Steam Turbine CFD Simulation, ANSYS Fluent Tutorial

$100.00 $50.00 Student Discount

- This study investigates the flow dynamics in a steam turbine using CFD analysis in ANSYS Fluent.

- The 3D geometry was created in ANSYS Design Modeler and meshed using ANSYS Meshing, resulting in 4,057,868 polyhedral elements.

- The simulation utilizes the Realizable k-ε turbulence model with standard wall function and includes the energy equation for temperature analysis.

- A density-based solver with real-gas-peng-robinson model is employed for compressible flow.

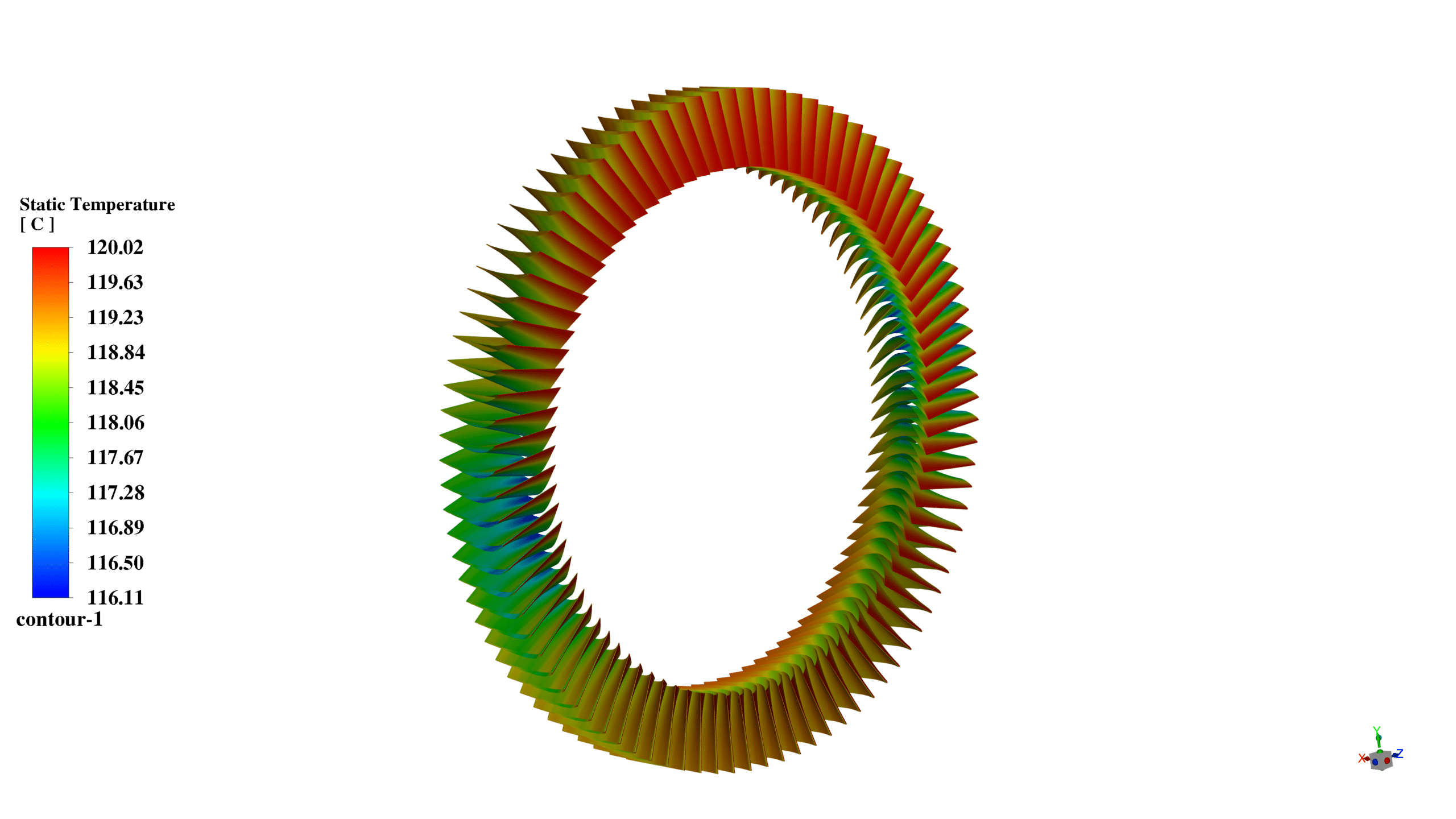

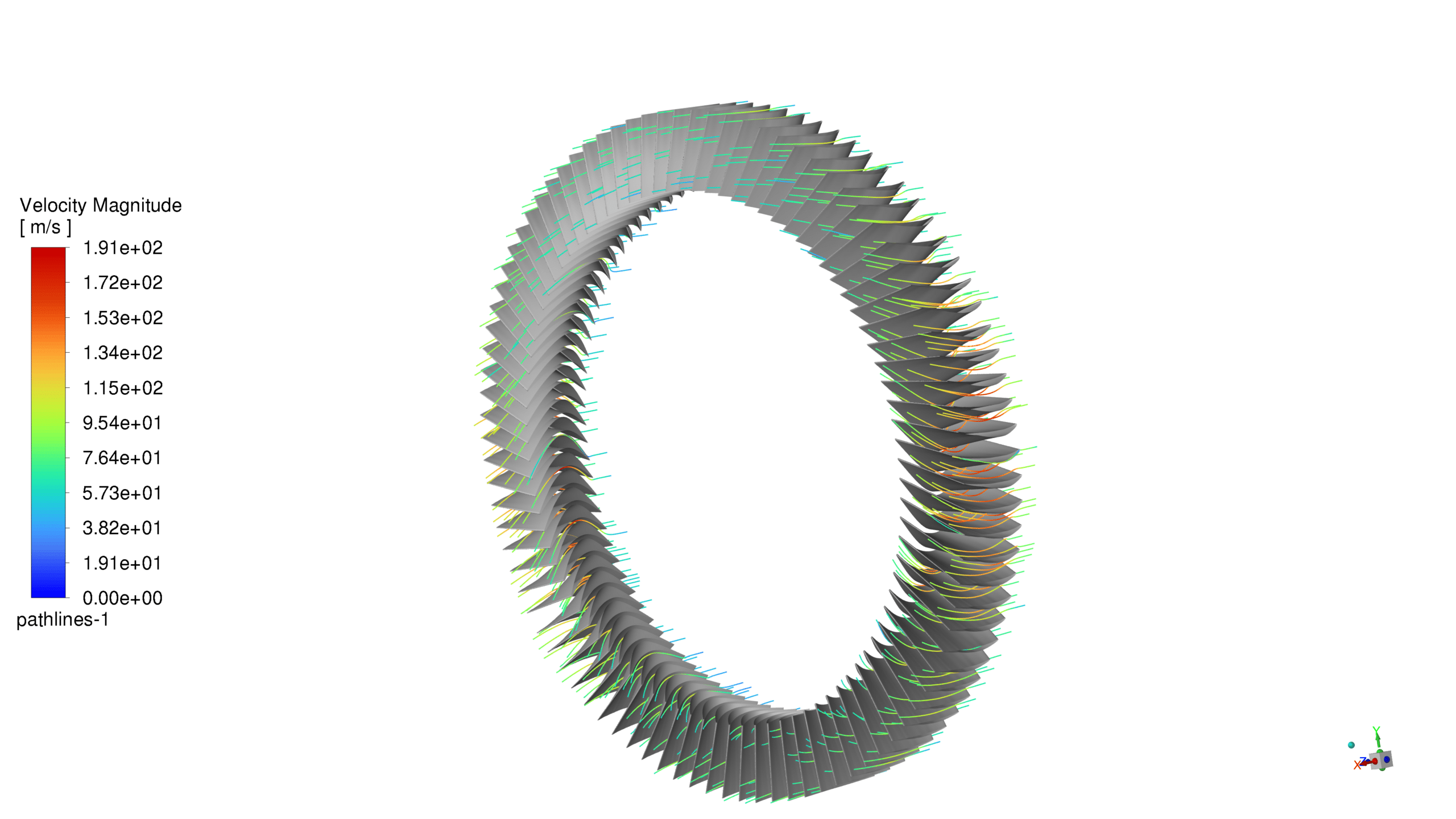

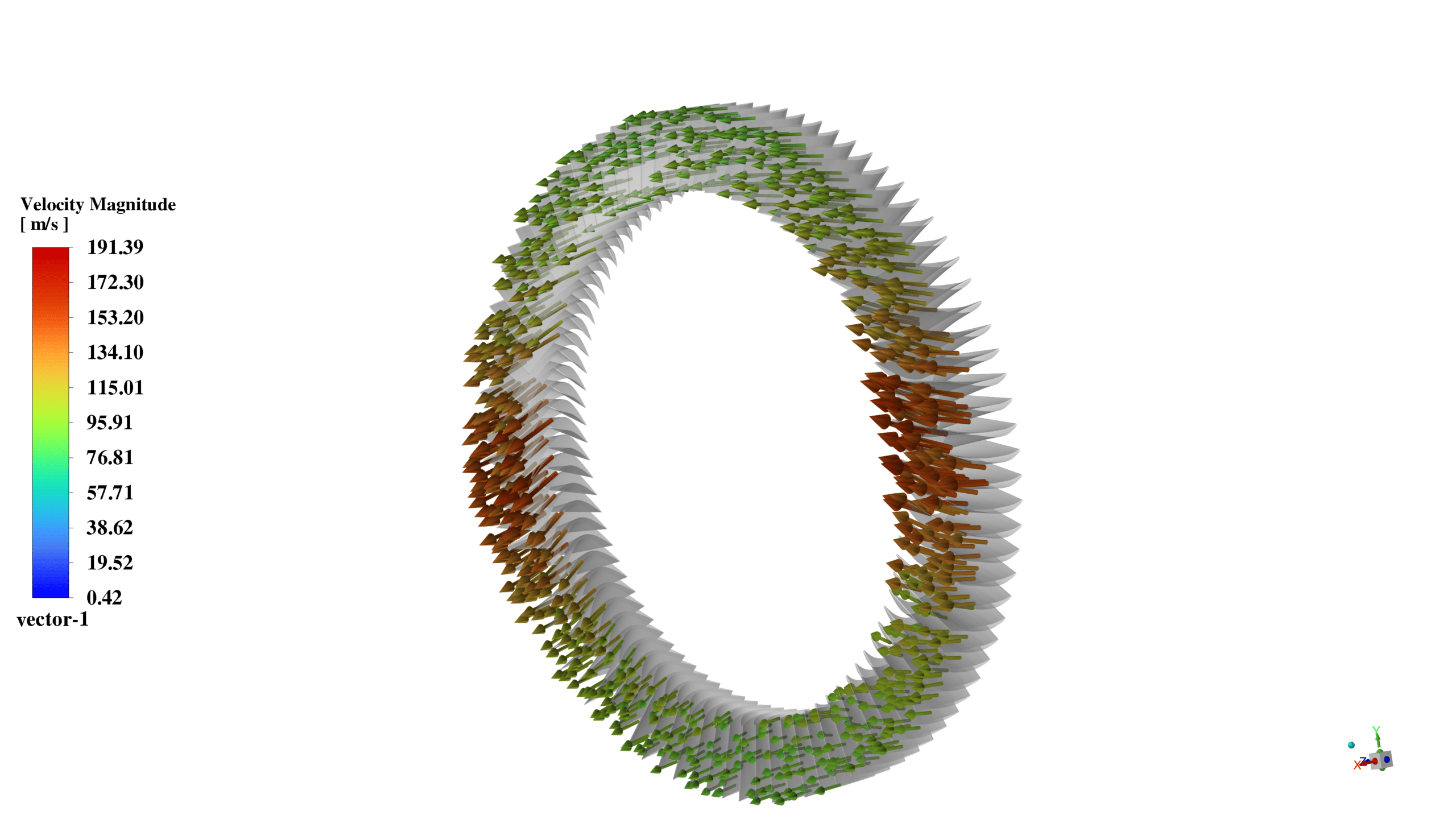

- The steady-state simulation examines pressure distributions (51.18-65.36 atm), temperature variations (116.11-120.02°C), and velocity profiles (max 191.39 m/s) within the turbine.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study investigates the flow dynamics within a steam turbine configuration using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the complex flow behavior, pressure distributions, temperature variations, and velocity profiles within the turbine. By employing advanced models for turbulence and real gas behavior, this research provides valuable insights into the performance and efficiency of steam turbines.

