Switchblade 300 (steady-state),Ansys Fluent CFD Simulation

$100.00 $50.00 Student Discount

- This study focuses on the aerodynamic analysis of the Switchblade 300 using ANSYS Fluent

- Two scenarios are simulated: one with the rear blade stationary and the other with the rear blade in motion.

- The geometry of the Switchblade was created using SpaceClaim software,The meshing was performed in Fluent Meshing, utilizing a polyhedral mesh with over 7,600,000 elements

- The Multiple Reference Frame (MRF) approach was employed to simulate the rotating rear blade at 5000 RPM.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

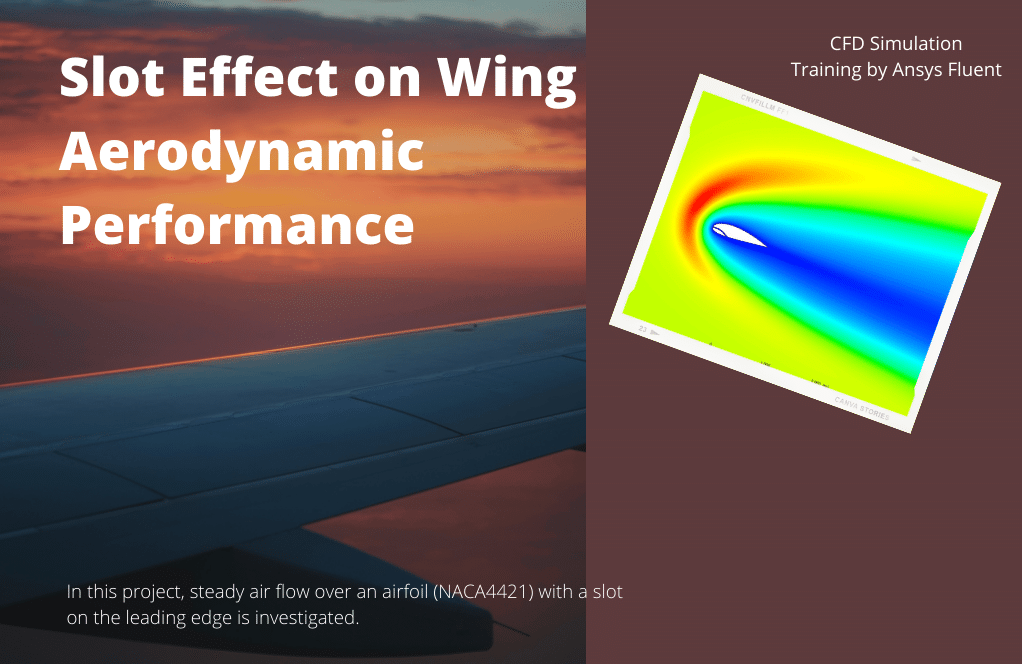

Introduction

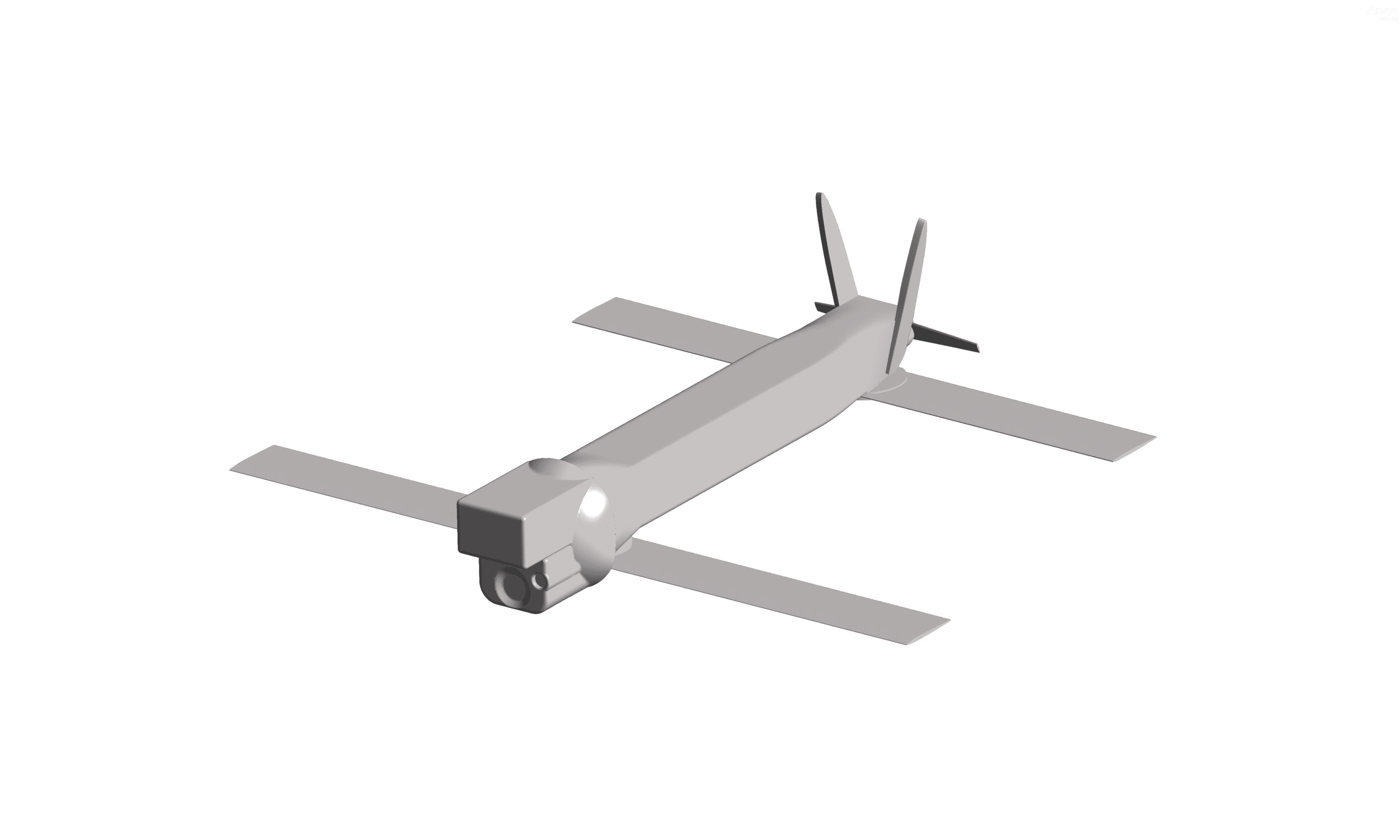

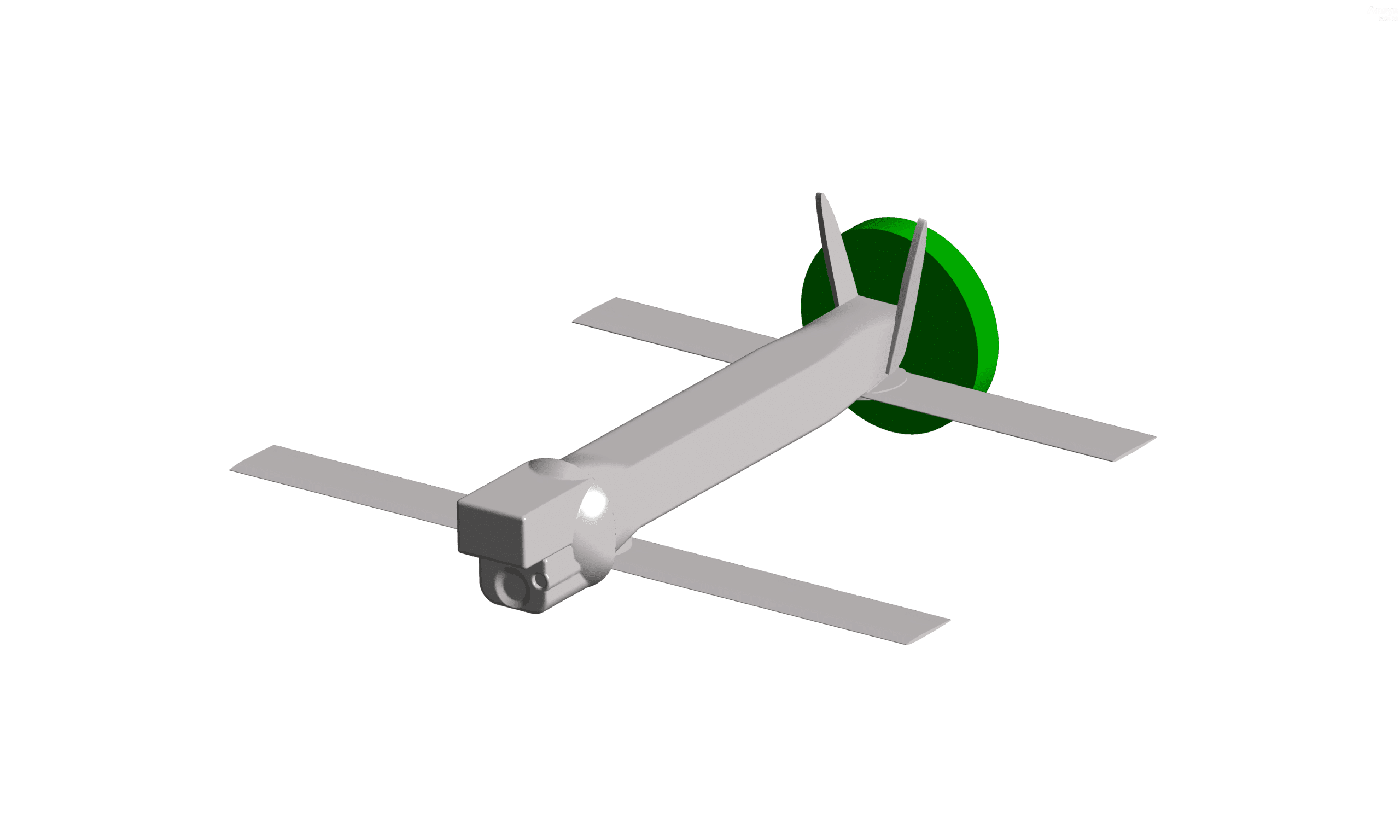

This study focuses on the aerodynamic analysis of the Switchblade 300 using ANSYS Fluent. The primary objective is to evaluate the airflow characteristics around the UAV under different operational conditions. Two scenarios are simulated: one with the rear blade stationary and the other with the rear blade in motion.

