Switchblade 300 (transient), Ansys Fluent CFD Simulation

$100.00 $50.00 Student Discount

- This report discusses the CFD simulation conducted for the Switchblade 300 using ANSYS Fluent software

- The geometry of the Switchblade 300 was created using SpaceClaim

- Initially, Using ANSYS Meshing, a non-conformal mesh with approximately 40 million tetrahedral cells was generated, after that We decided to change the mesh type to polyhedral in Ansys fluent to decrease the number of mesh elements from 40,000,000 to 7,000,000

- The setup included a velocity inlet of 28.05 m/s, an angle of attack of 5 degrees, and a rotational speed of 5000 RPM

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This report discusses the computational fluid dynamics (CFD) simulation conducted for the Switchblade 300 using ANSYS Fluent software. The primary objective was to analyze the fluid dynamics around the geometry under specified conditions of motion and environmental parameters.

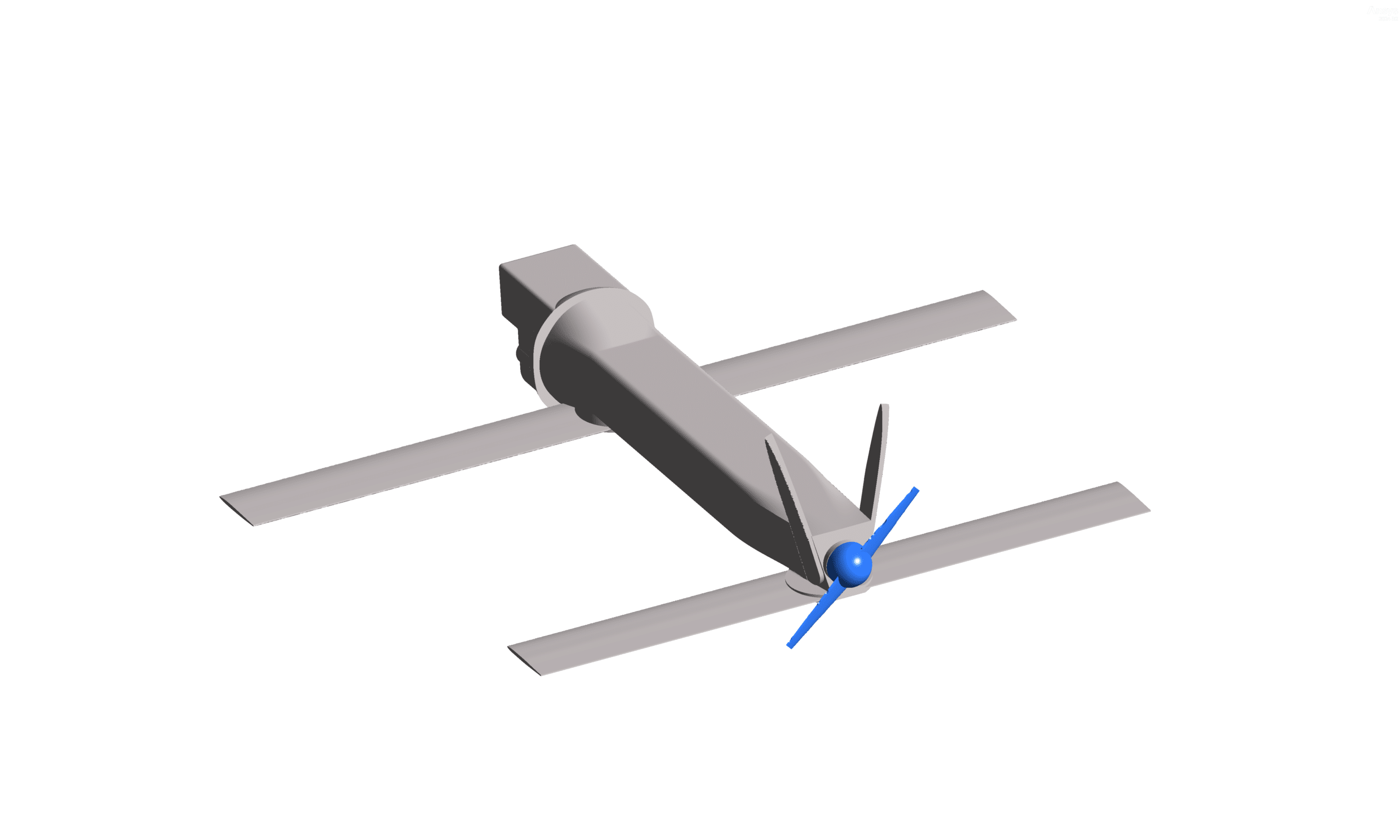

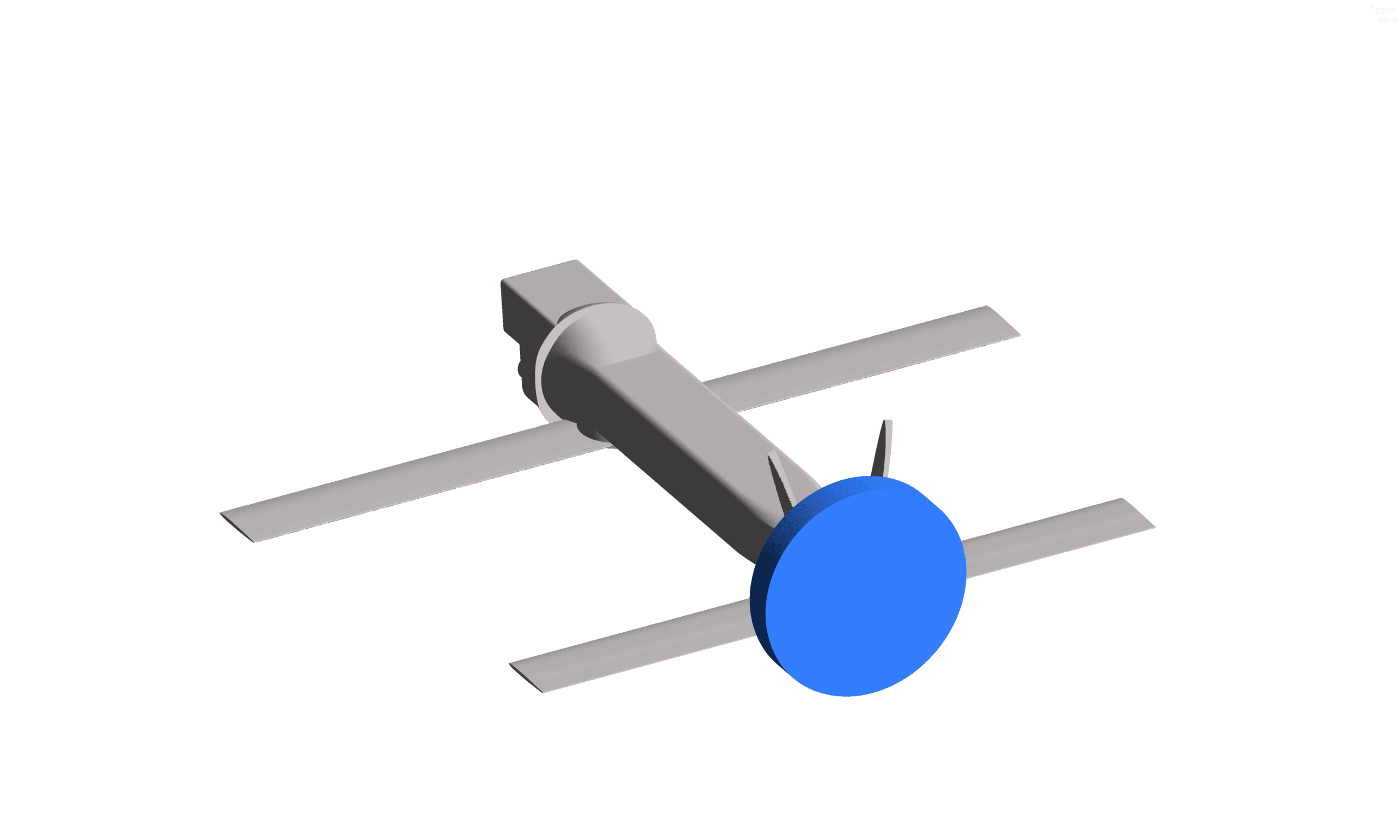

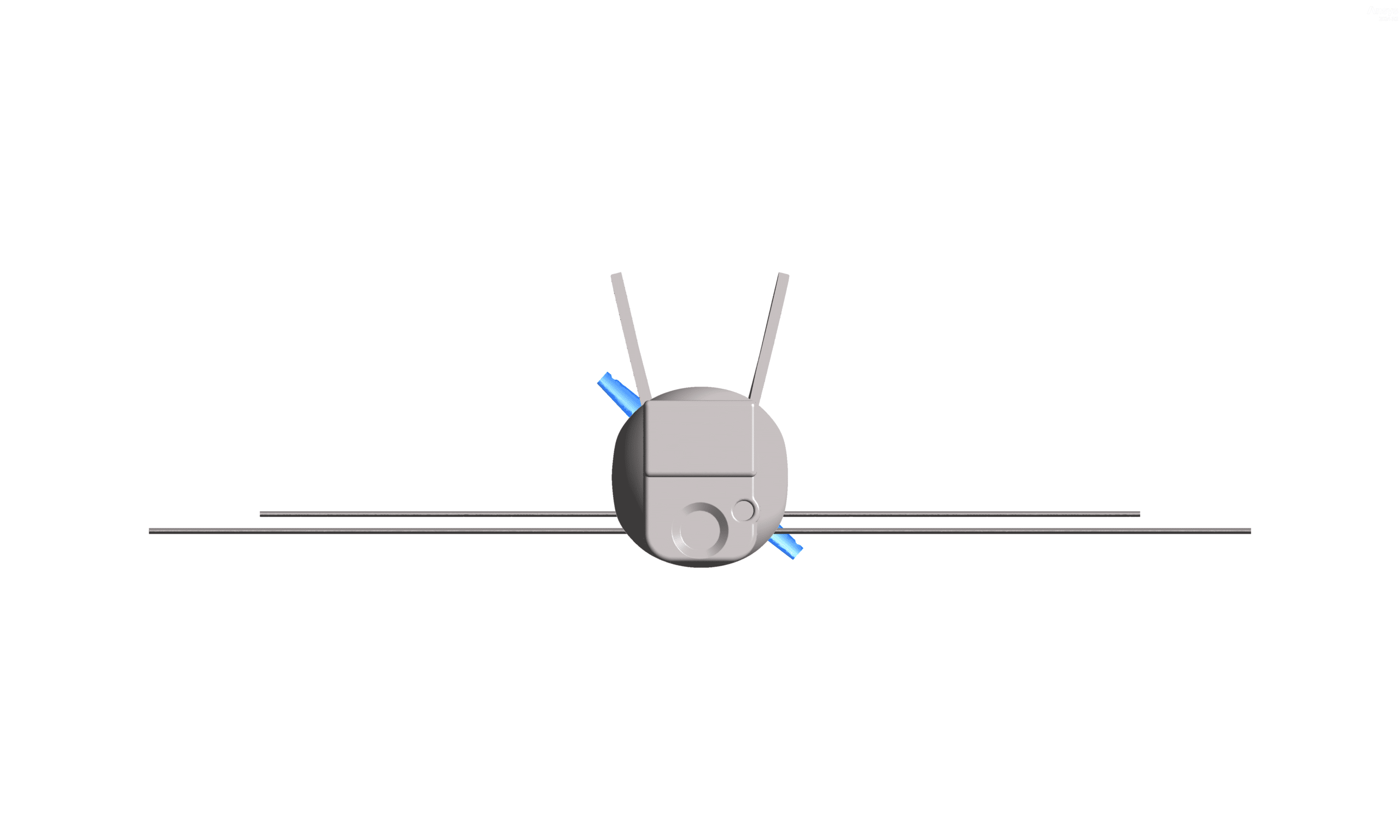

Geometry Creation: The geometry of the Switchblade 300 was created using SpaceClaim.

