Splitter Plates Effects on the Pin Fin Heat Sinks CFD Simulation

$80.00 $40.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Splitter Plates Effects on the Pin Fin Heat Sinks CFD Simulation, ANSYS Fluent Tutorial

Introduction

Heat sinks are crucial components in thermal management systems, particularly for electronic devices and power systems. They are designed to efficiently dissipate heat from a high-temperature object to a lower-temperature fluid medium, typically air. This study explores the thermal and fluid dynamic performance of a heat sink with cylindrical pin fins enhanced by the addition of splitter plates.

The primary objective of this research is to analyze the effect of the splitter plates on the heat transfer and fluid flow characteristics of the pin fin heat sink. By introducing splitter plates, we aim to disrupt the wake region behind the cylindrical pins, potentially improving heat transfer and reducing the overall thermal resistance of the system.

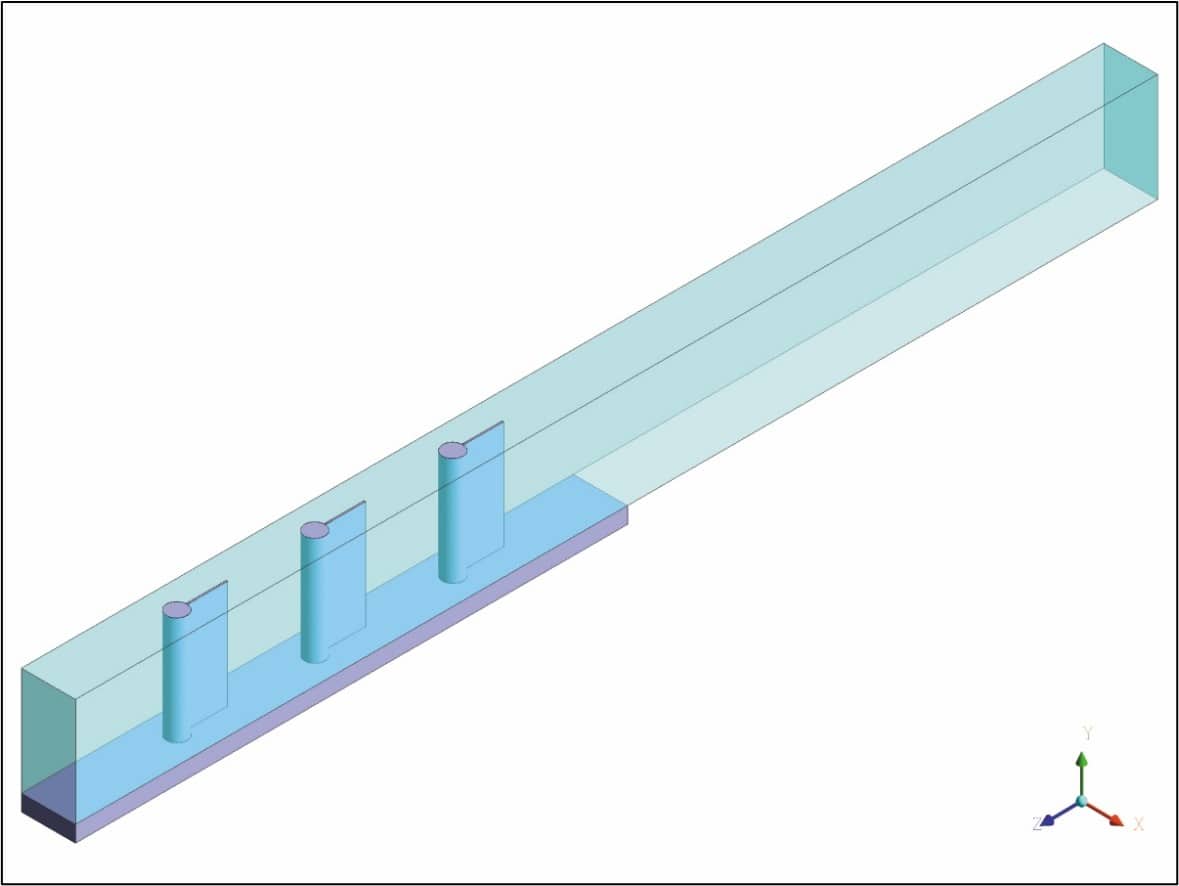

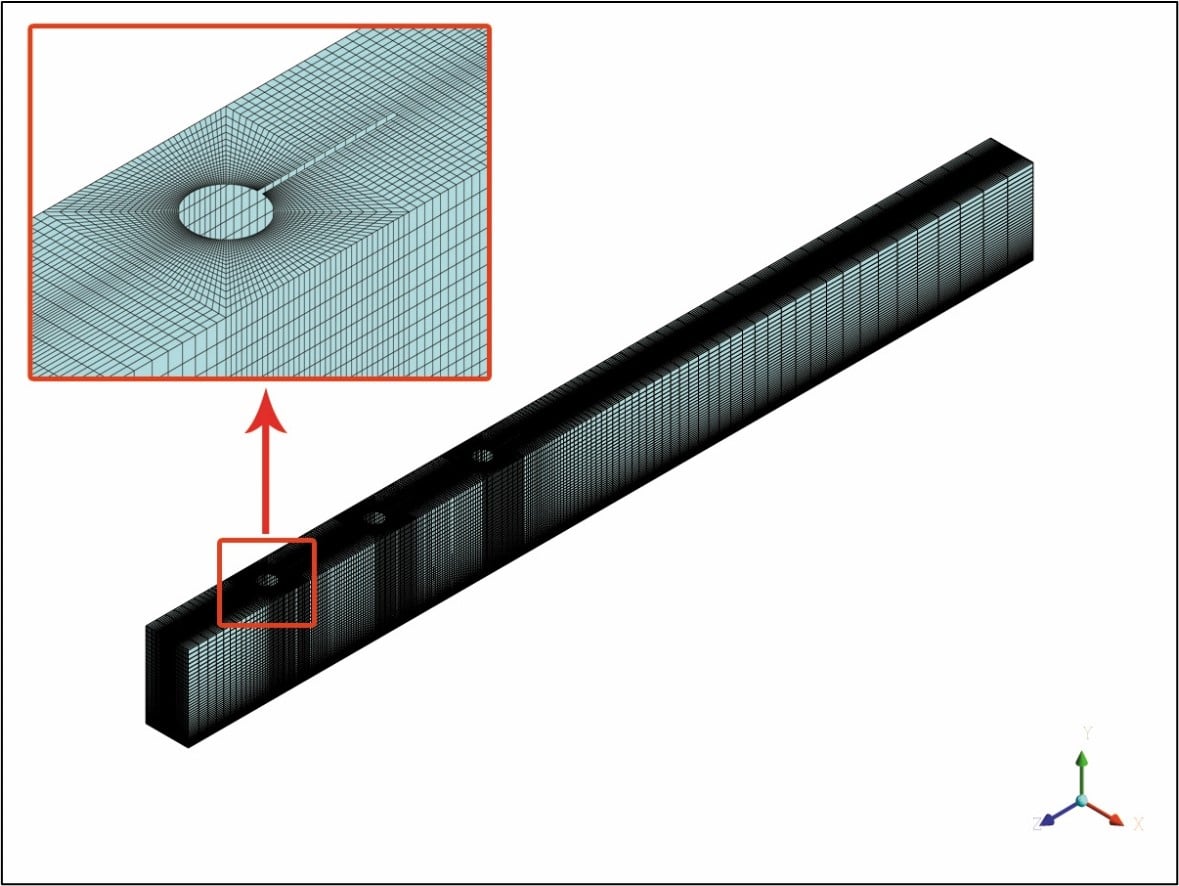

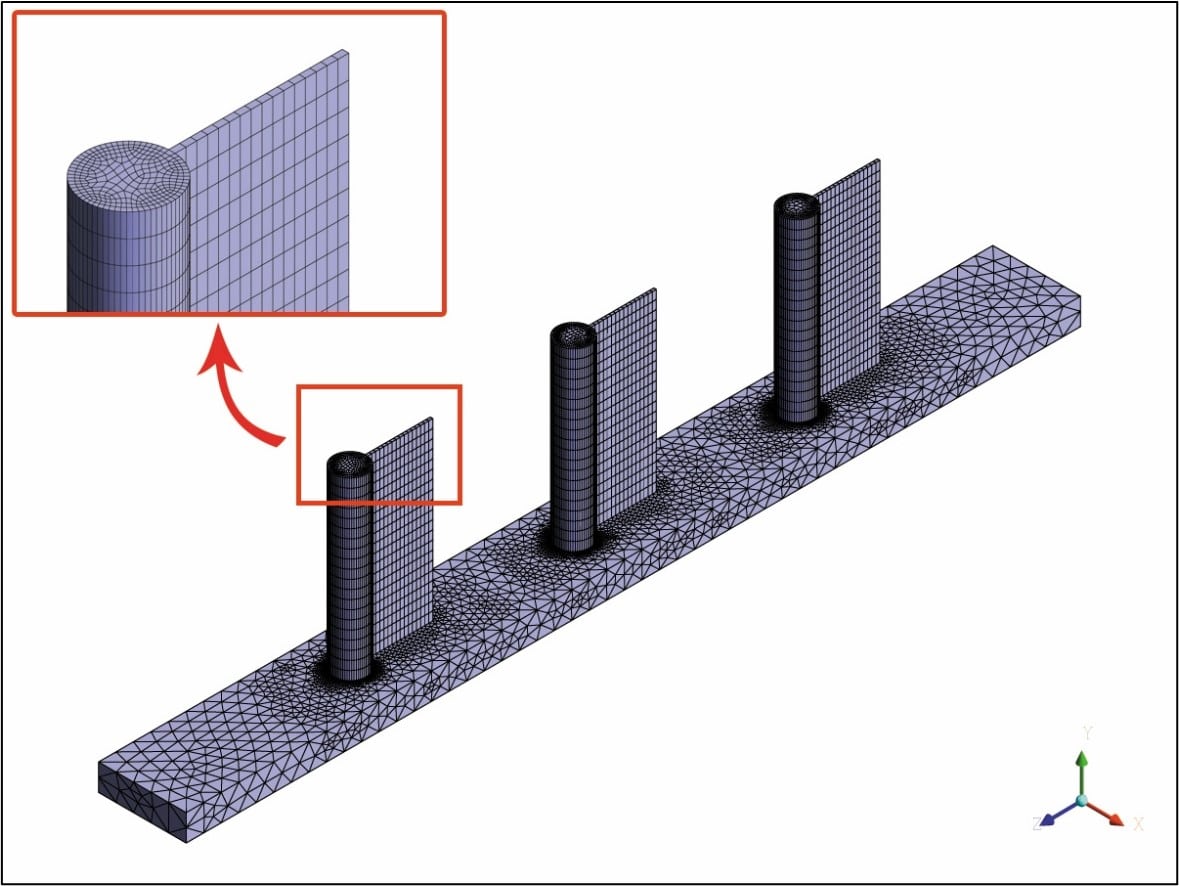

The heat sink geometry shows a linear arrangement of cylindrical pins with splitter plates positioned behind each pin. The structured mesh demonstrates high-quality elements, particularly refined near the pin and splitter plate surfaces, to capture boundary layer effects accurately.

The CFD simulations were conducted using ANSYS Fluent software. The geometry was designed in ANSYS Design Modeler and meshed using ANSYS Meshing software, resulting in a high-fidelity structured mesh of 804,434 elements.

Methodology

The simulation employs a pressure-based solver suitable for incompressible flows typically encountered in heat sink applications.

A steady-state solution approach was adopted to simulate the continuous operation of the heat sink under constant thermal load.

The Reynolds-Averaged Navier-Stokes (RANS) equations were solved using an appropriate turbulence model to account for the complex flow patterns around the pin fins and splitter plates.

The energy equation was included to model heat transfer from the base and fins to the surrounding fluid.

Results

The CFD simulations reveal significant insights into the thermal and fluid dynamic behavior of the heat sink:

