Thermoacoustics Analysis in Combustion Chamber CFD Simulation, ANSYS Fluent

$180.00 $90.00 Student Discount

- In this project, we have simulated the Thermoacoustics Analysis in Combustion Chamber using ANSYS Fluent software.

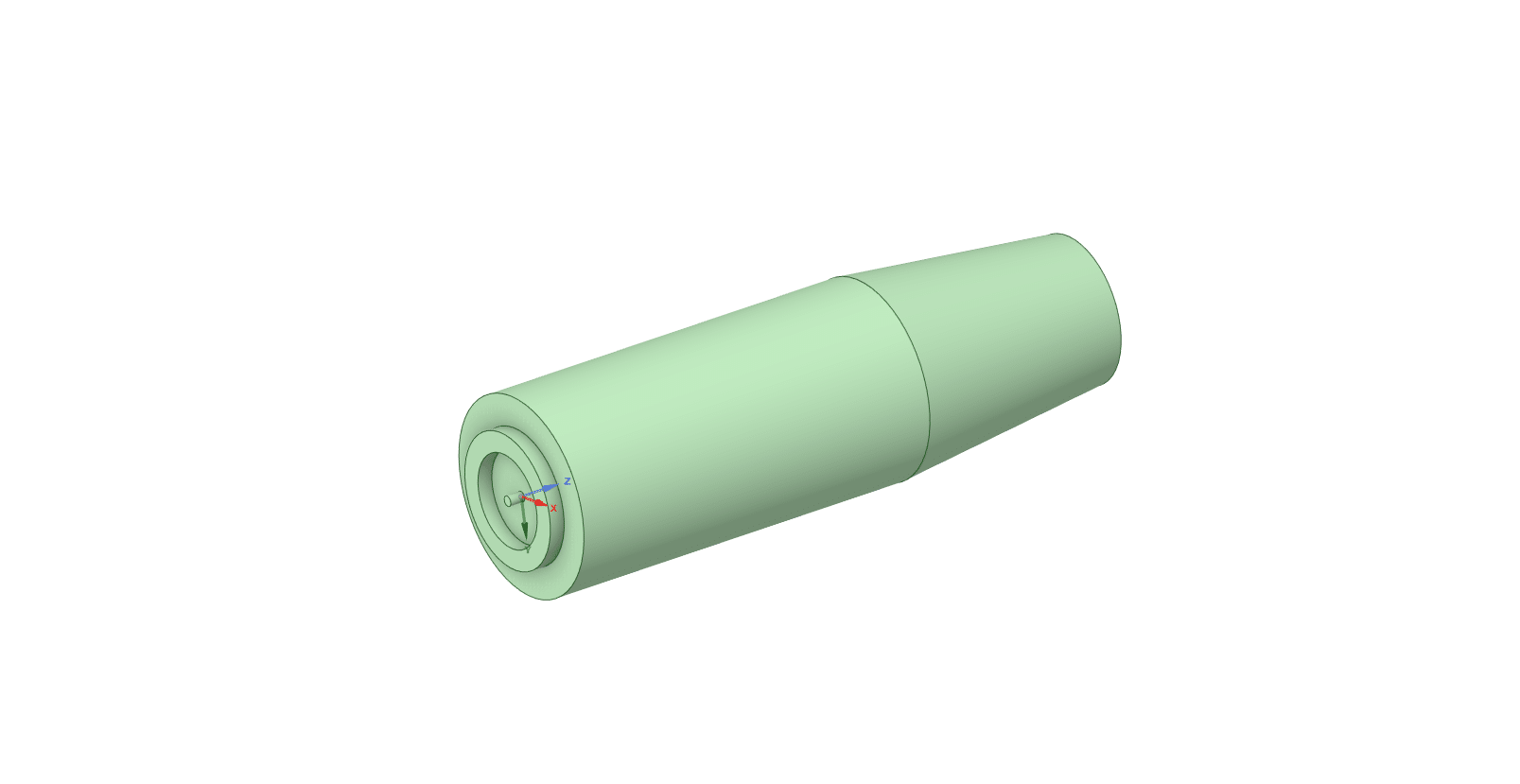

- Three-dimensional modeling was done using SpaceClaim software.