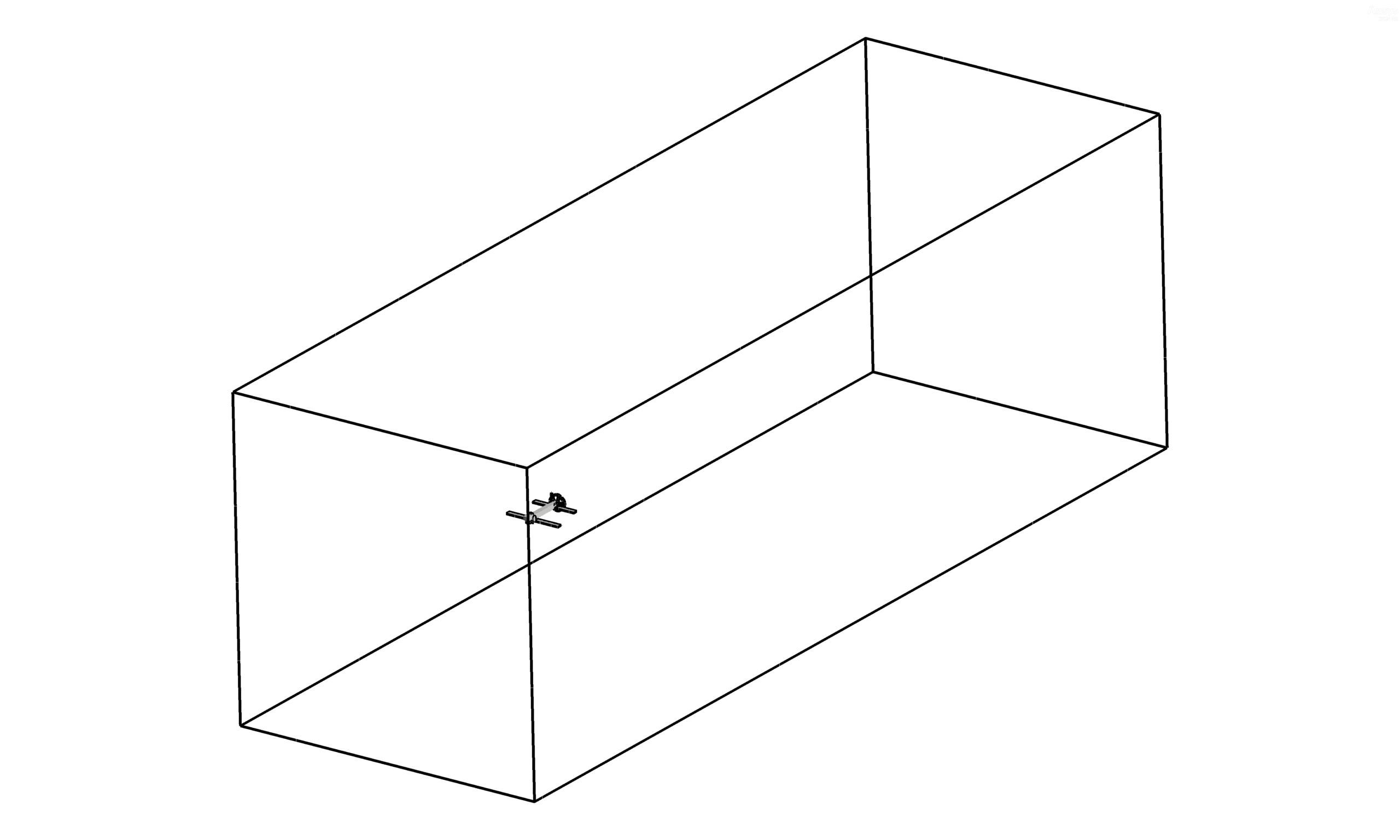

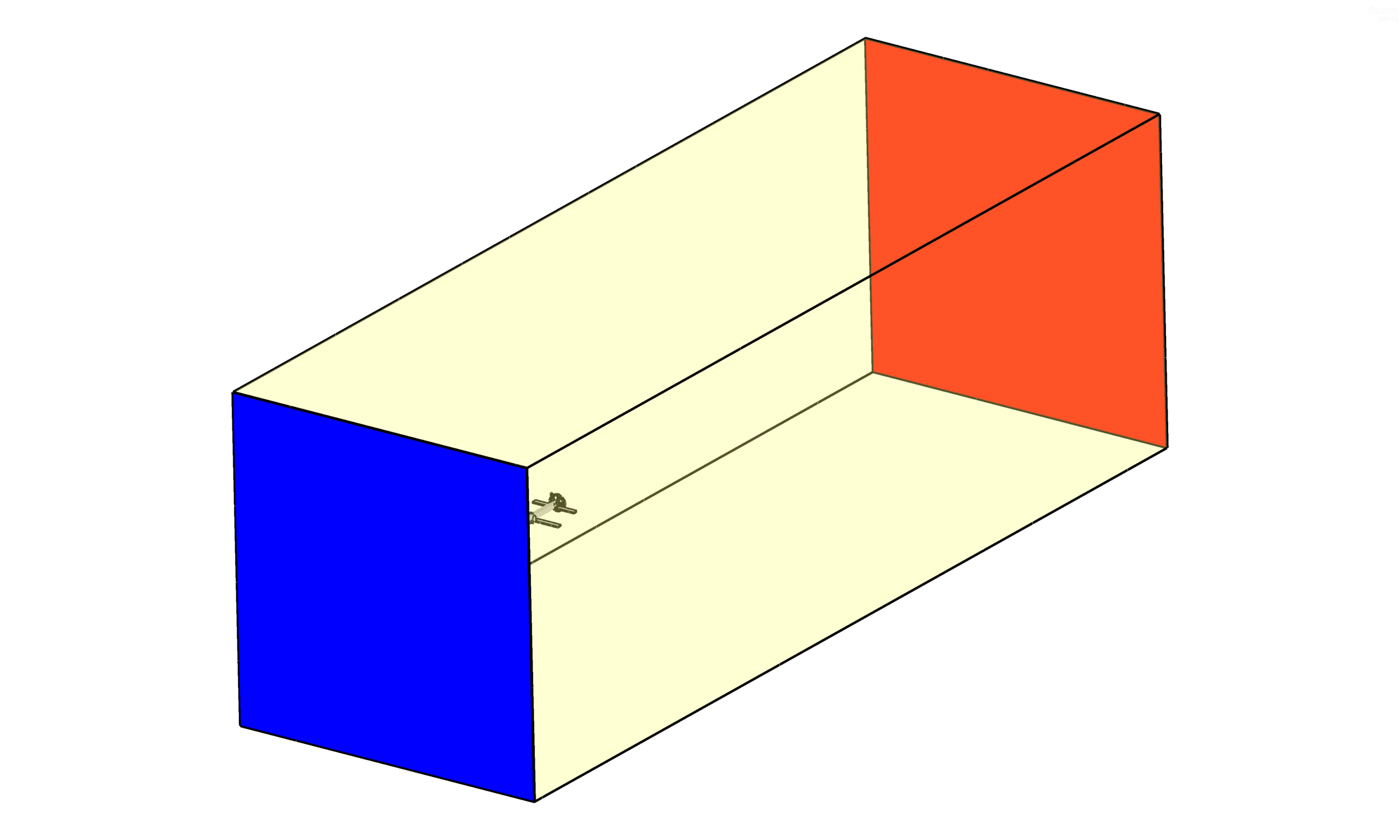

The geometry of the Switchblade was created using SpaceClaim software. The model includes critical components such as the inlet and outlet regions for airflow analysis.

