned to specific chemical reactions, making this system versatile and adaptable to various industrial processes. The porous media reactor tube with molten salt catalyst is thus a promising technology for future sustainable and efficient chemical production.

In this simulation, the reactor tube is modeled using ANSYS Fluent software. The simulation’s geometry was created with Design Modeler software, and all the necessary data was provided. We used ANSYS Meshing software to generate a mesh grid and chose an unstructured grid with tet elements. We ensured the boundary layer had five orthogonal elements, resulting in 4,255,042 elements.

Methodology: Single Tubular Porous Reactor, Numerical Investigation of Flow and Heat Transfer

To simulate the behavior of molten salt and reactor inlet flow, the multiphase VOF Eulerian model is utilized. The Porous Media model is employed to represent the flow inside the reactor.

Additionally, for the reactions, the Species Transport model with two reactions is used to provide accurate results.

Conclusion

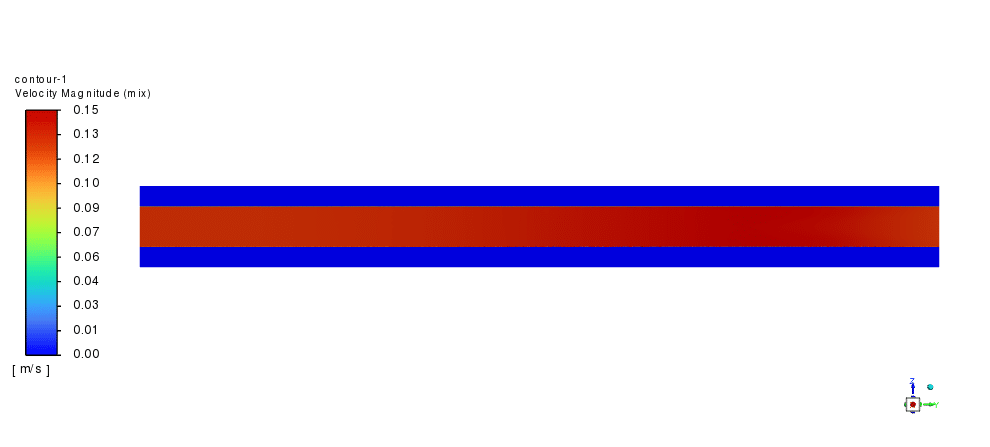

The simulation process is a critical step in understanding the behavior of various parameters in a given system. After the simulation, we obtained contours and vectors for parameters such as velocity, pressure, and species. These visual representations provide a clear and comprehensive picture of the behavior and interaction of these parameters within the system.

One significant observation was the velocity contours. These contours serve as a visual representation of the disturbance of velocity within the porous media. The porous media, acting as a filter, can significantly affect the velocity of the flow. By examining the velocity contours, we can understand how the flow is disturbed as it passes through the porous media and how it might affect other parameters.

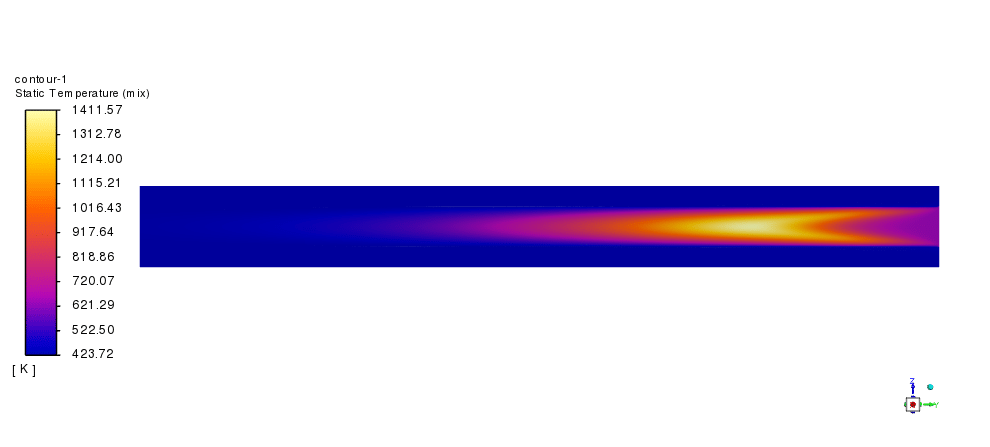

In addition to the velocity contours, the temperature contours were also obtained. These contours illustrate the distribution of temperature within the tractor tube. It was observed that the temperature exchanges heat with the molten salt and eventually reaches a stable temperature point. This heat exchange process is crucial as it can significantly impact the efficiency and performance of the system.

