Solar Indirect Dryer CFD Simulation, ANSYS Fluent

$160.00 $80.00 Student Discount

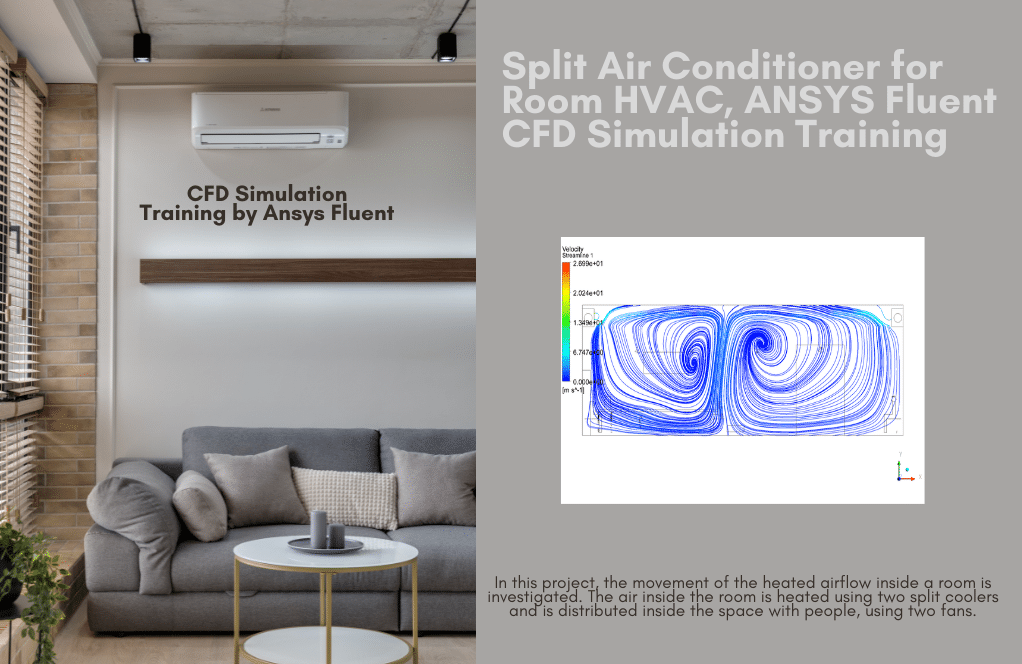

- In this project, the airflow within a solar indirect dryer is simulated using ANSYS Fluent.