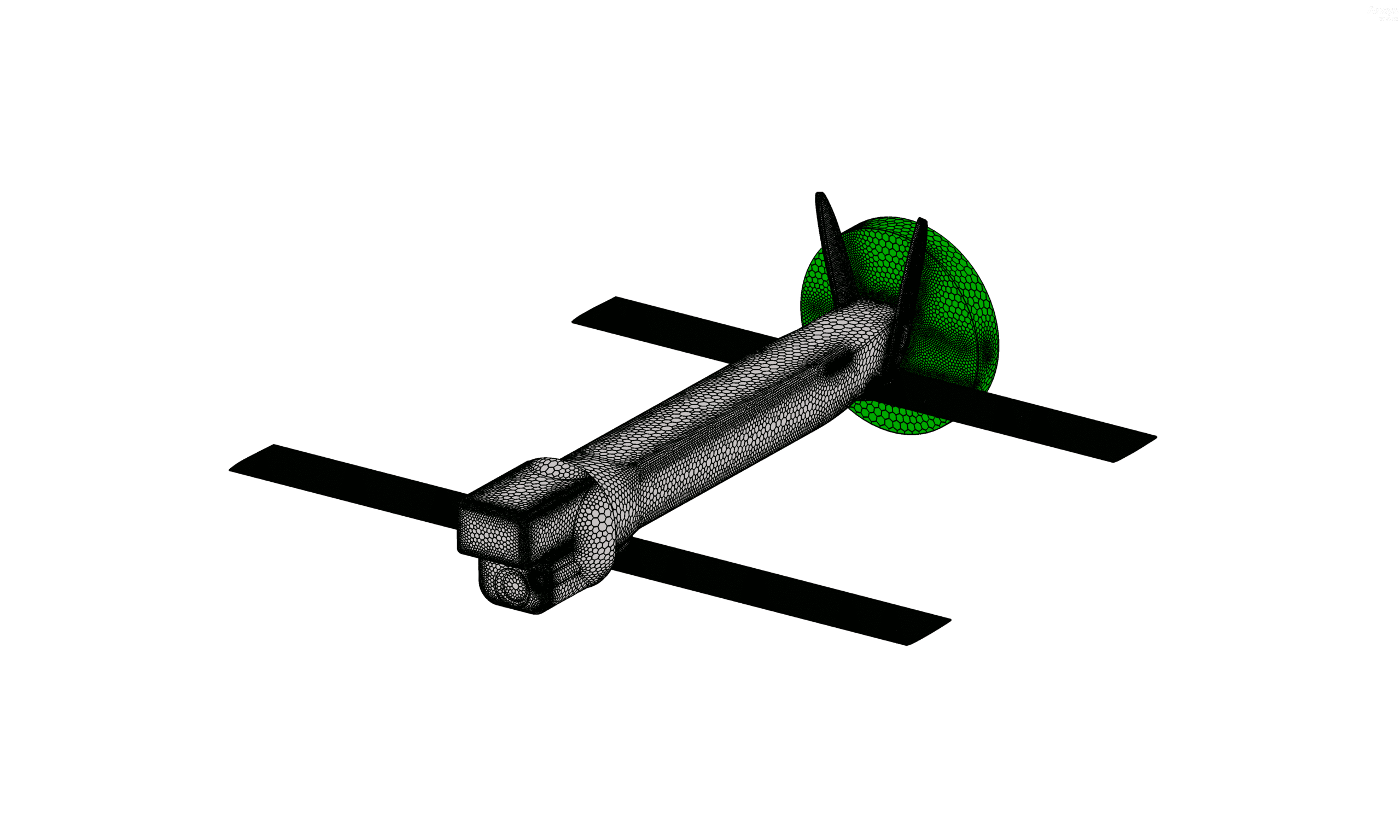

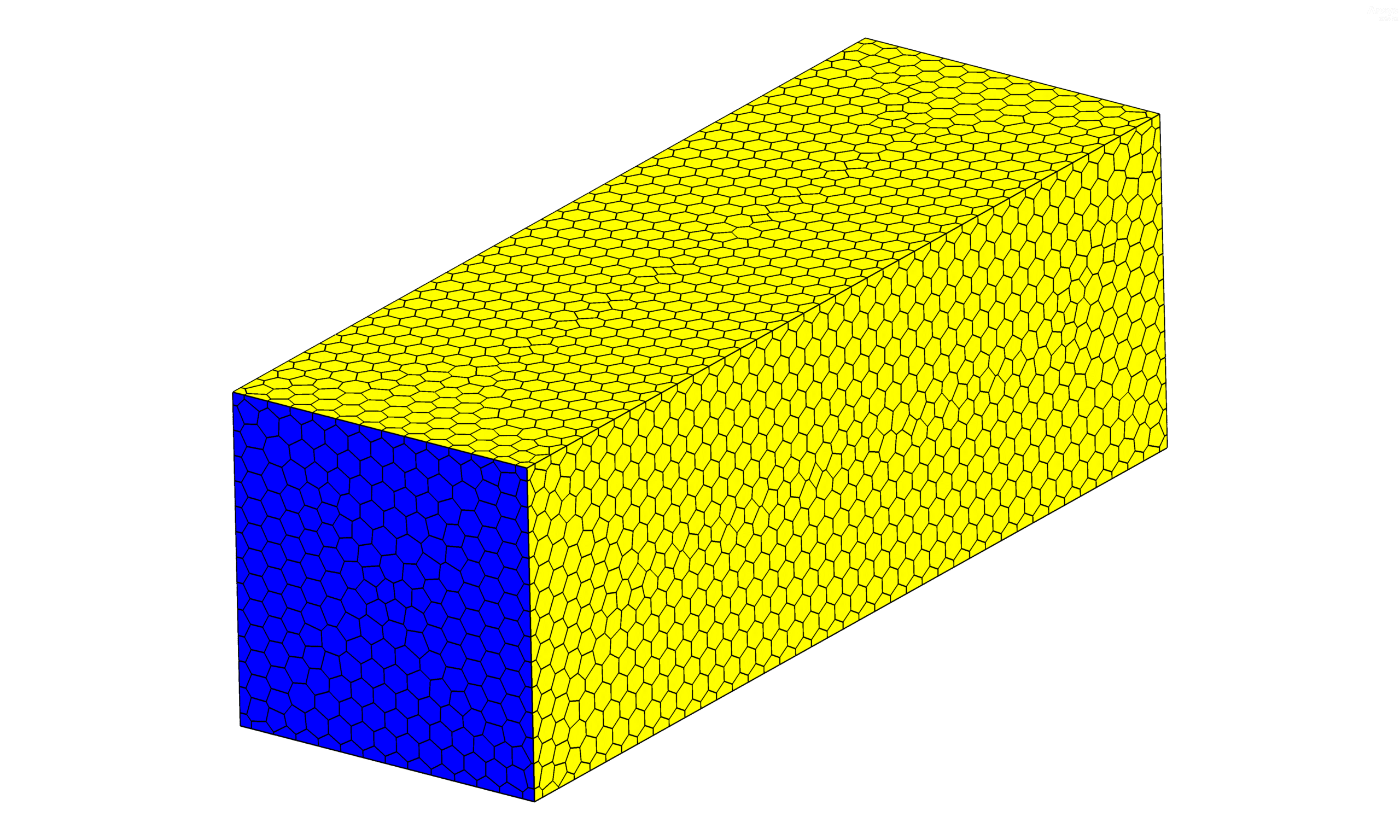

The meshing was performed in Fluent Meshing, utilizing a polyhedral mesh with over 7,600,000 elements. This type of mesh offers enhanced accuracy and efficiency in capturing complex flow patterns around the UAV.

Simulation Settings

Simulations were conducted using ANSYS Fluent with a pressure-based solver and the SIMPLE algorithm for pressure-velocity coupling. Key conditions include an inlet velocity of 28.05 m/s and an angle of attack of 5 degrees. The Multiple Reference Frame (MRF) approach was employed to simulate the rotating rear blade at 5000 RPM.

Results

Flow Analysis

Two simulations were conducted: a baseline case with stationary rear blades and an enhanced one with rotating blades.

