Surface injection using DPM CFD Simulation

$80.00 $40.00 Student Discount

- The problem numerically simulates the Surface Injection using ANSYS Fluent software.

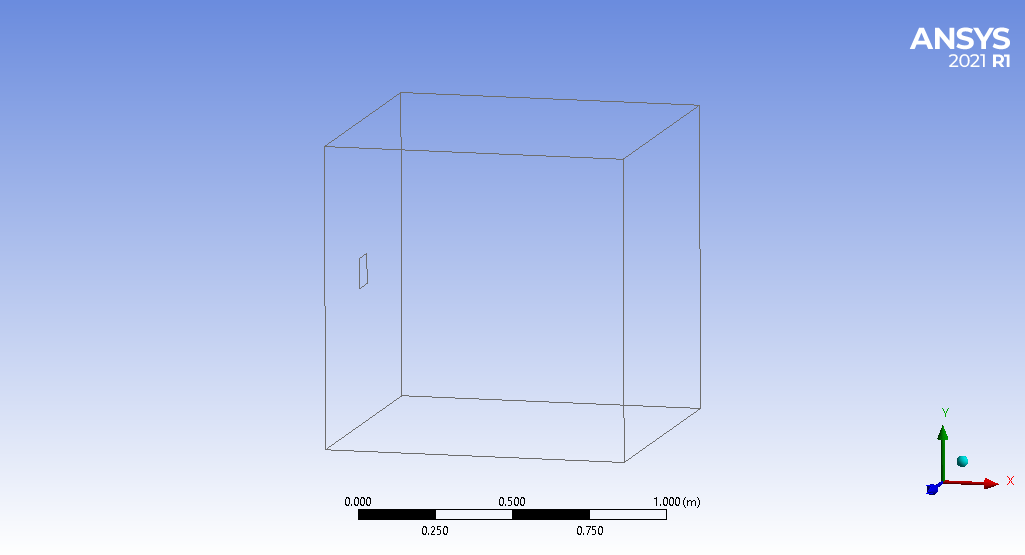

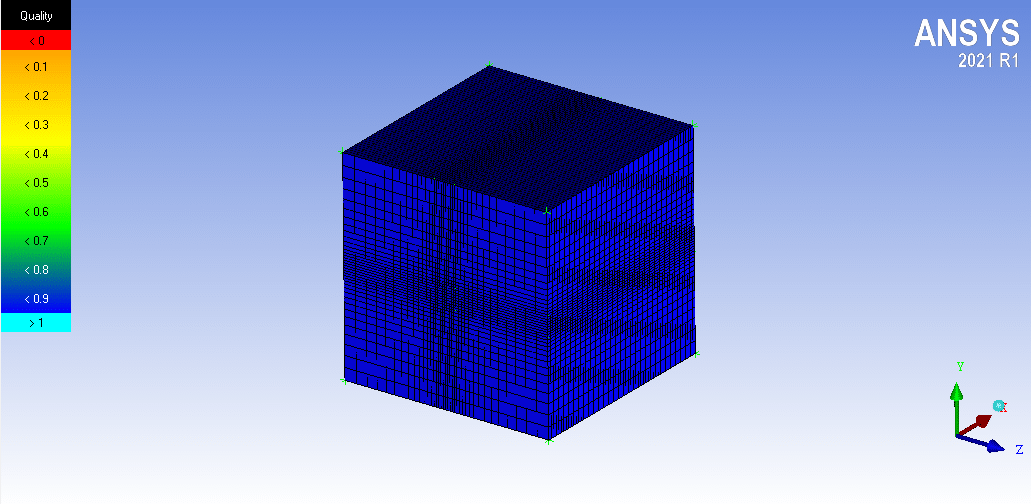

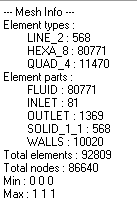

- We design the 3-D model by the Design Modeler and mesh the model with ANSYS ICEM software.

- The mesh type is Structured, and the element number equals 92,809.

- We perform this simulation as unsteady (Transient).

- The Discrete Phase Model (DPM) model defines the particle’s movement.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Surface injection using DPM CFD Simulation, ANSYS Fluent Tutorial

Description

The discrete Phase Model is a method to simulate Multiphase flows.