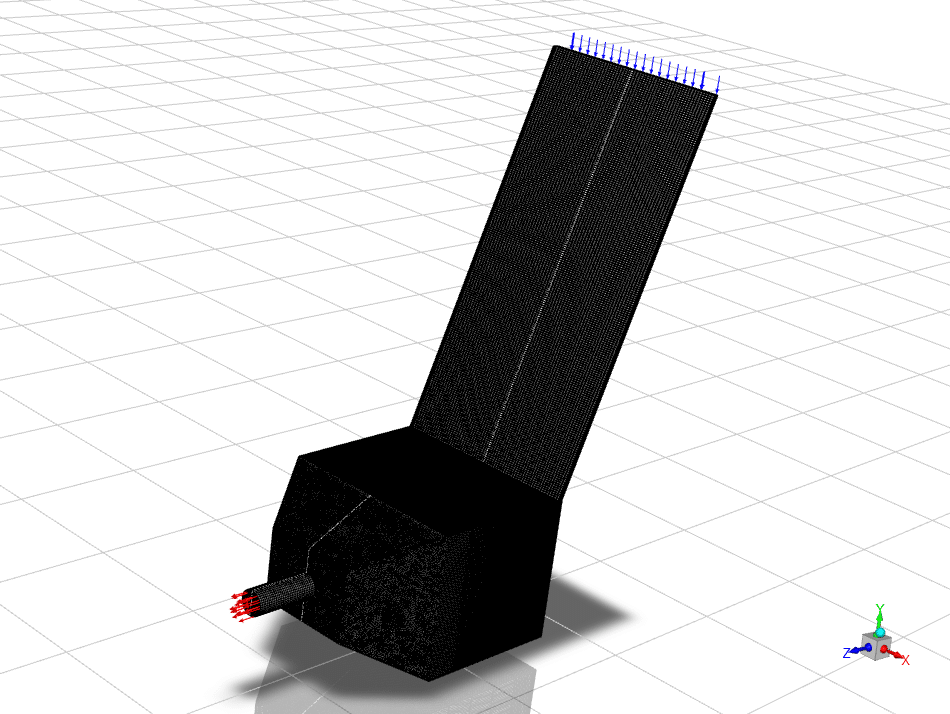

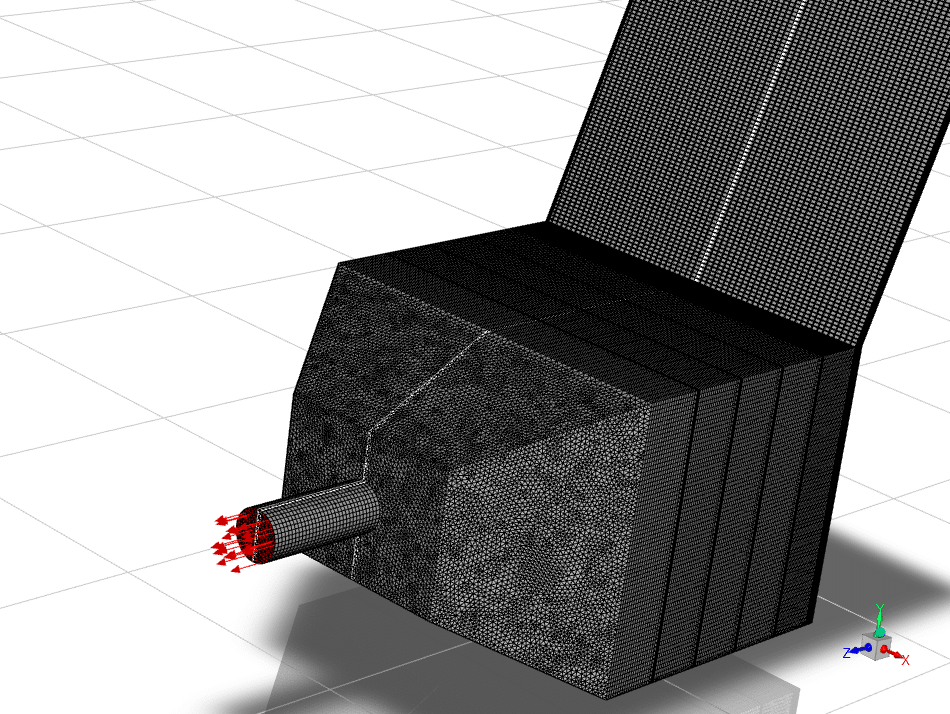

- The geometry was designed in SpaceClaim, and a mesh with 1,330,000 elements was generated using ANSYS Meshing.

- In this simulation, the food trays are modeled as porous.

- DO is chosen for the radiation model.

- The density model in the material is chosen as incompressible ideal gas.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

A solar indirect dryer is a passive method of ventilation that operates based on solar energy. In fact, it consists of two parts: The first is a collector that absorbs heat radiation from the Sun, and the second is a chamber where food or fruit is arranged in trays. Air flows through these trays and removes moisture from them.

The temperature of the collector walls increases as they absorb solar radiation, which causes the air inside the collector to warm up. As the temperature of the air increases, its density decreases, and the air starts to flow upward due to the buoyancy effect.

In this project, an indirect solar dryer was simulated in Egypt on July 1 at 12:00 PM. The collector has a surface area of 8 m², and the chamber can accommodate four trays.

The geometry was designed in SpaceClaim, and a mesh with 1,330,000 elements was generated in Ansys Meshing.