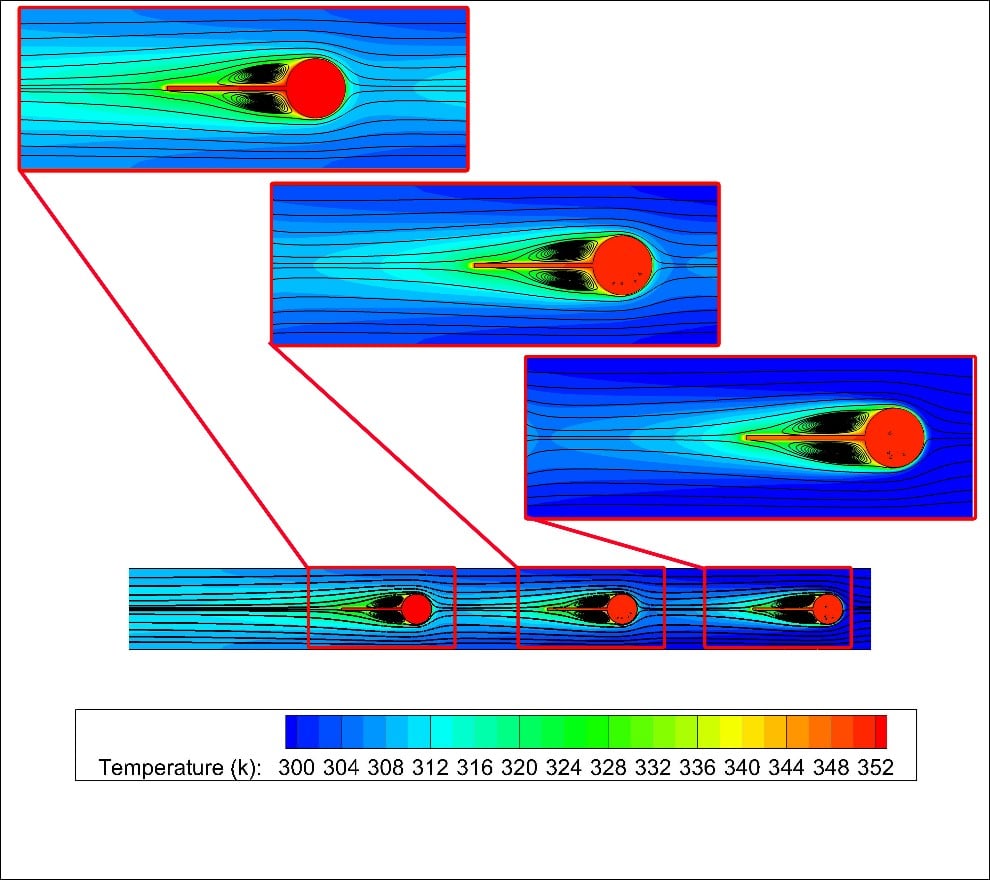

The temperature contours show a gradual increase in fluid temperature as it flows across the heat sink. The cylindrical pins effectively extend the heat transfer surface area, creating localized high-temperature regions around each pin. The splitter plates appear to influence the temperature distribution in the wake region of the pins, potentially enhancing heat transfer in these areas.

