Thermal Management of Battery Using Nano Fluid

$270.00 $135.00 Student Discount

In this project, Thermal Management of Battery (using Nano Fluid) has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Thermal Management of Battery (Using Nano Fluid), CFD Simulation Ansys Fluent Training

The present problem simulates the Thermal Management of Battery Using Nano Fluid (Two-Phase) by Ansys Fluent software. This simulation is related to a Dual-Potential MSMD (multiscale multidomain) battery model. Generally, a battery can store electrical energy in chemical energy. If the current is requested from the battery, the chemical energy is converted into electrical energy, and when the battery is charged, the electrical energy is converted into chemical energy. Also, heat can be generated from multiple sources, including internal losses of joule heating and local electrode overpotentials, the entropy of the cell reaction, the heat of mixing, and side reactions.

Previously a modular, efficient battery simulation model (MSMD model) was introduced to aid the scale-up of Li-ion material & electrode designs to complete cell and pack designs, capturing electrochemical interplay with 3-D electronic current pathways and thermal response. The expandable and flexible architecture connects the physics of battery charge/discharge processes, thermal control, safety, and reliability computationally efficiently.

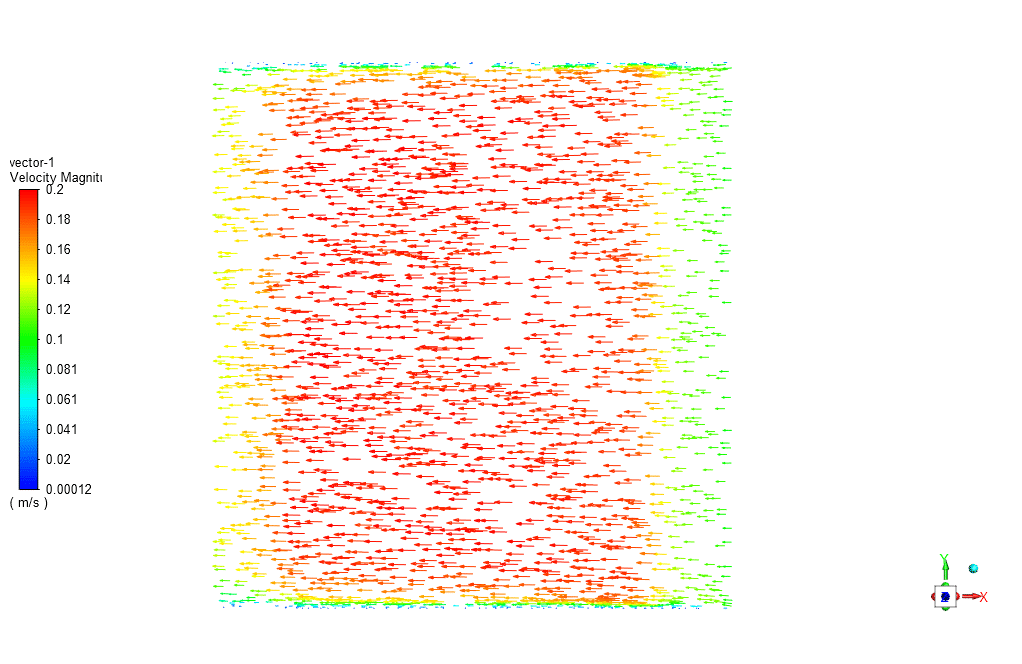

The present simulation is performed with Mixture multiphase model, and the effect of nanofluid flow in heat transfer enhancement of the battery is investigated. This work aims to investigate the effectiveness of phase change materials in the cooling process of the battery. The nanofluid material is water as base fluid and aluminum as nanoparticles, and the velocity of the nanofluid at the inlet face is equal to 0.1 m/s. The volume fraction of nanoparticles is 0.05.

GK empirical model is set for E–Chemistry. The Specified C-rate of 0.5 and numerical cell capacity of 14.6 are chosen as Electrical parameters.

