Storage Container Room Ventilation CFD Simulation, ANSYS Fluent Tutorial

$80.00 $40.00 Student Discount

- The problem numerically simulates Storage Container Room Ventilation using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 115635.

- The Energy Equation is activated to consider heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, the steady airflow (ventilation) in a storage container room with two walls is investigated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

The three-dimensional geometry of this project has been produced with Design modeler software.

The meshing of this project has been done with ANSYS Meshing software. The mesh type is Structured, and the element number is 115635.

Storage Container Room Methodology

In this project, ANSYS Fluent software investigates steady airflow in a storage container room with two walls. Container rooms are often used to store perishable industrial goods and must be kept under the influence of steady airflow for cooling and ventilation.

In the present work, steady air flow is simulated in a 0.5 * 0.5 * 1 room with two walls against the airflow path, which represents containing chamber.

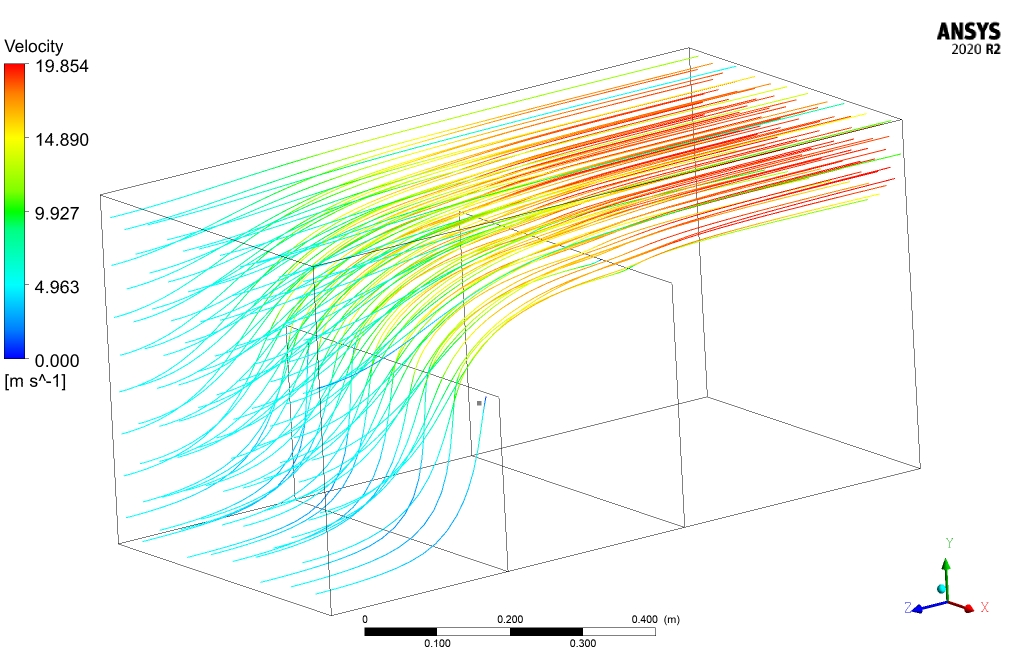

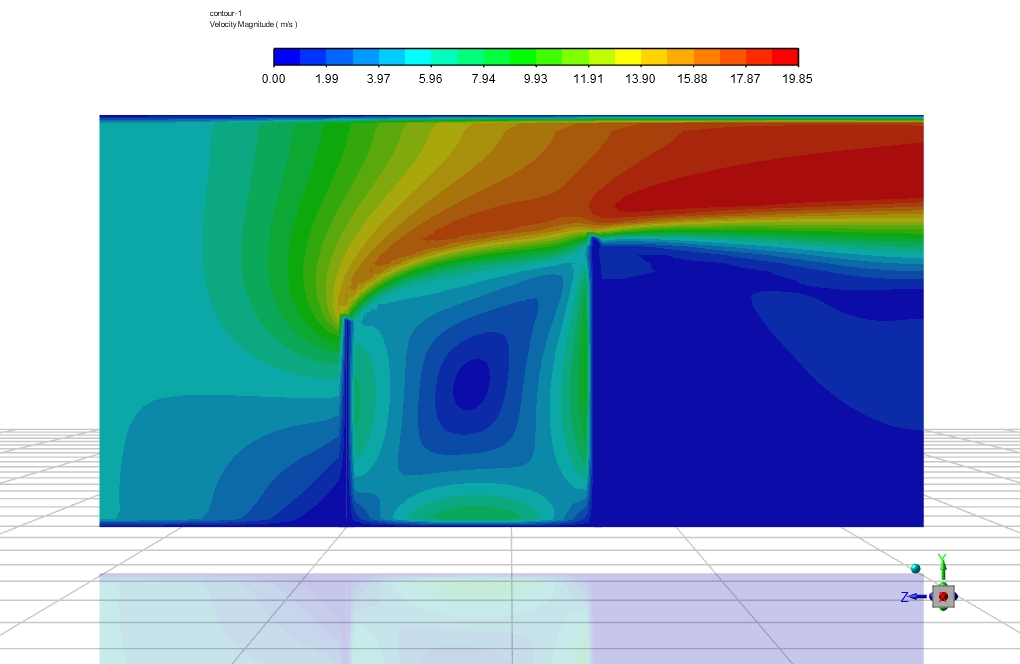

Air enters the domain with a velocity equal to 5 m/s and reaches a maximum velocity of approximately 20 m/s in the domain after flowing over the second wall.

