Solid Oxide Fuel Cell, SOFC, Cooling System, CFD Simulation

$300.00 $150.00 Student Discount

- The problem numerically simulates Fuel Cell with Cooling System using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 4,984,882.

- We use the Fuel Cell and Electrolysis Model to define a fuel cell.

- We used the SOFC sub-model to define a solid oxide fuel cell.

- We used the Species model to define H2, O2, and H2O.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Solid Oxide Fuel Cell, SOFC, Cooling System, CFD Simulation, ANSYS Fluent Tutorial

Description

In this project, we perform the numerical simulation of a Fuel Cell with a Cooling System using ANSYS Fluent software.

This product is the 5th chapter of the Fuel Cell Training Course.

A fuel cell is an energy conversion device that converts the chemical energy of fuel into electrical energy. A fuel cell produces electricity through a chemical reaction. Fuel cells have two electrical poles (electrodes) called anode and cathode. These chemical reactions take place in these electrodes and lead to the production of electricity.

In addition, fuel cells have an electrolyte and a catalyst. The electrolyte layer is used to transport charged particles (ions) between the electrodes, while the catalyst layer increases the speed of reactions in the electrode layers. The hydrogen is fed to the fuel cell as the main fuel. However, oxygen is also required for the reaction to take place

.One of the most important advantages of the fuel cell is that electricity is produced with the least amount of pollution. In fact, most of the oxygen and hydrogen input to the fuel cell is eventually released in the form of a harmless byproduct, that is, water. Another advantage of fuel cell is that fuel cell produces electricity chemically and not by combustion reaction. Therefore, the fuel cell is more efficient in producing energy from fuel.

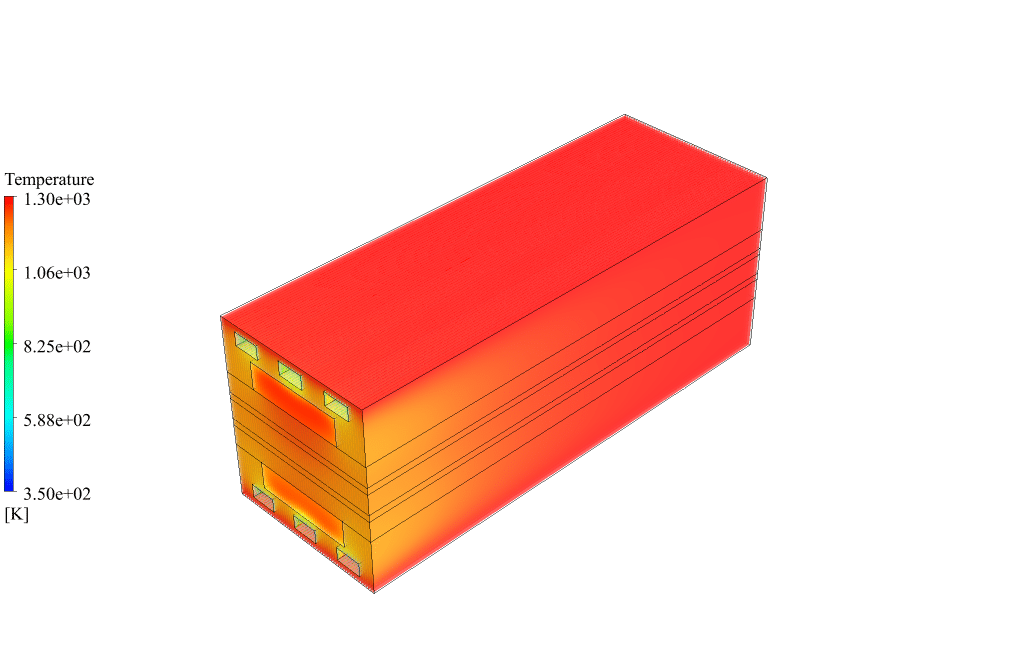

There are different types of fuel cells. In this project, we have simulated the solid oxide fuel cell (SOFC). Solid oxide fuel cells operate at very high temperatures. Therefore, we have used a cooling system in these fuel cells. In this way, we have placed two rows of cooling channels on both sides of the anode and cathode of the fuel cell.

We simulated this project based on the CFD method by ANSYS Fluent software. First, we designed the geometry of the model in 3D using Design Modeler software. The computational domain of the model is related to the interior space of a fuel cell. Then, we meshed the model using ANYS Meshing software. The meshing is unstructured, and 4,984,882 cells are generated. Finally, we performed the simulation process in Fluent software.

SOFC Methodology

For this simulation, we used the fuel cell model in Ansys Fluent software. The fuel cell model is an add-on module in Ansys Fluent software. There are three different fuel cell add-on modules available in the software. We have used the fuel cell and electrolysis model. Here, there are three submodels. We have used the SOFC model.

In the fuel cell model setting, we determine the different layers of the fuel cell. These layers include the cathode and anode layers, along with the electrolyte layer. Each of the anode and cathode layers consists of current collectors, gas diffusion layers (electrode layers), catalyst layers, and flow channels. Since we used the cooling system for this fuel cell, we need to use the coolant channel option.

Also, the species transport model is automatically activated. The species transport model defines the species present in the fuel cell, including H2, O2, and H2O.