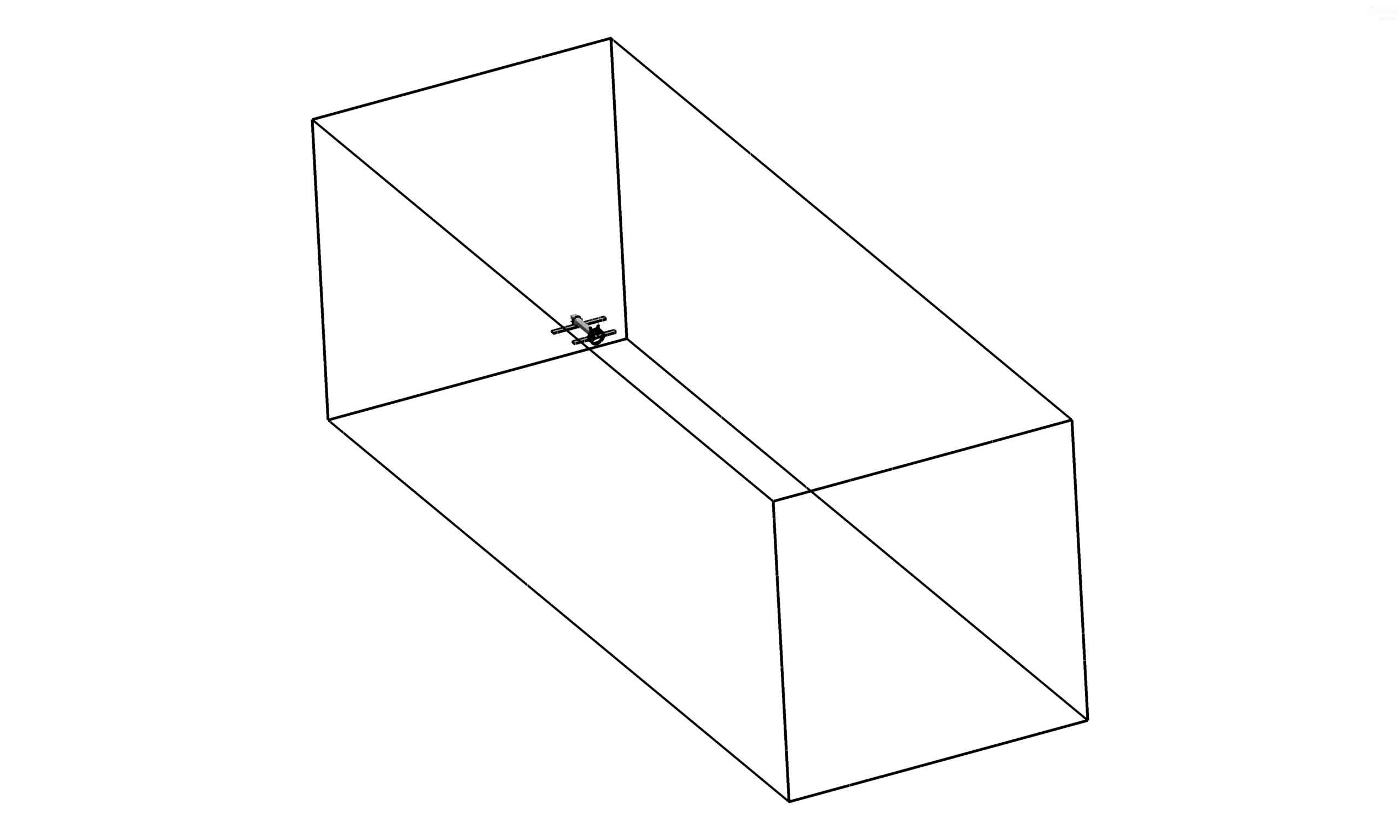

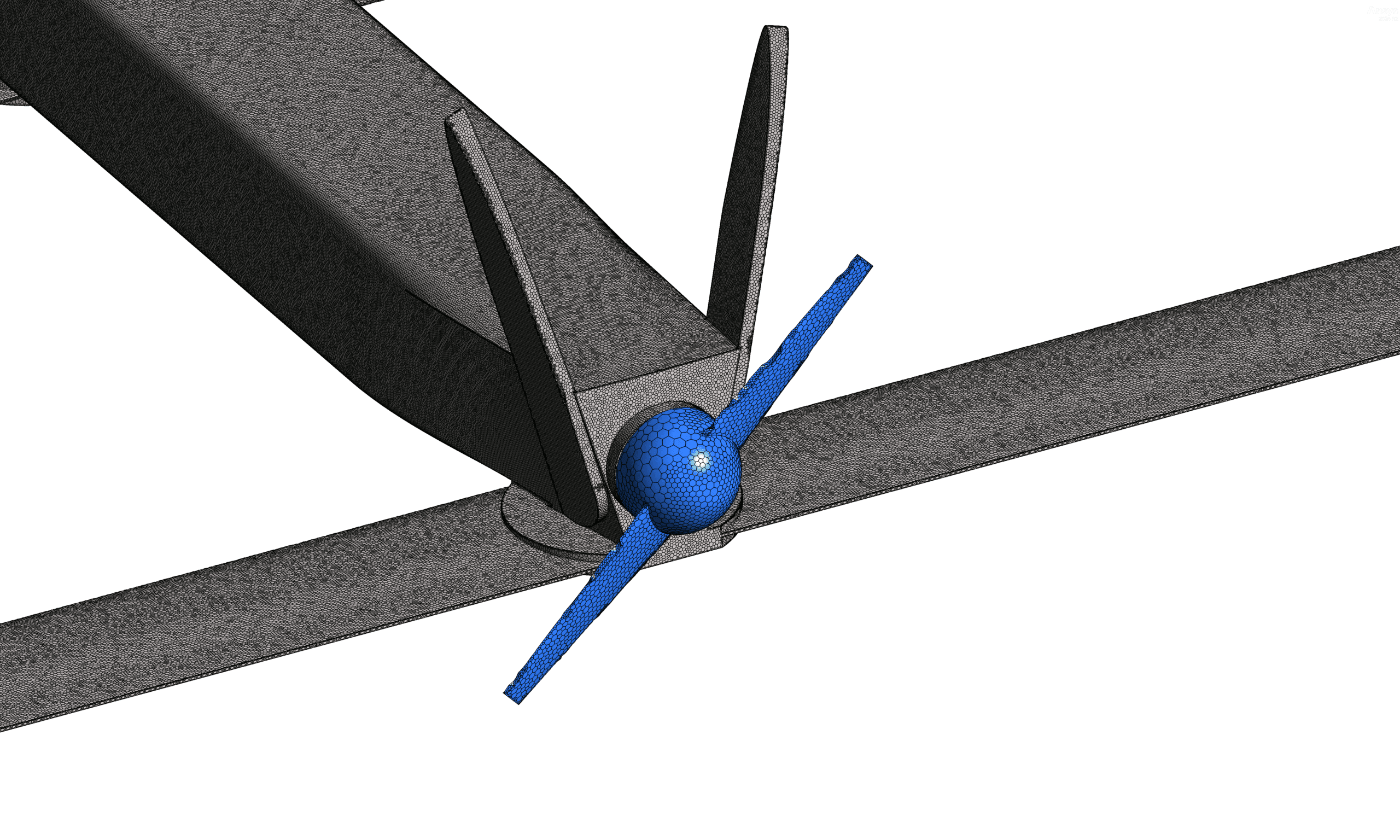

Mesh Details: Using ANSYS Meshing, a non-conformal mesh with approximately 40 million tetrahedral cells was generated. This dense mesh ensured high resolution of the flow features around the geometry and was deemed appropriate for capturing the intricate details of the flow dynamics.

Initially, our mesh consisted of 40,000,000 elements, which presented significant computational challenges. We decided to change the mesh type to polyhedral to optimize our simulation process. This strategic modification allowed us to decrease the number of mesh elements dramatically from 40,000,000 to 7,000,000.