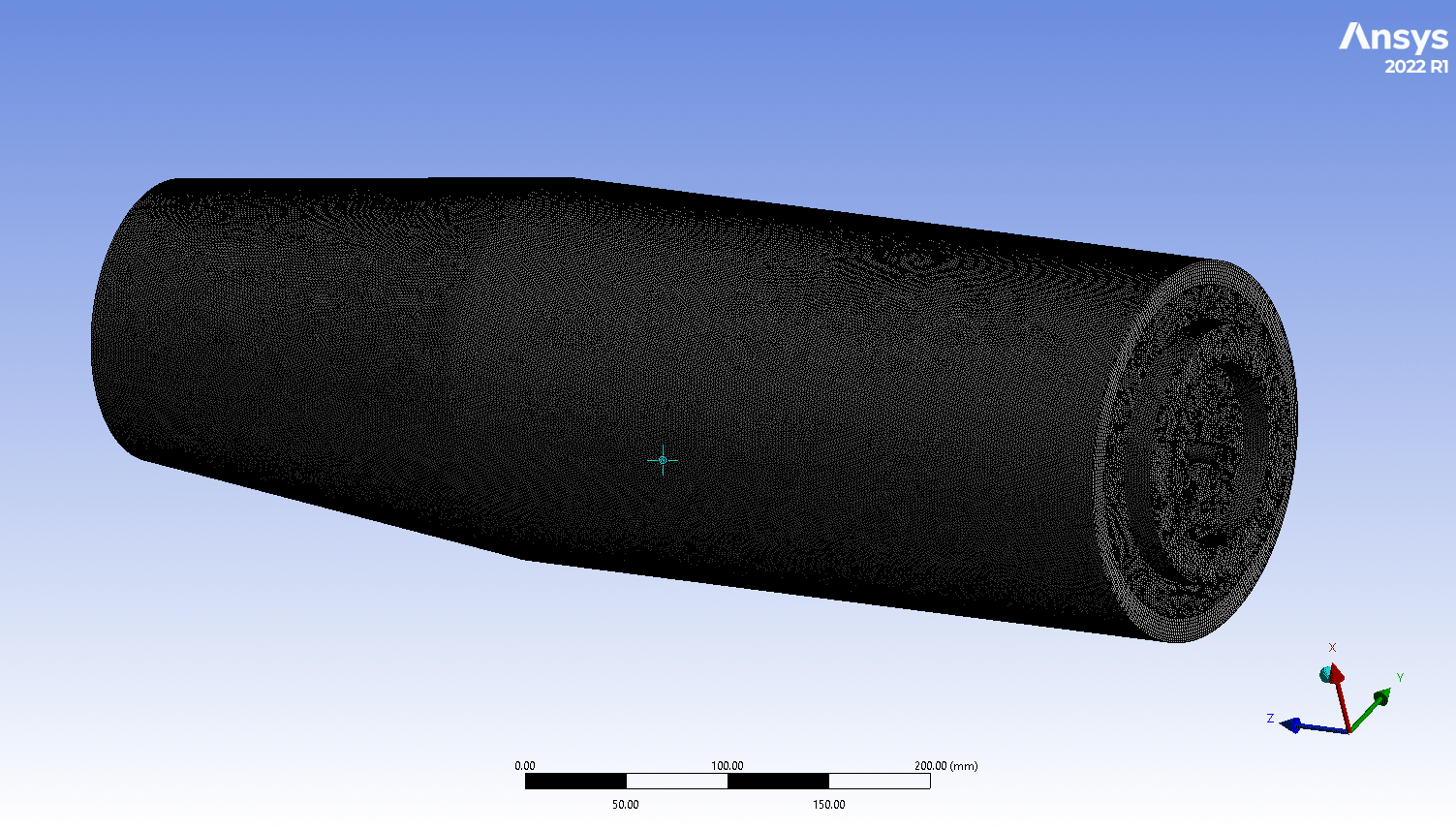

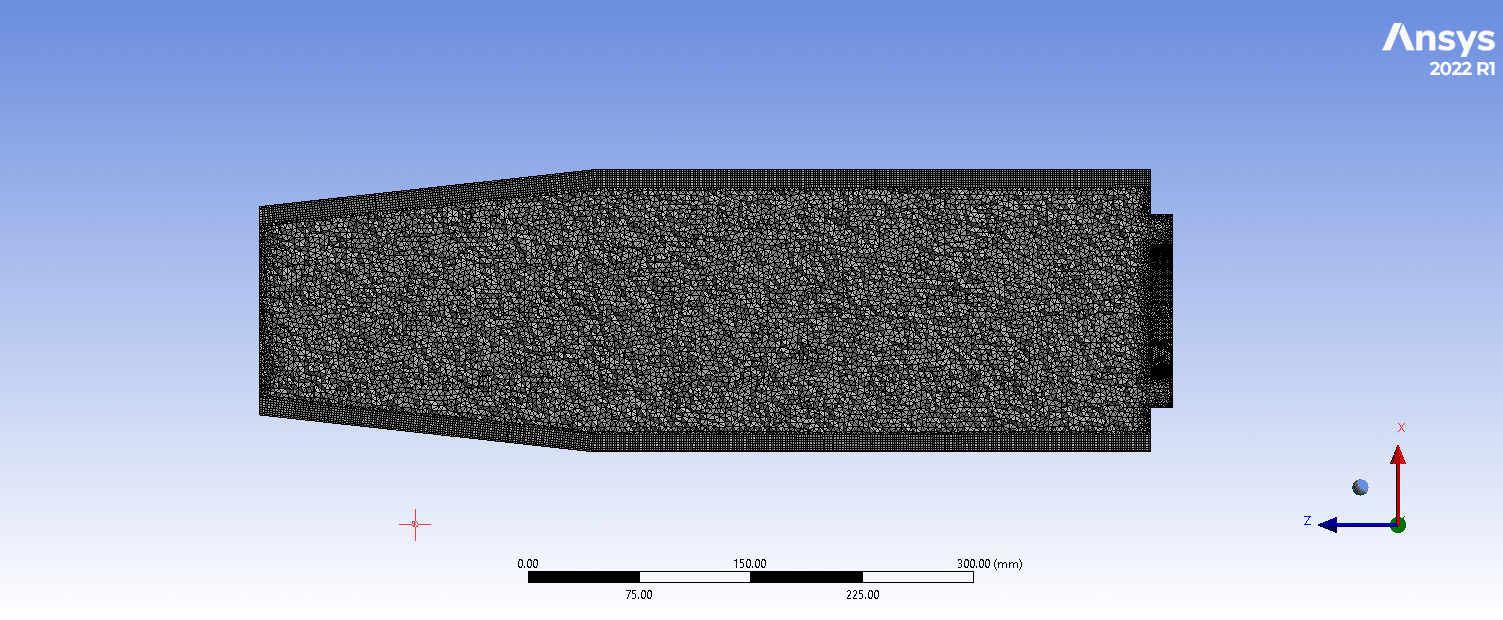

- The meshing of the model has been done using ANSYS Meshing software.

- The Non-Adiabatic Non-Premixed Combustion model models the combustion.

- The acoustic is modeled via the Broadband Noise Source model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

ThermoAcoustics Analysis in Combustion Chamber, CFD Simulation Tutorial

Description

This project, Non-Premixed Combustion & Acoustics, investigates a Thermoacoustic phenomenon inside a chamber using CFD simulation in ANSYS Fluent software. In thermoacoustic systems, heat is used to generate sound waves, which can then be used to perform various tasks like pumping heat or producing electricity. The process involves no moving parts, making it a reliable and low-maintenance technology.