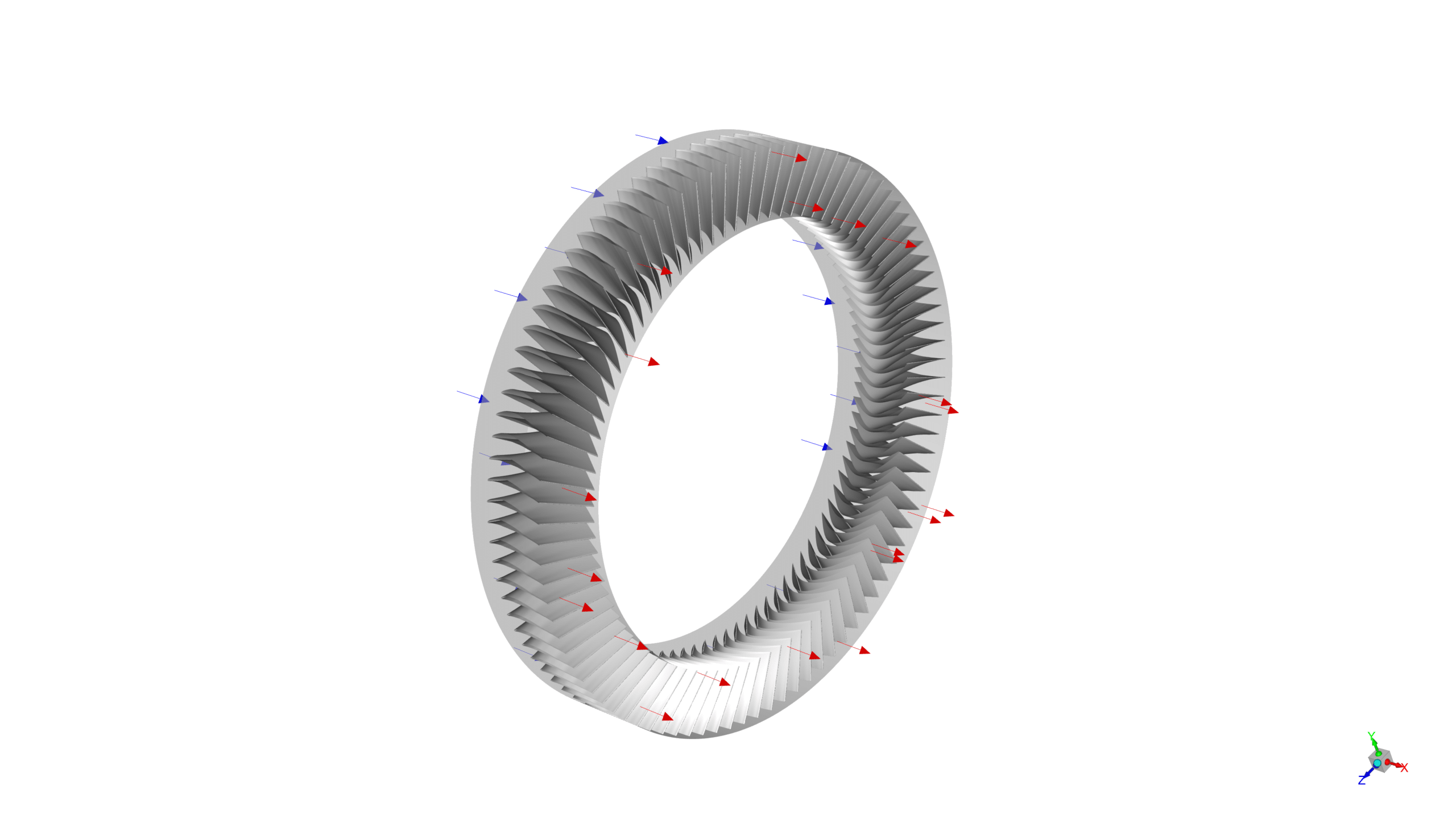

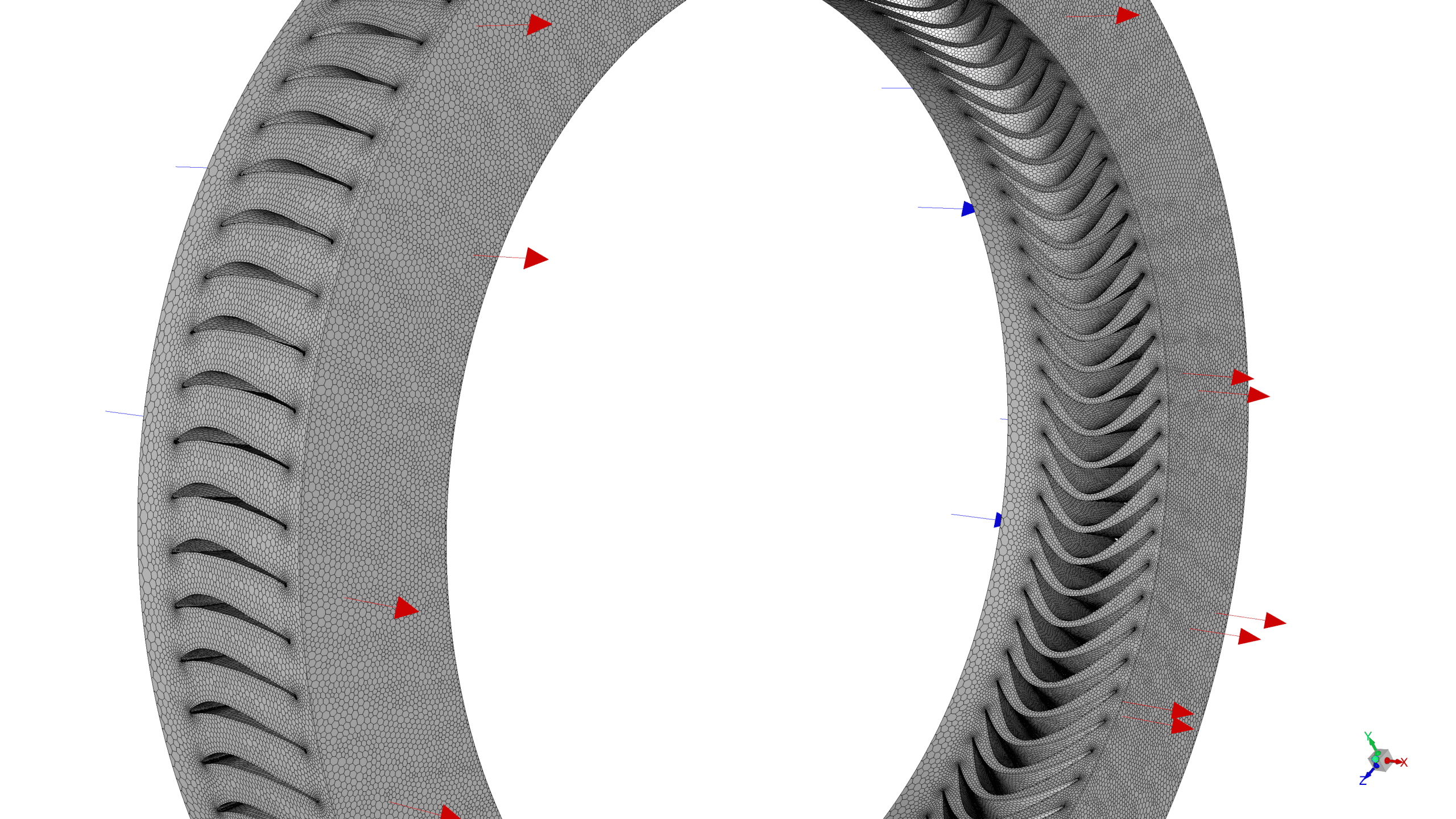

The CFD simulations were conducted using ANSYS Fluent software. The geometry, which is designed in ANSYS Design Modeler, represents a 3-dimensional steam turbine configuration, with the mesh generated in ANSYS Meshing.

The mesh consists of 4,057,868 polyhedral elements, providing a high-quality representation of the complex turbine geometry.

Methodology

For turbulence modeling, the Realizable k-ε model with standard wall function is utilized, known for its robustness in predicting complex turbulent flows.

The energy equation is enabled to solve for temperature distributions and heat transfer effects.

The working fluid is air, with density modeled using the real-gas-peng-robinson equation of state to account for high-pressure conditions.

A density-based solver is employed for the solution and is suitable for compressible flow simulations.