Methodology

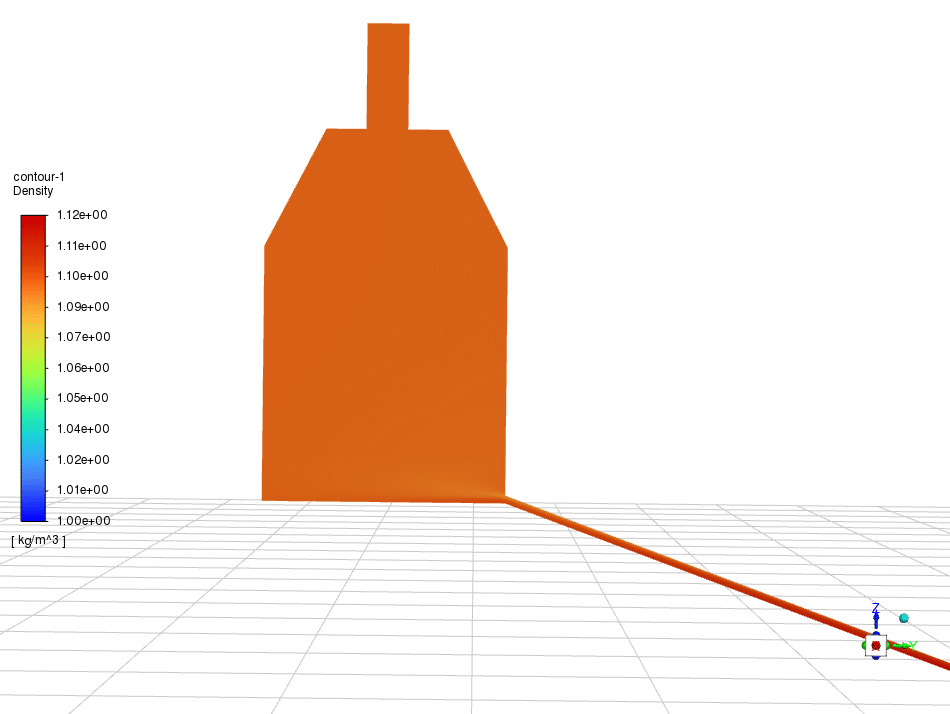

According to the physics of this problem, we need to capture the density difference with temperature for the buoyancy effect. Therefore, the density model in the material is chosen as “incompressible ideal gas,” and the operating density is specified at 1.225 kg/m^3.

The energy model is activated, as well as the radiation model, and DO is chosen for the radiation model because the air participates in the radiation. Solar ray tracing is used to take solar radiation into account.

To show the effect of the trays and foods on the flow and pressure drop in the simulation without explicitly meshing their intricate geometry, a porous medium has been utilized.