Velocity Distribution

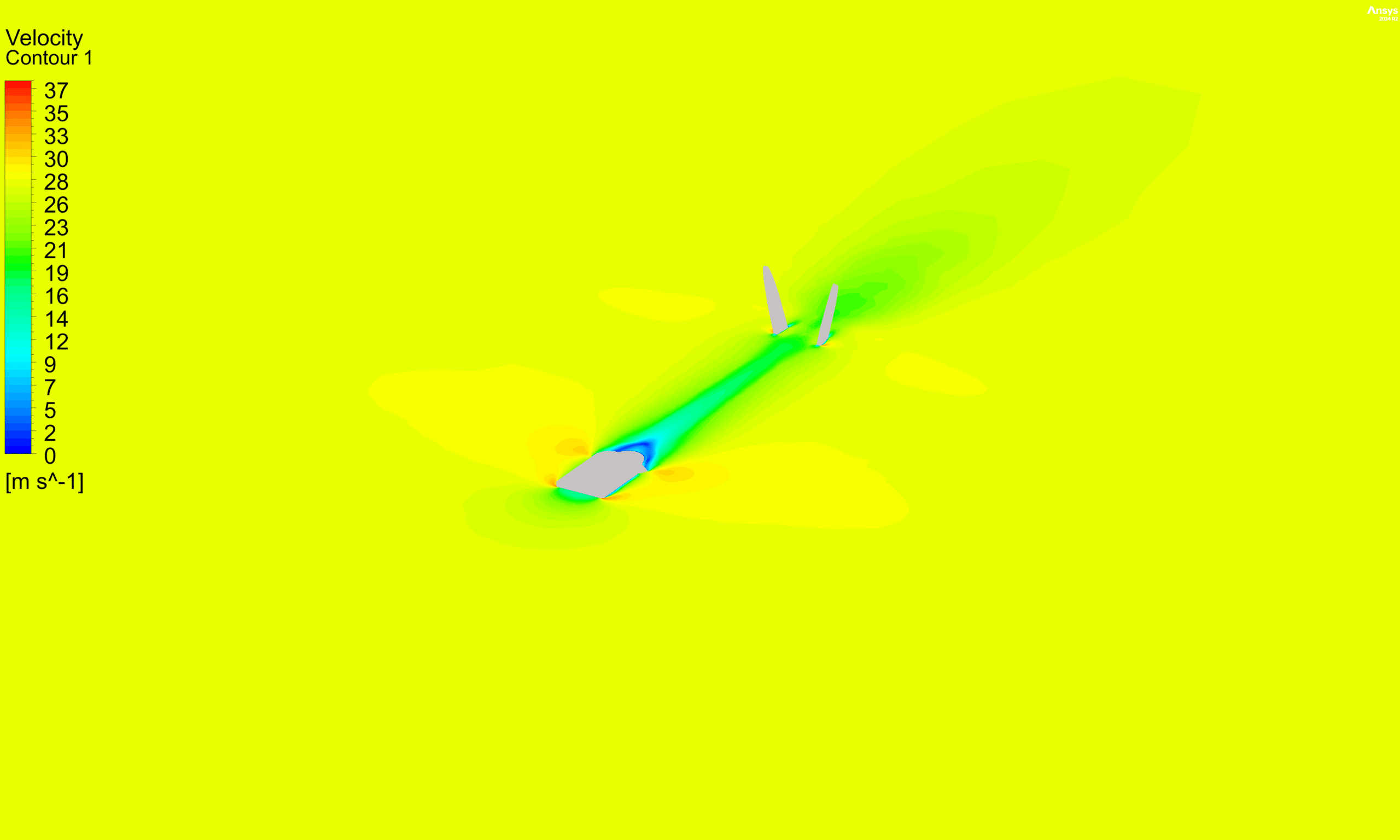

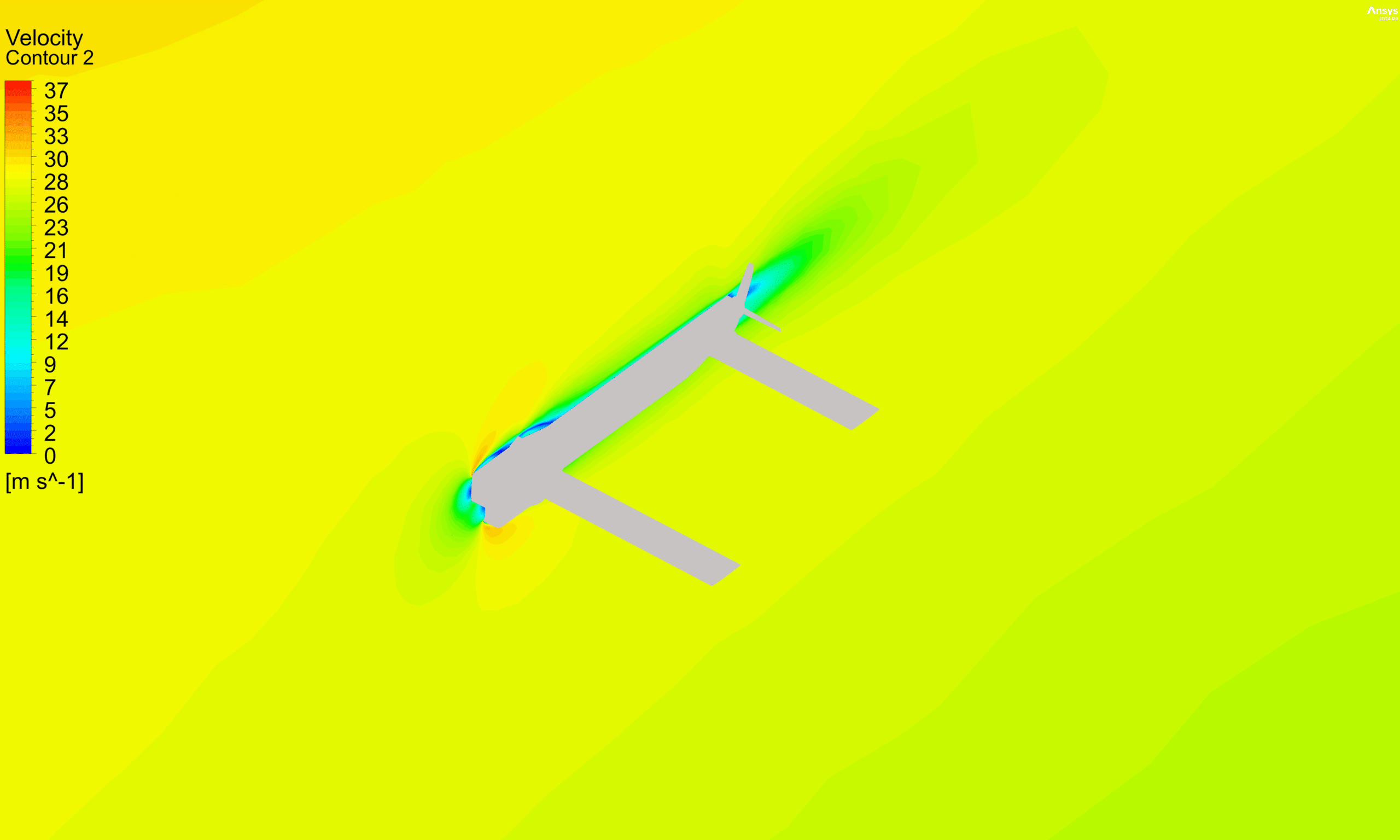

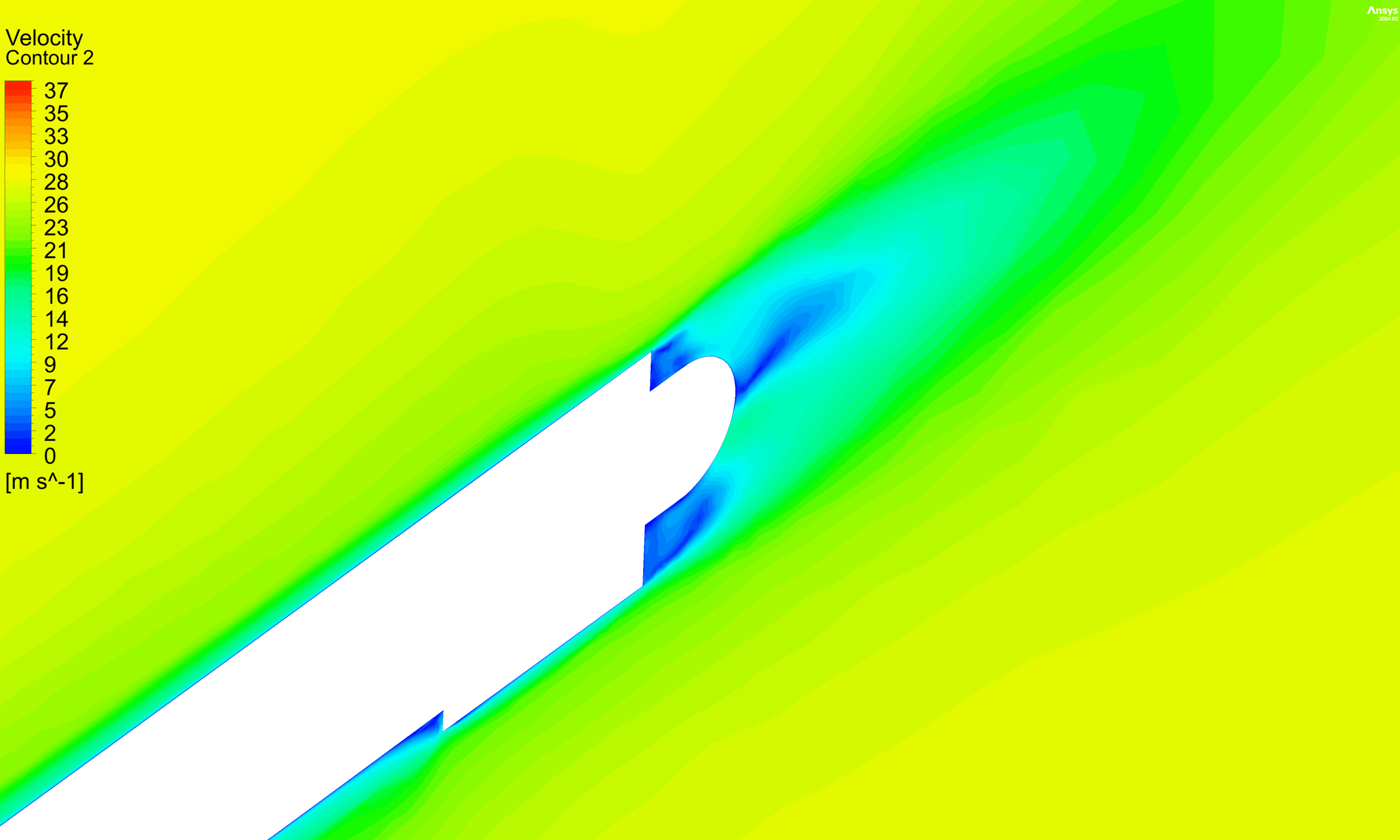

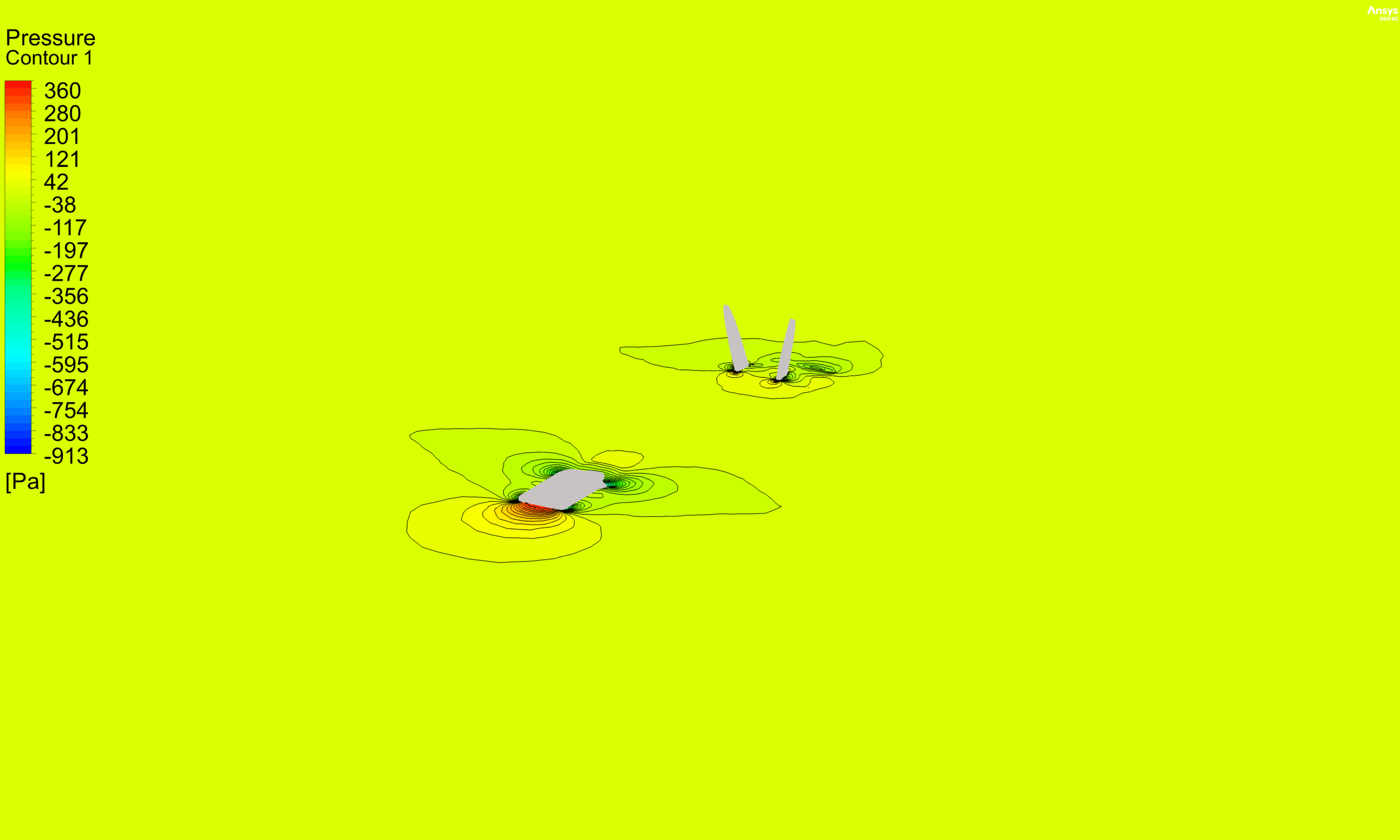

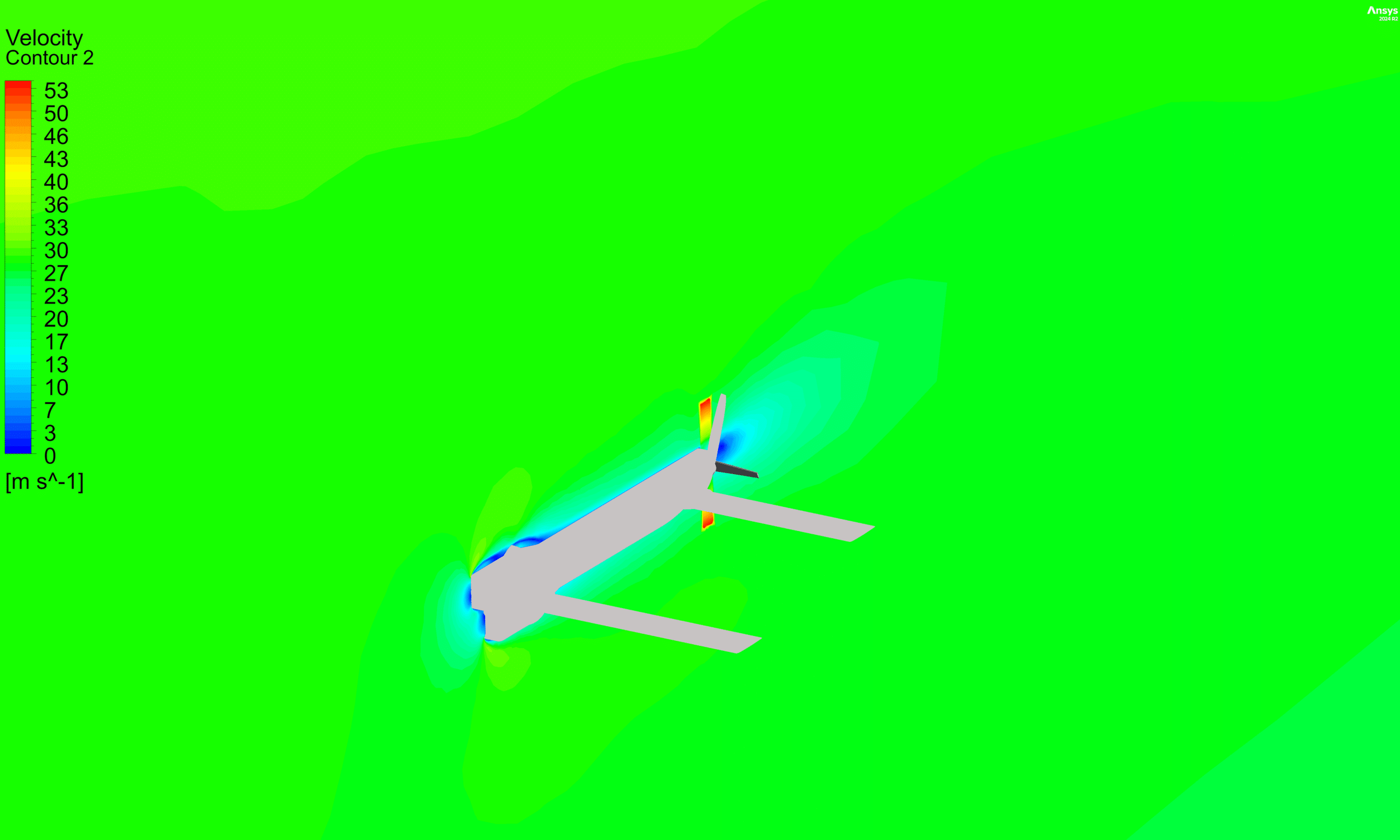

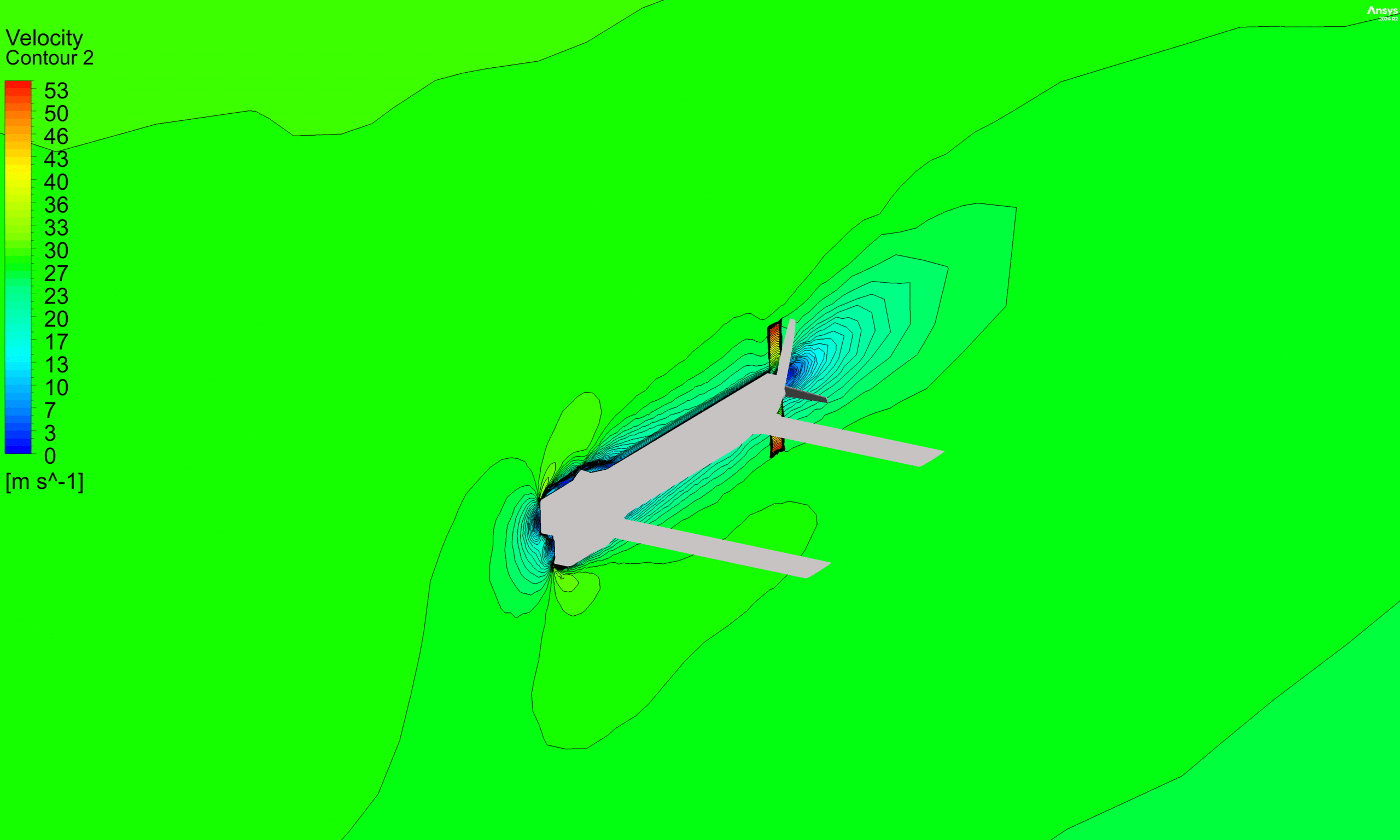