SOFC Conclusion

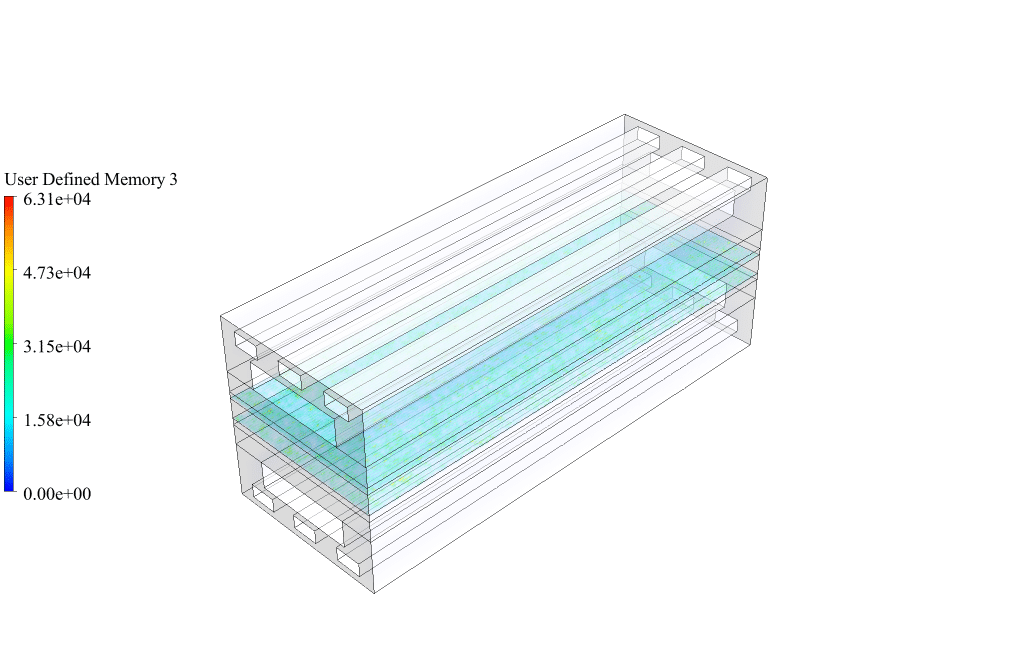

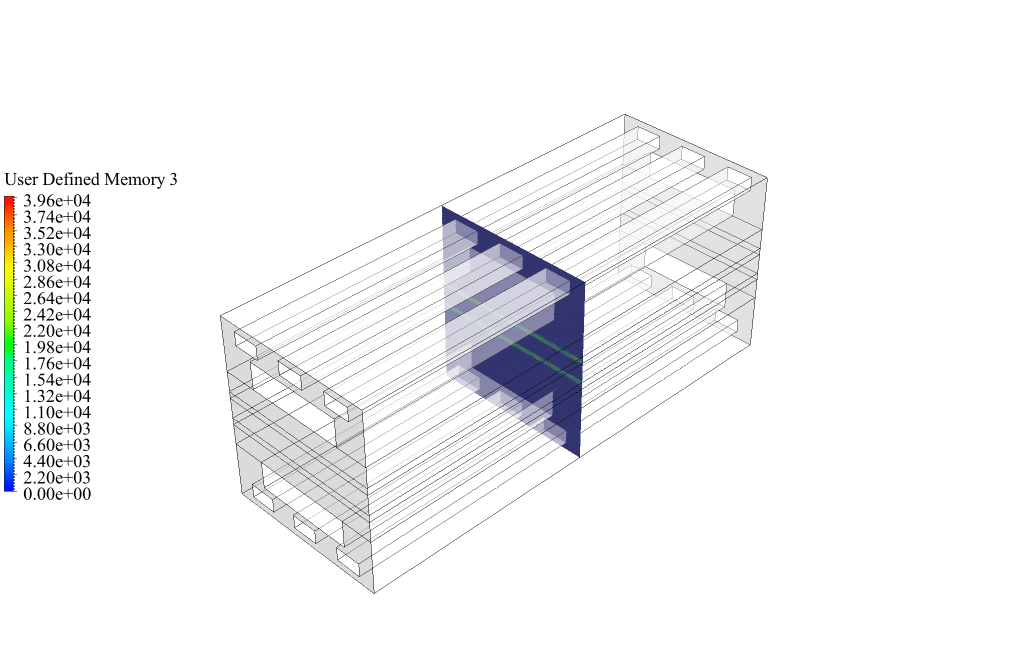

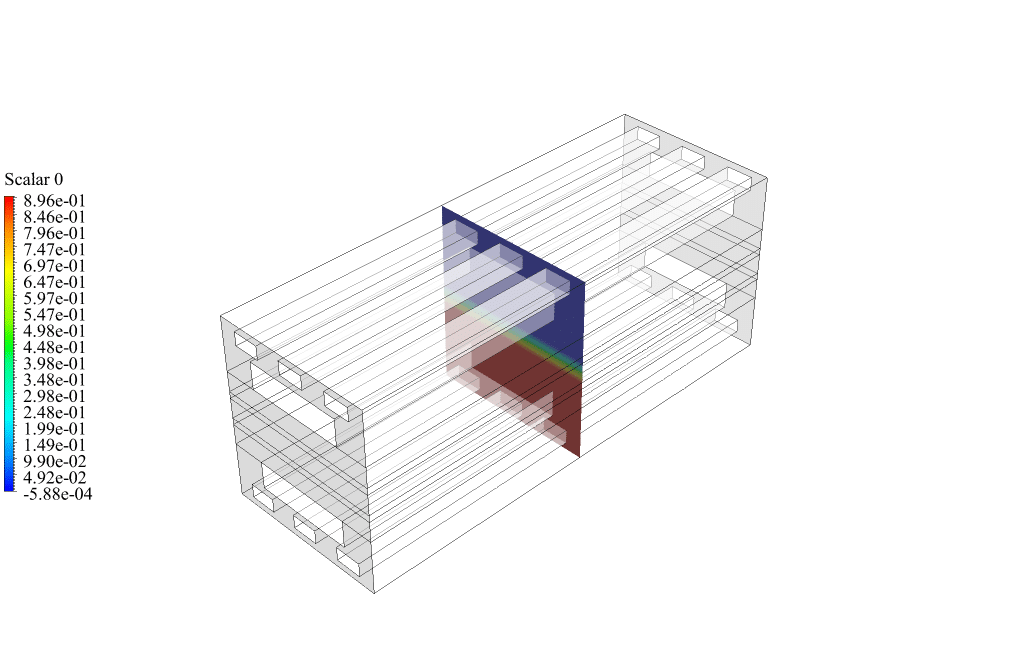

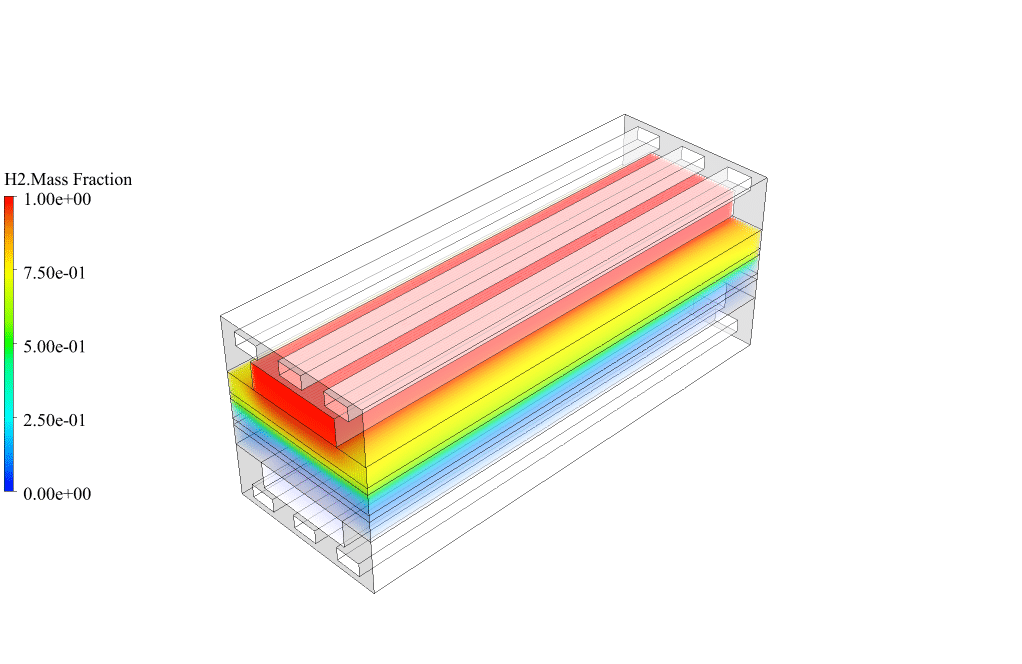

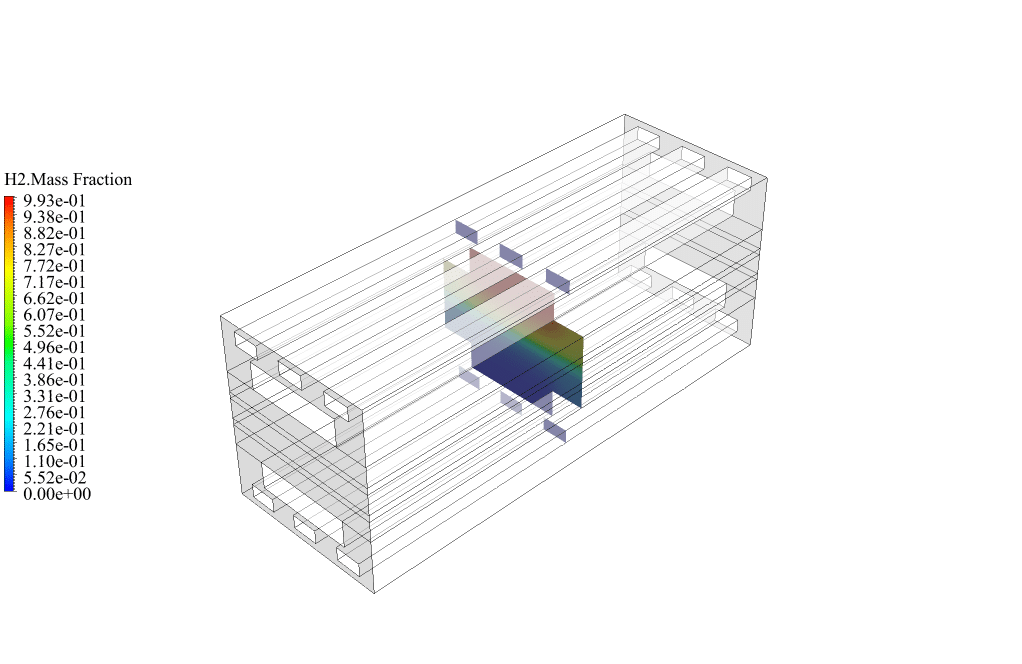

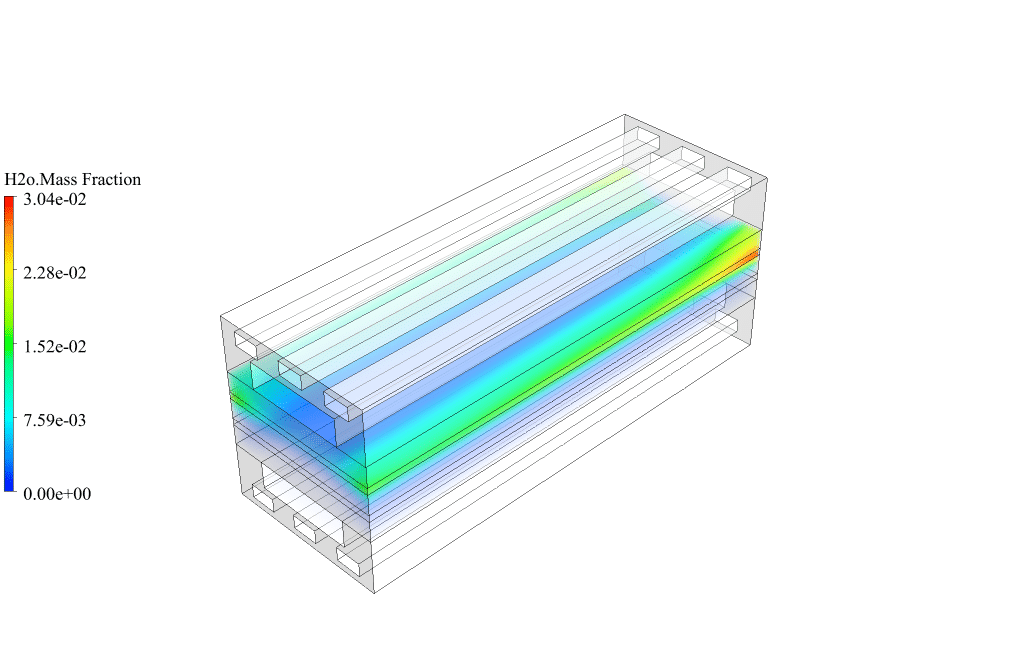

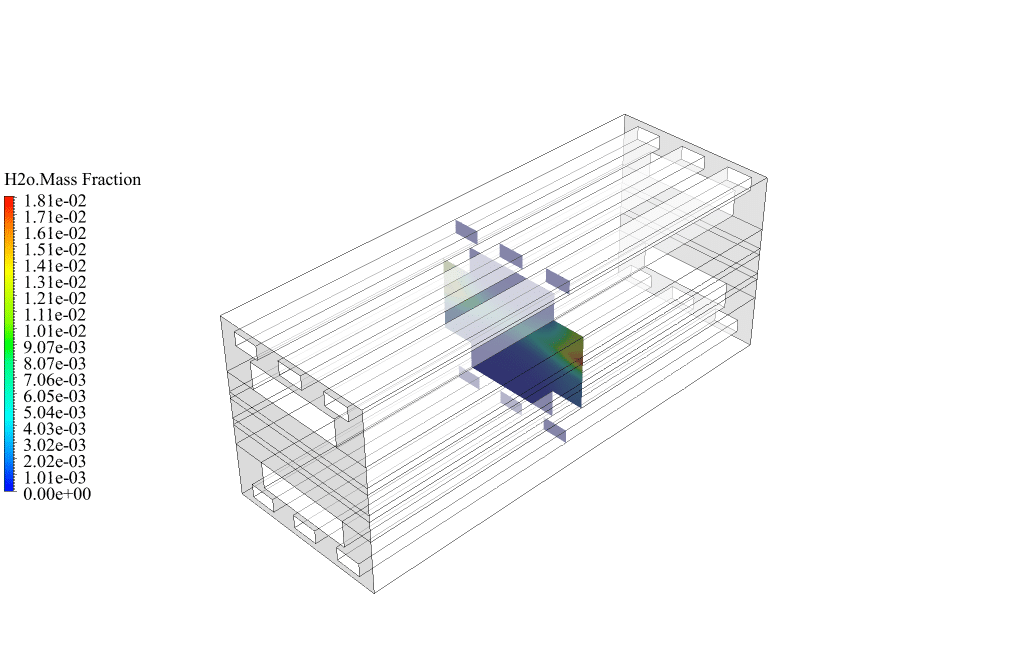

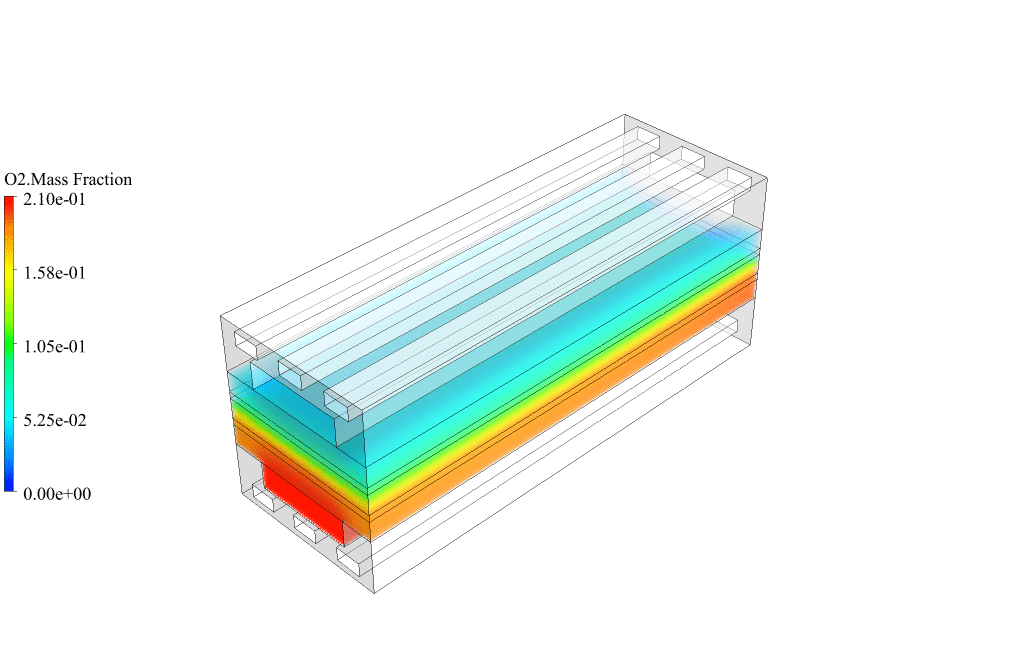

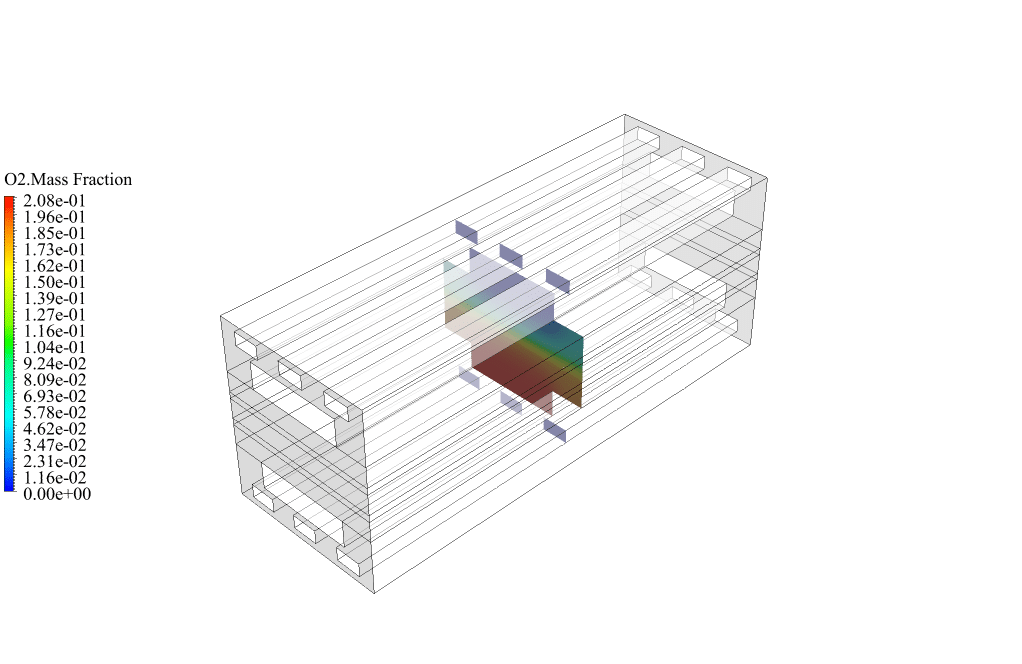

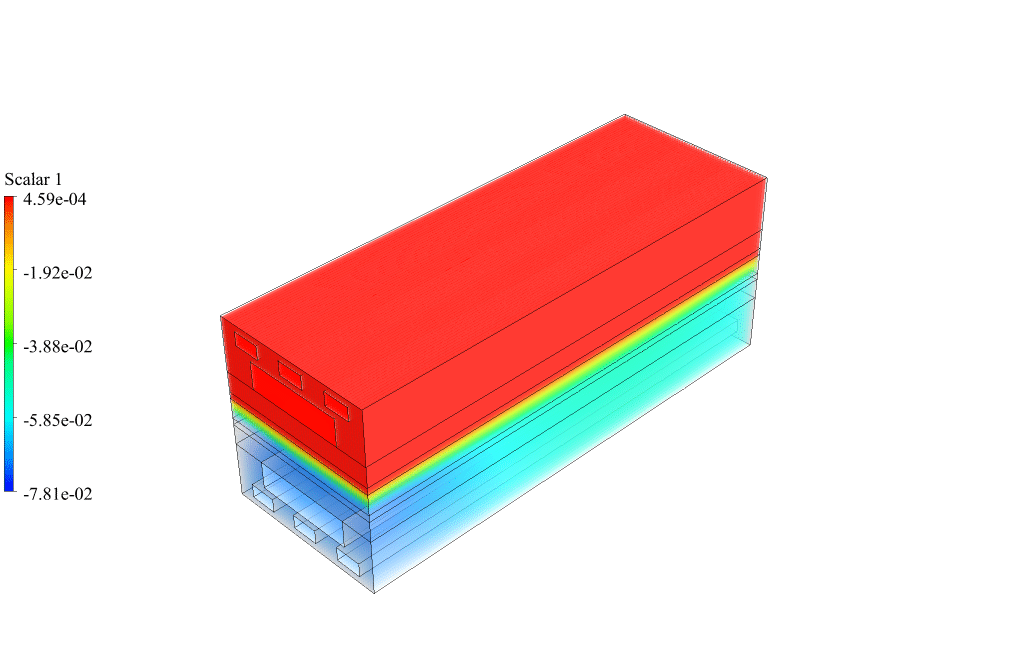

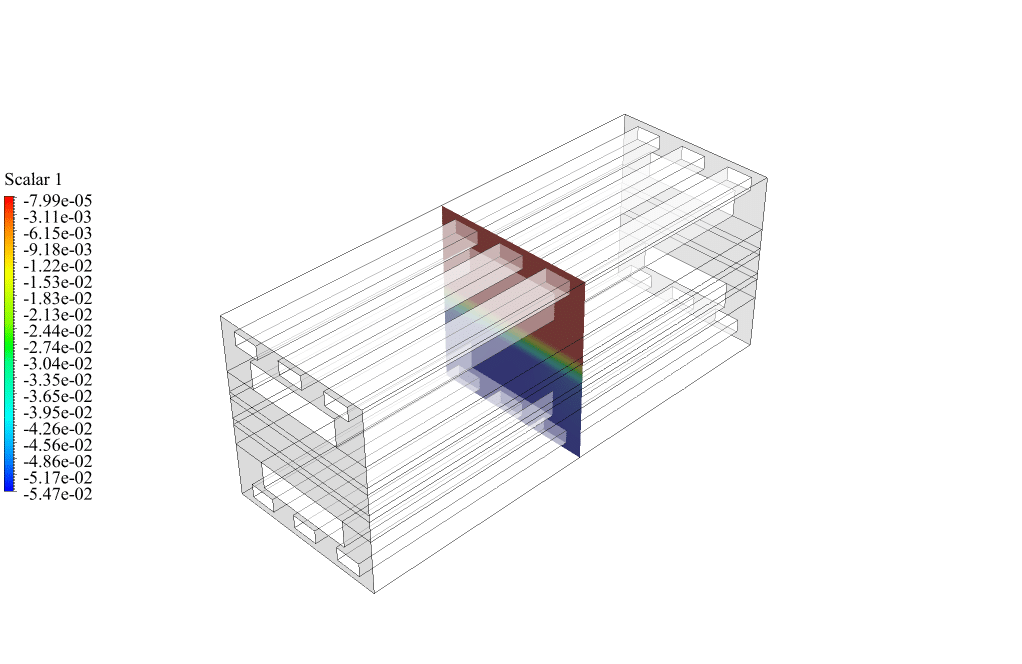

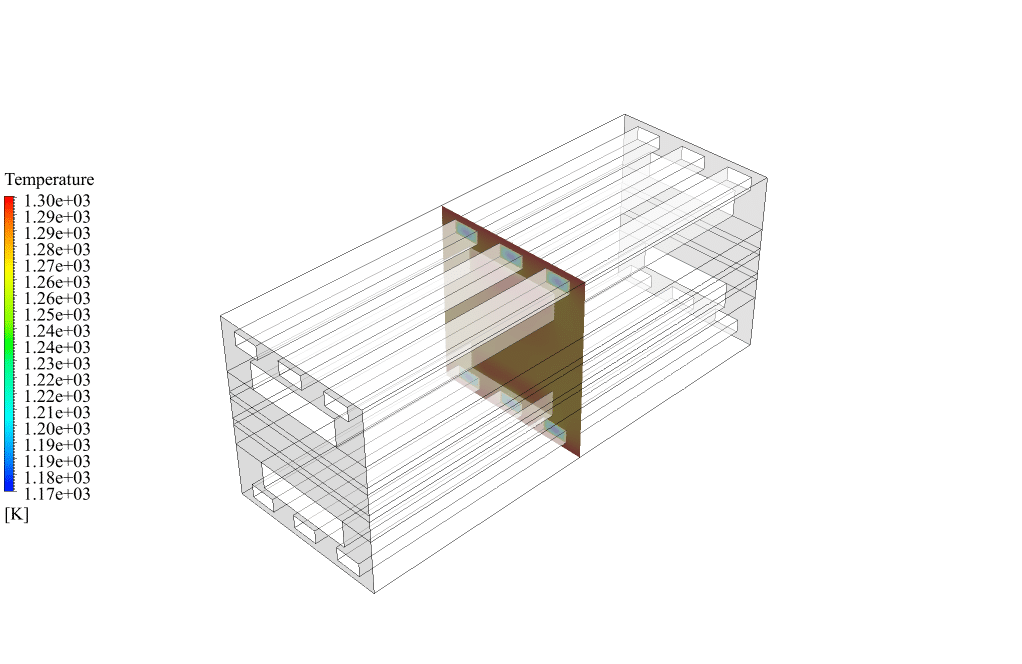

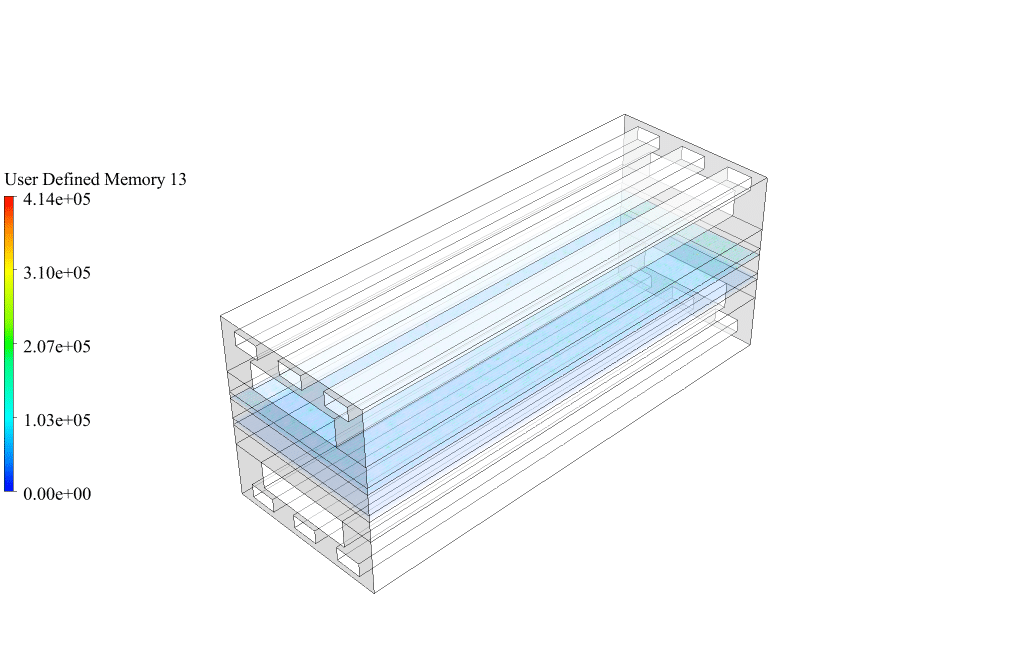

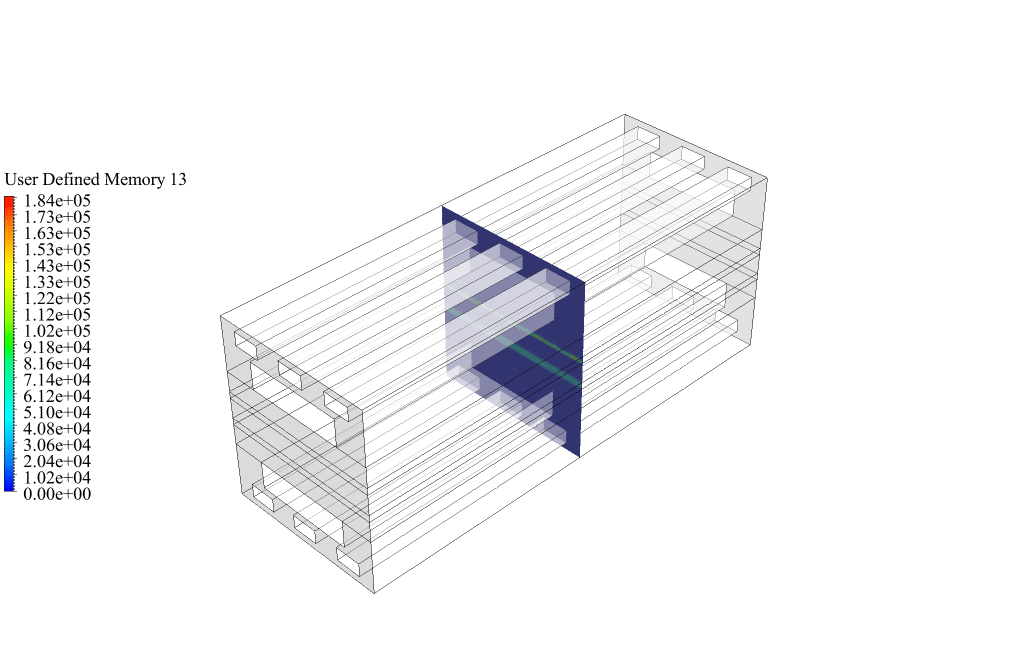

After conclusion, we have obtained the contours related to temperature, electric potential, protonic potential, current flux density magnitude, transfer current, and mass fraction of H2, O2, and H2O.