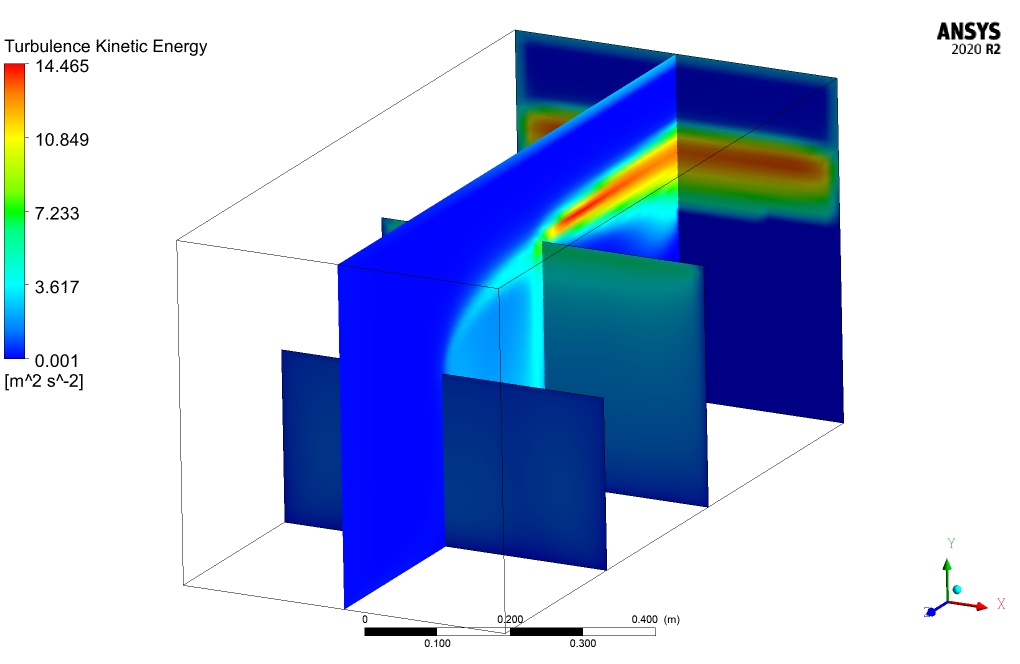

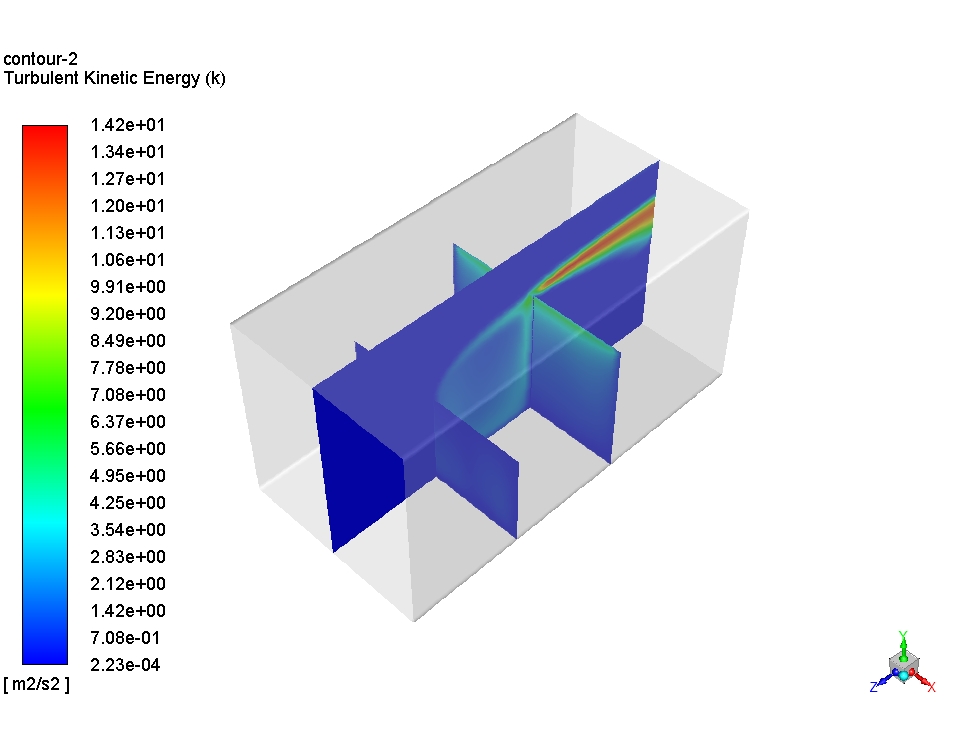

Moreover, the standard k-epsilon model and energy equation are enabled to solve the turbulent fluid equations and calculate temperature distribution within the domain.