Geometry & Mesh

The Geometry of this model is designed in Design Modeler software three-dimensionally, and the scale of it is as follows:

Xmin: -0.007 m Xmax: 0.007 m

Ymin: -0.008 m Ymax: 0.0087 m

Zmin: -0.0008325 m Zmax: 0.002 m

We carry out the model’s meshing using ANSYS Meshing software. The mesh type is polyhedral, and the cell number is 362734. The following figure shows the mesh:

Battery CFD Simulation

We consider several assumptions to simulate the present model:

- Solver is pressure-based.

- The simulation is transient.

- The gravity effect is set at -9.81 in the Y direction.

The following table represents a summary of the defining steps of the problem and its solution:

| General | ||||||||

|

||||||||

| Models | ||||||||

| Viscous | Laminar | |||||||

| Energy | on | |||||||

| multiphase | Mixture Model | |||||||

| Interface Modeling | Dispersed | |||||||

| Formulation | Implicit | |||||||

| Granular | on | |||||||

|

|

Particle Diameter

|

1e-5

|

||||||

|

|

Slip Velocity

|

On

|

||||||

| Inlet | Velocity Inlet | |||||||

| velocity magnitude | 0.1 m.s-1 | |||||||

| Volume Fraction | 0.05 | |||||||

| Temperature | 298 k | |||||||

| Outlet | Pressure Outlet | |||||||

| gauge pressure | 0 pascal | |||||||

| Walls | Wall | |||||||

| wall motion | stationary wall | |||||||

| Battery Model | on | |||||||

| Solution Method | MSMD | |||||||

| E-Chemistry Model | NTGK Empirical Model | |||||||

| Solution Options | Specified C-Rate | |||||||

| C-Rate | 0.5 | |||||||

| Min. Stop Voltage | 3 | |||||||

| Max. Stop Voltage | 4.3 | |||||||

| Initial DoD | 0.2 | |||||||

| Methods | ||||||||

| Pressure-Velocity Coupling | SIMPLE | |||||||

| Pressure | PRESTO! | |||||||

| momentum | first-order upwind | |||||||

| Volume Fraction | first-order upwind | |||||||