The temperature contours show that the fuel cell temperature is very high, as expected. However, the use of cooling channels has reduced the temperature. So the cooling system has worked properly. The H2, O2, and H2O mass fraction contours show that hydrogen enters from the anode side, oxygen enters from the cathode side, and water vapor is produced in the anode section. This behavior is exactly according to the functional mechanism of the SOFC fuel cell system.

When we use the fuel cell model, some user-defined scalars (UDS) are enabled. Here, we obtained the contours of electric potential (scalar 0) and protonic potential (scalar 1). These contours show that the potential equations of the fuel cell model are solved correctly. Hence, the effect of electrons and protons in fuel cell layers is understandable.

Also, when we use the fuel cell model, several user-defined memories (UDM) are enabled. Here, we obtained contours of current flux density magnitude (user-defined memory 3) and transfer current (user-defined memory 13). These contours show that the current is generated based on the voltage we defined for the fuel cell.

Alycia Lueilwitz MD –

The CFD simulation of the SOFC with cooling channels performed in ANSYS Fluent provides incredibly detailed results. Observing the direct functionality of the cooling system through temperature contour analysis is impressive and ensures sufficient cooling. Moreover, seeing the distribution of species like H2, O2, and H2O validates the chemical reactions occurring within the fuel cell and confirms the proper operation of this energy conversion device. The simulation’s outcomes highlight the efficacy of the SOFC system and underscore Fluent’s capabilities in such complex analyses. Excellent work on this tutorial that showcases how simulation can optimize the performance of energy systems while also contributing to a deeper understanding of the underlying physics.

MR CFD Support –

Thank you for your thoughtful remarks on the Solid Oxide Fuel Cell simulation tutorial with a cooling system. We are pleased that it met your expectations and that you found the detailed analysis useful. It’s heartening to see our efforts in crafting comprehensive learning products acknowledged. Your feedback validates our commitment to delivering exceptional educational content. We look forward to continuing to support your learning journey in computational fluid dynamics.

Kellie Jacobson –

I’m really impressed with the level of detail in the simulation of the SOFC cooling system, especially the cooling channels’ effectiveness. Thanks for the comprehensive guide!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found our simulation guide comprehensive and helpful. Our team strives to provide detailed and accurate simulations to ensure our users have a good understanding of the system’s functionality. Don’t hesitate to reach out if you have more feedback or need further assistance!

Camryn Crist –

This product seems incredibly detailed! Can you tell me if the tutorial covers how to interpret all the other results extracted from the simulation besides temperature and mass fraction contours?

MR CFD Support –

Yes, the tutorial covers how to interpret all the simulation outcomes. In addition to temperature and mass fraction contours, it also guides you through the interpretation of electric and protonic potentials, current flux density, and transfer current, ensuring you have a comprehensive understanding of the fuel cell’s performance.