Results

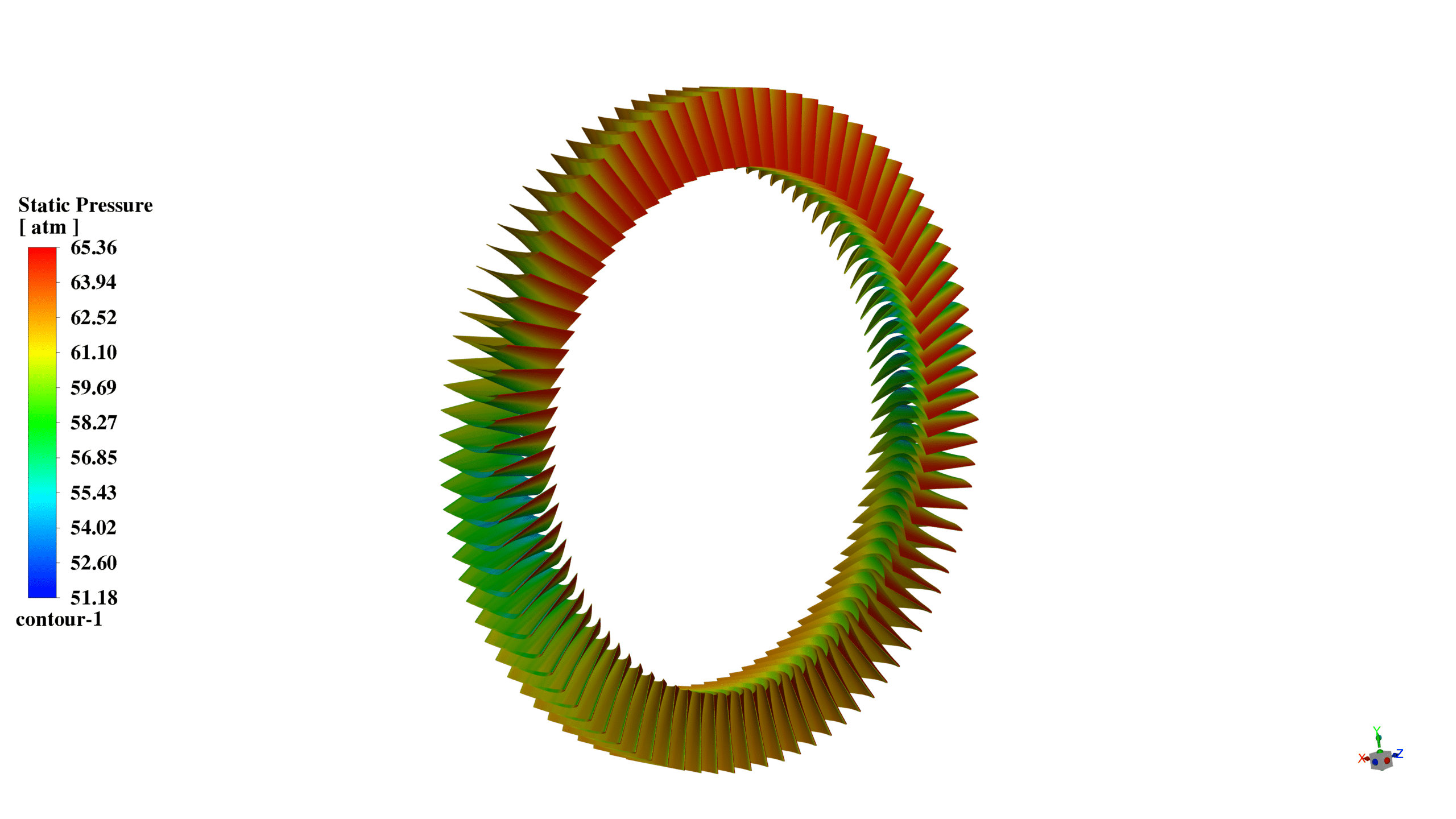

The simulation results demonstrate the intricate flow behavior within the steam turbine. The pressure and temperature distributions provide insights into the energy conversion process, while the velocity profiles reveal the flow acceleration through the blade passages.

The static pressure contour indicates a maximum pressure of 65.36 atm and a minimum of 51.18 atm. Higher pressures are observed at the inlet region, gradually decreasing as the flow progresses through the turbine blades.

The static temperature contour shows a temperature range from 116.11°C to 120.02°C. The temperature distribution reveals slight variations due to expansion and compression effects within the turbine.

The velocity magnitude contour displays a maximum velocity of 191.39 m/s. Higher velocities are observed in the regions between turbine blades, indicating acceleration of the flow as it passes through the blade passages.

The pathlines and velocity vectors visualize the complex flow patterns within the turbine, highlighting areas of high velocity and potential vortex formation.

Reviews

There are no reviews yet.