| Energy | first-order upwind | |||||||

| Transient Formulation | First Order Implicit | |||||||

| Wrapped-Face Gradient Correction | on | |||||||

| Initialization | ||||||||

| Initialization methods | Standard | |||||||

| gauge pressure | 0 pascal | |||||||

| x-velocity | -0.1 m.s-1 | |||||||

| y-velocity | 0 m.s-1 | |||||||

| z-velocity | 0 m.s-1 | |||||||

| Temperature | 298 k | |||||||

| Phase-2 Granular Temperature | 0.0001 m2/s2 | |||||||

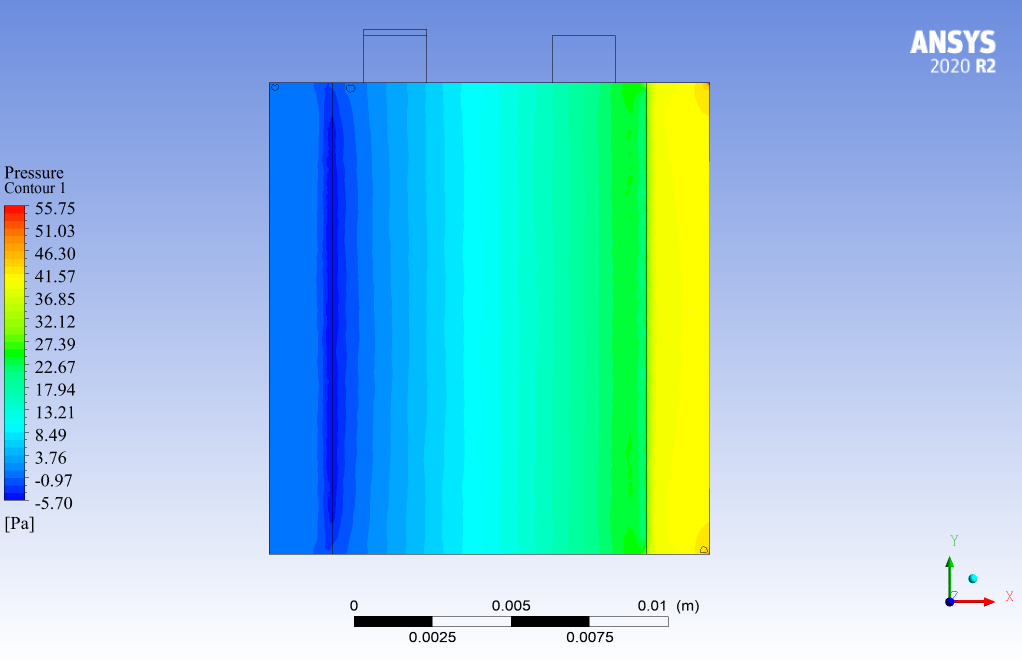

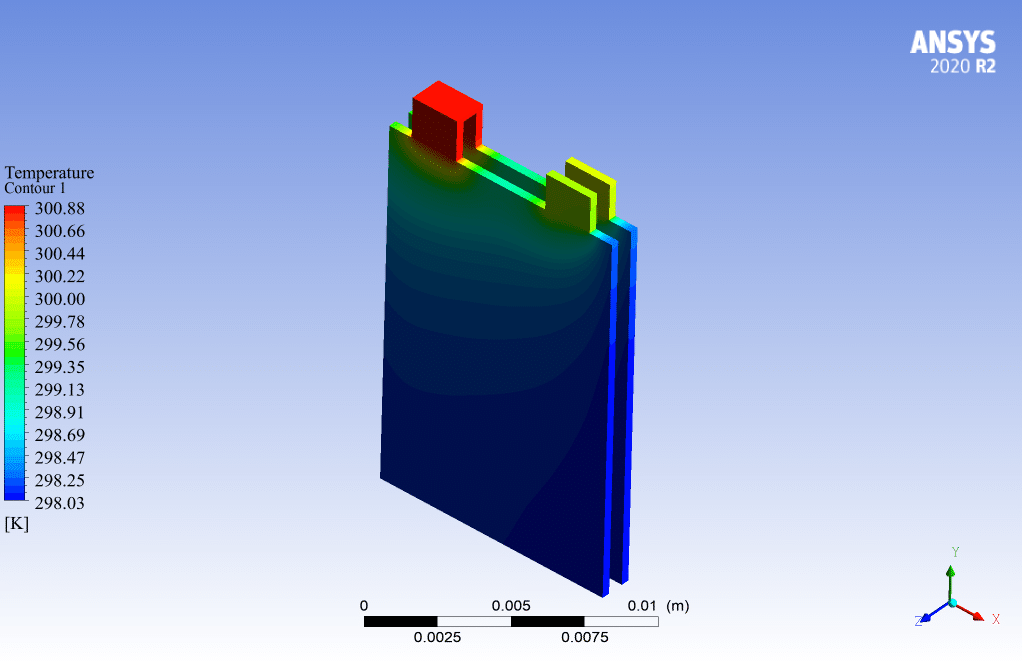

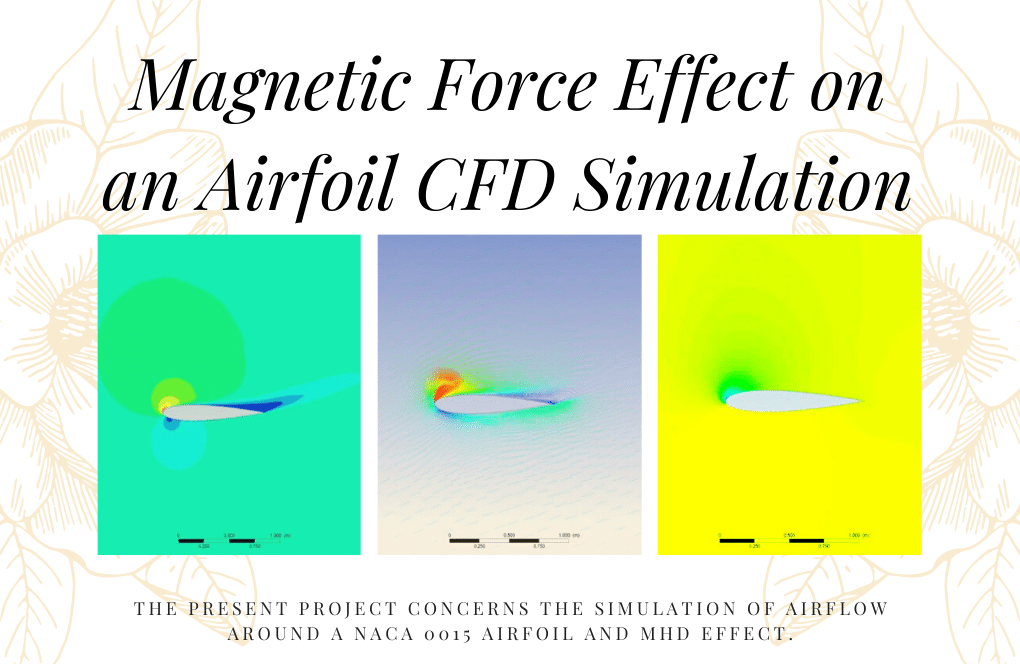

Thermal Management of Battery Using Nano Fluid Results

We obtained two-dimensional and three-dimensional pressure and temperature contours, respectively, at the end of the solution process. We presented this chart in 500 Seconds. The results show that applying a Nanofluid flow to the battery body will cool and reduce the temperature growth rate.

Alan Brown –

The use of the nanofluid mixture in battery cooling truly seems remarkable! I was floored by the detailed analysis and the visual presentation of temperature gradients. Such a complex simulation, executed excellently, makes data interpretation much more manageable. Impressive work leveraging Ansys Fluent’s capabilities!

MR CFD Support –

Thank you so much for your kind words! We strive to deliver detailed and high-quality simulations that aid in the comprehensible analysis of complex phenomena like thermal management with nanofluids. If you’ve got any further questions or need more insight, don’t hesitate to reach out! We’re delighted that you found the visualization and the data helpful for interpretation. Your satisfaction with our Ansys Fluent training material truly means the world to us!

Jonatan Gibson –