Storage Container Room Conclusion

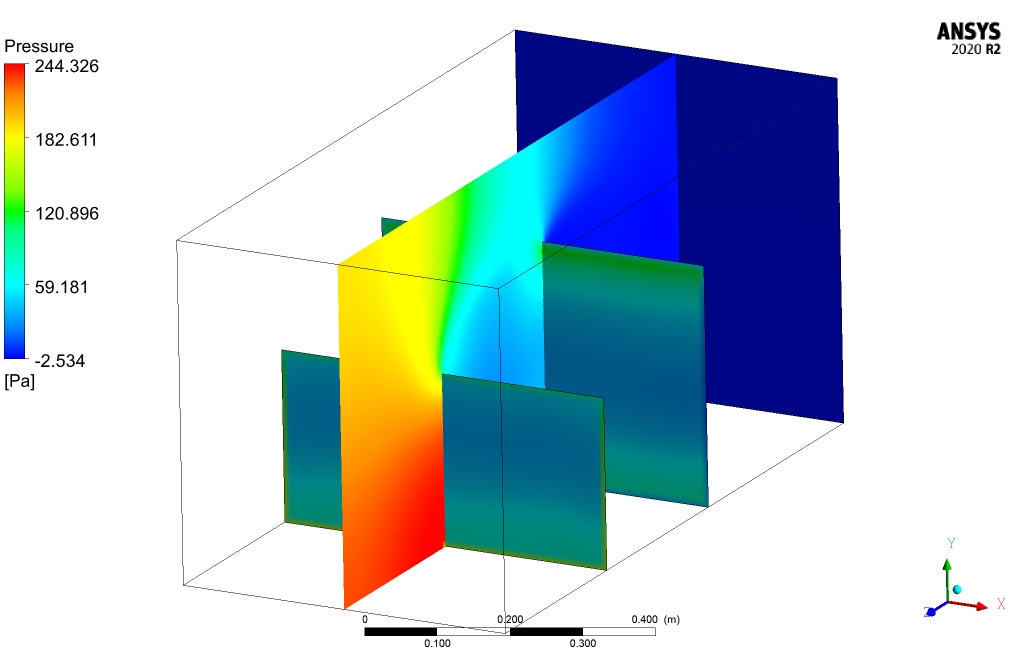

At the end of the solution process, two-dimensional contours related to pressure, velocity, and streamlines are obtained. As can be seen, air velocity at the inlet is equal to 5 m/s, which due to the geometry specifications of the problem, reaches a maximum value of 20 m/s.

The normal force exerted on the walls in the domain is equal to 15.8526 [N]. We can observe the extreme turbulence in space between two walls where turbulent kinetic energy reaches values of up to 2 j/kg.

Delta Cole –

I’m interested in the meshing strategy used in this simulation. Can you provide more details?

MR CFD Support –

The simulation uses a structured mesh, which provides a balance between computational efficiency and accuracy. The mesh is refined in areas of interest to capture the important flow details.

Mckenna Wilkinson –

Can this simulation be extended to model multi-phase flows, such as the evaporation of a liquid within the storage container?

MR CFD Support –

While the current model is set up for single-phase flow, it can certainly be extended to model multi-phase flows. We’re open to contributions and can accommodate your desired simulations.

Dr. Maximilian Sporer –

Can we adjust the model to simulate different weather conditions to see how it might affect the ventilation of the storage container room?

MR CFD Support –

Yes, that’s possible. You can modify the boundary conditions and model parameters within ANSYS Fluent to simulate different weather conditions, such as various temperature profiles or external wind pressures. Adjusting these parameters would help you understand how weather conditions can impact the airflow and temperature distribution in the storage container room.

Jeromy Leuschke –

The tutorial on Storage Container Room Ventilation was concise and informative. I’ve learned a lot about setting up a simulation for industrial storage units which not only enhances safety but also helps in preserving perishable goods effectively.

MR CFD Support –

Thank you for your positive feedback on our Storage Container Room Ventilation tutorial! We’re delighted to hear that you’ve found the information useful and applicable to your work with industrial storage. Your success with simulation work is very encouraging to us, and we appreciate you taking the time to complement the tutorial.