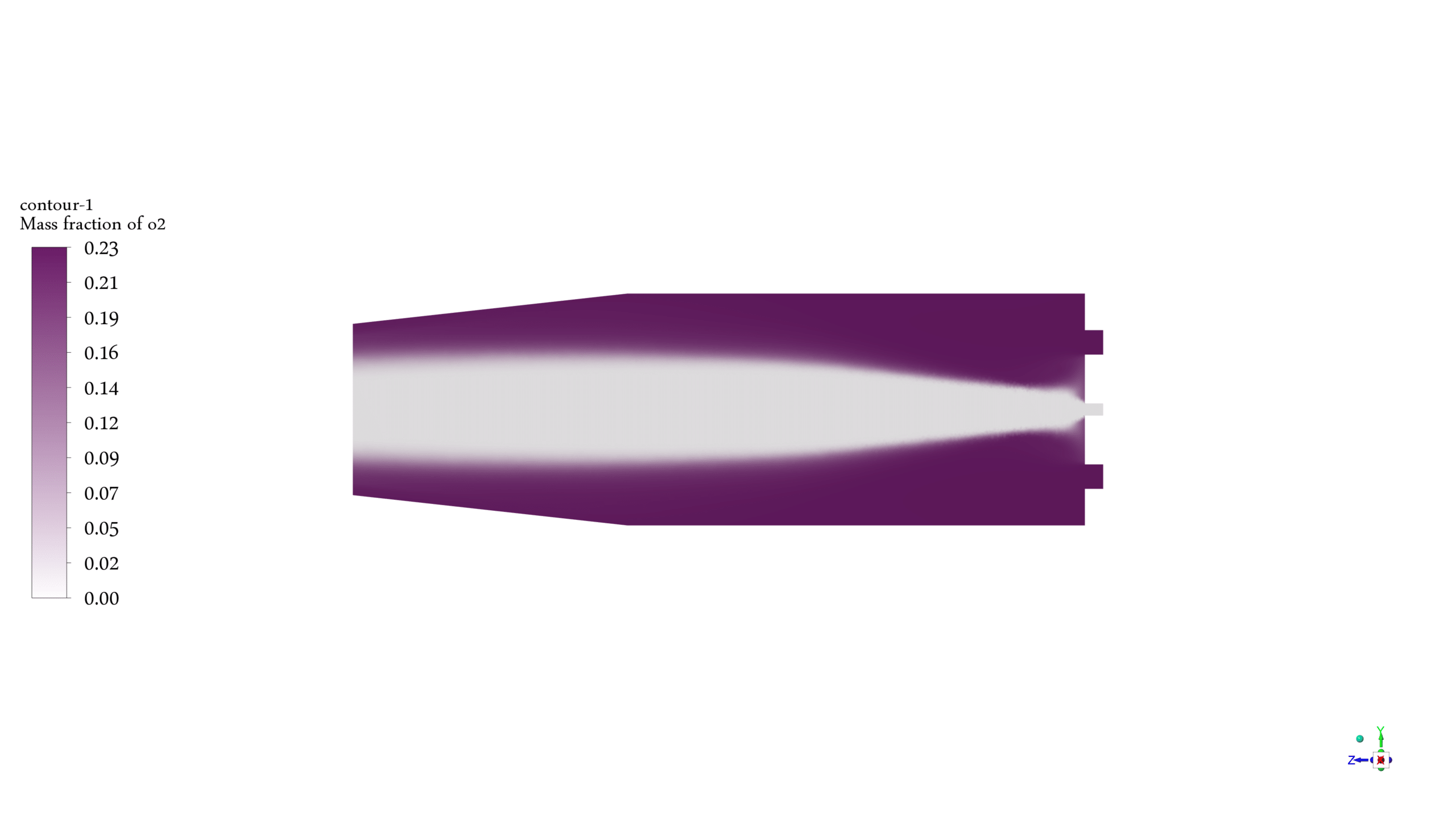

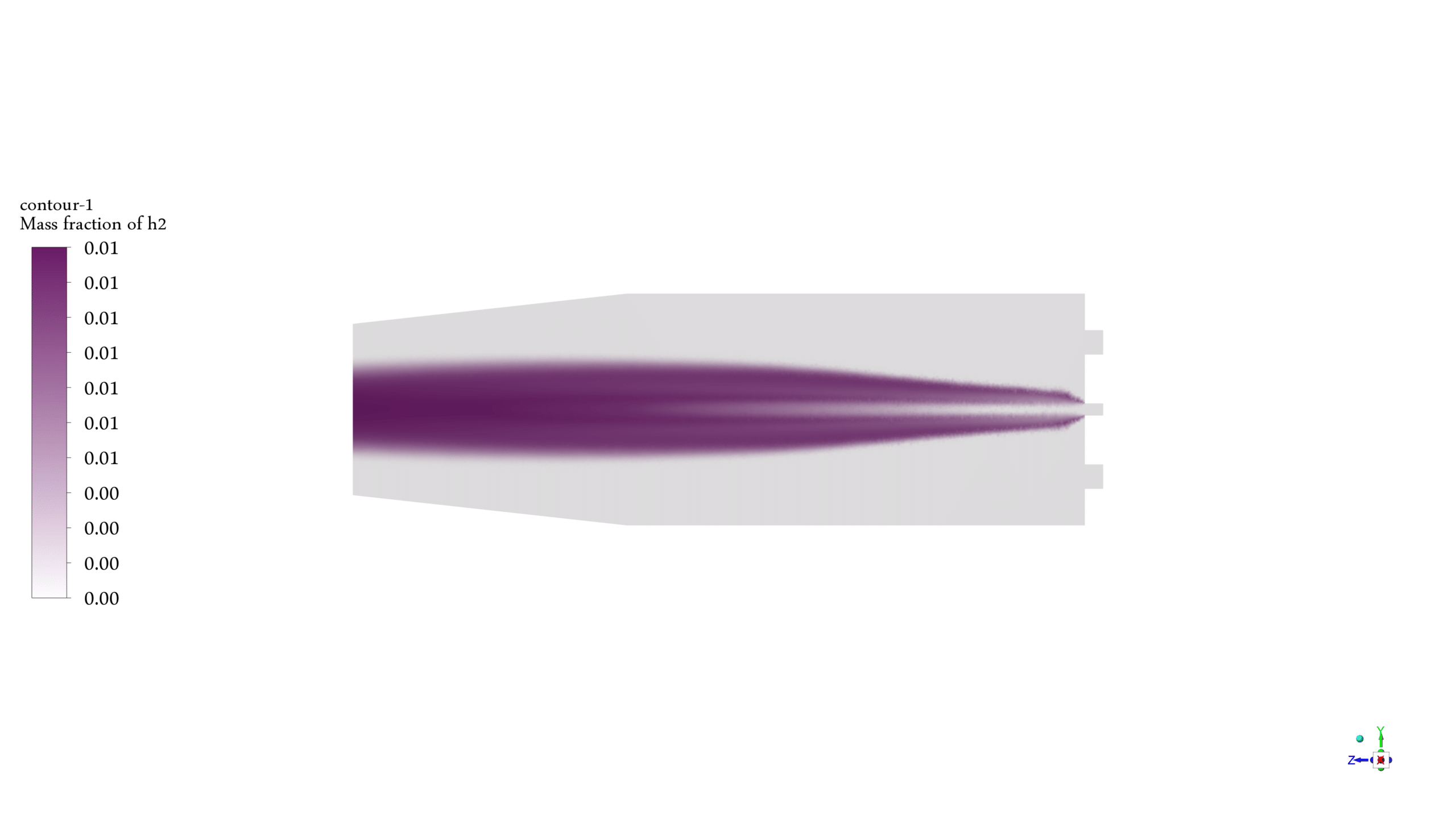

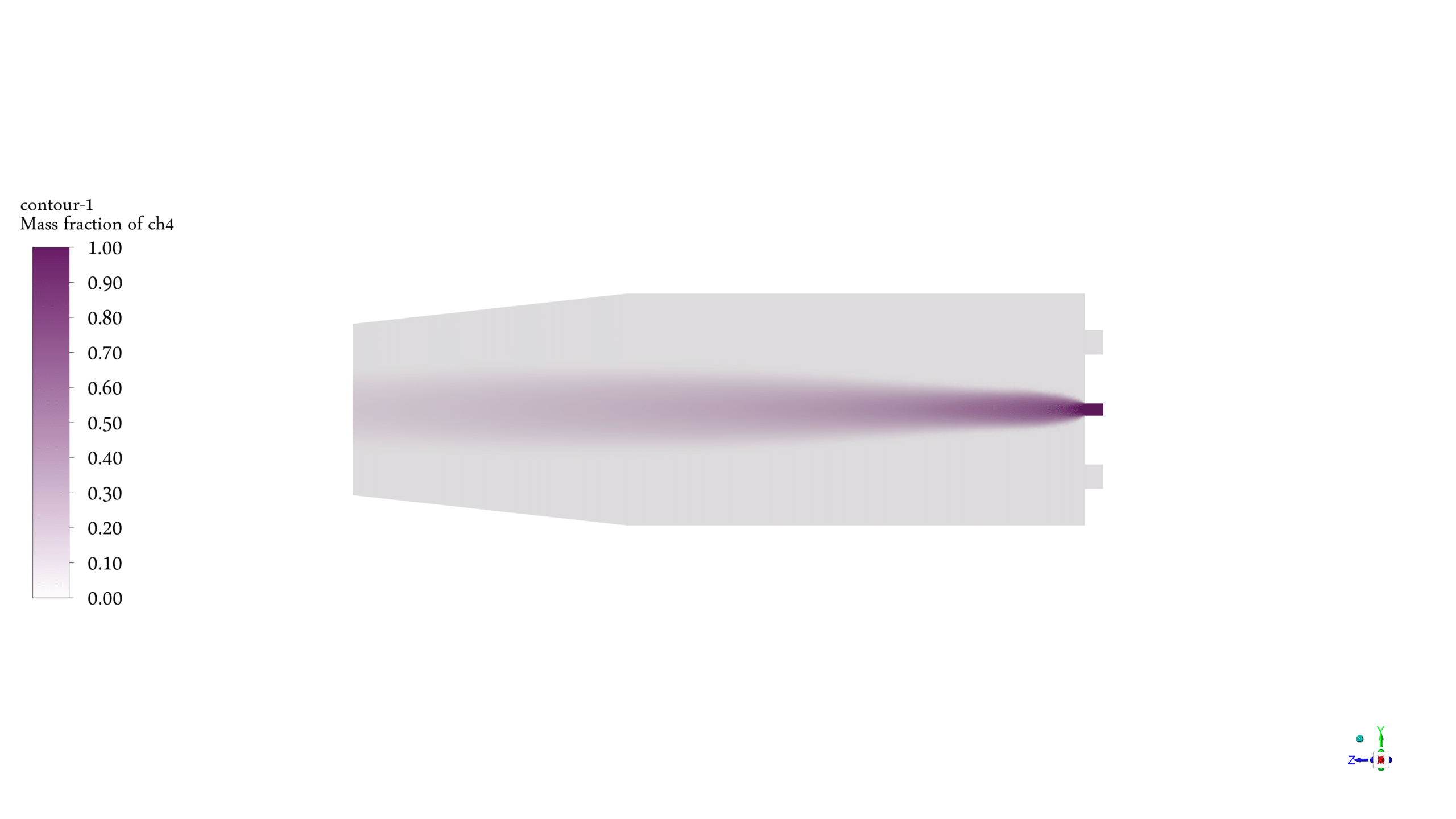

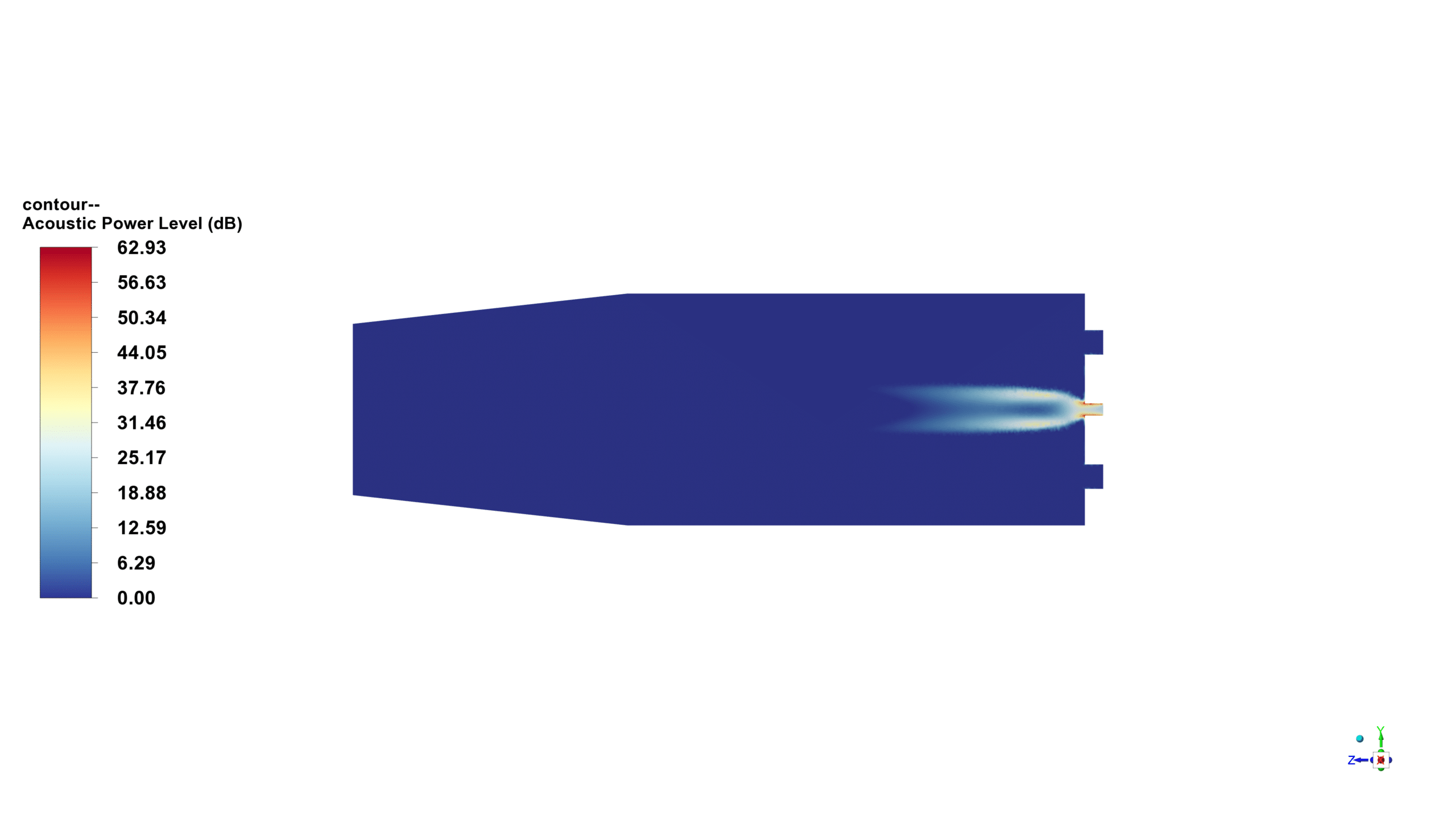

The methane and oxygen enter the domain from different inlet boundary conditions with a mass flow rate of 0.001kg/s and 0.025 kg/s, respectively, and after mixing, the combustion occurs. In this case, the Acoustic Power Level (db) and Surface Acoustic Power Level (db) (Acoustic Power Level measures the total sound power, while Surface Acoustic Power Level measures the sound power per unit area.) are extracted using the steady-state acoustic model available in the software.

The geometry of the solution is designed in SpaceClaim software, and the elements of the meshing process are generated in ANSYS Meshing software.

Methodology of ThermoAcoustics Analysis in Combustion Chamber, CFD Simulation Tutorial

In this simulation, the Non-Adiabatic, Non-Premixed Combustion model models the combustion. The Non-Adiabatic, Non-Premixed Combustion model considers the heat loss that can occur during combustion. This means that some of the heat generated by the combustion is lost to the surroundings. This model is more realistic and is used in practical calculations where heat loss cannot be ignored.

Also, the acoustic is modeled via the Broadband Noise Source model. This model predicts the broadband noise of turbulent flows in a computational fluid dynamics (CFD) simulation.