I’ve always wondered how efficient nanofluids are in terms of thermal management for batteries. It’s great to see practical applications of this through your simulation. The data presented on heat transfer enhancement and maintenance of cooler battery temperatures offers insightful benefits of using nano-fluids in battery systems.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our simulation provided you with a clearer understanding of nanofluids’ role in thermal management for batteries. Your acknowledgment of the practical applications highlighted in our study means a lot to us. Should you have any further inquiries or need for additional details about this application and its benefits, please feel free to reach out.

Mrs. Antoinette Connelly II –

The demonstrated temperature control in the battery using nanofluid simulation looks impressive! The comprehensive analysis and application of two-phase Ansys Fluent modelling to explore thermal management in batteries showcases the potential of utilizing nanoparticles enhancement. Excited to see such promising advances in battery technology modeling.

MR CFD Support –

Thank you for your appreciation! We always strive to provide in-depth analyses and realistic simulations to help understand and improve technology performance. It’s gratifying to hear that our efforts in illustrating the potential of nano-enhanced thermal management for battery systems are valuable to our customers. Should you have any further queries or need assistance in your projects, don’t hesitate to reach out.

Laron Bartoletti PhD –

The course content and structure for thermal management using nano fluid simulation were spot on! The combination of practical application with the detailed theoretical background helped me to fully grasp the nano fluid’s impact on improving battery thermal conditions. Looking forward to applying this knowledge to my work.