Mrs. Carolina Gorczany –

I am fascinated by the cooling system you’ve implemented in this SOFC simulation. Can you tell me more about how the cooling channels impact the overall performance of the fuel cell?

MR CFD Support –

In our SOFC simulation with a cooling system, the cooling channels play a crucial role in maintaining optimal operating temperatures despite the high intrinsic temperature of fuel cell operation. These channels help prevent overheating by dissipating excess heat away from active cell areas, which supports sustained chemical reactions and prolongs the cell’s lifespan. Temperature regulation achieved by cooling channels contributes to the fuel cell’s efficiency and prevents thermal-related degradation or failure, ensuring a stable production of electricity.

Damon Rippin –

The cooling system you’ve implemented is fascinating! Could you elaborate on how it integrates with the fuel cell design without affecting its performance?

MR CFD Support –

The cooling system in this SOFC simulation is designed to manage the high operating temperatures effectively. It’s integrated by placing cooling channels on both sides of the electrodes that actively control the temperature without hampering the chemical reaction process which is crucial for the fuel cell operation. This balance ensures that the performance of the fuel cell is not compromised while maintaining operational safety and efficiency.

Retha Corwin –

I’m truly fascinated by the details in this simulation! Could you explain how the cooling channels manage to reduce the high temperature of the SOFC? And how does it affect the overall efficiency of the fuel cell?

MR CFD Support –

The cooling channels in the SOFC are designed to absorb heat generated during the operation of the fuel cell due to its high working temperature. These channels usually contain a coolant fluid that circulates through them, absorbing the excess heat. This process prevents overheating and maintains the cell components at an optimal temperature for efficient operation. Efficient cooling can improve the SOFC’s longevity and performance, as temperature control is crucial for maintaining the integrity of the material properties within the cell. The overall efficiency is influenced partly by the ability of the cooling system to remove excess heat without causing significant thermal gradients that could lead to stresses and affect the electrochemical reactions within the cell.

Karen Spencer PhD –

I really appreciated the comprehensive explanation of the solid oxide fuel cell cooling system simulation. The detailed methodology shows that all essential aspects, including temperature management, hydrogen, oxygen, and water reactions, as well as the electrical and protonic potentials, were addressed in the simulation. Understanding that the contours illustrate functional efficiency and the successful integration of the cooling channels truly highlights the sophistication of the SOFC CFD model. Fantastic work on balancing the complex interactions within the fuel cell!

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the CFD simulation tutorial for the SOFC cooling system detailed and informative. It’s rewarding to see our efforts in creating a sophisticated and realistic model are being appreciated. Your understanding of the critical aspects and interactions that were simulated shows that our goal of assisting users to better grasp the complexities of SOFC has been achieved. If you have any more questions or need further information in the future, don’t hesitate to contact us.

Katherine Funk –

I am very impressed by how effectively the cooling system in the SOFC simulation worked to manage high temperatures. It seems like the design was highly successful based on the temperature contours provided in the analysis. Great work on achieving accurate results that show efficient cooling in action!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the cooling system in the SOFC simulation to be effective. This speaks volumes about the precision of our CFD modeling and simulation capabilities. If you ever have more questions or need further assistance, don’t hesitate to reach out. We’re here to help!

Eulalia Heathcote I –

I purchased the SOFC cooling system simulation tutorial and I’m thrilled by the level of detail. However, I’m curious if the cooling channel design can be customized for different applications or if it’s fixed in the simulation,

MR CFD Support –

We are glad you’re satisfied with the level of detail in our SOFC cooling system simulation tutorial. Yes, the cooling channel design can be customized to suit different applications according to the specific thermal management requirements. You can adjust the cooling channel geometry, placement, and flow parameters to achieve the desired thermal regulation for your particular use case.

Jannie Rempel –

The cooling channels seem crucial for the SOFC. How are the cooling flow rates determined and managed in the simulation to ensure efficient cooling of the fuel cell?

MR CFD Support –

In the simulation, the cooling flow rates are determined based on the amount of heat generated during the operation of the SOFC and the desired temperature range you want to maintain. The flow rates are managed by choosing appropriate coolant properties, inlet temperatures, and flow velocities to efficiently remove heat from the cell. Adjustments to the flow rates can be conducted in the boundary conditions settings within ANSYS Fluent.

Dr. Houston Schaefer II –

This was a thorough and well-presented project overview, demonstrating practical usage and benefits of fuel cells. I was especially impressed by the insights into how the cooling system integration impacts SOFC performance, maintaining efficiency at high operational temperatures.

MR CFD Support –

Thank you for your detailed review and for noting the significance of the cooling system within our numerical simulation tutorial. We are glad to hear about your appreciation for our comprehensive content and functional analysis of the SOFC. Your feedback is immensely valued!

Dixie Mayert DDS –

This review for the MR CFD tutorial was immensely helpful in explaining the simulation details. The insight into how cooling systems impact SOFC performance is particularly enlightening and clearly demonstrates the efficiency of the design. I am also impressed with the detailed explanation of the simulation methodology, especially the incorporation of different layers in the fuel cell and the usage of a fuel cell model add-on in ANSYS Fluent software. Well done!

MR CFD Support –

Thank you very much for your positive feedback! We’re delighted to hear that the tutorial on the SOFC Cooling System was informative and beneficial for your understanding of high-temperature fuel cells and their cooling mechanisms. Our team is committed to providing comprehensive and clear instructions to assist learners like you. We appreciate your appreciation and are here for any further assistance you may need.