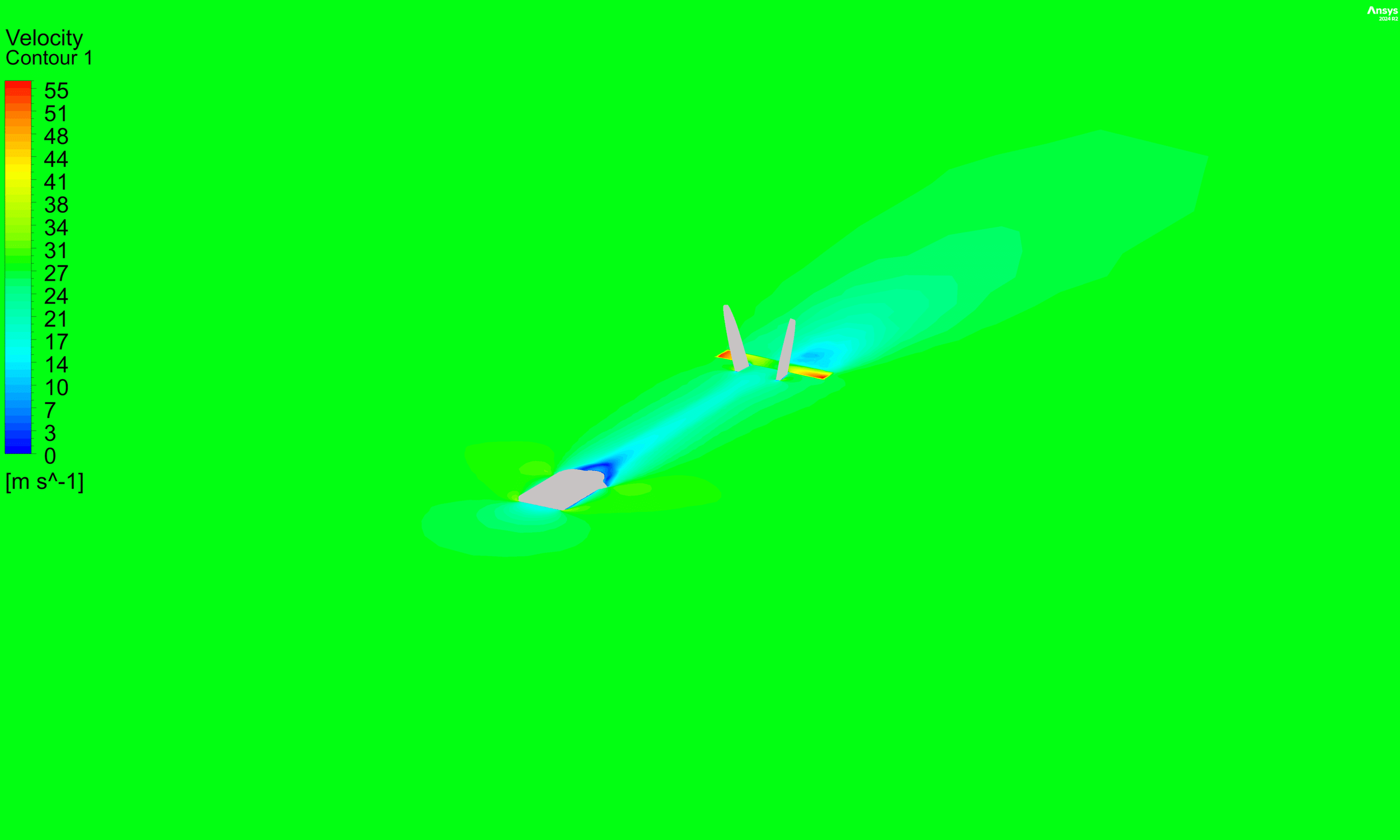

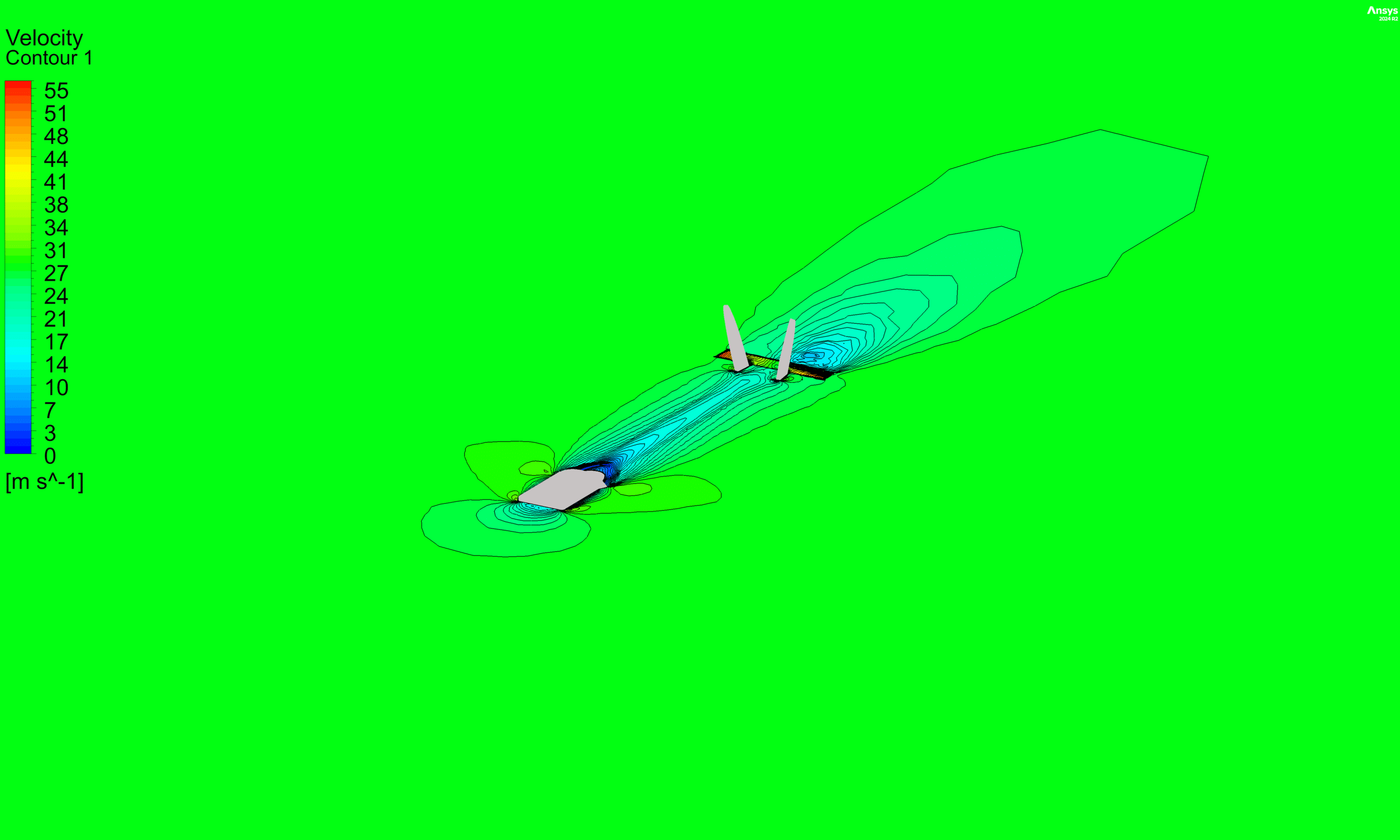

Figure 3 illustrates the velocity contours for both scenarios. The introduction of rear blade rotation using MRF significantly alters the velocity profile, impacting the aerodynamic performance.