Conclusion

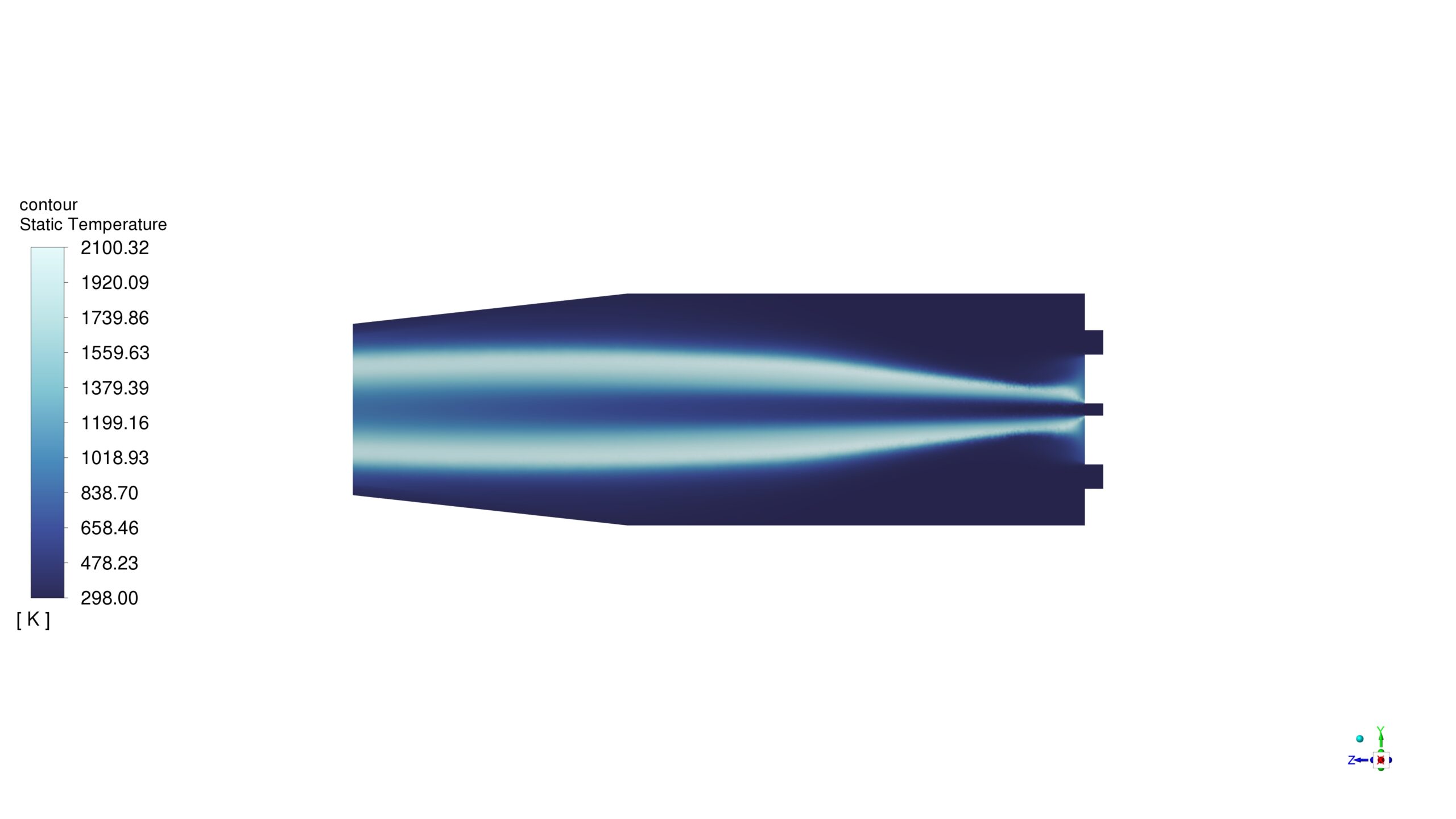

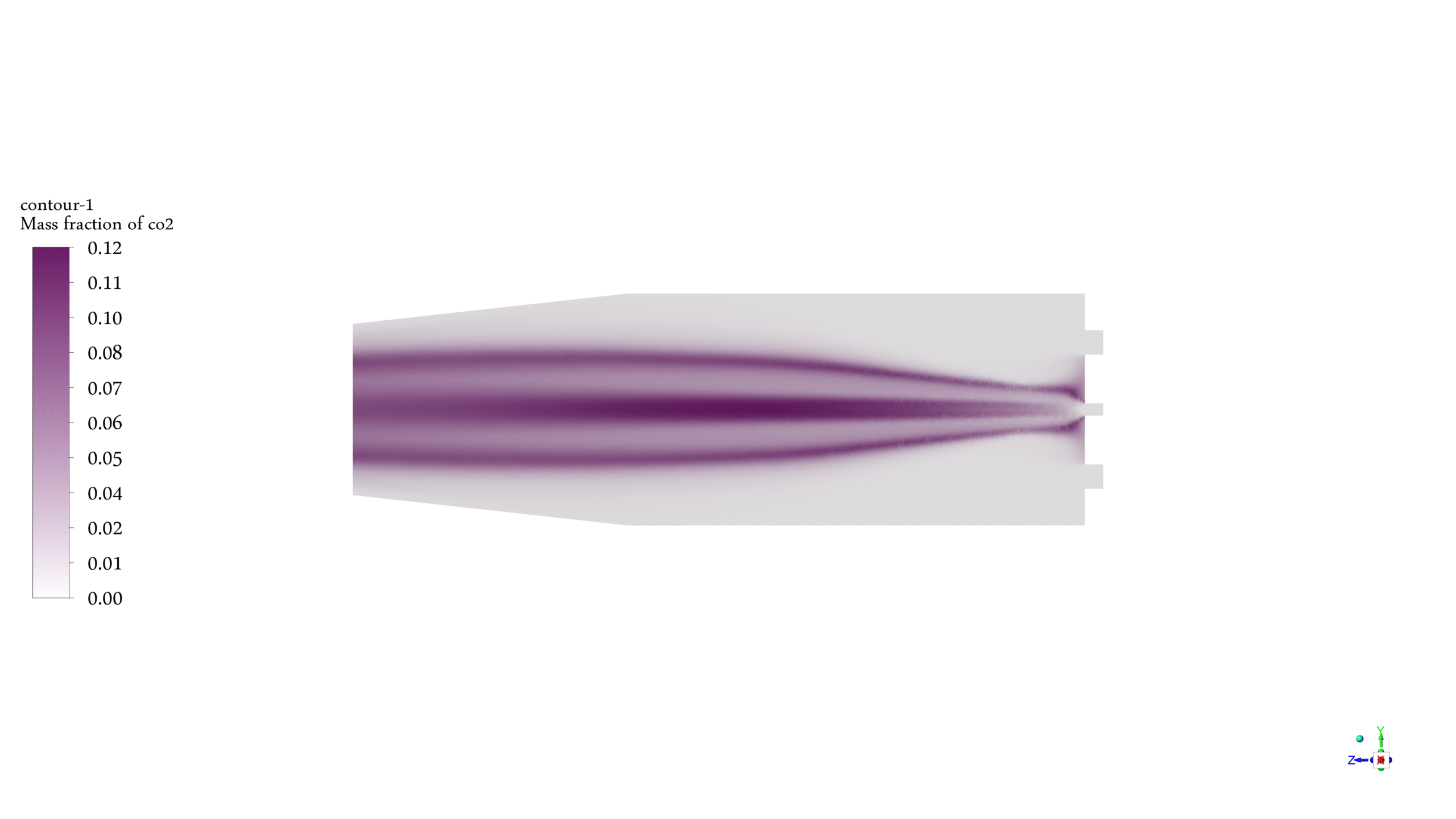

The figures extracted from ANSYS Fluent software show the different contours of various parameters. The mass fraction of the material indicates its entry into the domain from the center of the inlet plate. Additionally, air with a mass fraction of 0.23 oxygen and the rest of the nitrogen enters the zone surrounding the fuel inlet. Also, the mass fraction contours of and, which are the products of the reaction, are visible.