Figure 2 shows the mesh configuration, highlighting the non-conformal mesh regions imperative for capturing fluid interactions accurately.

Simulation Setup

The simulation was conducted using ANSYS Fluent, capitalizing on its mesh motion capabilities to analyze flow characteristics. The setup included a velocity inlet of 28.05 m/s, an angle of attack of 5 degrees, and a rotational speed of 5000 RPM. The k-ω SST turbulence model was chosen for its effectiveness in predicting boundary layer separation and managing complex flow dynamics. For numerical methods, the SIMPLE algorithm was used for pressure-velocity coupling, and standard initialization was employed to set the initial flow conditions within the solution domain.

Results

Velocity Contour:

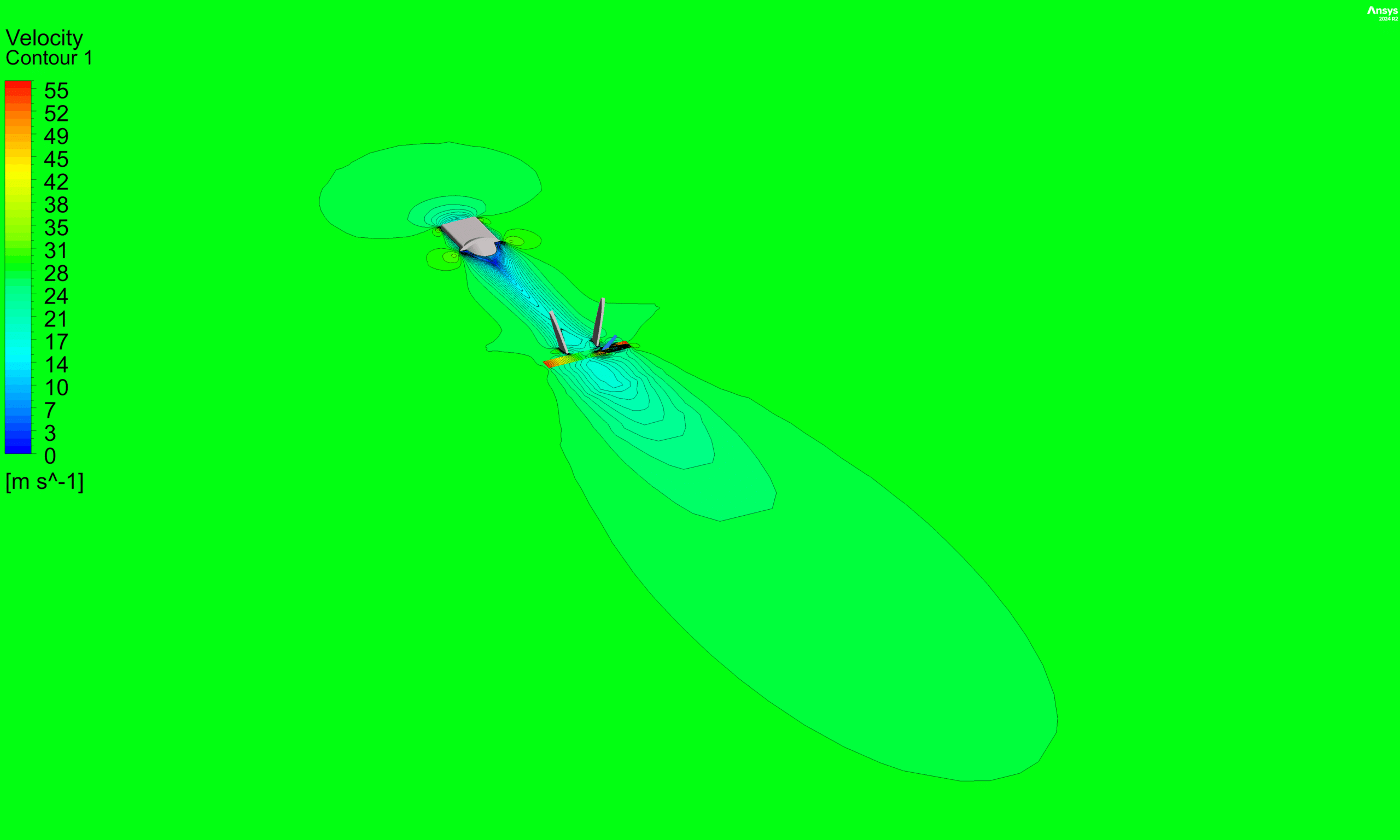

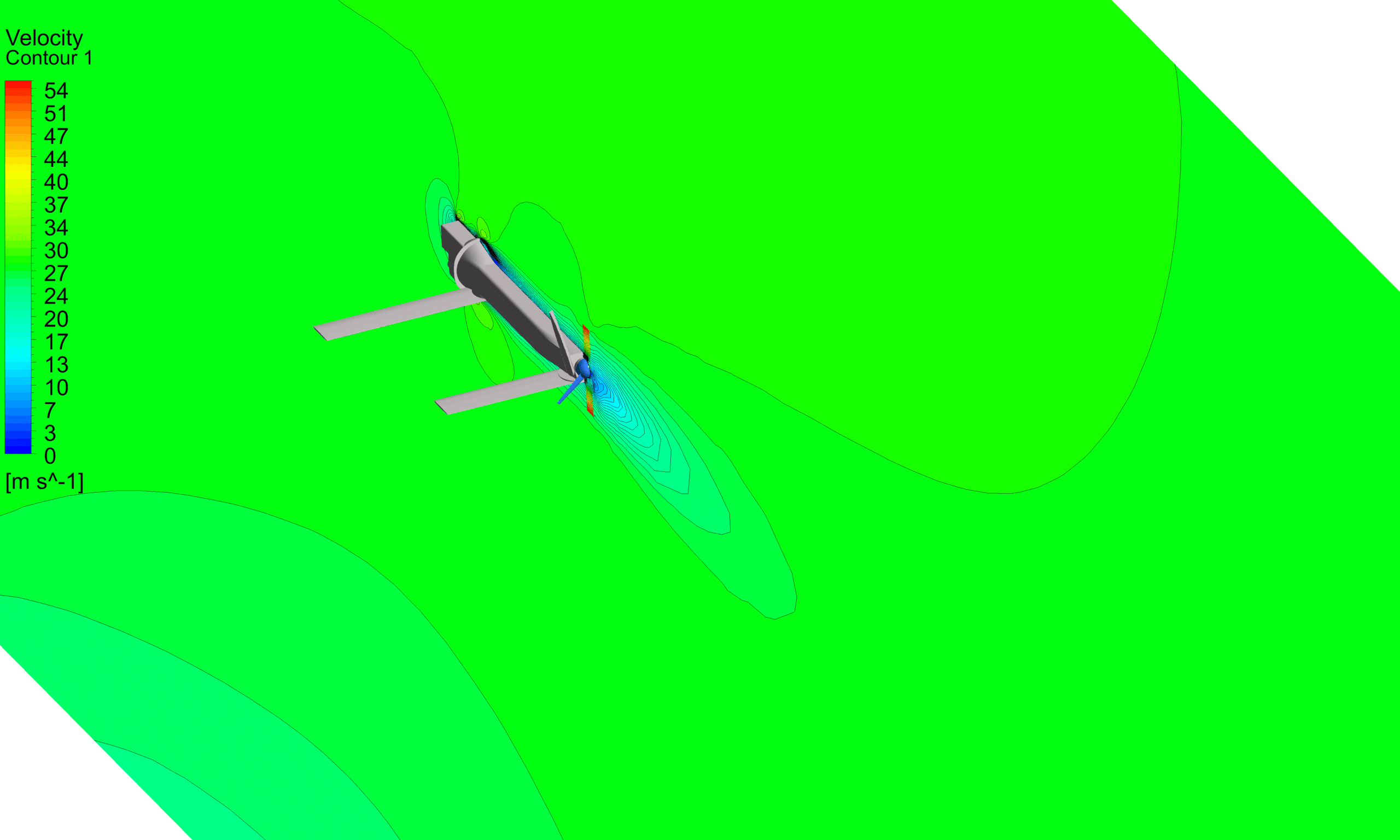

Presented in Figure 3, the velocity contour depicts the flow characteristics around the Switchblade 300, identifying regions of high and low-speed flow due to the angle of attack and rotation.