A discrete phase model (DPM) is used when the aim is to investigate the behavior of the particles from a Lagrangian view and a discrete perspective, so it is more accurate compared to other models such as Mixture, Volume of Fluid and Eulerian- Eulerian, which investigate the behavior of the particles from Eulerian view; however, the calculation cost is much higher.

The geometry of the solution is a 3D cubic domain whose length in X and Y and the Z direction is 5cm, respectively. There is a square surface inlet on the cube’s left side with an edge size of 0.005m. Plus, Design Modeler software is used to create the geometry of the solution. ANSYS ICEM software is used for generating 92,809 Structured grids.

This CFD project is the 8th episode of the ANSYS Fluent General Training Course.

Methodology: Surface injection DPM

The simulation is transient, and the Pressure-based solver type is used due to the incompressibility of the working fluid. The gravitational acceleration effects are considered in the negative direction of the Y-axis. The Surface Injection type is used in the Discrete Phase Model (DPM) to model the particles.

Conclusion

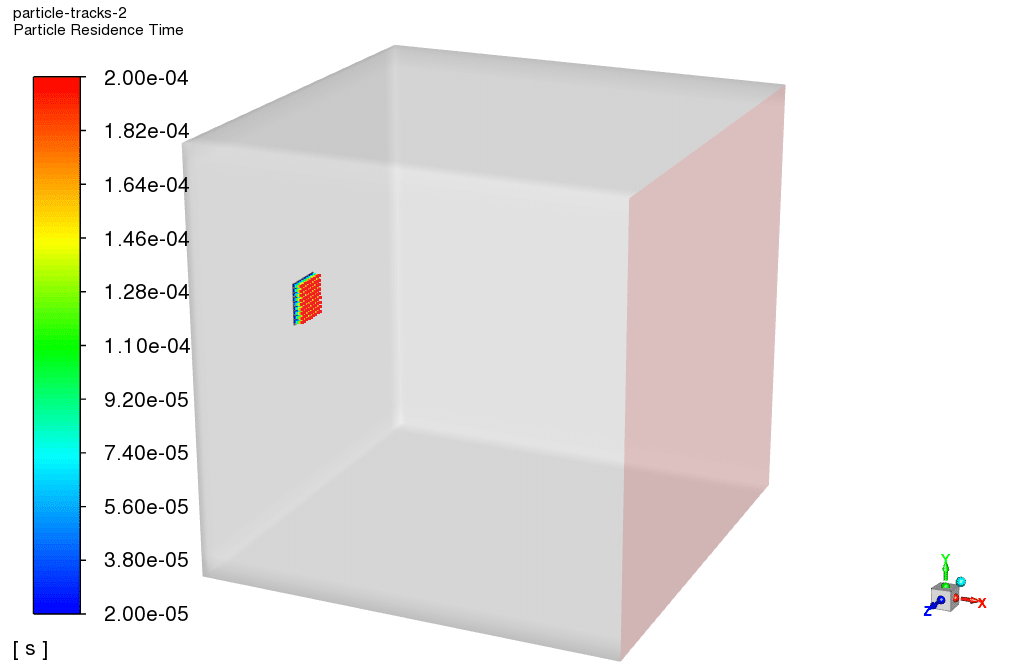

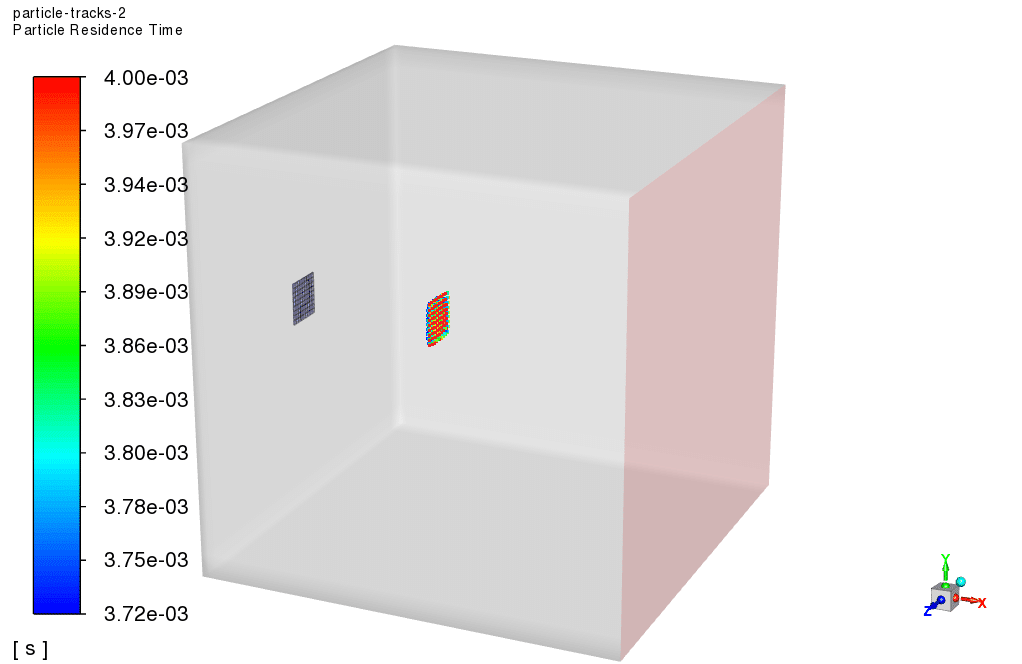

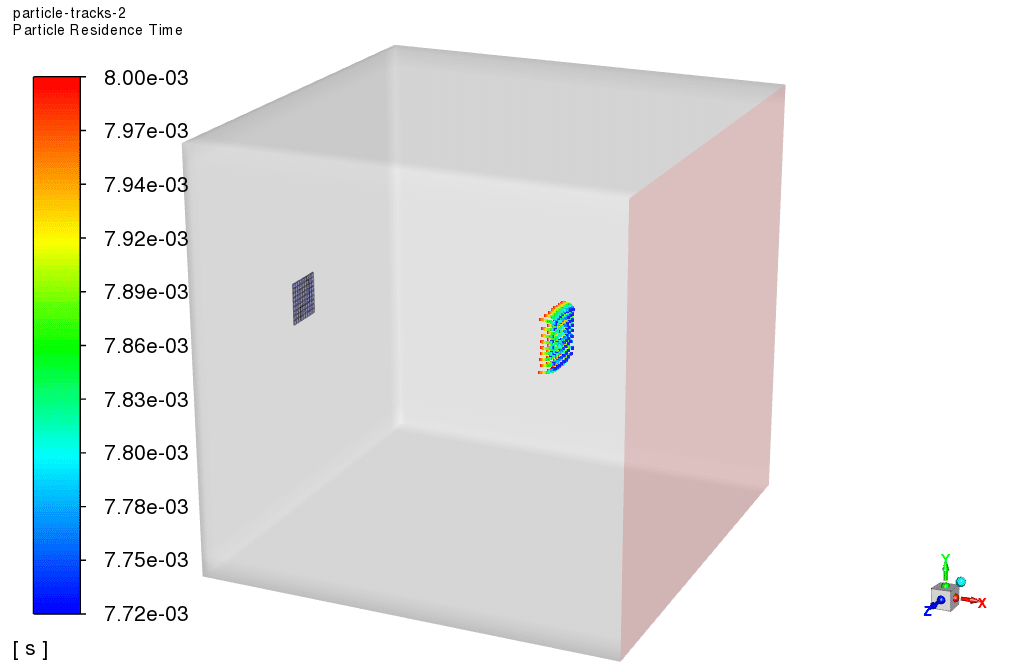

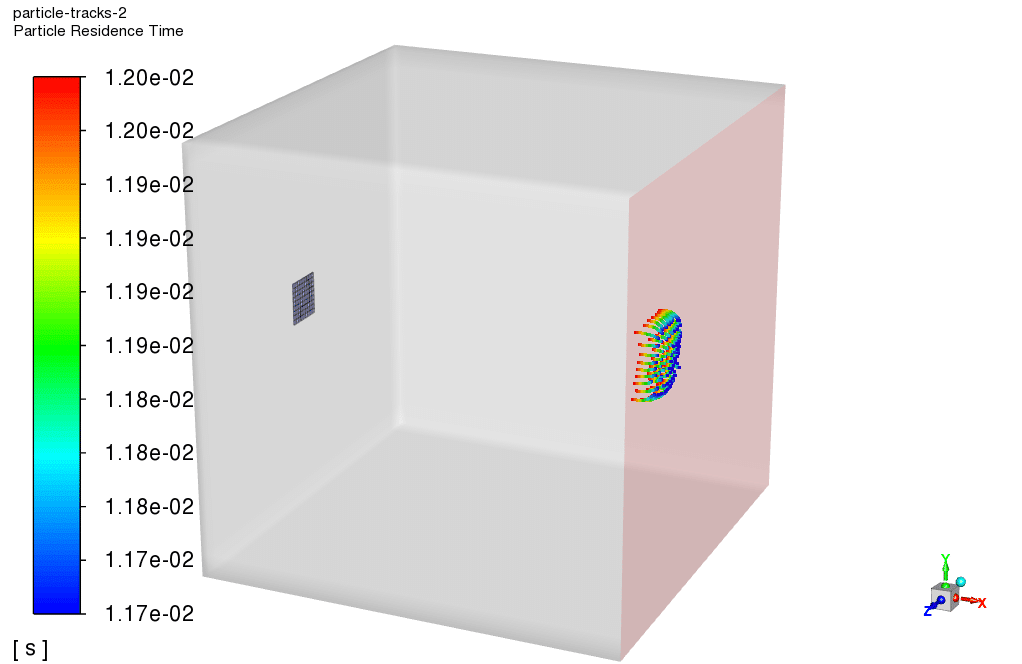