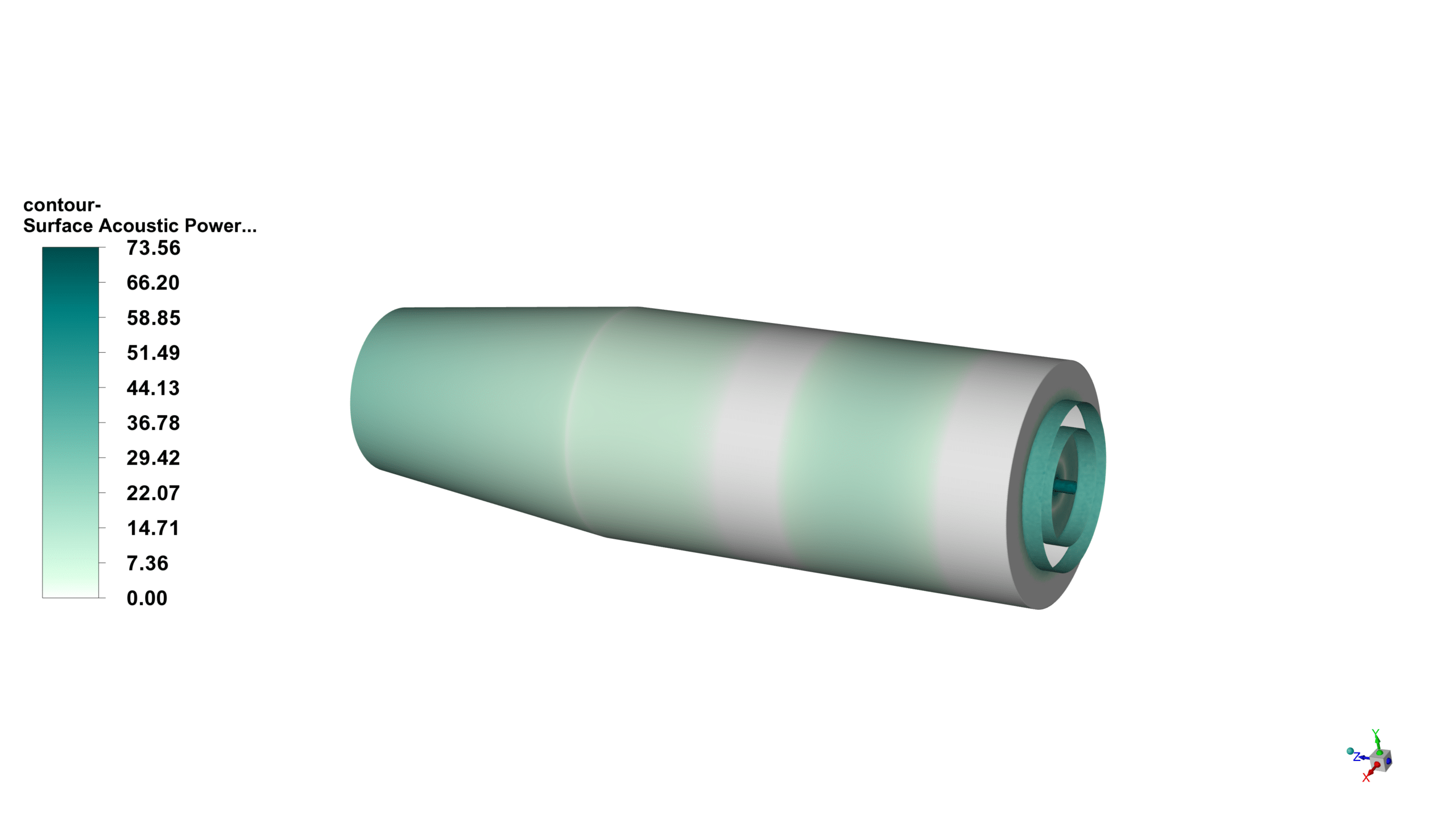

At last, the contours of the Surface Acoustic Power Level on the chamber walls and Acoustic Power Level in the plane defined in the center of the chamber are apparent. The maximum amount for the Surface Acoustic Power Level is 73.56 db. This Surface Acoustic Power Level value is lower but is 62.93.

Nayeli Schamberger II –

I’m fascinated with the observed thermoacoustics in the Combustion Chamber simulation. However, I’d love to understand more about the causative connection between the heat generated during the non-premixed combustion and the sound waves produced. How does this simulation illustrate that fundamental relationship?

MR CFD Support –

In the simulation, the non-premixed combustion process generates heat, with a portion being lost to the surroundings due to the non-adiabatic conditions. This heat influences the air density and creates pressure waves. These waves are essentially sound waves, which can be intensified in a resonant chamber, leading up to what we refer to as thermoacoustic waves. ANSYS Fluent computes these effects using the combination of non-premixed combustion and acoustic models, thus illustrating the relationship by mapping out acoustic power levels that are a direct consequence of heat release patterns within the combustor.

Davion Crooks –

I’m incredibly impressed with the scope of this simulation project on Thermoacoustic Analysis in the Combustion Chamber, using ANSYS Fluent. The use of CFD to couple both fluid dynamics and acoustics for analyzing the Thermoacoustic phenomena within a combustion chamber is fascinating. It sounds like a complex system, capturing intriguing dynamics of combustion and sound wave generation that has practical applications in diverse fields. Definitely a study worth diving into for its innovative approach to technology!