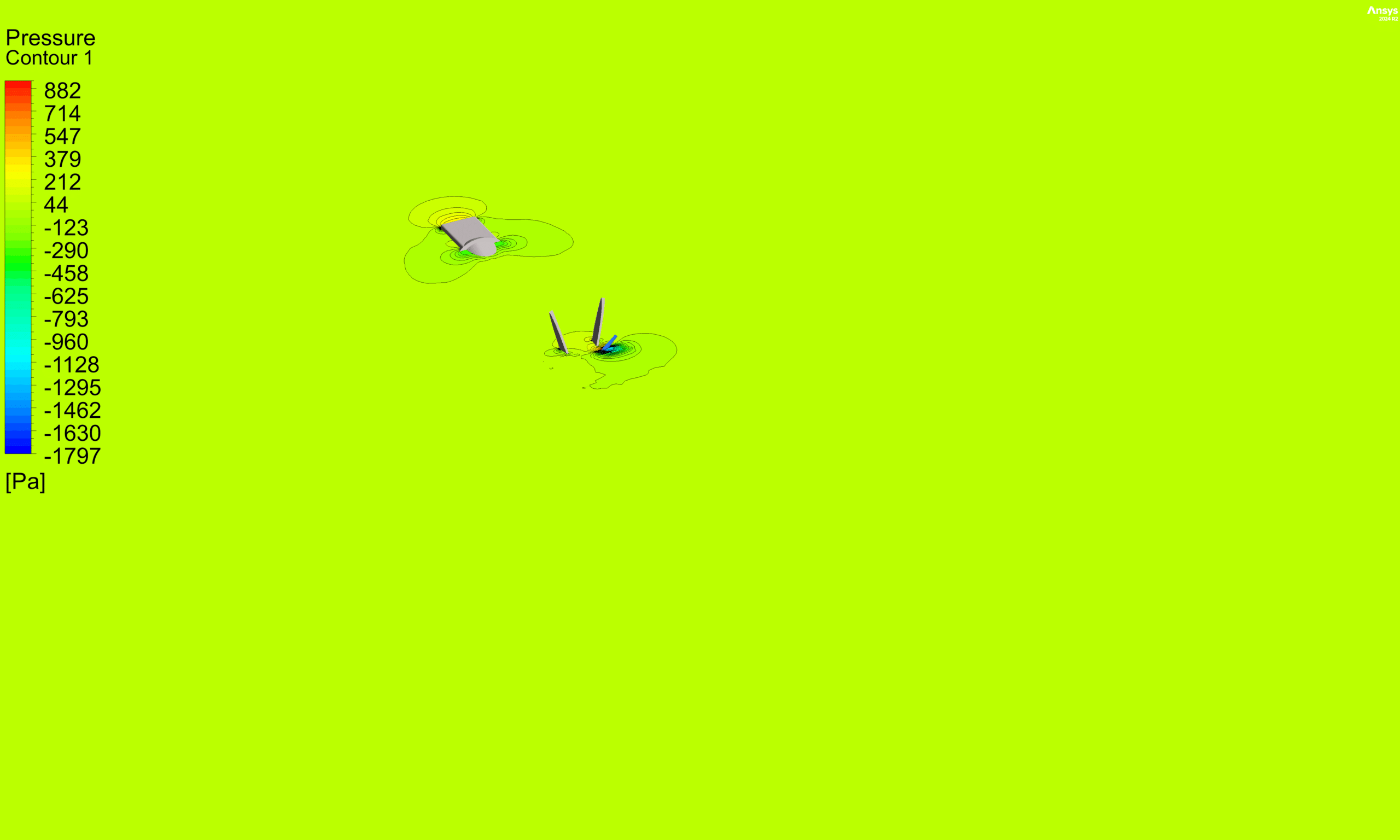

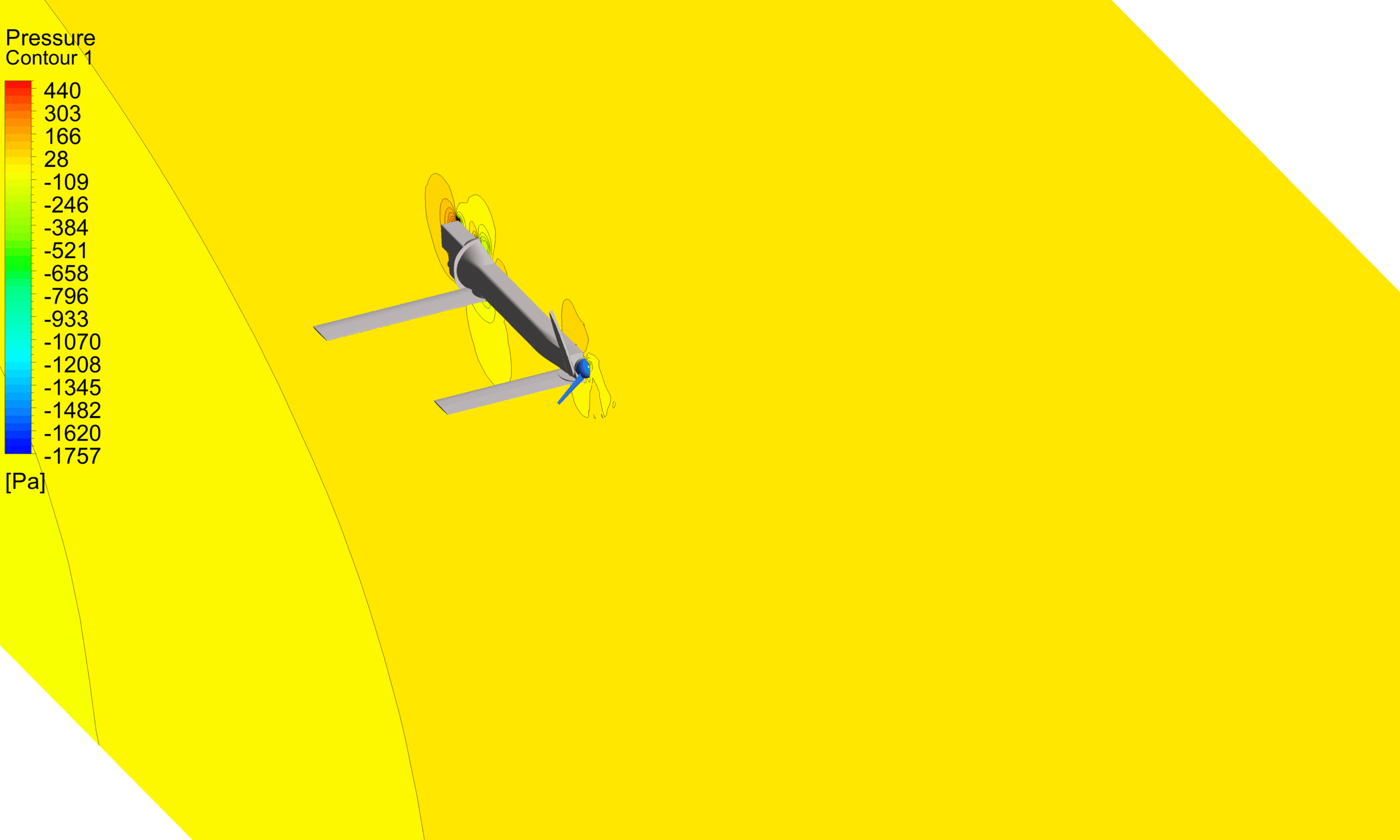

Pressure Contour:

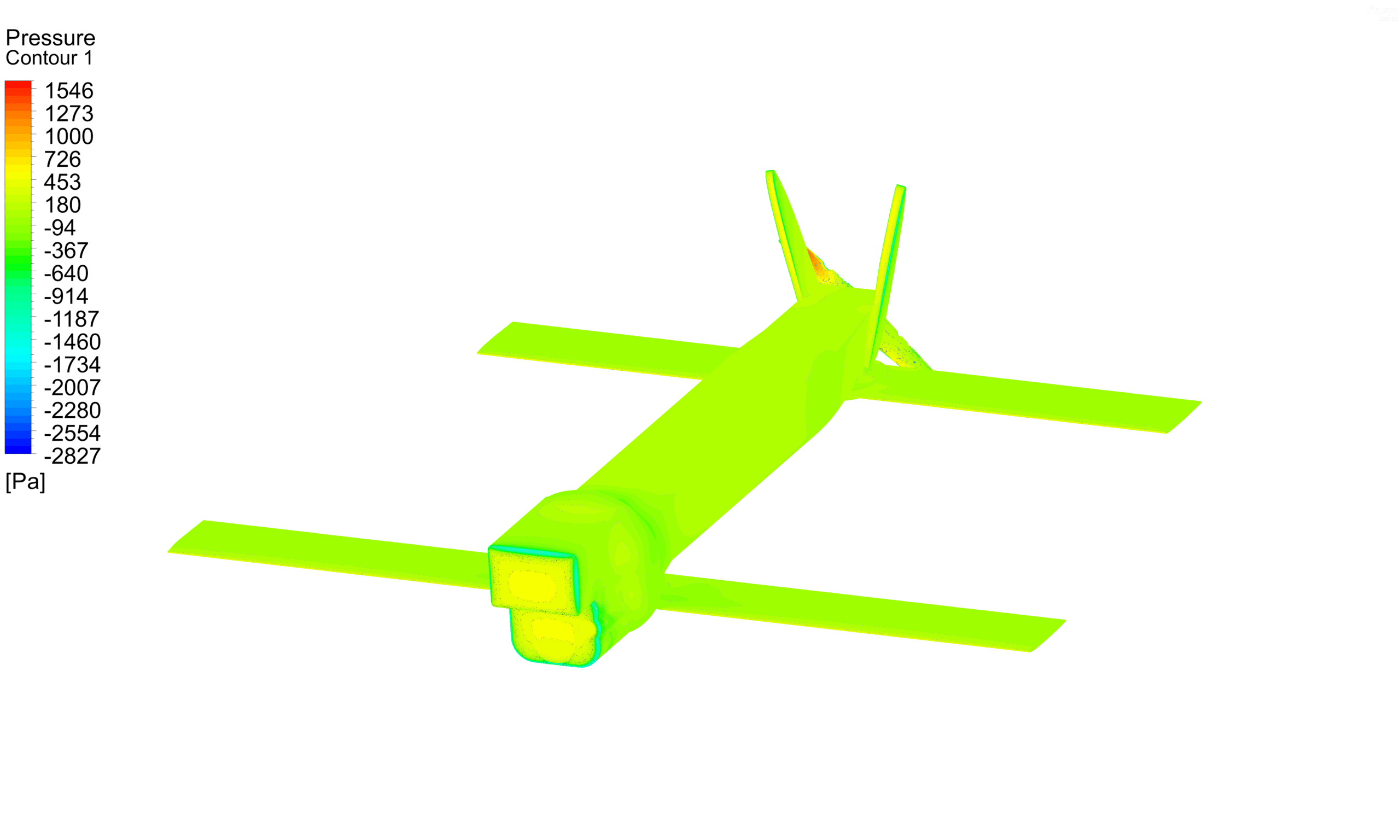

Displayed in Figure 4, the pressure contour illustrates the varying pressure distribution, critical for identifying aerodynamic forces such as lift and drag acting on the geometry.

Conclusion

The simulation results provide a detailed understanding of the aerodynamic performance of the Switchblade 300, revealing significant insights into the effects of rotational speed, velocity, and degree of attack on overall flow behavior. These findings support the optimization of the design and operation parameters to enhance performance. Further simulations with varied conditions are recommended to explore other operational scenarios and improve predictive accuracy.

Reviews

There are no reviews yet.