MR CFD Support –

We’re thrilled to hear that our CFD simulation course on the Thermal Management of Battery using Nano Fluid has been beneficial to you. It’s great to know you’re able to apply the knowledge to your work. Thank you for sharing your experience. Don’t hesitate to reach out to us if you need any further assistance or have questions in the future!

Prof. Eden Goodwin DVM –

The CFD simulation of thermal management using nanofluid is really fascinating. The level of detail and the methodology implemented provide a comprehensive understanding of the cooling process in batteries. Great work!

MR CFD Support –

Thank you for your kind review! We are thrilled to hear that you found the simulation detail and methodology comprehensive and helpful. Our team strives to provide in-depth analyses to enhance understanding of complex systems such as battery thermal management. If you have any further questions or interests in our simulations, please don’t hesitate to reach out.

Georgianna Raynor –

This CFD simulation of thermal management appears thorough. I particularly appreciate the focus on enhancing heat transfer via nanofluid flow, which seems to be a forward-thinking application. Accuracy in modeling the electrochemistry alongside thermal phenomena is crucial in battery simulations, and it seems like this training accounted for it comprehensively.

MR CFD Support –

Thank you for your positive feedback on our Thermal Management of Battery Using Nano Fluid simulation training. We’re glad to hear that you find the application of nanofluid flow in thermal management innovative and the modeling aspects of the battery’s thermal and electrochemical interaction comprehensive. Our goal is to provide accurate and current CFD training and we are pleased that our efforts resonate with your needs. If there’s anything further you’d like to learn or explore about this topic, please don’t hesitate to get in touch with us.

Adella Kuvalis –

The explanation of the simulation workflow is very impressive! It’s clear that a great deal of effort has gone into developing a comprehensive thermal management solution for batteries using nanofluids. I particularly appreciated the attention to detail in the meshing process, and the use of polyhedral cells that offer accuracy in CFD computations.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our attention to detail and the comprehensive nature of the simulation workflow has met your expectations. If you have any further questions or require additional information about the simulation and the results it yields, please do not hesitate to reach out.

Osbaldo Homenick –

The use of nanoparticles indeed raises concerns about agglomeration and settling in the fluid over time. Was there an evaluation of the stability of the nanofluid over time in your simulations?

MR CFD Support –

The simulation doesn’t specifically focus on the long-term stability issues such as particle agglomeration or settling. However, if stability and particle distribution over time is a concern, we recommend doing a further detailed analysis to include these effects for a comprehensive thermal management study.

Mr. Torrey Reilly –

The training covered the thermal management of batteries using nanofluids, which includes vital aspects such as simulation settings and results. However, I’m interested to know how the nanofluid positively impacts the thermal performance as compared to conventional fluids.

MR CFD Support –

Using nanofluid enhances the thermal performance of a battery cooling system due to the increased thermal conductivity that nanoparticles provide. These small particles dispersed within the base fluid (like water) form a nanofluid that can carry away heat more effectively, ensuring the battery operates within an optimal temperature range, improves efficiency and extends battery life. The CFD simulation demonstrates reduced temperature growth rates when utilizing nanofluid compared to using the base fluid alone.

Maci Morissette I –

I found the results mentioned in the description very intriguing. Just to clarify, were any specific patterns or areas of improvement in cooling efficiency identified by using the Nano Fluid (Two-Phase) model that might be applicable to improving commercial battery systems?

MR CFD Support –

Yes, the simulation results indicated that employing a nanofluid flow around the battery notably enhanced the cooling effectiveness. Particularly, the nanoparticle-infused fluid helped in more uniform thermal distribution and potentially reduced peak temperatures. Suggestions for improvement could involve optimizing nanoparticle concentrations and flow rates, which might be applicable to advance thermal management in commercial battery systems.

Rosamond Koss –

Loved the level of detail in the Thermal Management of Battery using Nanofluid simulation. The integration of the nanotechnology for cooling is remarkable. Great job MR CFD!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you appreciated the detailed simulation and the innovative application of nanofluid for thermal management. Your feedback is much appreciated, and we’re glad you found our product remarkable.