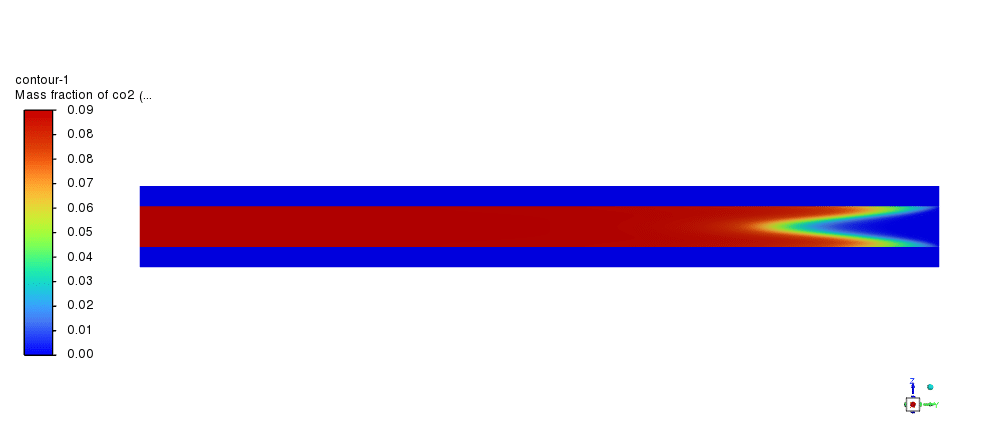

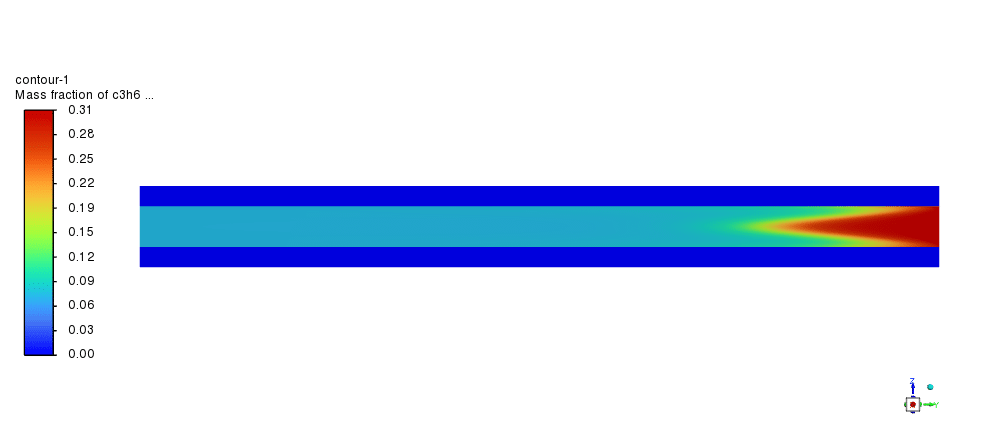

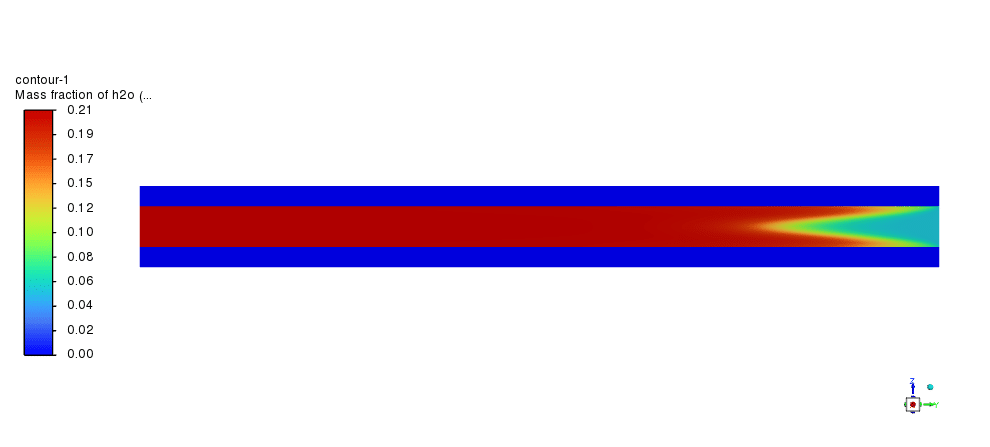

Furthermore, the disturbance of the species contour was also analyzed. This contour shows the generation and usage of reactants and products inside the reactor tube. It provides an understanding of the chemical reactions inside the tube and how they affect the overall process. By analyzing the value of each mass fraction, we can understand the proportion of each species in the mixture and how it changes over time.

Overall, the simulation process provided valuable insights into the behavior of various parameters within the system. It allowed us to understand the disturbance and distribution of velocity, temperature, and species inside the reactor tube and porous media. These insights can be used to optimize the system and improve its efficiency and performance.

Prof. Kendall Bins –

I just completed the simulation on Single Tubular Porous Reactor using ANSYS Fluent, and it was remarkable. The detailed methodology allowed me to fully understand the interactions within the reactor. The clarity of the contours and vectors made it easy to visualize the results and comprehend the system’s behavior.

MR CFD Support –

We’re thrilled to hear that our simulation product helped you achieve a deep understanding of the Single Tubular Porous Reactor system. Visualization is key for complex systems, and we’re glad the contours and vectors were clear and useful for your analysis. Thank you for choosing our ANSYS Fluent simulation, and we look forward to providing you with more high-quality learning products in the future.

Mrs. Eleanora Wehner Sr. –

I am immensely impressed by the comprehensive simulation of the Single Tubular Porous Reactor. The attention to detail in setting up the flow and reacting conditions through porous media to observe heat and mass transfer is commendable. Well done on achieving stability and clear visual results. It enhances understanding of the reactor’s functionality immensely.

MR CFD Support –

Thank you for recognizing our efforts with the Single Tubular Porous Reactor simulation. We strive to create detailed and accurate simulations to help understand complex chemical processes and appreciate your positive feedback. If you’re interested in further information or have any questions regarding the reactor or the simulation process, please do not hesitate to contact us.