At the end of the solution process, three-dimensional tracking of the injected particles is achieved. Also, their movement animation is recorded every five-time steps. As can be seen in the figures above, the particles are injected into the domain from the left side of the box.

The particles move a little down due to gravity, and the farther they go, the more they spread around until they exit from the right side of the domain.

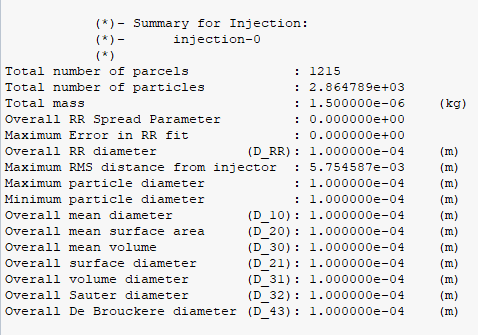

Also, the injection summary is clear in the following figure, which shows the number of parcels, particles, and so on.

Donato Keeling III –

I recently completed the ‘Surface Injection using DPM CFD Simulation’ tutorial and I was fascinated by the particle tracking visualization. Is it possible to also track the temperature of the particles throughout the domain, and if so, how would that affect the simulation results?

MR CFD Support –

In the discrete phase model, it is indeed possible to track additional scalar properties of particles such as temperature. If enabled, you’d see how particle temperature changes as they interact with the continuous phase — the fluid temperature and possibly heat sources within the domain. This would require activating energy equations and appropriate heat transfer models. Particles could gain or lose heat, affecting their temperature and potentially the surrounding fluid’s temperature if heat exchange is significant — it may affect the buoyancy and the flow, providing more insight into the process being modeled.

Oleta Gerlach –

The tutorial was fantastic! I learned a lot about using the DPM model and can confidently tackle surface injection simulations now. The step-by-step breakdown made it all very easy to understand.

MR CFD Support –

Thank you for your kind review! We’re delighted to hear that our Surface Injection using DPM CFD simulation tutorial was helpful and that you now feel confident with the model. We strive to create informative and user-friendly tutorials, so it’s great to know we’ve achieved that. If you ever have any further queries or need assistance with other simulations, remember we’re here to help!

Josianne Legros –

Everything explained in the tutorial was clear, but I was wondering what kind of particles were used in the simulation and what properties they had?

MR CFD Support –

In the simulation for the DPM tutorial, the properties of the particles would typically be defined to match the characteristics of the real particles intended to be simulated. Possible properties include particle size, density, specific heat capacity, and material type. The exact specifications would be set in the ANSYS Fluent software to accurately reflect the behavior of the particles under study.