Mr. Otto Johnson –

The tutorial was informative and I appreciate the comprehensive explanation provided. Venturing into the realm of CFD for battery thermal management with nanofluids was a new challenge for me, but your training made it approachable. The way the simulation connected thermal and electrochemical responses is particularly interesting. However, does your dataset provide the temperature difference between the nanofluid inlet and the nanofluid outlet after heat exchange?

MR CFD Support –

Thank you for your positive feedback on our simulation tutorial! Regarding your query, the dataset includes temperature results which show the effectiveness of the nanofluid in cooling the battery, but specific inlet and outlet temperature values are typically part of the simulation results that you should be able to visualize or calculate using Ansys Fluent software. Temperature differences across the nanofluid circuit can be crucial indicators of heat exchange performance and should indeed be available after you complete the simulation steps as documented in the training.

Dwight Ortiz –

The way nano fluids impact battery’s thermal management looks fascinating. Really excited to see such innovation applied in practical scenarios.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you’re excited about the innovative application of nano fluids in thermal management for batteries. At MR CFD, we continually strive to explore and provide the most cutting-edge simulations to aid in real-world applications. Your enthusiasm truly encourages us to keep pushing the boundaries of computational fluid dynamics. If you have any further questions or need more information, feel free to reach out.

Prof. Darrin Denesik –

I appreciated the detailed explanation of the Thermal Management of Battery using Nano Fluid simulation and particularly found the discussion on nanofluid material characteristics insightful. Nickel-sized kudos to MR CFD for this compelling CFD training material, which has significantly broadened my understanding of battery cooling strategies. The training’s thoroughness illustrates the complexity of the subject, yet it was conveyed in clear, accessible terms. Thank you, MR CFD, for another top-tier learning experience!

MR CFD Support –

Thank you so much for your remarkable feedback. We are elated to hear that the training material on Thermal Management of Battery Using Nano Fluid was informative and added to your knowledge. Your understanding and appreciation of the intricacies involved is exactly what we strive to support through our training offerings at MR CFD. If you need further assistance or have more inquiries, feel free to reach out. Happy learning!

Logan Lakin –

I found the details of the simulation incredibly comprehensive. I’m really delighted to see how thermal management can improve battery performance and safety. Phenomenal work!

MR CFD Support –

Thank you for your positive feedback. We are glad that you found the simulation details comprehensive and helpful! At MR CFD Company, we are constantly working to create simulations that not only serve educational purposes but also have practical applications like improving performance and safety. Your kind words are greatly appreciated, and they motivate us to continue delivering high-quality learning products to our customers.

Dorothea Cruickshank –

The course was extremely instructional, offering insights into managing battery heat with the use of nanofluids. The detailed simulation process provided a clear understanding of the thermal dynamics involved. My only question after completing the module is, how does the addition of nanoparticles to the base fluid enhance the thermal management performance in the batteries?

MR CFD Support –

The addition of nanoparticles to the base fluid enhances the thermal management performance in batteries primarily due to the increase in thermal conductivity the nanoparticles offer. These nano-sized particles have a higher surface area to volume ratio compared to their macro-sized counterparts. When suspended in the base fluid, they improve thermal connectivity, leading to more efficient heat transfer. This results in better distribution and dissipation of heat generated within the battery system.

Darryl Schaefer –

I found the use of nanoparticles in cooling the battery quite interesting and would love to know how it impacts overall battery performance beyond temperature control. Is there an evaluation in the learning product about battery efficiency or lifecycle related to nanofluid use in thermal management?

MR CFD Support –

Glad to hear you found the application of nanoparticles interesting! The main focus of the simulation is on the thermal management aspect, evaluating the efficacy of the nanofluid in controlling the temperature of the battery. There is some analysis regarding the impact on the battery’s efficiency, as temperature control can have positive effects on battery life and performance. However, detailed analysis on lifecycle improvement is complex and may not be exhaustively covered in this product. It’s worth noting that optimal temperature management typically leads to a more stable battery output and could potentially extend the lifecycle of the battery by preventing overheating-related degradation.