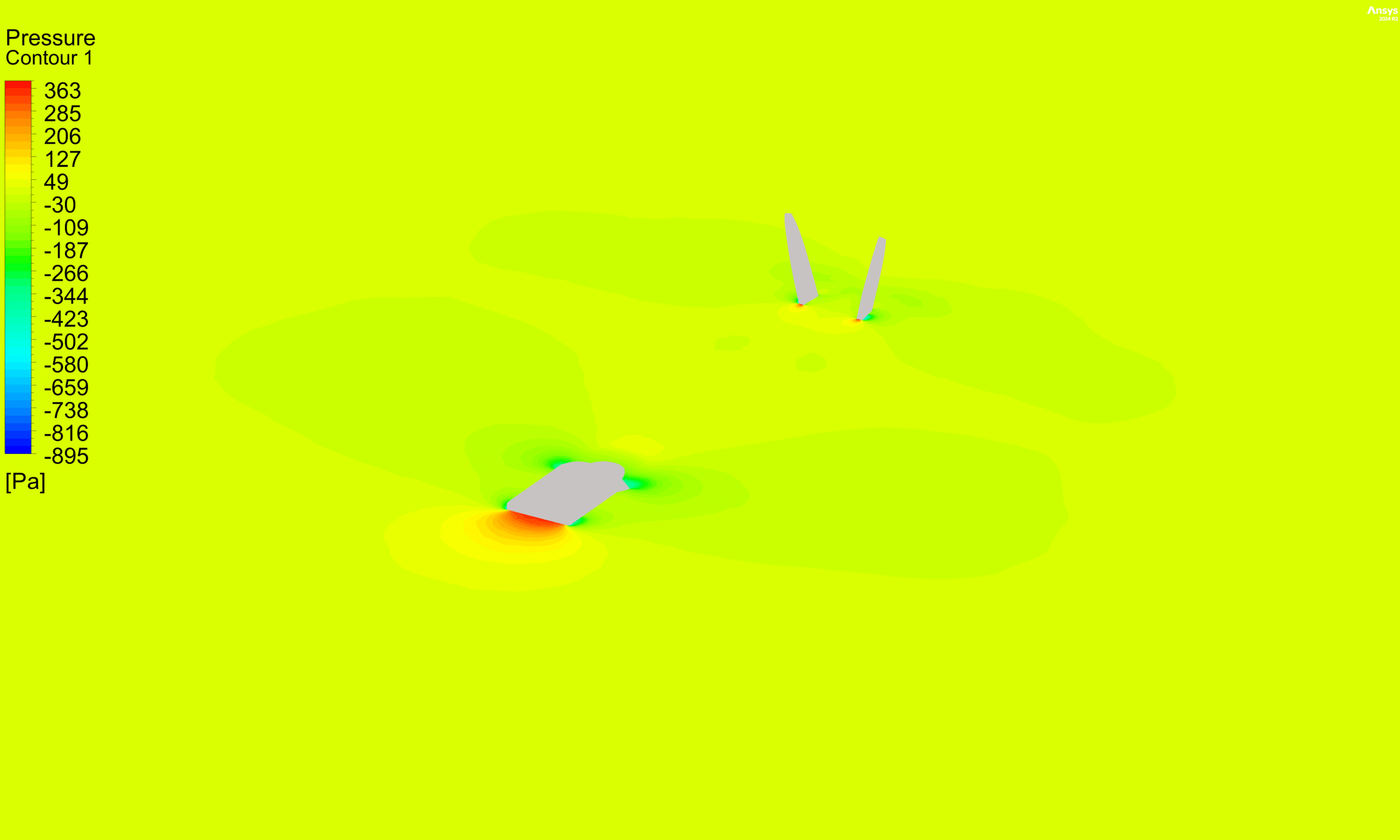

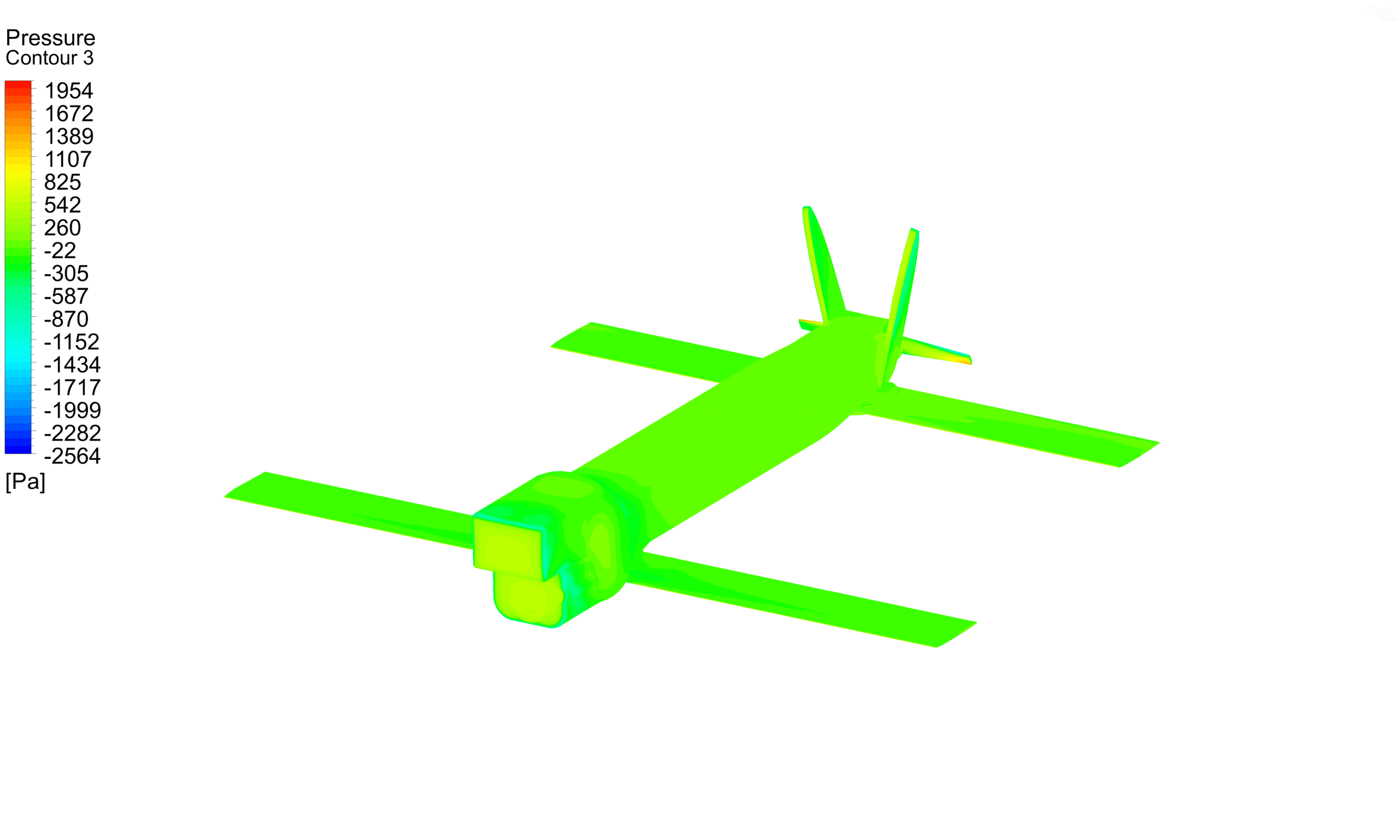

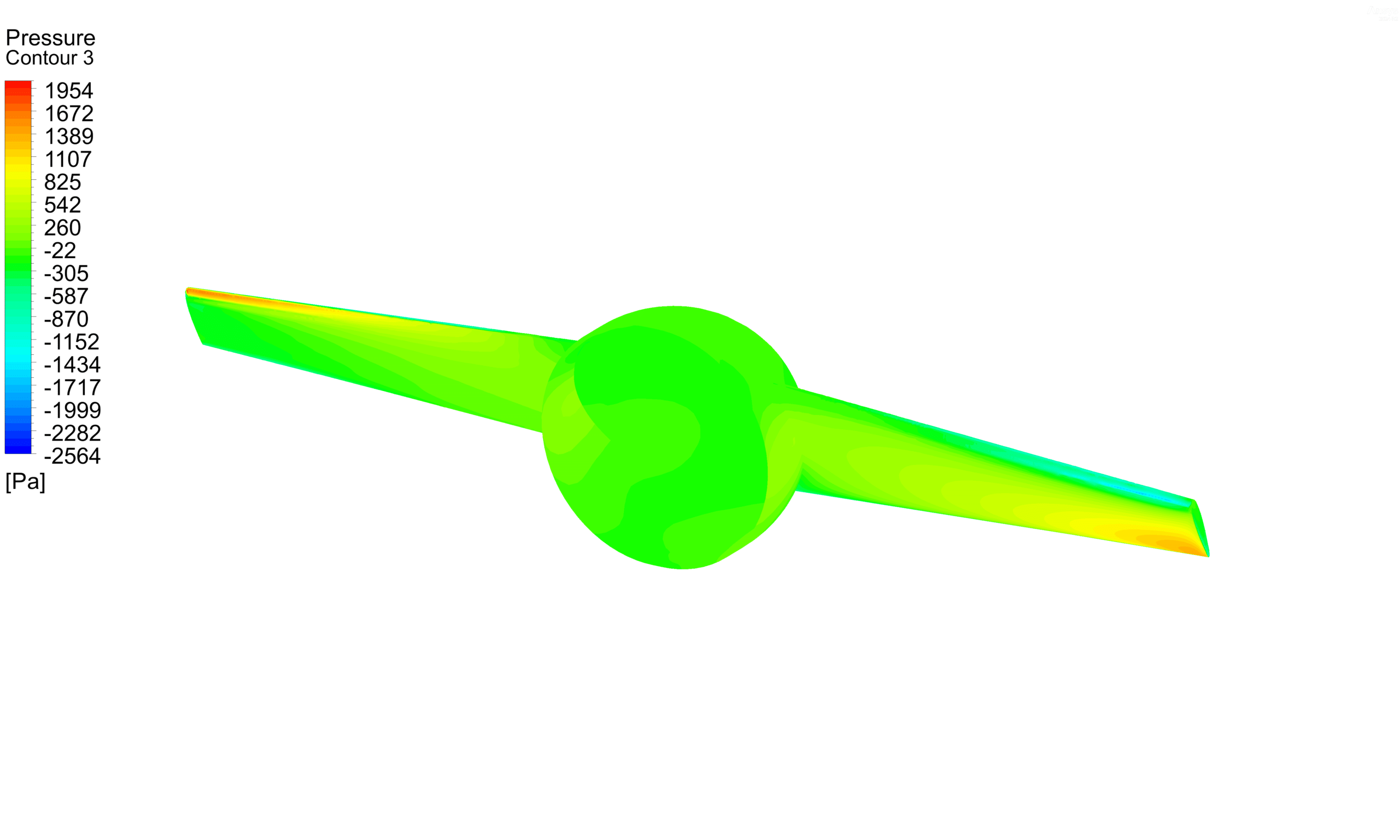

Pressure Distribution

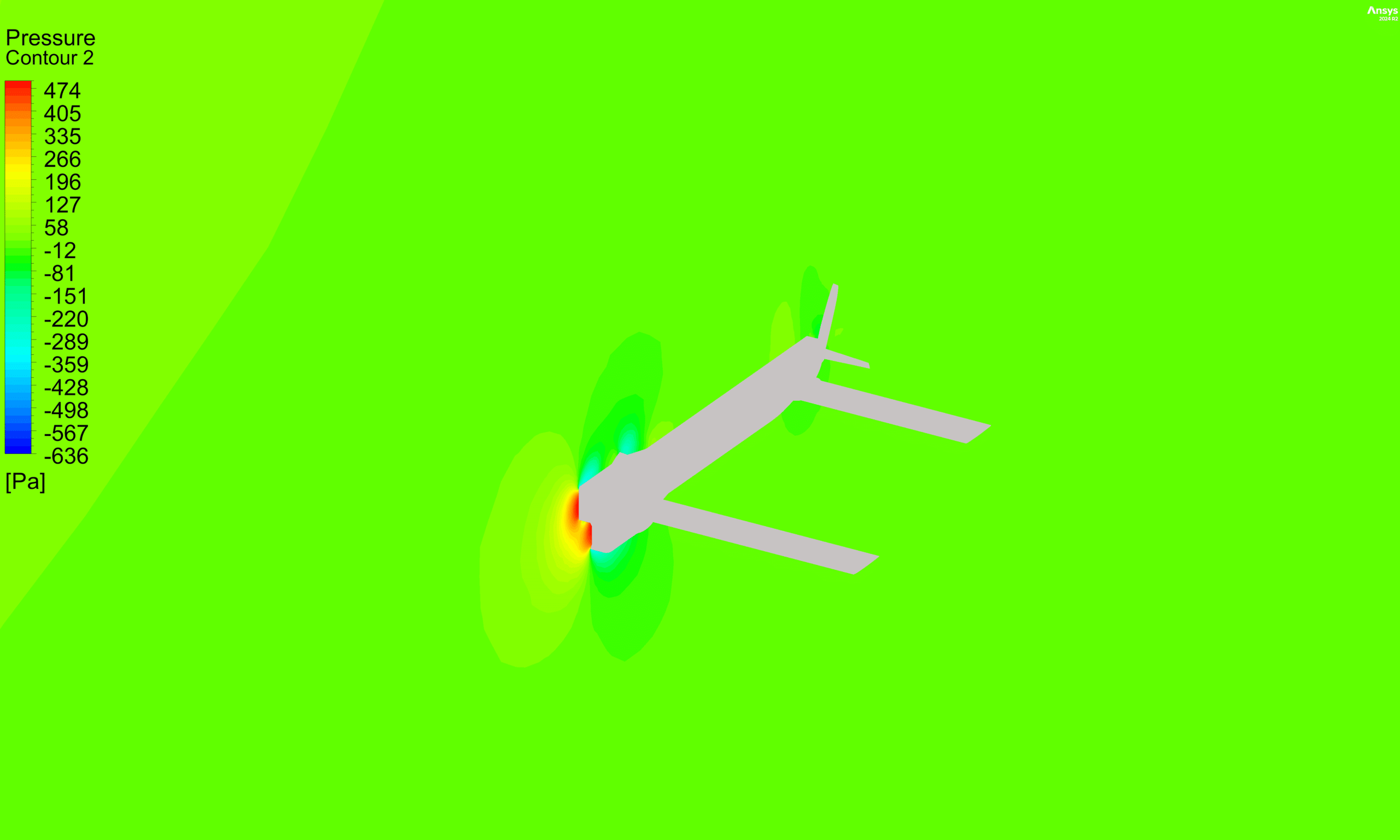

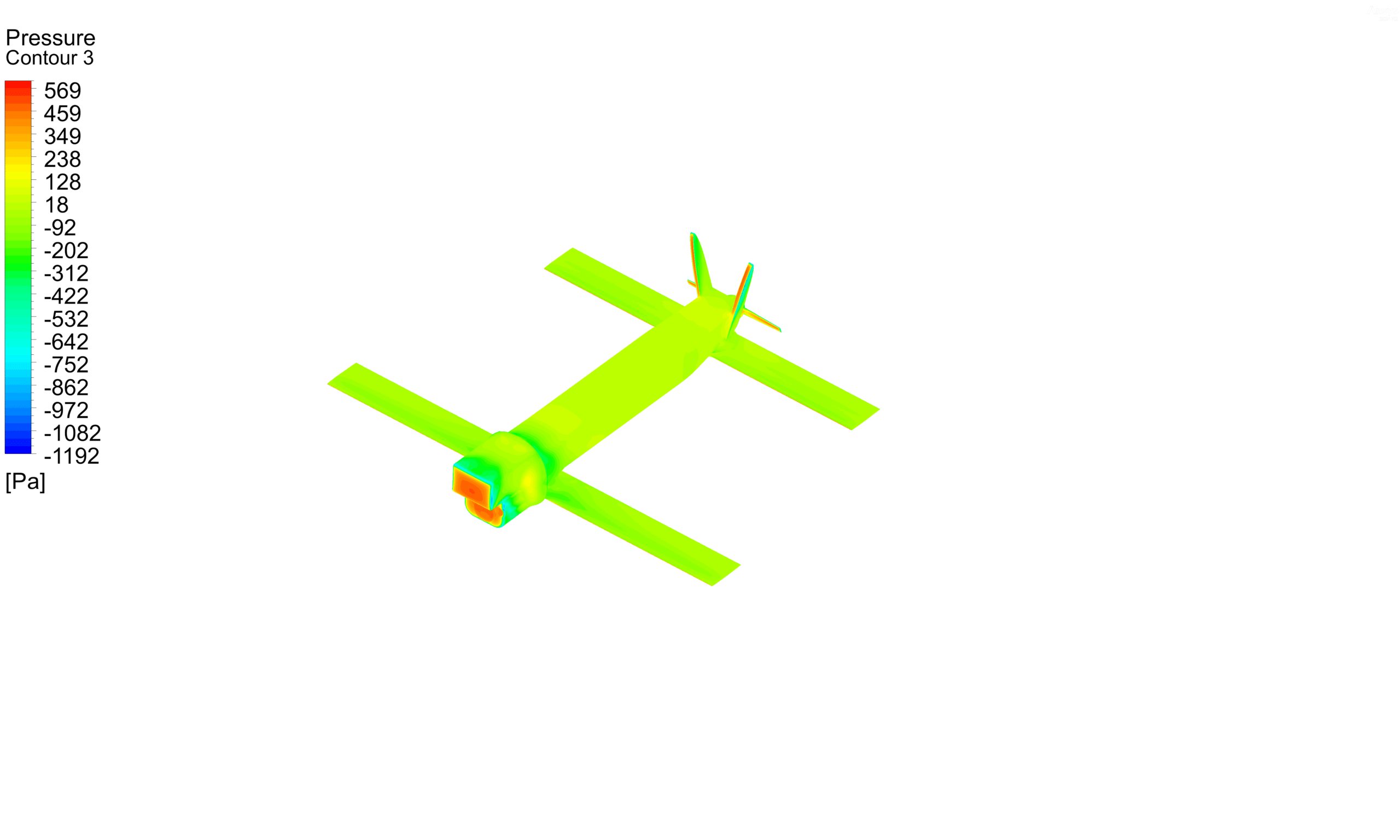

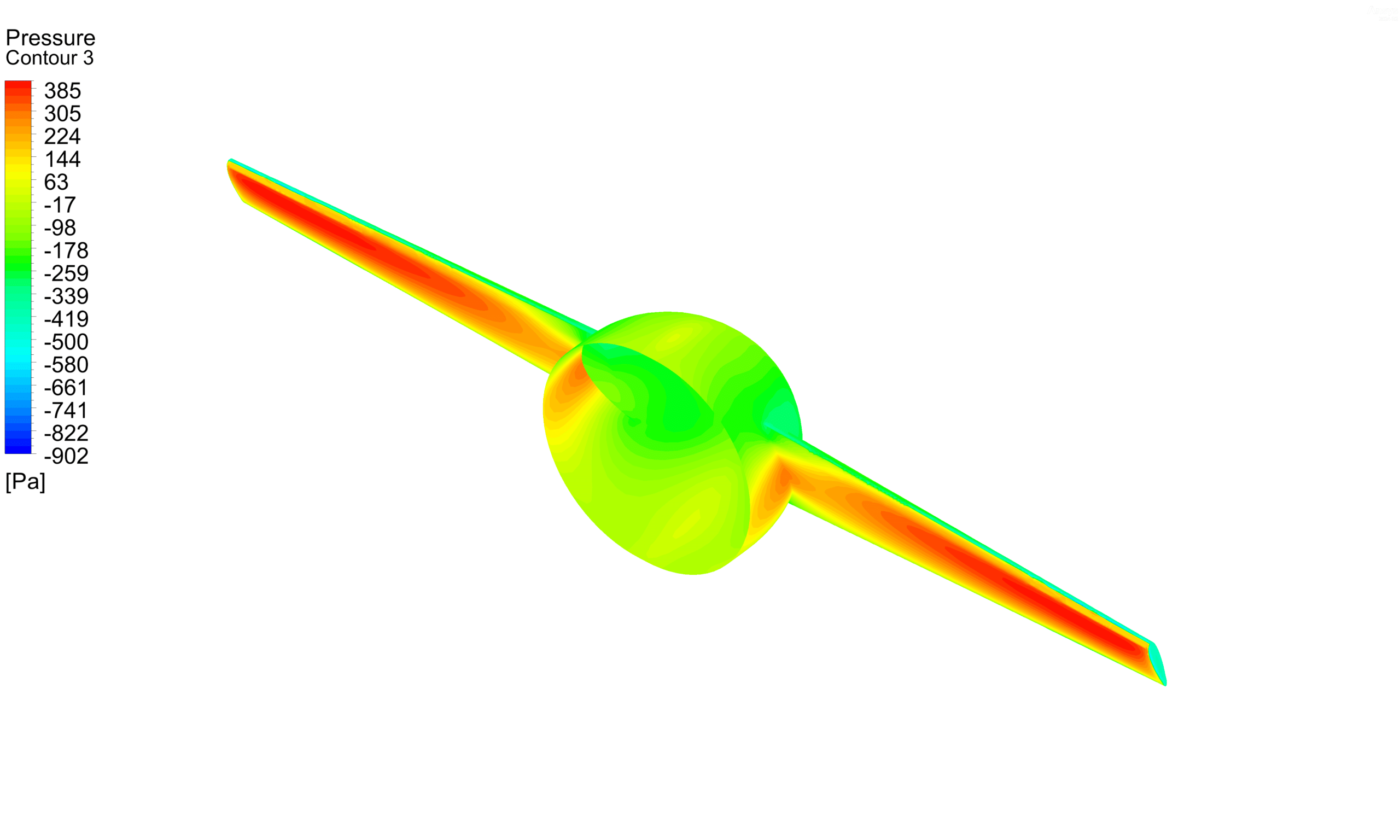

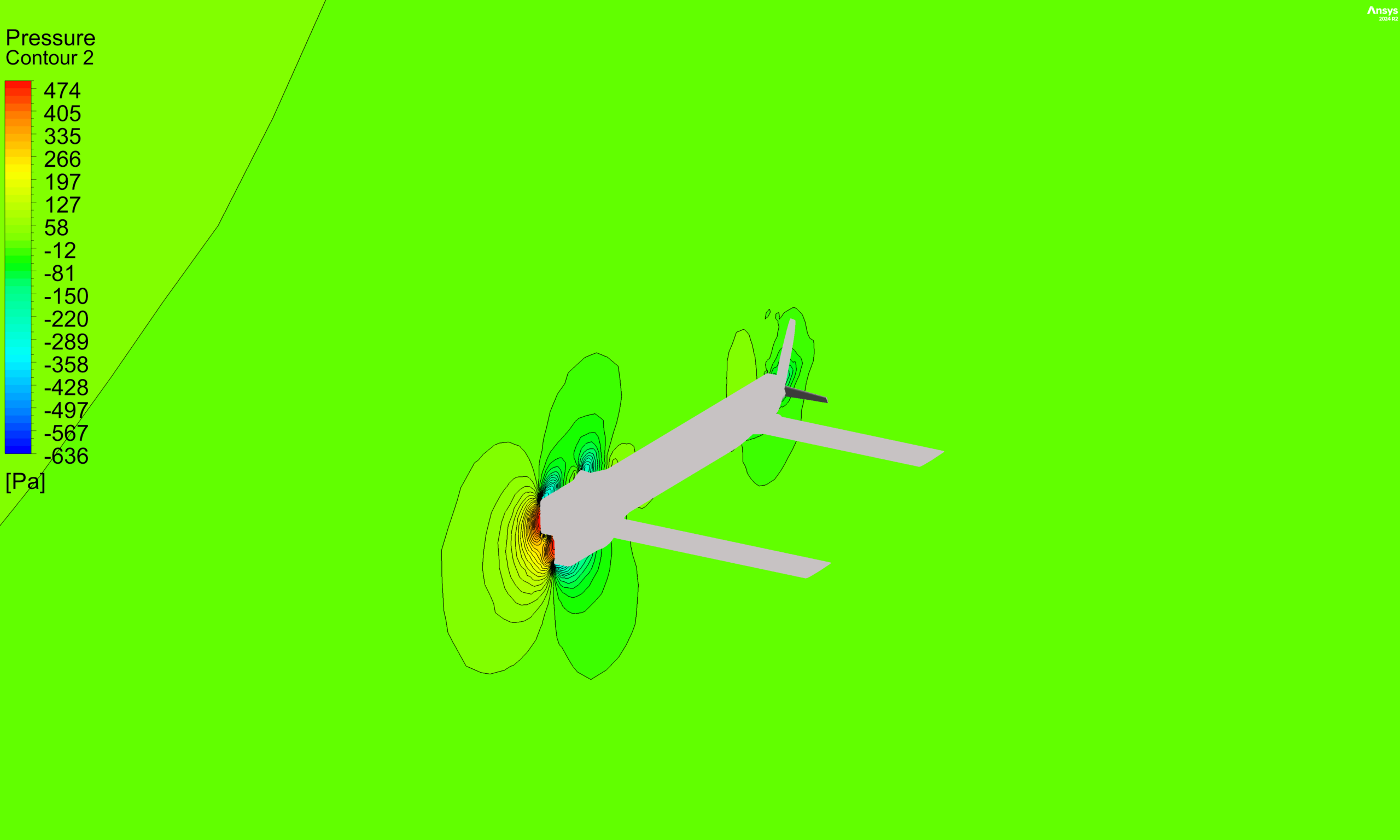

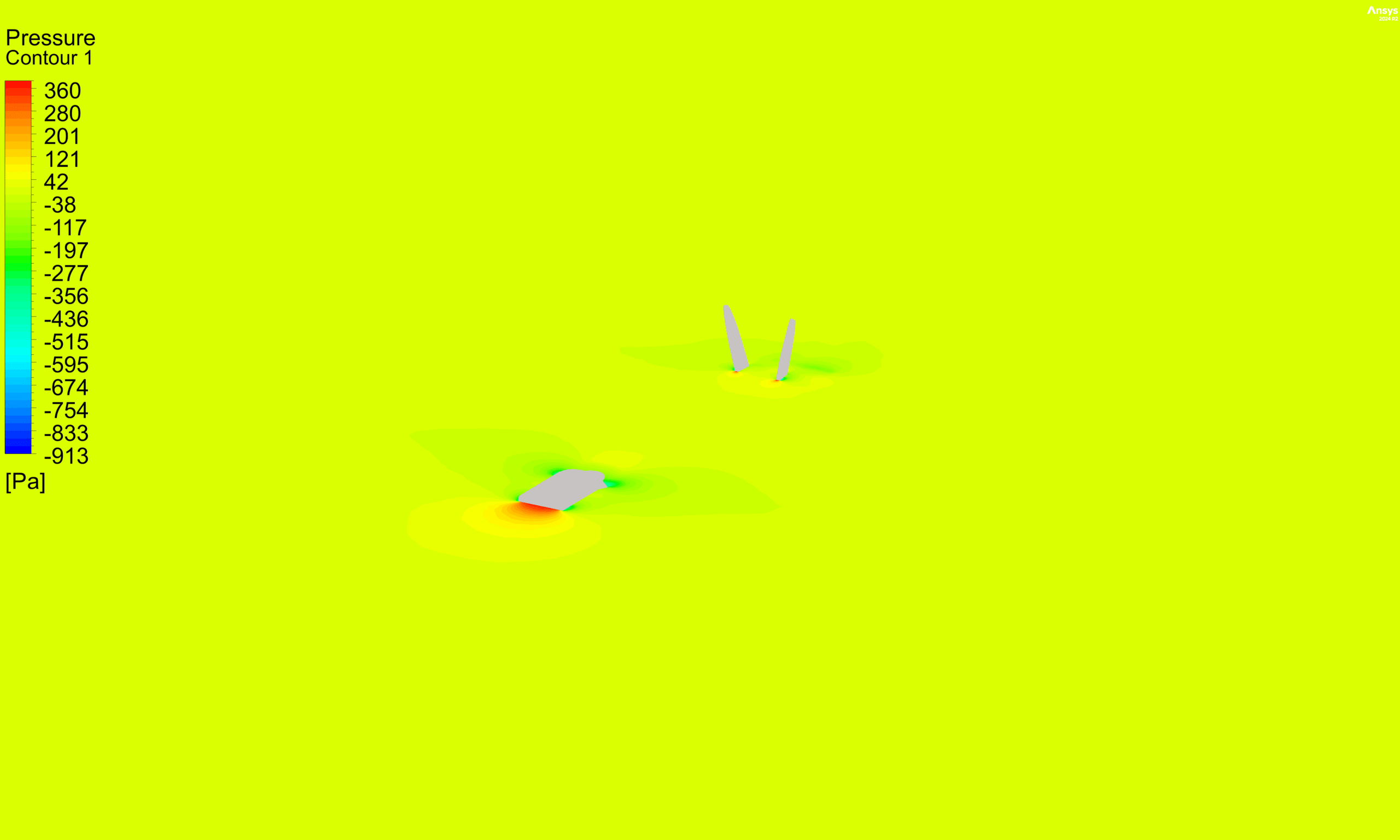

As depicted in Figure 4, the pressure contours reveal variations in high and low-pressure