Conclusion

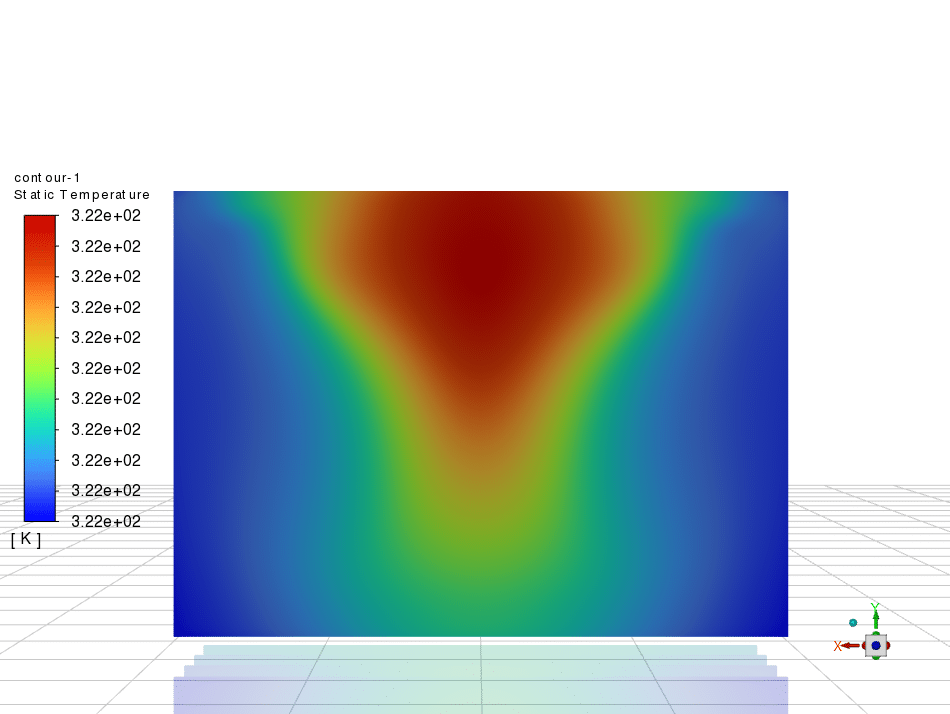

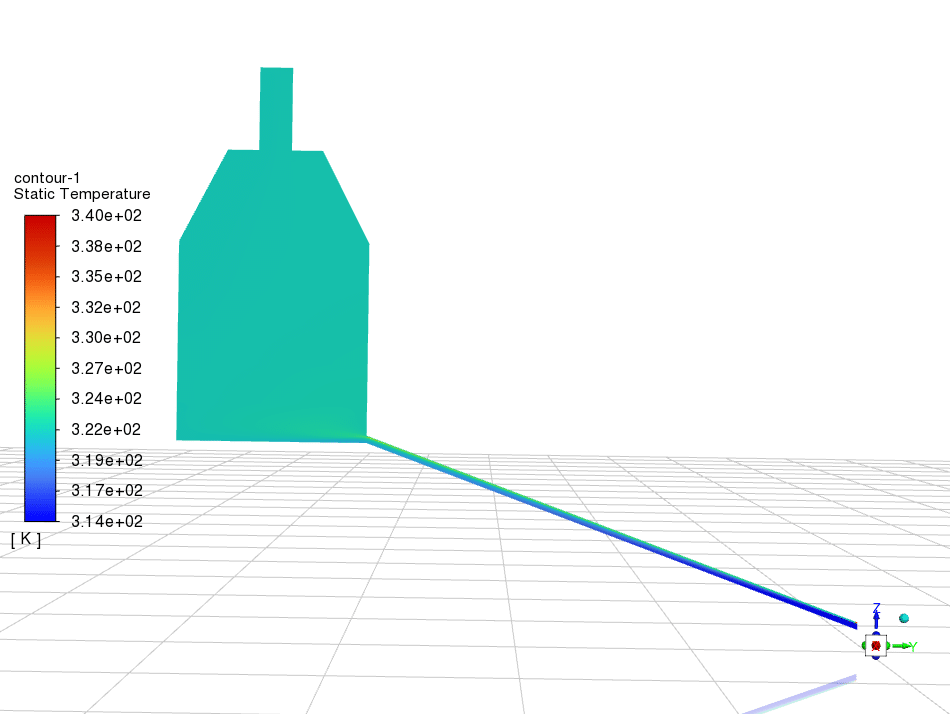

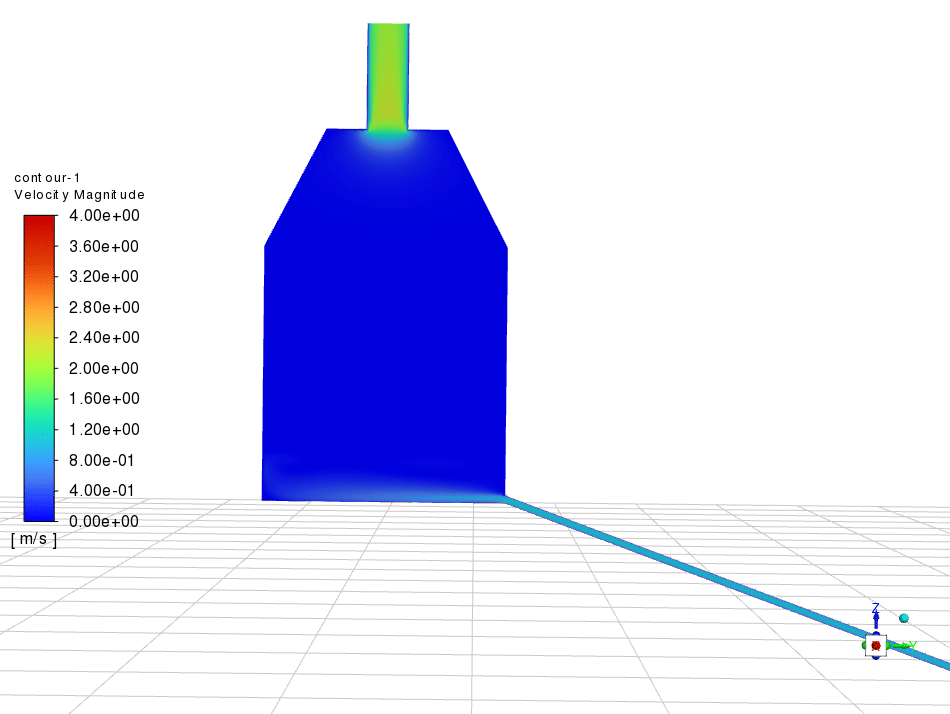

As a result, the velocity and temperature contours are reported. The temperature and density contours indicate that air near the wall absorbs heat, leading to a decrease in its density. At the inlet, the air temperature is 314 K, and after passing through the collector, its