Miss Fiona Fritsch DVM –

I am really impressed with how the nanofluid contributes to the cooling efficiency. Can you provide more information on how the use of aluminum nanoparticles impacts the overall thermal conductivity compared to just using water as the cooling medium?

MR CFD Support –

Thank you for your positive feedback! Nanoparticles like aluminum have a higher thermal conductivity than base fluids such as water. When these nanoparticles are suspended in the base fluid, they enhance its thermal conductivity. The increase depends on the concentration of nanoparticles and several other factors including nanoparticle material, shape, size, and distribution. The CFD simulation likely shows improved thermal management performance when using aluminum nanoparticles in a water base compared to water alone due to this enhanced thermal conductivity.

Magali Beer DDS –

I was amazed to see the temperature control achieved with nanofluid flow in this CFD Simulation. It’s fascinating how aluminum nanoparticles enhance the thermal conductivity.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the effect of nanofluid flow on battery cooling in our CFD simulation impressed you. It’s rewarding to know our product could convey the complex thermal management benefits of nanoparticles effectively. Your feedback motivates us to continue delivering high-quality learning materials.

Eve Rolfson –

Super impressed with the detailed analysis on thermal management using nanofluid in batteries. Great work on integrating complex models to derive insightful results!

MR CFD Support –

Thank you for your kind words! We’re thrilled that the detail and complexity of our thermal management simulation met your expectations and provided you with valuable insights. We continuously strive to deliver high-quality simulations that can effectively contribute to advancements in battery technology.

Dr. Amani Schuster –

The work on thermal management using nanofluid is incredible. The detailed approach on simulation shows the potential for significant improvements in battery technology. It’s groundbreaking to see how nanofluids can be used to enhance thermal performance efficiently.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you recognize the potential of using nanofluids for thermal management in battery technology. It is indeed a groundbreaking approach, and we are committed to pushing the boundaries of what’s possible in CFD simulation. Your appreciation motivates us to keep delivering high-quality and innovative learning products.

Jeremie Ankunding MD –

The CFD simulation tutorial was exceptionally informative! It provided thorough insights into enhancing battery performance using the cutting-edge application of nanofluids. Really shows the commitment to advancing practical solutions in thermal management.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that the tutorial on thermal management of batteries using nanofluid was helpful and informative. It’s great to see our dedication to providing practical, innovative solutions recognized. If you have any more questions or need further assistance, please don’t hesitate to reach out.

Hudson Gislason MD –

The training was impressive, especially the detailed meshing using ANSYS Meshing software. It helped me understand better how your CFD simulation works for thermal management. The polyhedral mesh with over 360,000 cells was neatly showcased in the figures.

MR CFD Support –

Thank you for your positive feedback! We are glad that you found the training helpful and that the meshing process using ANSYS Meshing software contributed to your understanding of the CFD simulation for thermal management. Our goal is to provide comprehensive training that not only guides but also enhances user comprehension of complex simulations.

Geo Bailey Sr. –

Fantastic training material! The tutorial for ‘Thermal Management of Battery Using Nano Fluid’ offers a real deep-dive into practical CFD applications. Seeing the nanofluid’s effect on battery temperature control was truly insightful. The step-by-step guide through the process parameters, coupled with the simulation setup specifics, was crucial for understanding the complete process. Great work on creating such a detailed and nuanced simulation project. A very resourceful training for anyone interested in battery thermal management!

MR CFD Support –

We’re thrilled to hear that you had such a positive experience with our ‘Thermal Management of Battery Using Nano Fluid’ tutorial. Your feedback is greatly appreciated, and we are glad that the complex aspects of the simulation were valuable to you. Thank you for taking the time to share your thoughts; customers like you make our work very rewarding. If there’s anything else you’d like to learn or explore, we’re always here to help!