Arnaldo Gerlach –

The illustrations of velocity and temperature contours were instrumental in understanding the system. The detail in conveying how the porous media influenced the flow and the stabilization effects on temperature were eye-opening. Eager to implement these insights in our work!

MR CFD Support –

Thank you for your positive feedback on our simulation illustration for the Single Tubular Porous Reactor! We are thrilled to hear that the detail provided in the velocity and temperature contours helped you better understand the system’s intricacies. It’s fulfilling to know that the information presented is not only helpful but also actionable in your work. If you have any further questions or need assistance with implementing these insights, please don’t hesitate to reach out to us. We’re here to support your efforts in optimizing efficiency and performance.

Elsie Ratke –

The simulation was straightforward and the results were easy to interpret thanks to the clear visuals. It really highlighted the importance of the porous medium in enhancing reaction efficiency!

MR CFD Support –

Thank you for your positive review! We’re glad to hear that the simulation provided clear and interpretable results, and that the role of the porous medium was well demonstrated. If you have any more questions or need further information, please feel free to reach out to us. We’re here to help!

Alysa Fay –

Wonderful simulation design details on the Single Tubular Porous Reactor! I love how informative your description is. It seems like a truly innovative approach to chemical reaction optimization. Thanks for providing such a clear understanding of the process and its benefits.

MR CFD Support –

Thank you for your review and appreciation of the Single Tubular Porous Reactor’s simulation! It’s wonderful to hear how our detailed description has helped to provide clarity. We’re thrilled that the innovation and applications excited you. Your feedback is invaluable. If you have further questions or another area you’re curious about, feel free to ask!