temperature reaches 322 K. Concurrently, its density decreases from 1.225 at the inlet to 1.095851 at the exit of the collector. Therefore, due to buoyancy, the air rises.

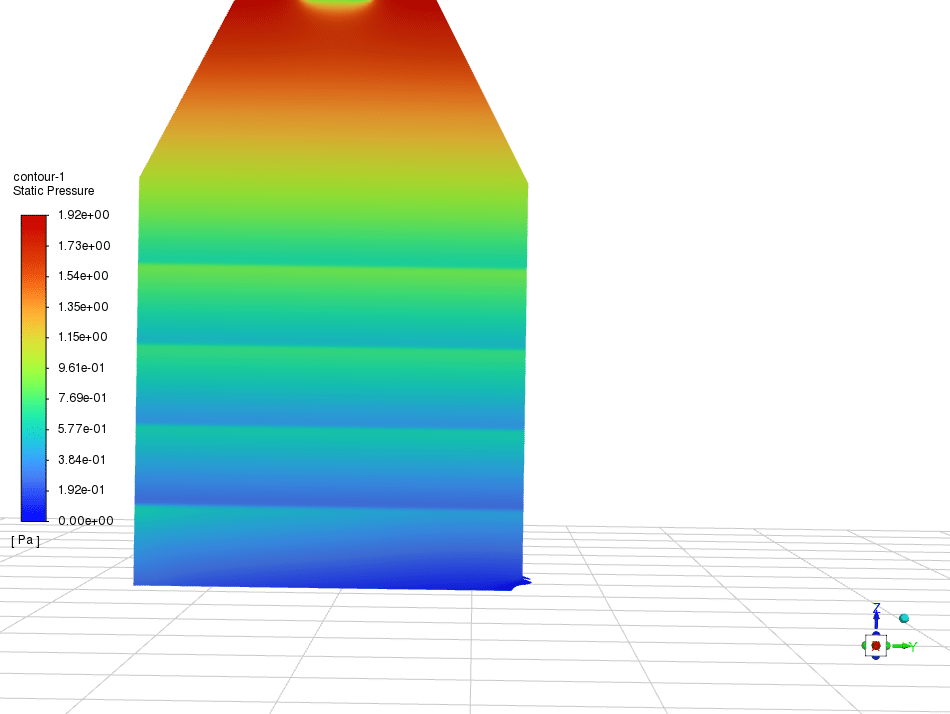

The pressure contour indicates a pressure drop as air passes through the trays. Heat transfer from the collector walls to the air causes a natural airflow with a mass flow rate of 0.0908 kg/m³ in the dryer.