Prof. Newell Kessler –

This course on nano fluid thermal management for batteries sounds cutting-edge. Has this course been updated recently to include the latest advancements in battery technology?

MR CFD Support –

Thank you for your interest! Yes, our courses are continuously updated to reflect the latest advancements in the industry. Our course on Thermal Management of Battery Using Nano Fluid incorporates the most up-to-date simulations and analytical methods to provide comprehensive knowledge on the subject.

Dr. Eleazar Dare I –

The simulation demonstrates excellent results in managing battery heat with the applied nanofluid. The intricate details in geometry and precise setup uncomplicate battery simulations, leading to a convincingly practical approach towards thermal management with nanofluids. Kudos!

MR CFD Support –

Thank you so much for your appreciation of our product ‘Thermal Management of Battery Using Nano Fluid, CFD Simulation Ansys Fluent Training’. We are glad that you found the detailed geometry and setup helpful and practical for thermal management applications. It is gratifying to hear that the results met your expectations. If you have any further feedback or require assistance, please feel free to reach out to us!

Prof. Luz Barton –

I really learned a lot from the ‘Thermal Management of Battery Using Nano Fluid’ CFD Simulation training. The content was well-structured and the simulation stages were clearly explained. Thanks for creating such an informative and comprehensive course that enhanced my understanding of battery thermal management strategies and the application of nanofluids for more efficient thermal control systems in battery technologies.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the ‘Thermal Management of Battery Using Nano Fluid’ CFD Simulation training was beneficial to you. At MR CFD, we strive to provide detail-oriented and practical learning experiences for our customers. We appreciate your acknowledgment of the course structure and clarity of the simulation stages. Your enthusiastic response is a great motivation for us to keep delivering high-quality educational content. If you have any further questions or need assistance with future simulations, do not hesitate to reach out.

Camille Boyer –

I am impressed by the level of detail in the CFD simulation for battery thermal management using nano fluids. The use of polyhedral meshing and inclusion of both electrical and thermal responses provides a comprehensive understanding of the battery’s behavior under thermal load. It’s particularly interesting to see the GK empirical model in use for electrochemistry. The results indicating effective battery cooling with nanofluid flow are promising for advanced battery system designs.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our detailed simulation approach, especially the use of the GK empirical model, and our meshing strategy met your expectations. It is our goal to provide comprehensive and high-fidelity simulations that can assist in the understanding and innovation on thermal management systems for batteries. We appreciate your comments and look forward to continuing to support your learning experience.

Neil Bednar PhD –

Just wanted to express how satisfied I am with the Thermal Management of Battery Using Nano Fluid CFD training. It has provided an in-depth analysis and clear understanding of how nano fluids can enhance the cooling performance of battery systems. The detailed simulation results clearly demonstrate the effectiveness of the nano fluid cooling mechanism, which is crucial in the design and operation of high-performance batteries. I especially appreciate the inclusion of various parameters and how they interact to achieve optimal thermal management. Thanks for providing such valuable insight through this learning product!

MR CFD Support –

Thank you for taking the time to share your positive experience with the Thermal Management of Battery Using Nano Fluid CFD training. We’re delighted to hear that the content was informative and helpful to your understanding of the sophisticated battery cooling processes. We pride ourselves on providing detailed simulations to support learning, and we are glad that you appreciate the depth of information provided. If you have any further questions or need assistance in future learning endeavors, please feel free to reach out!

Brionna Turcotte –

This nano fluid thermal management simulation sounds impressive! The detailed results for temperature control within the battery must be very insightful for designing cooling strategies.

MR CFD Support –

Thank you for your kind words! We’re pleased to hear the details provided in the simulation were helpful and insightful. Effective thermal management is crucial for battery longevity and safety, and we’re glad our simulation could provide valuable information for cooling strategy design. If you have further interest or need additional information, feel free to explore our other learning materials or contact us directly.