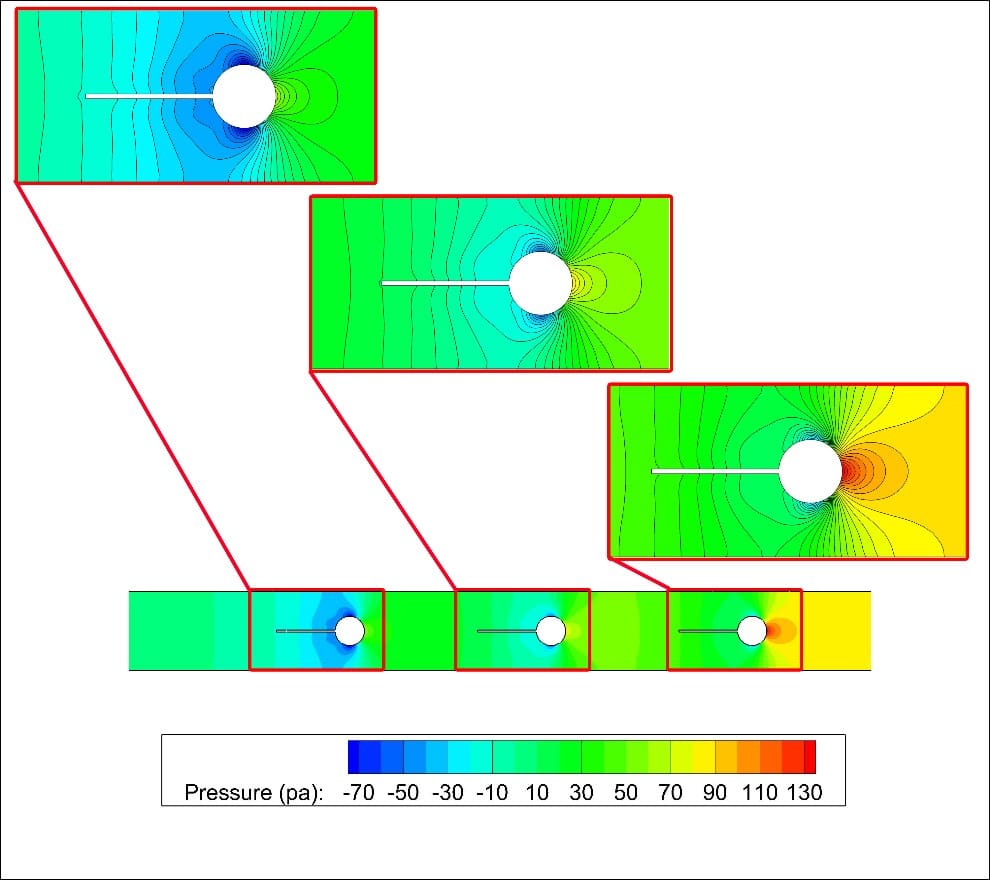

The pressure contours indicate high-pressure areas at the leading edge of the cylindrical pins and low pressure in their wake. The splitter plates create additional pressure gradients, which can help break up the wake region and promote turbulent mixing. This effect is particularly noticeable in the varying pressure patterns observed along the length of the heat sink.