Reviews

Related products

-

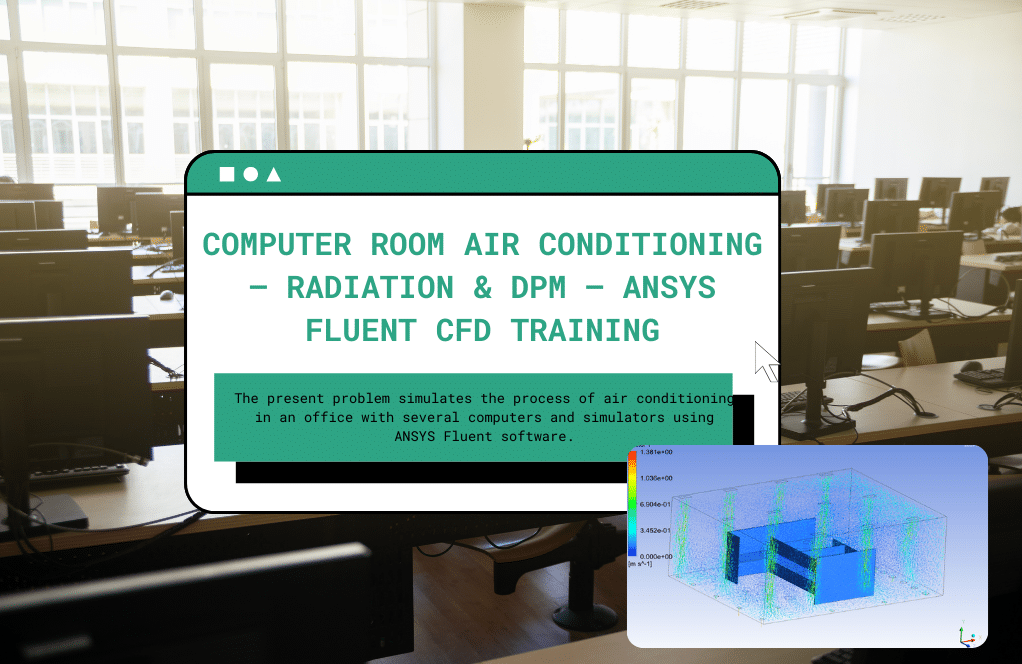

Computer Room Air Conditioning CFD Simulation, DPM

Rated 4.50 out of 5$160.00$80.00 Student Discount

Marielle Will –

I appreciate your dedication. The results of this simulation are critical for understanding natural airflow in solar dryers. Thanks for a great product!

MR CFD Support –

We’re thrilled to hear that you’re satisfied with the simulation results and it fulfills its educational purpose. Thank you very much for your kind words and for choosing our product!

Therese Considine –

What specific features of ANSYS Fluent were most helpful in simulating the solar indirect dryer?

MR CFD Support –

In this simulation, ANSYS Fluent features like the “incompressible ideal gas” density model, the energy model, the Discrete Ordinates (DO) radiation model, and solar ray tracing, were particularly beneficial as they enabled accurate capture of the buoyancy effect, temperature-dependent air density changes, solar radiation impact, and the realistic simulation of airflow and heat transfer within the dryer.

Freida Krajcik –

I’m so impressed by how the solar indirect dryer efficiently uses solar energy for drying purposes. The design seems innovative, and the details provided about the simulation method reassure me about its accuracy and functionality. A job well done indeed!

MR CFD Support –

Thank you so much for the kind words and for recognizing the efforts behind our simulation work. We’re delighted to hear that the product has lived up to your expectations and that the innovative design has impressed you. If you have any more inquiries or need further assistance, feel free to reach out to us.

Allene Wiegand –

I’m really impressed with the level of detail in this solar indirect dryer simulation. The way the buoyancy effects and the porous medium were handled sounds fascinating!

MR CFD Support –

Thank you very much for your appreciation! We’re delighted to hear that the simulation’s details and our efforts to meticulously model the dynamics of solar indirect drying impressed you. If you have any further questions or require more information on our simulations, we’re here to help.

Abraham Schulist –

Very appreciative of how the simulation captures the solar drying process complexity! Truly showcases the power of ANSYS Fluent in modeling renewable energy systems.

MR CFD Support –

Thank you so much for your positive feedback! We’re glad you recognize the capabilities of ANSYS Fluent in bringing renewable energy simulations to life. Your appreciation motivates us to keep providing high-quality simulation experiences.

Florida Purdy DDS –

The detailed insights on heat transfers and air velocity make the CFD analysis highly comprehensive. A well-simulated process that provides a clear picture of how effective a solar indirect dryer can be, especially with respect to energy utilization and moisture removal efficiency. Great work on executing complex simulations and presenting them in an understandable manner.

MR CFD Support –

Thank you for your kind words and positive feedback on our CFD simulation of a solar indirect dryer. We are thrilled to hear that our efforts to present the data in an accessible and comprehensive way have been successful. Your appreciation motivates us to continue providing high-quality simulations and clear insights into various phenomena. If you ever have more questions or need further information on our simulations and services, please don’t hesitate to contact us.