Raheem Bailey –

This Surface Injection DPM tutorial appears quite comprehensive. I’m particularly interested in analyzing how the particles behave when their properties vary, like their temperature or diameter. Does the tutorial offer guidance on assessing the impact of varying particle properties during the simulation?

MR CFD Support –

The tutorial indeed includes guidance on varying particle properties, such as temperature and diameter, within the Discrete Phase Model. You will learn how to adjust these parameters and analyze their impact using DPM in ANSYS Fluent.

Kelsi Jakubowski IV –

The tutorial was incredibly informative and detailed. The focus on particle tracking using DPM provided a great understanding of the complex multiphase flows and made it much simpler to get to grips with such simulations. The step-by-step guidance is perfect for beginners.

MR CFD Support –

Thank you for the positive feedback. We’re delighted to hear that the tutorial on surface injection using DPM was helpful and easy to understand. It’s great to know that the materials were informative and beneficial to your learning process. If you have any more questions or need further assistance in the future, please feel free to reach out!

Dr. Anjali Stamm –

The tutorial sounds highly informative. The coverage of the Discrete Phase Model and the surface injection simulation seems well executed. It’s great to learn that the product offers a clear demonstration of particle tracking and the gravity effect on particulate motion.

MR CFD Support –

We’re delighted to hear that you found the tutorial comprehensive and valuable. It’s fantastic to know that the simulation demonstrations have enhanced your understanding of particle dynamics in fluid flow. Thank you for your positive review, and we are always here to enhance your experience and knowledge with our products.

Titus Green –

I just finished the Surface injection using DPM CFD Simulation tutorial, and was amazed by how well it demonstrated particle tracking using the Discrete Phase Model. The clarity of instructions and the depth of explanation made complex phenomena easy to understand. Well done on a phenomenal tutorial!

MR CFD Support –

Thank you for your complimentary review! We’re thrilled to hear that our tutorial was clear and helpful. Our goal is to make complex concepts accessible and we’re glad we succeeded with this tutorial. If you have any more feedback or need further assistance, feel free to reach out!

Dr. Rory Langworth II –

The tutorial was impeccable. The step-by-step approach to setting up the surface injection using DPM was clear, and now I understand the impact of gravity on particle dynamics!

MR CFD Support –

We’re delighted to hear that you found our tutorial clear and helpful! Understanding complex particle dynamics can indeed be gratifying. Thank you for your positive feedback, and we’re here if you have any more questions!

Dr. Everette Denesik –

I’m truly fascinated by how well the Surface Injection DPM tutorial was presented. Observing the particles being tracked and modeled was visually striking and informative.

MR CFD Support –

We’re delighted to hear that you found the Surface Injection DPM tutorial informative and visually appealing! Your positive feedback motivates us to continue providing high-quality content. Thank you for taking the time to review our product.

Prof. Lee Dietrich DDS –

I was truly fascinated by the DPM tutorial on surface injection! Watching the discrete phase particle movement and the spreading due to gravity added so much depth to my understanding. The animations and the detailed tracking brought the concept to life. It’s amazing how CFD methods like this can illuminate such complex behaviors in particles.

MR CFD Support –

We’re thrilled that you found the Discrete Phase Model (DPM) surface injection tutorial enlightening and engaging. Observing how particles behave and move inside fluid domains indeed adds a valuable perspective to CFD analysis. Thank you for taking the time to share your positive experience with our product. We look forward to continuing to support your learning journey!

Ford Weissnat –

Is it possible to track specific particles and analyze their behavior individually in detail with the DPM method in ANSYS Fluent?

MR CFD Support –

Yes, it is possible to individually track specific particles and analyze their behavior in detail using the Discrete Phase Model (DPM) in ANSYS Fluent. The software provides tools for tracking and recording the path and state of single particles or groups of particles, offering insights into their dynamics, interaction with fluid phases, and the impact of forces like drag and gravity.

Guillermo Cole –

The tutorial was incredibly helpful for visualizing particle behavior with DPM! The step-by-step approach and the detailed explanation made it much easier to understand. The gravity effect on particle trajectory was particularly interesting to observe.

MR CFD Support –

Thank you for your fantastic feedback! We’re thrilled to hear the Surface Injection using DPM CFD Simulation tutorial was clear and educational. If you need further clarification or have more questions on the topic, we’re here to help.