Dr. Harmon Lindgren –

I’m loving the detailing in the Storage Container Room Ventilation simulation tutorial. The explanation of airflow patterns and turbulence was exceptional and helped me better understand my project requirements.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our tutorial has provided you with valuable insights and contributed to a better understanding of your project. Your satisfaction is our top priority, and we’re glad to have been of help!

Idella Kuhlman IV –

Is it possible to change the boundary conditions in the simulation to model different scenarios?

MR CFD Support –

Absolutely, our simulations are fully customizable. You can adjust the boundary conditions to simulate different scenarios according to your needs.

Ashleigh Maggio –

I’ve used the tutorial to model ventilation in my own storage design. It was clear and comprehensive, capturing all the crucial steps.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial on Storage Container Room Ventilation was helpful in modeling ventilation for your storage design. If you need further assistance or have more projects to undertake, remember that our resources and support team are here to help.

Mr. Olen Feest –

I’m extremely impressed with how detailed the CFD analysis is, particularly how the velocity increases noticeably after flowing over the second wall. The streamlines depicted give a great insight into airflow patterns inside the container. Well done!

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that the detailed analysis and results met your expectations and provided valuable insights into the airflow patterns. If you have any further questions or need more assistance, we’re here to help!

Gordon Krajcik –

The tutorial for the storage container room ventilation was clear and digestible. I am impressed by how it tackles real-world applications, and the velocity changes were particularly interesting!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial was helpful and that the real-world application aspect of the simulation resonated with you. It’s fantastic that you found the details about velocity changes intriguing. Your satisfaction with our learning product is our top priority. If you have any further questions or need assistance with other simulations, feel free to reach out!