regions induced by blade motion. This alteration is crucial for understanding the lift and drag characteristics of the UAV.

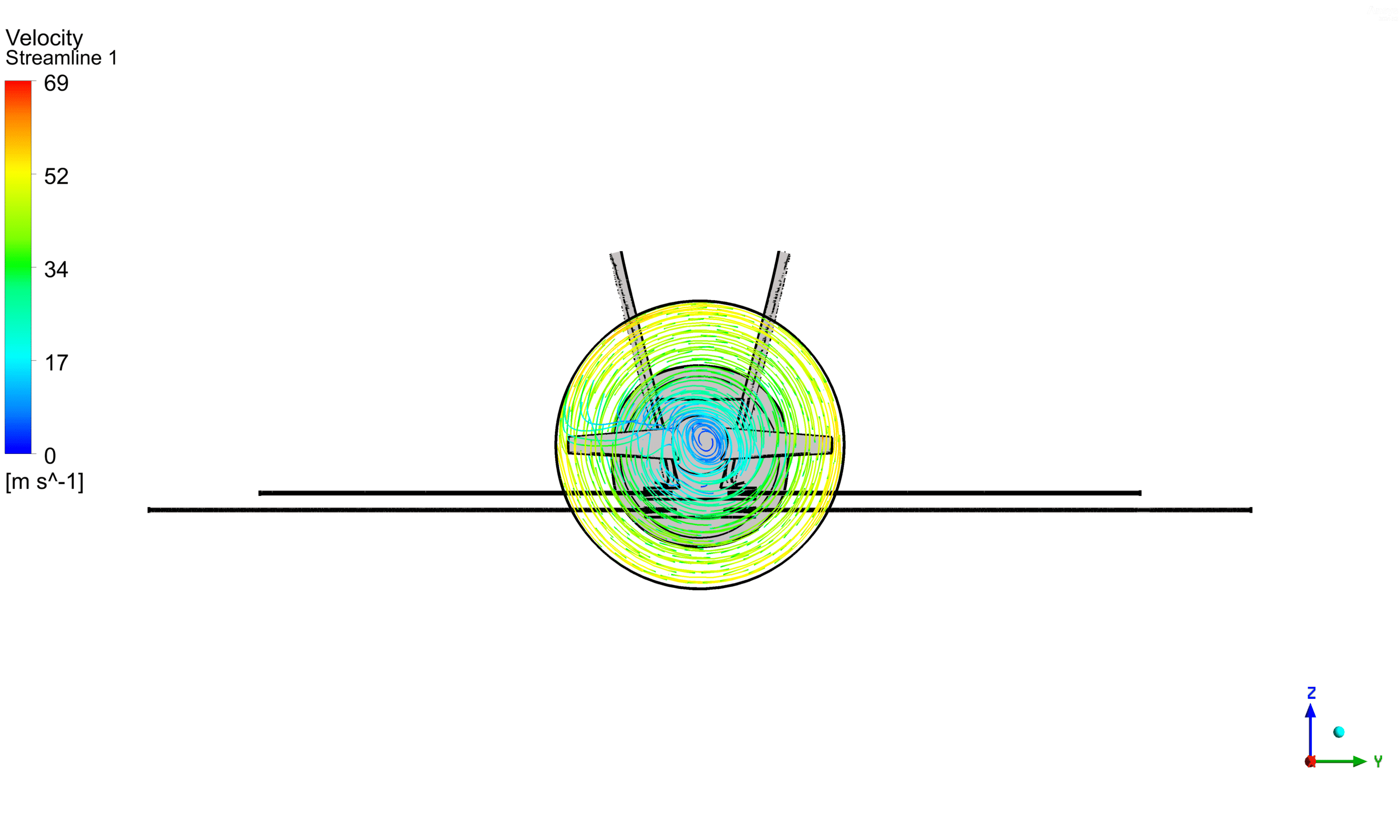

Streamlines

Figure 5 shows the streamlines in the presence of the rotating Zone. These lines provide insight into how the blade rotation influences the flow path and circulation around the UAV.

Conclusion

The simulation results reveal that blade rotation profoundly affects the airflow patterns and pressure distribution around the Switchblade 300. Using a polyhedral mesh and the MRF approach ensures that our analysis accurately captures the complexities of flow dynamics. These findings are essential for improving the aerodynamic efficiency and performance of the UAV. Further studies and optimizations can lead to enhanced design capabilities and operational effectiveness.

Reviews

There are no reviews yet.