Nat Herzog DDS –

I am thrilled with the way that the Single Tubular Porous Reactor simulation makes it easy to understand complex flow interactions and heat transfer mechanisms. The visual outputs such as contours and vectors are particularly insightful, shedding light on the efficiency of this chemical process.

MR CFD Support –

We’re so glad to hear that the simulation outputs were able to clarify the complex interactions in the Single Tubular Porous Reactor. Clear visualizations are crucial for understanding these dynamics, and we are pleased that they have aided in your comprehension of the process efficiency. Thank you for your positive feedback!

Lelia Treutel –

The visuals from this simulation sound intriguing. Could you possibly share any insights into how the flow of the molten salt within the porous media affects the efficiency of the chemical reactions?

MR CFD Support –

Unfortunately, I cannot provide any additional insights apart from what is shared in the description. However, from what is described, it is clear that the flow of molten salt within the porous media plays a crucial role in enhancing the efficiency of the chemical reactions by ensuring proper distribution of the catalyst and optimizing the surface area for reactions. The disturbances in velocity, as depicted by the velocity contours, contribute to increased interaction between reactants and the molten salt, thereby influencing reaction rates and efficiencies.

Joyce Cruickshank –

I’ve learned a lot from this successful simulation about the tubular porous reactor. The interplay of heat transfer and fluid dynamics in this application is simply impressive!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the information about the single tubular porous reactor simulation insightful and that you were impressed with the interplay of heat transfer and flow dynamics showcased in our study. Your appreciation motivates us to continue delivering high-quality simulations and analyses. If you have any further questions or need more information, feel free to reach out.

Dr. Nelle Hansen –

The depth of detail in the simulation is impressive! The careful considerations in modeling the flow and heat transfer within the Single Tubular Porous Reactor shed light on key processes. It’s clear that these insights could be instrumental in refining the design to maximize efficiency and performance.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the thoroughness and level of detail in our Single Tubular Porous Reactor simulation have been met with your satisfaction. We strive to provide comprehensive data that aids our customers in enhancing their systems’ performance.

Jamison Parker –

I’ve read about the detailed work on the Single Tubular Porous Reactor simulation and how everything was meticulously set up in ANSYS Fluent. I’m just curious, was any specific flow regime (e.g., laminar, turbulent) assumed in the numerical simulation for the flow of the molten salt catalyst within the porous medium, and how was this influencing the results?

MR CFD Support –

In this simulation, if the goal is replicating realistic operating conditions, the flow regime within the porous reactor, whether laminar or turbulent, would typically be determined based on the calculated Reynolds number or specified explicitly based on expected operating conditions. Given the properties of molten salts and the potential high temperatures involved, it’s quite plausible that the simulation would use a turbulence model suitable for capturing the complex behaviors of the flow. Such details would directly affect predictions of species distribution, reaction rates, and overall heat transfer properties, which are crucial for designing an efficient and effective reactor.

Naomie Davis Jr. –

I’m really curious about how you were able to set up and monitor the species transport within the reactor. Was this process complex to simulate?

MR CFD Support –

In ANSYS Fluent, the Species Transport model is used to simulate the distribution and reaction of chemical species within the reactor. Setting up the species transport model involves defining each chemical species present, their initial concentrations, and the specific reaction rates. You can monitor the concentration of each species over time or within different reactor sections by visualizing contour plots. Although complex, this process is manageable due to the detailed user interface of ANSYS Fluent and its extensive models and options for chemical reaction simulations.

Kirk Fritsch –

The tubular porous reactor simulation sounds highly advanced. Just wondering, what were the challenges faced during the simulation, particularly with regard to the mesh generation around the porous media?

MR CFD Support –

Thank you for your inquiry about the simulation of the Single Tubular Porous Reactor. Meshing around the porous media can be challenging due to the need to capture the small scale geometries and void spaces accurately. Creating a fine enough mesh to resolve the local gradients without overly increasing the computational cost is one of the main challenges. In this simulation, an unstructured grid with tetrahedral elements was chosen, considering both the complexity of the porous structure and the computational efficiency. The strategy ensured that the boundary layer had five orthogonal elements, which are critical for capturing boundary effects while maintaining a manageable total number of elements.