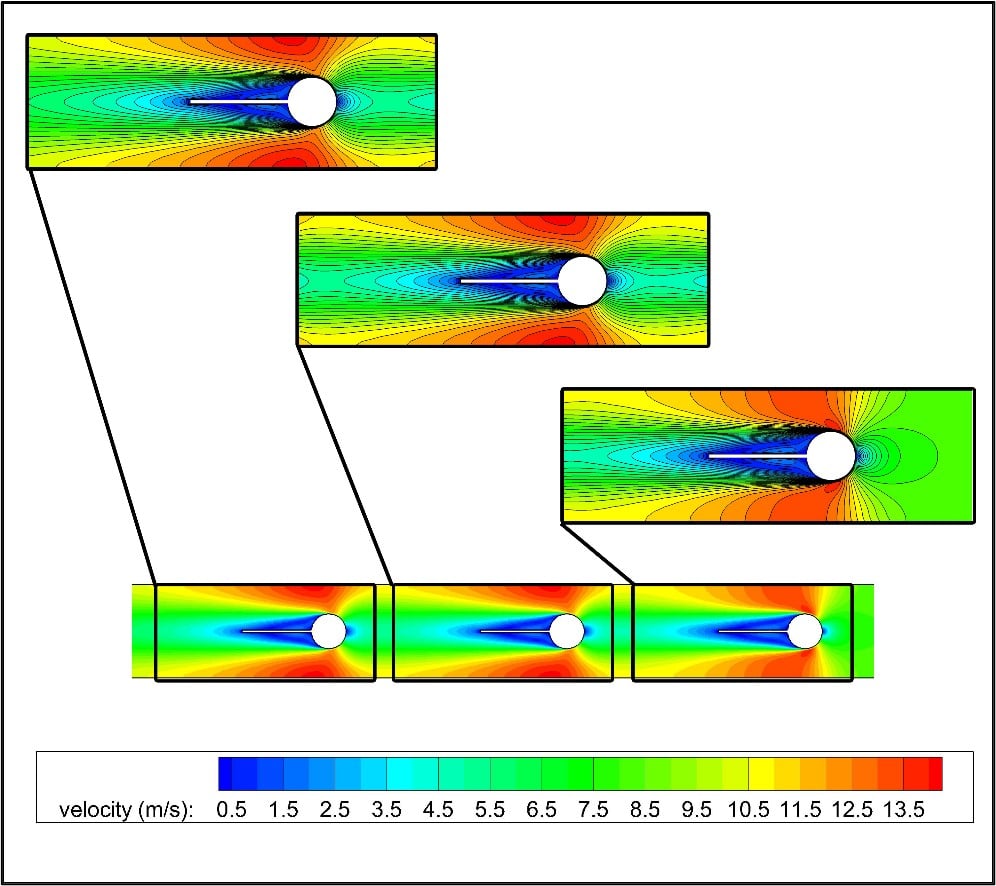

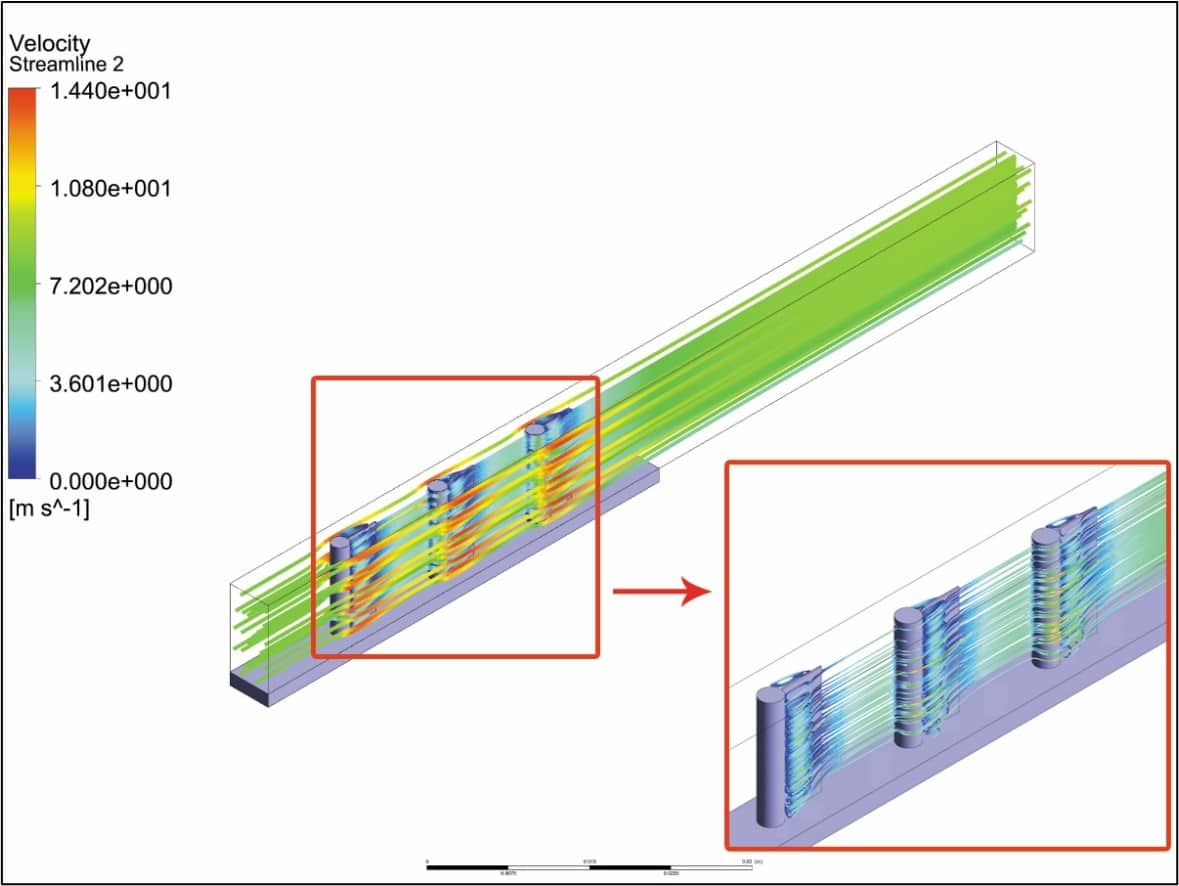

The velocity streamline visualization provides crucial insights into the flow behavior. The flow accelerates as it passes between the pins and splitter plates, reaching velocities up to 14.4 m/s. The splitter plates effectively guide the flow, creating complex vortex structures in the wake of the pins. This increased turbulence and mixing can lead to enhanced heat transfer from the pin surfaces to the fluid.

The introduction of splitter plates appears to have a significant impact on both the fluid flow and heat transfer characteristics of the pin fin heat sink. By disrupting the wake region behind the cylindrical pins, the splitter plates promote turbulent mixing and potentially reduce the overall thermal resistance of the system. The complex flow structures observed in the velocity streamlines suggest enhanced convective heat transfer, which could lead to improved cooling performance compared to a standard pin fin design without splitter plates.

Reviews

There are no reviews yet.