MR CFD Support –

Thank you for sharing your wonderful feedback with us. We are thrilled to hear that you appreciate the complexity and innovation of the Thermoacoustic Analysis in Combustion Chamber project. It’s always encouraging to know when our users find value and intriguing insights in the simulations we provide. Your compliments are greatly valued, and we look forward to offering you more cutting-edge simulation products. If there’s anything else you’re curious about or if you have any more questions, please feel free to ask. Otherwise, we hope you continue to enjoy exploring our simulation tutorials!

Lea Hill –

The review compliments the CFD tutorial for providing clarity on ThermoAcoustics Analysis in a Combustion Chamber, appreciating how all crucial concepts and outcomes from the ANSYS Fluent software are showcased. The reader is praised for highlighting the separation between variables such as oxygen and methane at intake, and the reaction products, along with detailed insight into the Surface Acoustic Power Level readings on chamber walls.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our ThermoAcoustics Analysis in Combustion Chamber CFD Simulation tutorial was clear and informative for you. Understanding the complexity of thermoacoustic phenomena and the associated acoustic power level in a combustion chamber is essential, and we are glad that our tutorial helped in achieving that clarity.

Luna Kirlin PhD –

The description was comprehensive, but I’m curious about the type of solver used. Was this simulation run using a steady-state solver for the acoustic calculations, or was it transient?

MR CFD Support –

The simulation you’re asking about utilized a steady-state solver for the acoustic calculations in ANSYS Fluent software, appropriate for capturing the acoustic power levels without the need to compute the transient behavior of the flow.

Linnie Hyatt III –

The step-by-step procedure and insights in this Thermoacoustics Analysis tutorial were extraordinary. The graphs and simulation outputs really brought the concepts to life, assisting me in better understanding the relationship between combustion phenomena and generated sound waves. A first-class learning experience, indeed!

MR CFD Support –

We’re thrilled to hear that you had a great learning experience with our Thermoacoustics Analysis in Combustion Chamber CFD Simulation! It’s excellent to know that the provided materials were able to help you better understand the intricate relationship between combustion and sound waves. Thank you for your thoughtful feedback.

Charlotte Kozey –

What types of analyses can be performed with the data extracted from this type of thermoacoustic simulation?

MR CFD Support –

With data extracted from a thermoacoustic simulation, several types of analyses can be performed, such as performance optimization, stability assessment of the combustion process, identification of noise generation mechanisms, prediction of acoustic fatigue on structures, and design alterations to minimize noise pollution.

Curt Moen –

Is there a specific reason for the chosen mass flow rates of methane and oxygen? Does it affect the Acoustic Power Level results?

MR CFD Support –

In a thermoacoustic system, the mass flow rates of methane and oxygen determine the combustion efficiency and temperature distribution, which are crucial for inducing sound waves effectively. The chosen rates typically ensure an optimal stoichiometric mixture for complete combustion. Yes, these flow rates affect the Acoustic Power Level, as variations in combustion intensity can change the sound waves’ amplitude and frequency generated within the chamber.

Sandy Windler –

The tutorial has made it quite straightforward to set up a ThermoAcoustic analysis in ANSYS Fluent. Was pleasantly surprised to witness accurate simulations of sound waves resulting from the combustion process!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our tutorial effectively guided you through the complex process of ThermoAcoustic analysis and that the results met your expectations. It’s our aim to make high-level simulations accessible and accurate for our users. If you have more feedback or need further assistance, feel free to reach out!

Reagan Goodwin –

What kind of applications can benefit from this type of thermoacoustic analysis in combustion chambers?

MR CFD Support –

Thermoacoustic analysis in combustion chambers can significantly benefit industries and applications such as power generation, aerospace engineering, the design of more efficient engines, HVAC systems, and the development of silent combustion systems. Additionally, this technology is utilized for understanding and preventing unwanted noise or vibrations in industrial combustion systems, which could lead to structural damage or loss of efficiency.

Mr. Emerson Tromp III –

I found the thermoacoustics analysis simulation fascinating! Your work on the behavior of sound waves generated through heat in the chamber was particularly insightful. I’m impressed by how the simulation makes complex engineering concepts accessible and demonstrates the practical applications of thermoacoustics. Nicely done!

MR CFD Support –

We greatly appreciate your feedback and are delighted to hear that you found our thermoacoustics analysis in the combustion chamber simulation insightful. Thank you for taking the time to compliment our work. If you have any further interest or need assistance with similar simulations, feel free to reach out!

Deven Kassulke –

I found the explanation of the Surface Acoustic Power Level fascinating. It’s interesting that you can measure the sound power in such a detailed manner inside a chamber. Can you tell me more about the practical applications of this phenomenon?

MR CFD Support –

Practical applications of thermoacoustics, particularly in measuring sound power levels inside a chamber, include the design and optimization of more efficient and quiet combustion systems and exhaust systems in automotive engineering, the improvement of energy converters that utilize sound waves to generate electricity, and the development of heat pumps and refrigerators that operate using thermoacoustic cycles. Additionally, understanding the thermoacoustic interactions could also aid in enhancing the safety and operability of industrial burners and gas turbine engines by preventing unwanted oscillations that can lead to structural damage or combustion inefficiencies.

Dr. Rene Bergstrom II –

I absolutely loved the detailed explanation of the thermoacoustic phenomena and how ANSYS Fluent can be used to analyze such a complex process. The interplay of heat and sound to potentially generate electricity is fascinating, and the project captures it effectively. Great job on outlining both the non-adiabatic combustion model, as dealing with heat losses is critical for realistic simulations!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our explanation of thermoacoustic phenomena and the use of ANSYS Fluent in the simulation was clear and informative. It’s gratifying to know that our work in demonstrating complex processes is appreciated. If you have any additional feedback or require further insights, feel free to reach out.